Correction of errors made by the construction of the house on the example of the history of the reconstruction of a two-story building from foam blocks

Our readers are asked if the fate of the house, which we told in the article "Caution," underwash, published in the "IVD", 2008, No. 2. And this interest is understandable, because such situations, unfortunately, are often found in private construction. The reconstruction of the dwelling is completed, and we present a report as it happened.

"Scary, already horror"

The owners of the house and lucky, and not lucky at the same time. We were lucky because they were able to purchase a plot very close to Moscow. It was not lucky because the General Contractor was used to use the work of the unqualified workers of the Warmhouse, which did not even intervene in the actions of which did not interfere.

|

|

|

|

1. The outer side of the foundation belts was carefully cleaned and leveled. Along the sole of the foundation laid drainage pipes and fell asleep over with sand.

2. To prevent the penetration of moisture from the soil into the tape of the foundation and prepare them for insulation, the concrete was hand-made polymer bitumen mastic in several layers.

3, 4. The foundation tapes below the soil line were insulated with a solid polystyrene foam with a thickness of 70mm, and above this line - an extruded polystyrene foam 50mm thick. Trenches with drenami covered with sand, which was tamped (4). On top of it, pipes for removing water from the receivers installed under the drainters (3) were laid.

Kzima owners received a box at home, covered with insulated (as it seemed) the roof prepared under the laying of roofing coating - soft bitumen tiles. The finish of the walls folded from the foam blocks was absent, the "earth" floor covered the ceramisite layer, inside of which were laid (more precisely, buried) heating pipes. The owner translated the general contractor seems to be honestly earned by the company, but before concluding an agreement for the next stage, decided to dispel it to his suspicions that "something is impudent in the Danish kingdom." He called Ardis (Russia) and invited her experts to drive up to the site and carry out the examination of the construction. They agreed.

First of all, they checked the state of the rafter system. They tear off the rails of the inner crate, tried to look under Parchment. But for some reason he stubbornly did not want to break away from the rafter. It turned out that it was firmly glued to wooden elements ... mold. Different from the inside of the house part of the roof and saw a terrible picture - water dripped out of the insulation, and the cutting and racks of the crates covered the mold. Why did it happen?

The fact is that the builders allowed several mistakes at once, the "fatal" combination of which led to the fact that the roof was almost joined in just one winter. Let's start with the fact that in the house there were no floors of the first floor - a layer of claymps was added right to the ground, which heated the pipes of the permanent "heating system". The result is the moisture evaporated from the soil into the inner space of the building in a huge amount. And at this stage, it was not necessary to include hydraulic heating, because the work in the house was not conducted. It happens to this, there would be no moisture thoughted roof.

Errors allowed when creating roofing structures played their role. For example, vaporizolation was laid by the "trough" between the rafters, and whether it was, as it should, continuously, the moisture pair in such a volume would not be able to penetrate the roofing "pie". Moreover, the air intake holes of the ventilated gap in the lights of the roof were, but there were no weekends near the skate. That is, the Ventzor in the roof was, but he simply did not work: the air flow along the skate was not arose, which should carry moisture pairs, penetrated into the insulation from the room, and then released from it in the Ventzor. The result complex of moisture has been condensed in the insulation, covered on top of the membrane with numerous damage.

|

|

|

|

5, 6. To carry out the outer insulation of the walls of the house, the plates of polystyrene foam 70 and 100mm, first cut to the desired size (sometimes it was necessary to cut a curly blank), then applied to the billets of the glue composition "Seven" (5) and installed them in place (6).

7. While the adhesive composition was dried, the insulation plates were additionally fastened to the walls of the house with plastic plate dowels - "fungi".

8. Scaffolding for external warming and subsequent decoration of walls, scaffolding from wood was not erected - they were leased, which made it possible to slightly reduce the cost of construction

A little later, other miscalculations were revealed - both design and construction. For example, at the level of the second floor there were four open terraces of a significant area in the house, which in the conditions of our climate is not just an easy-acting, but even dangerous. After all, no matter how you waterproof the areas of the terraces, the moisture accumulating on them will certainly undertake inside the house.

Walls isolated from foam blocks, with a thickness of 40cm warmly not turned out - they had many brick and concrete inserts that are "cold bridges". All power steel elements (and in the design of the interhent overlap it was abound) covered the thick layer of rust. From masonry steel elements were not isolated, and in those places where they relied on the walls, missing concrete sites for such cases were missing. Dear wooden windows had insufficiently for their sizes, the cross section of the profile and were installed in and even on and even at different heights.

|

|

|

|

9. Walls of the house were insulated with the help of the "Knauf-Warm Wall" system ("Knauf"). This technological system, in addition to insulation, provides the class of fire hazard of the walls of the C0, that, subject to the device, fire dedication makes it possible to apply it in buildings of all degrees of fire resistance.

10.11. Created firebreaks from stone wool (10) around windows (11) and between floors.

12. The polystyrene was a protective layer of the mixture "Knauf-Seven", reinforcing it with a glasswork. This layer was primarily primed by the composition "Knauf-Isaogend", then a layer of decorative plaster "Knauf-diamond 260" was laid on it.

The conclusions were disappointing. The roof and the rafter design must be dismantled and revived. Walls of the house need additional outdoor insulation. The number of open terraces should be reduced; For this, the walls should be built on their perimeter, and on them - the roof. This will allow you to get 80m2 extra square on the second floor. Windows must be replaced. You will have to almost completely cut the supporting pad of the stairs on the second floor and make it anew with the staircase. Inconale, the power metal structures will be in order.

This was immediately informed by the owner. Now imagine the state of a person who has fallen into such a situation: you do not want, but you need to invest in the reconstruction of the house, which he already considered almost ready.

The first stage of work

Created a new project. After reading him, the owner agreed to conclude a contract for the reconstruction of the house. This process began with the construction around the perimeter of the terraces of bearing walls with a thickness of 30cm (it is quite enough, since the house decided to warm outside). To give the walls stiffness, every two rows of blocks were reinforced with a metal grid, and the belt was made from the monolithic reinforced concrete.

Next, completely dismantled the old roof and began to build a new solo system. All its elements made from the boards with a cross section of 150x50mm treated with firebike radiation composition. When the devices and the beams of the board were ragged, tightening them with galvanized bolts. The walls of the walls for the installation of these elements were cast references from concrete.

|

|

|

|

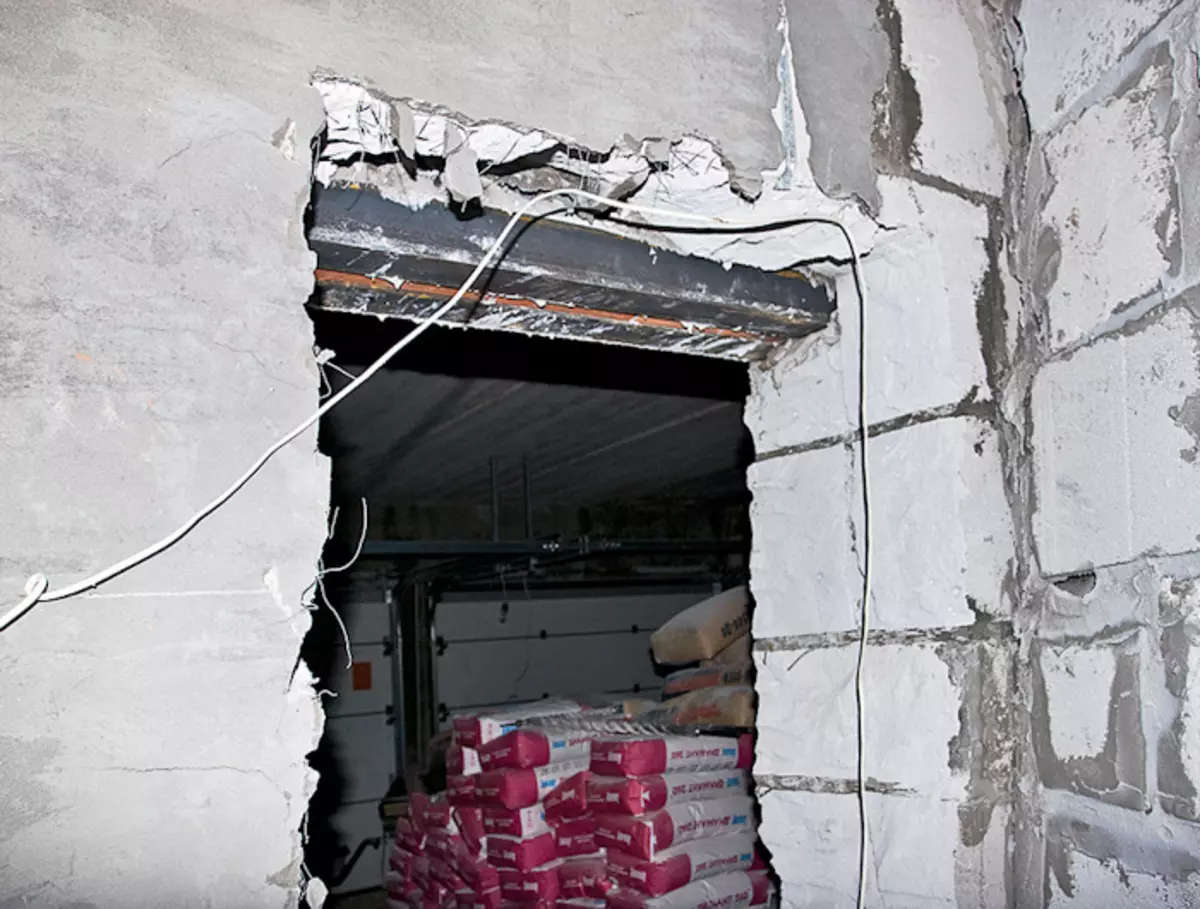

13, 14. When redeveloping the internal space of the house in the partitions folded from foam blocks, the partitions had to do. Narrow strengthened with a jumper from metal corners (13). For wide all over their perimeter, "strapping" (14) was mounted from the same corners. Additionally, a number of new brick interior partitions were erected inside the house.

15. Subsidiary of the boiler house made technospodel, where they placed the inputs of the water supply, gas and sewage output. The floor was cast here from a special waterproof concrete, in the crowd of which a powerful reinforcement frame was laid.

16. The walls were covered with coating waterproofing, insulated and laid brick. Over the technical, the overlap of the monolithic reinforced concrete was created in it, they left a small opening, which will be covered with hatch.

Unusual, but very warm was the roofing "Pie". Creating it, to the rafters from the bottom, perpendicular to them, knocked the rack of the crates, between which the plates of polystyrene foam 50mm were pasted. Then, on the side of the room, this material was covered with foil vapor barrier. Next, the slabs of the stone wool "Light Batts" (Rockwool, Russia) of the total thickness of 150mm (Rockwool, Russia) of the total thickness of 150mm (Rockwool, Russia) of the total thickness of 150mm were put in layers (Rockwool, Russia) and on top of the board with a cross section of 150x25mm. On top, all covered the diffusion membrane, which was pressed another counterbalaxy of 50x50mm bars. The shortcut, I knocked out the cutter from the board of 150x25mm, and it was attached to her solid flooring from OSP plates.

|

|

|

17, 18. Kdom made an extension. To do this, around the perimeter of the future walls, the trench was pulled out, slept on its bottom a sand pillow (17), and then using a milking formwork, cast a ribbon from reinforced concrete cross section 60x40cm (18).

19. The walls of the extension erected using unable polystyrene foaming units. The first row of blocks installed directly on the foundation tape. The base and roofing overlap of the extension was made of monolithic concrete

|

|

|

20-22. For the creation of floors on the first floor, the old ceramzite was removed (its layer was uneven), they crushed the earth, and then the ceramzite layer 50 cm. They poured a layer of concrete on which waterproofing (20) was laid. On top of the waterproofing, a concrete screed with a thickness of 100mm was poured, it was reinforced with a wire mesh (21, 22).

A continuous ventilated horse was built by a building. The inlet openings in the ventiode staged a roof under the sink and covered with a metal grid. Further on the flooring from the OSP-slabs was put on a solid lining carpet, and on top of it - bituminous tile.

In the form of the house I met my second winter. On this we will end the excursion to the "List of the Object" and proceed to the description of the reconstruction conducted at the second stage.

What was next

The second stage of the work included a device of the drainage system and the rainwood, the insulation of the foundation, the exterior insulation of the walls of the building, the construction of a small extension, the creation of techpool, redevelopment of the space, insulation of floors on the first floor, the wiring of communications around the house, the construction of the stairs and, finally, the inner and exterior decoration. All this is detailed in the photos. We comment only what remained behind the scenes.

The device drainage and storm systems was performed simultaneously with the outer insulation of the foundation. Along the latter, we decided to pull the trench of such a depth to get to its sole. As it turned out, the foundation was tape. The depth of the sole is about 180 cm. The tapes were cast directly into the trench, so their surface was uneven, the perforator was "smoothed".

|

|

|

23-25. When laying communications, the sewage pipe was lifted above the screed level so that the polystyrene layer can be placed under them (23). The pipes of DHW and heating systems were either placed in a tubular insulation (24), or were hidden inside the polystyrene layers (25).

|

|

|

26, 27. In cases where the DHW system or heating system was laid on a screed or inter-location of the pipe or heating, it was possible to lay a layer of insulation, and it was no longer possible to put it on top of them, the pipes were covered on top of a layer of mounting foam. This option of insulation may be not very cheap, but very effective.

28. In addition to installed under the windows of convectors, all the rooms of the house are heated by water warm floors. To improve their arrangement, the steel grid was laid on the polystyrene layer, to which the plastic clamps attached the pipes PE-XC heating circuit. Later, their concrete screed will hide them.

The insulation of the walls of the house was performed using the KNAUF-Warm Wall Complete System (KNAUF, Russia), including everything necessary: Effective thermal insulation material - polystyrene foam plates Thermal FASADE 70 and 100mm, plaster-adhesive mixture "Seven", primer "Izogend ", Decorative plaster" Diamond 260 ". "KNAUF" produces an alternative version "Warm Wall II", which includes mineral wool slabs instead of polystyrene foam.

Such complete systems are convenient because all the additional items needed for installation are included: Tarbed dowels, fiberglass, plastering profiles IT.P. The cost of a set for insulation 1m2 of the wall surface when using polystyrene foam 100mm thick is 460 rubles. Almost a similar complete WEBER.THERM system in the Russian market is Saint-Gobain Weber Rus. Its set for 1m2 wall will cost from 560 rubles.

|

|

|

29. Electric and low-current cables were placed in corrugated polymer pipes and laid mainly on overlappings.

30. Performing an internal finish, to the walls of foam blocks before their plastering of dowels, a metal grid was fucked.

31. Domestic downtown roofing structures are smoothed with the help of crates from steel thin-walled profiles of the KNAUF system. Even more smooth, these rods will become after attaching the bent sheets of plasterboard.

In our opinion, another fact is very interesting. The magnitude of the deviation of the walls laid out of two rows of foam concrete blocks, from the design marks, both vertically and horizontally reached 7cm, so builders, warming the walls, at the same time were forced to align them. They did it, trimming the plates of polystyrene foam plates glued on the wall in thickness. This experience suggests that the possibilities of using complete insulation systems are actually somewhat wider than their manufacturers.

The construction of an extension builders took up at the request of the hosts. It was built on an independent foundation, which was a monolithic ribbon cross section 60xcm. The formexx non-removable formwork technology, the concrete wall at an altitude of 500mm above the foundation belt, attached with powerful reinforcement "anchors" to the old foundation, drilled in the last hole with a diameter of 130mm. The extension "tied" to the house and overlaps. To do this, we had to partially extend the concrete and expose the reinforcement inside the monolithic plates, which was knitted with a metal frame of an extension overlap.

|

|

|

32, 33. Despite the fact that plasterboard sheets have sufficient primary strength, when the attic of the attic of the attic to them, using the wet bend method, attached a smooth curvilinear form. Sheavited to profiles plasterboard covered (32) and painted water paint (33).

|

|

34-36. The ladder platform of the second floor and the staircase produced at the same time. At first, a general formwork was created from laminated plywood, it was put on the reinforcement frame (34, 35), then a special concrete was poured with the additive of granite. The finished design was polished, fence (36) was attached to it.

Technically under the room boiler room arose, it can be said spontaneously. The fact is that the pipes of the village water supply and sewage to the house were summed up after its construction was completed. Attacks as a building stands on a small elevation, these pipes were below the floor level almost 2.5m. To "let out" into the house, they had to hold "excavations" under the future boiler room. When a rather impressive size was formed there, the builders offered the owners not to fall asleep of him again, but to turn into techpodol. Those, of course, agreed.

A little more, perhaps, should be stopped on the problems that occurred during the interior decoration. They appeared because of all the same crookedly folded foam concrete walls. It was impossible to align them with plastered in one layer. Therefore, the builders were forced to plaster the walls of layers: first, the first layer of up to 4 cm was applied along the metal grid, and then in those places where necessary, the grid was rebounded and put the second layer.

|

|

|

|

37, 38. The heat boiler and boiler (37) became the heart of the heating system and GVS (37). Grooming of the heating system on the floors are removed into collector cabinets (38).

39. The recuperator serving the house of the supply and exhaust ventilation system has placed in a niche behind the ceiling of the mining.

40. Air intake and outlet of the ventilation system in all rooms at home are located under the ceiling.

It is impossible not to tell about the creation of the stairs, the design of which was very unusual. Mounted together with inter overlapping cantilever staircase turned out to be fragile. Builders had to partially cut it off and carefully smash the concrete in the zones adjacent to the walls, but at the same time, the reinforcement frame for the intention, so that the new one could be "tied". Another problem: the turntable between the floors was not to be opened, the wall of foam blocks such a load would not have endured, and the architect did not want to build a powerful "pedestal".

|

|

|

41. On terraces, builders alternated layers of polystyrene foam and waterproofing. This "cake" covered the screed with a flap towards the drain.

42. The base of the house and the scene was told by Kohlnight.

43. Water that comes on the waterproofs from the roof, as well as from the grooves installed along the grooves, is given along the pipes of the storm sewage into the drainage well, referred to from the house to the distance of 10m.

|

|

|

44. Sves, in which the inlets of roofing ventilation are located, were powered by a clapboard treated with a protective composition.

45, 46. Wooden fences, painted in the same color as the oops of the roof, were organically fit in the design of the house.

Designer-designer thought for a long time, how to do, and found an unusual solution. Respecting copyright, we will not go into its technical details and just say about the result. The staircase made of the monolithic concrete has only two "points" of the support: downstream, along with the foundation "Press", upstairs - on the newly created platform. The actual site only comes to the walls, but does not relieve them - "PARIT" in the air.

Epilogue with light sadness

And again the owners of the house and lucky, and not lucky at the same time. We were lucky that I found a firm that took the situation and able to do it. Her specialists were forced to look for a long time to look for a solution to a particular problem.

And sometimes they found several alternative options for one of them so that the owner could choose the most acceptable both from technical and financial point of view. I have been developed in design and estimate documentation. But, be that as it may, with all the difficulties they successfully coped.

Not lucky owners because the reconstruction cost, as they say, in a penny. After all, redoing already built is always more expensive than to build anew. So that you do not happen to this, choose the project and builders extremely carefully. In this market, unfortunately, there are not only professionals ...

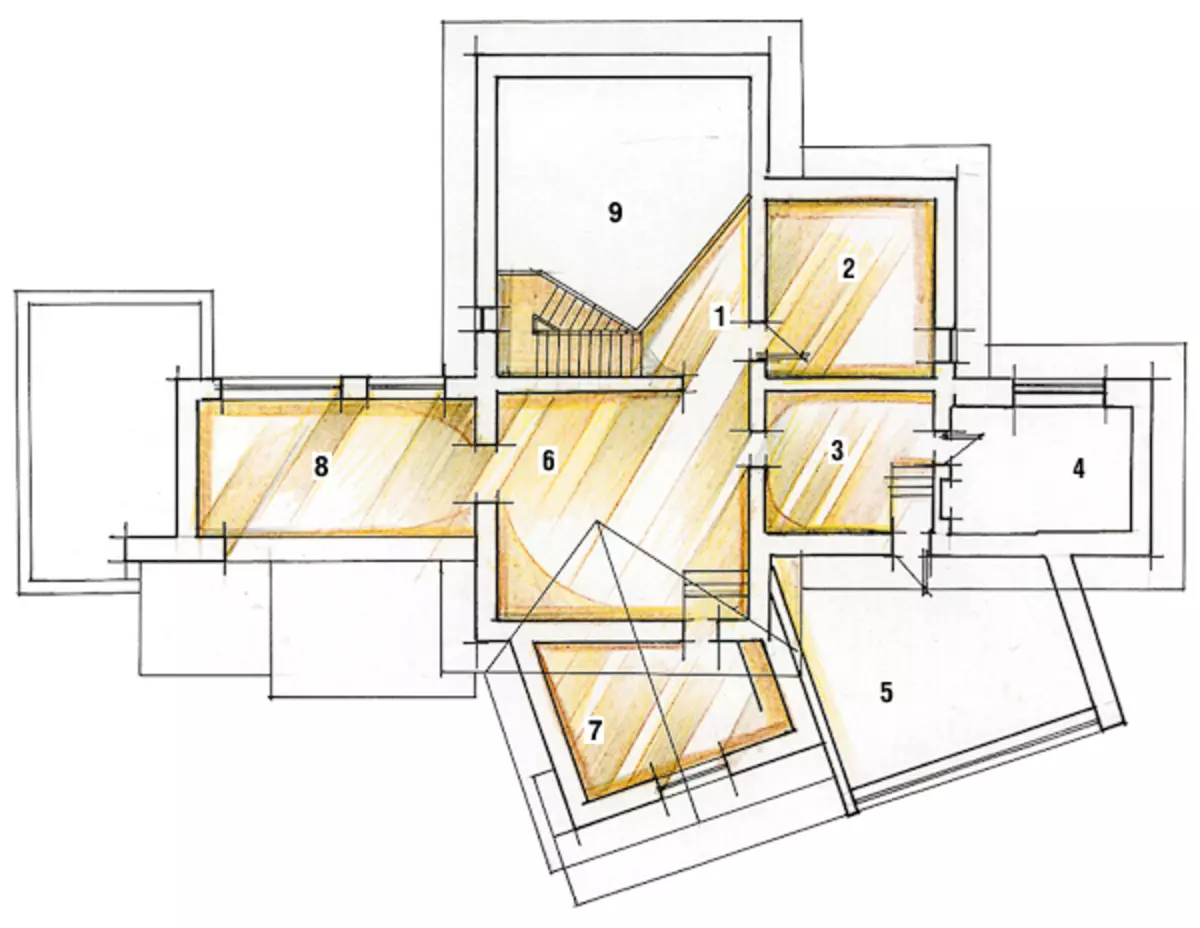

Explanation of the first floor

2. Wardrobe 7.5M2

3. Hall 22.9M2

4. Hall 7.5m2

5. Children's bathroom 5m2

6. Children's 14.1 m2

7. Game 23,4m2

8. Wardrobe 9,4M2

9. Guests 20,4m2

10. Living room 36.8m2

11. Staircase 6,6M2.

12. Kitchen 20m2

13. Tambour 4,5m2

14. Garage 39,4M2

15. Boiler room 9.7m2

16. Bathroom 2m2

17. Fast 10.2M2

Explanation of the second floor

2. Library 17.7m2

3. Gym 14.5m2

4. Bathroom 14,1m2

5. Open solarium 32.7m2

6. Bedroom 30,6m2

7. Wardrobe 16,7m2

8. Winter Garden 22,4m2

9. Second light

The editors thanks the company "Ardis" for help in preparing

Material and provided photos.