Laying outdoor coatings "floating" method: design features of laminate, parquet board and cork coverage, principles of base preparation and styling

Laminate planks, parquet board and cork coating are most often laid by a quick and simple "floating" way, without hard fastening to the base. But for the swimming of such sex was successful, certain conditions should be observed.

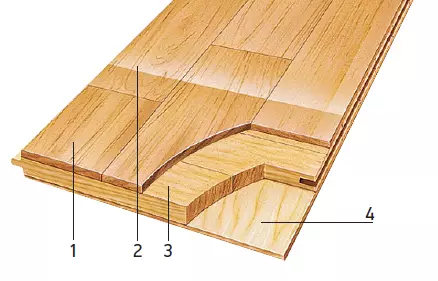

1 - wear-resistant protective layer;

2 is a decorative layer of special paper;

3 - HDF bearing plate with lock cut in it;

4 is a stabilizing layer of craft paper;

5 - Soundproofing Substrate (not everywhere)

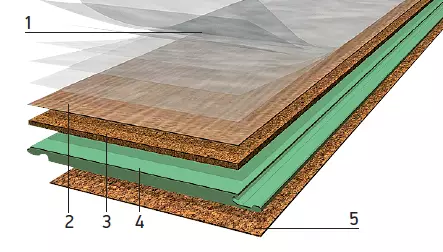

1 - several layers of varnish or oily-wax impregnation with ultraviolet curing;

2 is a working layer of valuable wood;

3 - medium layer from rails of inexpensive conifers;

4 - lower layer, most often from veneer of coniferous rocks

1 - wear-resistant varnish;

2 - decorative cork veneer;

3 - a layer of agglomerated cork;

4 - HDF cooker with lock;

5 - a layer of agglomerated traffic jam

A parquet board, as a rule, is a three-layer bar length just over 2000mm, 180-200mm width and 14-22mm thick. The top layer is made of valuable wood, medium and lower, from inexpensive wood of coniferous plants. Price 1M- from 800 rub. In the Russian market, such covers are presented by Barlinek (Poland) products, Junglewood (Indonesia), Khrs (Sweden), Trade Forest (Russia), Haro, Tarkett, Concern Forbo Idr.

There is another similar coating - Marmoleum Click, which, instead of a cork layer, a natural linoleum is attached to the carrier plate. Sizes of the plank - 900 300 9,8 mm. Price 1m- from 900 rub. This unusual material produces a Forbo concern.

|

|

|

On parquet boards, the finish coating (oil or varnish) is most often applied in the factory. Therefore, the surface is perfectly smooth, without extraneous inclusions (A, B).

Karelia

The top layer of the same-band parquet board is a solid lamella (C), which advantageously emphasizes the texture of the tree and creates the illusion of the array, but also the cost of such a floor above: 1M2- from 2 thousand rubles. Rustic-style boards often have a structured top layer.

"Europlas"

What common?

The listed flooring panels are equipped with a locking system of the connection. When assembling the floor, the spike of one board is inserted into the groove of the other and snap the lock quickly and simply. In addition, all coatings react to fluctuations in temperature and humidity, slightly changing their linear dimensions. Such a "behavior" of parquet boards does not cause questions because the "live" material. But the HDF plate, which forms the basis of the laminate planks, as well as similar coatings, is 90% of wood fibers. Therefore, the principles of the preparation of the foundation and laying of these materials have a lot in common. Having become acquainted with them, you can avoid common problems in which consumers vainly blame the manufacturers of flooring, presenting claims to the quality of the material, while the root of evil is completely different in the other.About moisture

First of all, they will sharpen attention on the preparatory work. It is intended to replace the floor covering or the new one, in most cases, first align the base - "wet" or "dry" method. The NC-standard document 9-94 permits to lay the finishing coating on the cement-sand tie, the humidity of which does not exceed 5%. Before purchasing this indicator, the screed 4cm is driving at least 2 months. Each additional centimeter increases the specified time for another 2 weeks. But the owners, and workers, seeking to reduce the time of repair, often missed this circumstance. Such carelessness leads to the fact that due to the constant penetration of moisture in the lower layer of laminate planks or the parquet board, it swells, the water goes on, upwards. As a result of the edge of the slats bend, and they turn into "boats". This field defect, according to specialists, is very difficult to correct. You can grind only a coating with a thick working layer (more than 4mm). Most often, spoiled material has to be replaced.

Many may fairly notice that the correct design of the floor involves waterproofing the base and laying the substrate. The latter sometimes performs both waterproofing functions. However, the moisture will still go out of the underdeveloped base. The question is where she will go? The most vulnerable places of the alternate waterproofing canvases. Their width should be at least 20cm, and the edge of the upper cloth is mounted onto the bottom tape. In practice, waterproofing sheets are often placed with a small adhesive, without sicking. Just on these lines are very likely to block the planks.

You can use the "dry" method of preparing the foundation using plywood sheets, GLC, GVL, OSP. However, their humidity on SNiP 3.04-01-87 "insulating and finishing coatings" should not exceed 12%.

|

|

|

|

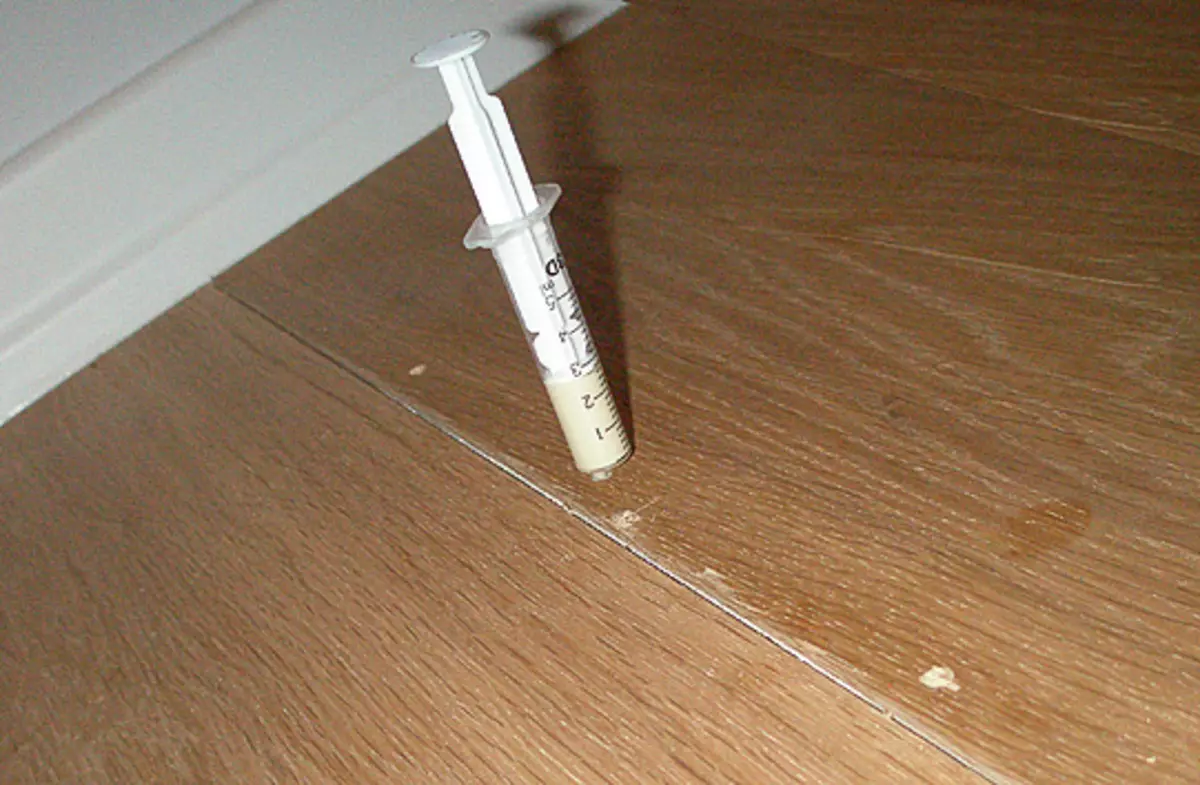

Elimination of a parquet board defect, which arose due to a sharp decline in humidity in the apartment: the upper layer of wood broke away from the average (a). Weighing a few holes (b) drill in them, poured glue into them with a syringe (B). The peeling portion is pressed by self-drawing by screwing them at different angles (g).

|

|

|

|

Melt the wax putty and mix it with sawdust (D). Fill the space over recessed screws (E). "Patchwork" decorated under the bitch (g) and under the tree (s)

Acclimatization

When the flooring is delivered to the apartment, it is necessary to give them acclimatize. All manufacturers recommend to withstand a parquet board in room conditions 48h, and laminate - during the day. During this time, the planks acquire equilibrium properties characteristic of this room.Why not hurry to fit the coating? Let us explain on simple examples. Suppose, laminate or parquet board brought with frost (or delivered from a cold warehouse) to a warm apartment. Naturally, condensate is immediately formed on the planks. A tree or wood-chip base absorb it and increases slightly in size. If such a material is deposited to the floor immediately, soon the slots will appear between the planks.

Planks laid in autumn, in the season of rains and high humidity, will behave differently. When the central heating includes, the relative humidity in the apartment decreases sharply. The difference can be significant: with normal 50-60% to critical 20-30%. The situation is fraught not only by the appearance of slots in the floor. Such extreme can lead to the rupture of laminate planks and the bundle of a parquet board or cork coating. Panacea from these troubles will be maintained in the apartment of constant humidity at the level of 50%, for example, using air humidifiers.

Gravity

Seasonal fluctuations in temperature and humidity cause minor changes in the size of the planks, as a result of which the "floating" floor is slightly expanding or narrows. In order not to interfere with its free moves, around the perimeter of the room and in the doorways leave compensation gaps about 1 cm wide. They are usually covered with decorative plinths and springs. If there are no gaps, with increasing moisture, the expanding coating has nowhere to move, and the planks will periodically "get up slid".

Such curvature may occur if there are heavy furniture walls or wardrobes on the "floating" floor. They create the effect of local "anchor" planks under them, and interfere with the floor to remain "floating." Before massive or rigidly attached to the floor, the cabinet is desirable to provide a small gap, but it will have to decorate with a molding or a spawning.

Probably, all these items put on the finished finish coating, and the compensation clearance cannot be done in advance. But there is a way out. After all, the probability of flooring is the greatest in spacious rooms, where the distance from the wardrobe to the opposite wall is more than 6m. Before this free wall, it is desirable to leave a wider compensation gap. But in narrow corridors, the flooring is minimal, and you can not worry that the planks will be quiet.

The editors thanks the company "Cork Center", "Polimpeks", "Atelier de Parquet", Egger, Khrs

For help in preparing the material.