Features of facing with decorative stone of various surfaces: sand concrete, brick, wooden, coated with insulation and dry-coated plasterboard

The decorative facing stone can decorate the surfaces of any external and interior walls: sand-concrete, brick, wooden coated with insulation and plasterboard covered with plasterboard. Success is most likely, if such a finish is provided for by the project of the house, and when performing work, the technical regulations are strictly observed.

Who is who?

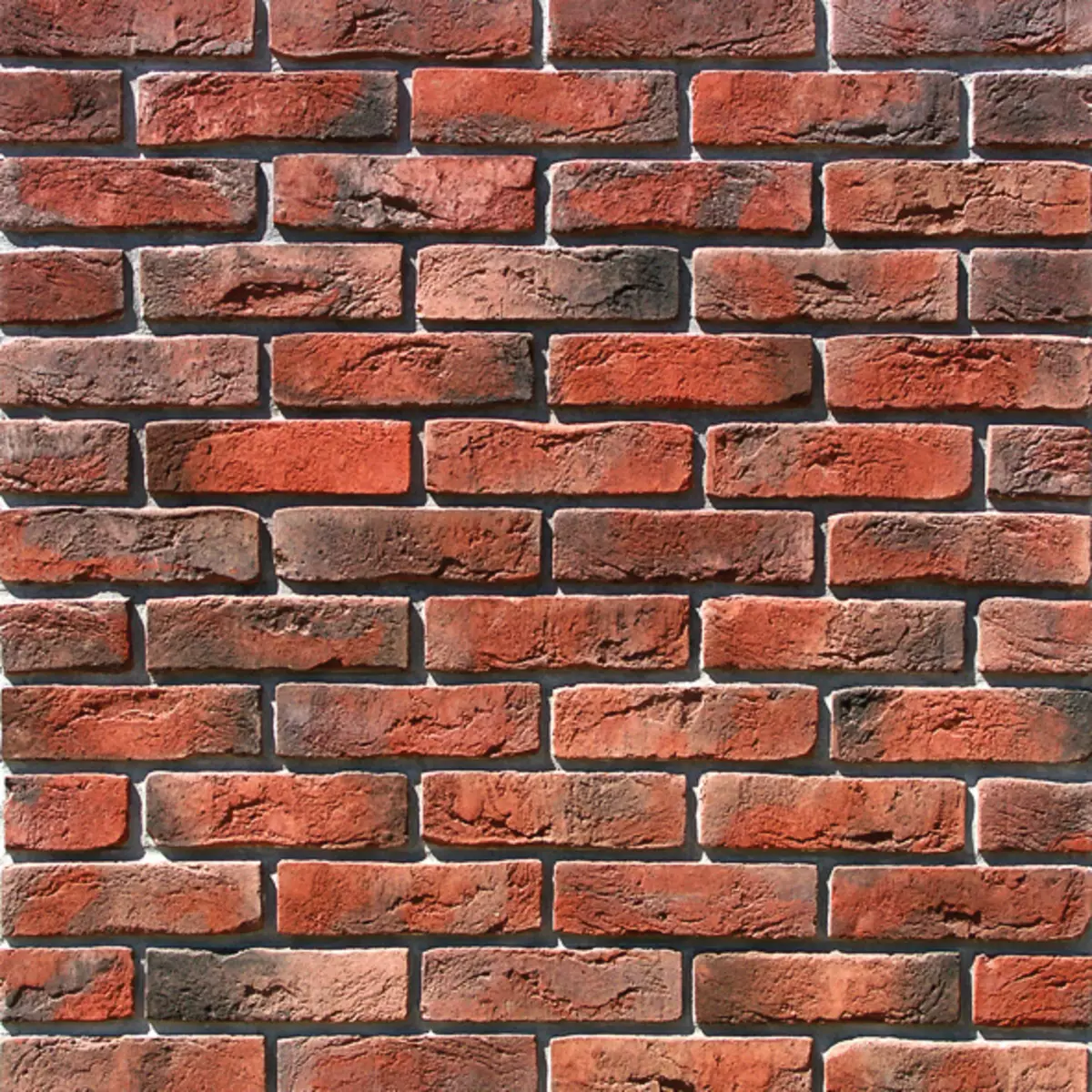

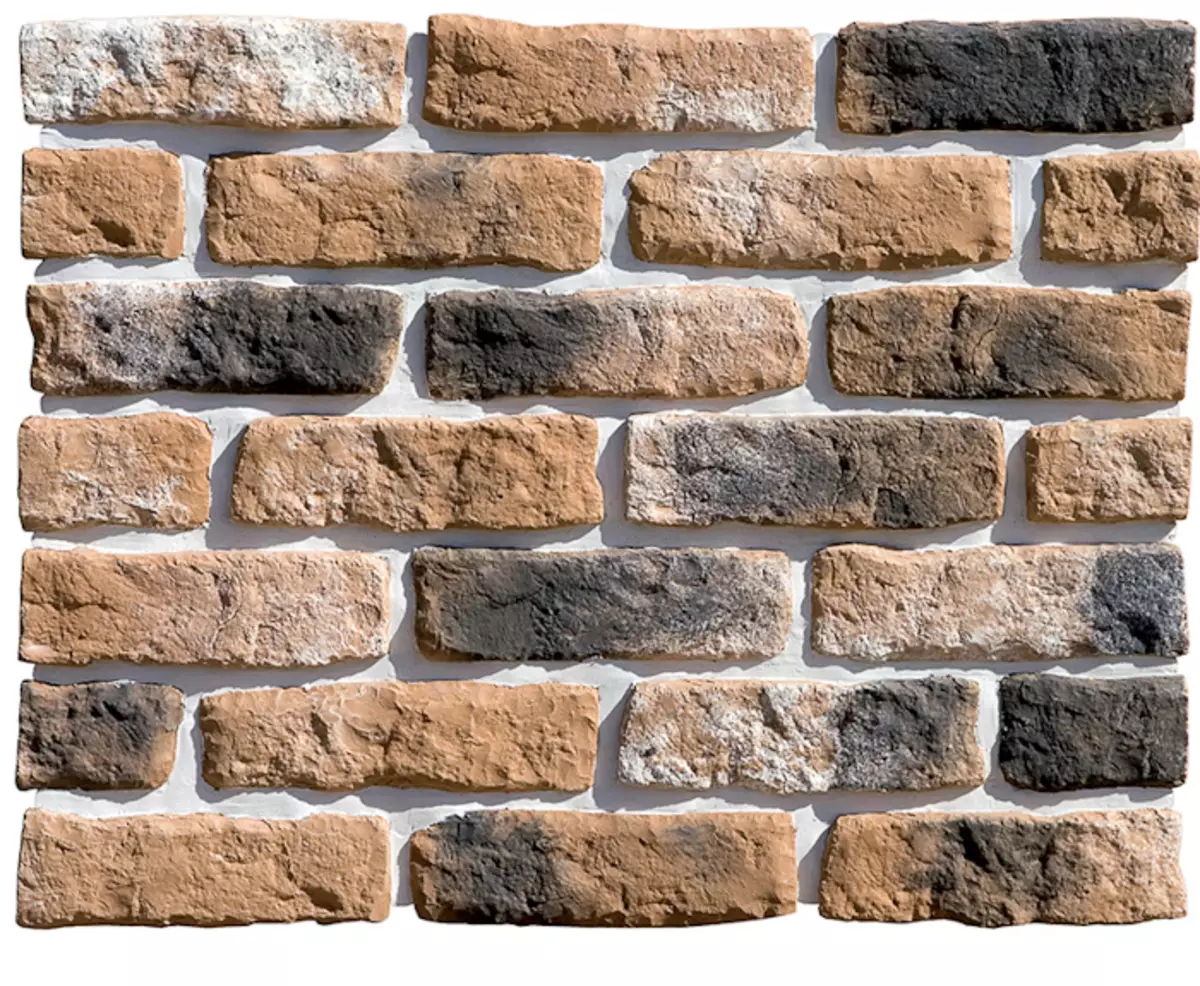

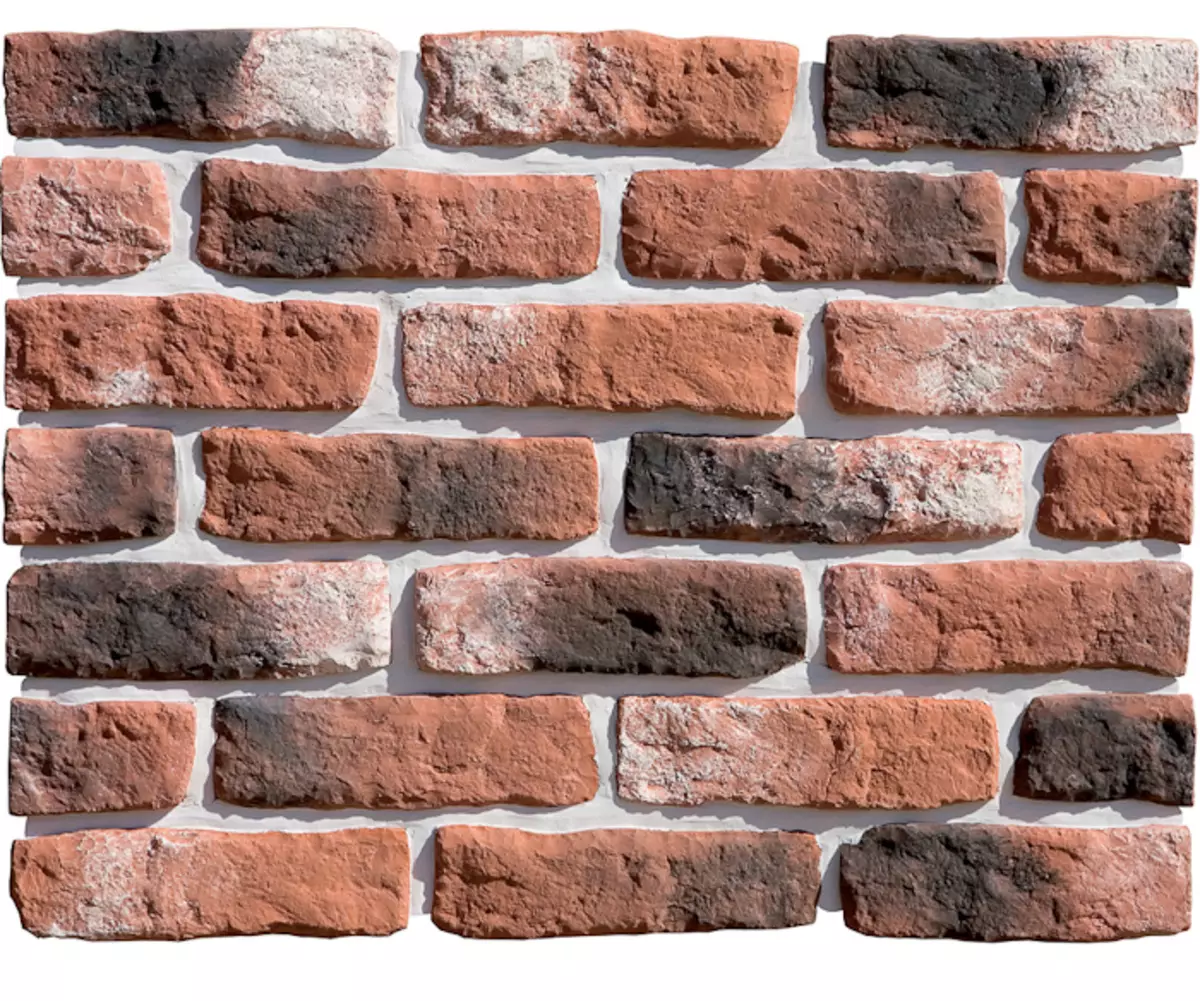

Decorative facing stone, sometimes called artificial, reliably reproduces the form, color and texture of real rocks: smooth and reservoir, sawn and brushing, river boulders and pebbles. However, the stone has unaffected origin. Its main components are cement (as a binder), sand, various fillers (ceramzite, perlite, pumice or mixtures thereof) and pigments. Sometimes to improve the properties of the stone, plasticizers are introduced into its composition, antiorious additives. Among the famous Russian companies - manufacturers of this material can be called White Hills, Kamrock, Chelsea Stone, Foreland, "Ecolt Trade", "Perfect Stone". Price 1m- 750-1400rub.

|

|

|

|

From small to large

The weight of the stone depends on its size and texture. Light is considered cladding weighing up to 20 kg / m; It includes popular collections of decorative bricks, the mass of the elements of which is incomparable with a mass of real bricks. Stones weighing 20-52 kg / m belong to the average weight category, more than 52kg / m to severe. In addition to them, the wall of the house should withstand the weight of putty, glue and grout. If the average consumption of glue and grouts per 1m 3-5kg, then even for almost the "weightless" cladding (17kg / m) the weight of the consumables will be 6-10kg, and this is a lot.

Another important parameter that needs to be taken into account is the ratio of mass and square of individual elements. Update bricks it is optimal. It is not by chance that they are used on any surfaces, including the sheltered GKL, coated with insulation, decorated with chipboard and not intended for large loads. Enclosures of large-factor stones One element of 1 dm can weigh 7kg. Choosing a similar type of finish, let's say, for the facade of a country house, you need to be sure that its weight will endure not only the design of the walls, but also the foundation. Judge for yourself: for a quick-scale house from the sandwich panels (100kg / m), a massive foundation of deep occurrence is required, and its plastered facade will not create any overweight problems. If the owners suddenly (not at the stage of creating a project or construction, and at the finishing stage) decided to decorate the walls with relief cobblestones (70kg / m), the weight of the building will increase by 1.5-2 times. Is this permissible on a lightweight foundation? An architect should be answered to such an actual question, but not a manufacturer or stacking stone.

The conclusion, as it seems, is obvious: the type and weight of the house cladding should be foreseen at the design stage, when the design of the foundation and walls are calculated.

|

|

|

Facing the decorative stone is harmonized with wooden surfaces (A, b), smoothly plastered walls. The "stone" facades are perfectly combined with tiled rods, wrought iron stairs and balconies.

A solid fence gives a country house solidity and ensures its safety. The fence, lined with decorative stone, fits well into any landscape, harmonizing with tracks, paved by the "stone" blocking, and without disturbing the natural charm of the area.

A, C - WHITE HILLS

B - Architect A. Ermakova, Photo V. Nefedova

Glue or plastering?

Most companies whose specialists perform the installation of decorative stone, use general principles of laying, but at the same time they adapt them to themselves. In other words, the "masonry system" differ in methods for fastening elements to walls used by consumables, strength parameters, errors of the shape and sizes of IT walls.

A simple example: so that the stone is reliably fixed, the glue composition should have a sufficiently strong adhesion to the base. In addition, he is forced to serve the damper between the wall and the stone (they, as a rule, have different linear expansion coefficients) at temperature fluctuations. After all, the spring surface of the wall, especially in the sun, is heated to + 15 ° C, and cool up to -5s at night. At the same time, the base is not warming up so intense as a stone, and therefore, the laying made of it expands stronger. If you apply the "wrong" glue composition, cracks will inevitably appear on the facing, and the stones will fall off over time.

Thus, choosing glue for decorative facing stone, it is important to take into account the properties of the base. However, it is necessary to keep in mind that the bag (25 kg) of the adhesive mixture for plastered surfaces costs 290-390 rubles, and for intensively absorbing (such as brick) - already 450-550 rubles. The price of professional compositions with even stronger adhesion (1.2-1.4 MPa) reaches 600-700 rubles. By their way, they are very firmly attached a stone to any wall, their cost will seem too high.

Want to save? Please have many ways. The simplest is to pre-shock and at the same time to align the surface of the wall with a thin layer (5-10mm) of the cement-sand mixture, and already apply the most democratic glue on top of it. By the way, dry adhesive compositions that offer manufacturers of decorative facing stone have an adhesion of 0.8-1MP and, as a rule, are intended for the prepared (plastered) grounds.

For surfaces with low adhesion to cement-sandy solutions, for example, a monolithic concrete, a method tested is used: first to the wall attach the grid, plastering, and then a stone mount on the adhesive composition. In this case, the total cost of consumables and the work performed will be about 400 rubles. For 1m. However, on the features of the facing of different types of foundations it is worth stopping in more detail.

|

|

|

|

Before mounting the decorative facing stone, a galvanized metal mesh is attached to the brick wall (A). Material masonry must be started with angular elements, and then decorate the walls (b).

In order to realize the full potential of expressive tools and the operational possibilities of a decorative stone, you must have special knowledge and comply with certain installation rules. Therefore, facing facades by this material should be trusted not to random people, but professional installers specializing in its laying. They will be able to fulfill the work of any complexity in the shortest possible time (C, D).

A, B - photo V. Kovaleva

C - "Perfect Stone"

D - Kamrock

Concrete and its derivatives

Why is it unwanted to glue the stone directly to the monolithic concrete, foam blocks, foundation blocks? After all, they look homogeneously smooth. It would seem, take and put it without any alignment ... The problem is just and is too smooth surface, which hardly passes the adhesive composition. To increase the adhesive properties of such grounds, you can apply special primers: Ceresit 19 (Henkel, Germany), "concrete asset" (UNIS), "Betokont T-55" ("Best", both - Russia). But still it is more reliable to take advantage of the proven way: to attach a galvanized or carciro (plastic) grid with the help of a construction gun and a dowel with washers, apply a plaster solution, and after it dry, proceed to the installation of stone.

|

|

|

|

|

|

|

Decorative stone trim (White Hills): first attach a metal plaster mesh (a) a dowel nail (b) throughout the ground area (B). Then the surface with the grid is covered with a small layer of cement plaster (g) and left until it dry. An artificial stone is mounted on the hardened plaster, checking the smooth masonry using the construction level (E). If necessary, the "stone" elements cut the corner grinding machine so that they acquire the desired size (E). The seams seal with a special cloud composition, squeezing it with the help of a building pistol (g)

Brick - Case Thin

Brick surfaces, on the contrary, are highly absorbing. They can be glued with a decorative stone of any weight without prior shocking. The wall is first covered by the appropriate soil, for example Ceresit 17 (Henkel), "deep penetration soil" (UNIS), "DIPCONT T-53" ("Best"), and use special glue: Ceresit CM 17 (Henkel), "StarPlits T-11 "(" BASES ")," FLEX "(KNAUF, Russia). A lining surface, the adhesive solution is carefully applied to the base, and on the stone. Costs will be small only with small volumes of work, when finishing a barbecue, base, wall fragments. When facing the facade of the building, workers are unlikely to thoroughly rub the glue into the surface of each individual element. The same consumption of expensive composition on an unwarked surface will increase markedly, and it is obligated. Therefore, it is worth thinking about the use of the above-mentioned proven method.On old molded brickwork or on the walls of low-quality bricks, as well as on monolith-concrete surfaces, it is necessary to use the grid. Captured bricks are fixed by a dowel-nail dowel, to slit-special dowels (type "Molly", "Butterfly") or anchors. Next, operate according to the well-known scheme. Similarly, they come with brick walls treated with hydrophobizers or means from heights (they are very difficult to glue on them).

Insulated walls

Eating country houses from a variety of building materials, including frame-shield and wooden, often use very efficient outdoor insulation from plates of polystyrene foam, mineral wool IT.D. Many may doubt that a loose and non-rigid surface of such walls can be a decorative stone. However, such technology has long been developed and tested in practice.

After the plates of the insulation are glued to the wall, they are additionally fixed by a dowel-nail or anchors depending on the type of base. Then the shell mesh is applied and immediately covered with adhesive composition by insulation so that it is in the middle of the layer. Next, the grid is attached by dowels to the base, that is, a double anchoring is carried out. Its task is not only fixing the heat insulating material, but also become a reliable support for facing. Inscess on the insulation, dents are formed, and they are leveled by adhesive composition for stone. At a prepared thus, a decorative stone of any kind, from the easiest to the most difficult. Having laid a certain type of facing into the project, you will only choose the insulation of the appropriate density, the desired number of dowels, a plaster mesh from a suitable material with an optimal cell size, as well as a glue composition.

Of course, the subtleties and nuances when working on the insulation, it is necessary to take into account a lot, for example, special attention is required to adjoin the junction of the windows and doors, the joints of the insulation, the external and internal angles of the IT.D. But it makes no sense to describe them. All of them must be marked in terms of work or other project documentation, and the brigade of the finishers remains only to be followed by him.

|

|

|

|

|

|

Wooden walls: a special approach

The most difficult for the "stone" finish is the foundation of wood, often referred to as "alive" material. Thus, a wall with an area of 10m with temperature and humidity drops can change linear dimensions up to 10 cm. Not every facing will endure such advances, and not every brigade will take over such work.There is a way out, and not one. You can warm the house from the bar outside, and the insulation is to fade a stone. Such a system allows you to level linear extensions of the tree, but it must be correctly calculated, and the facing must necessarily have deformation seams. They are usually done on the corners, under the windows of the IT.P., that is, where they are least noticeable.

Opinion of a specialist

After the laying is finally driving, the lining from the decorative stone is desirable to be treated with a special hydrophobic composition. It forms an elastic semi-permeable membrane on its surface, which repels water, protects the material from the effects of the external environment. It is easier to care for such a finish, because it is easier to clean from dust and dirt. Wtem places, where the facing stone will be exposed to frequent temperature fluctuations and aggressive media, and also in contact with water, processing the hydrophobizer is mandatory. It is applied in two layers of wet wet. The surface of the stone acquires beneficial properties after 2-3 days. "Works" coverage is about 5-7 years, after which the procedure is repeated.

Denis Panov, CEO of WHITE HILLS

There is another option. Mount the external walls of the house design resembling the system of the ventilated facade: to attach metal guides to the walls, two layers of the CSP, then the grid, impose plaster and, finally, bind the stone. In a similar way, small parts of the walls are usually made, and the stone is glued directly to the CSP, since these plates have good adhesion to cement-sandy solutions.

|

|

|

The decorative stone arrange the outer and inner walls, fireplaces and chimneys, the surface temperature of which does not exceed 70 s (a, b).

Architect A. Buzyitsky

Photo N. Serebryakova

Thin and light artificial stone are often used to finish interior. Installation of elements does not cause special difficulties, and the service life of such a finish is almost unlimited (C).

Architect A. Grishin

Photo R. Shelomenseva

What inside?

Inside the premises, finishing often have to deal with walls and plasterboard partitions. There are no special problems with their cladding decorative stone. We will pay attention only to one nuance, which needs to be taken into account when erecting a wall designed to finish with a heavy material (more than 52kg / m). Standard pitch of metal guides for fastening GLK-60SM. Under the massive cladding they are installed more often than 30cm. Non-alone fastening is fixed, but two layers of moisture-resistant GLK. Further operate according to the standard scheme: they shoot a thin plaster grid with the help of a construction stapler and brackets, wash it with glue and after a day begin to separate the wall with decorative stone.Opinion of a specialist

Switching - the final stage of installation of decorative stone. It solves the constructive task of seaming seams. It is impossible to leave the seams open, through them moisture will penetrate the lining, and with periodic cycles of freezing and thawing, destroy the masonry. In addition, the batch of seams gives facing a more aesthetic appearance. You should not fill in the seams by the remaining masonry solution - it is sticky, it is hardly extruded through the gun, and as a result of the seam, it turns out inactive. For this purpose, special grouts manufactured by almost all manufacturers of stone are intended. The most simple in circulation of the compositions, which are applied using a construction pistol or homemade "syringe" made from the package, Tuba IT.P. The seams between the individual elements are filled with a wet mass, waiting for 30-40 minutes, while it gets dry, and then flipped with a spatula.

Alexander Terentyev, Chief Technologist of Kamrock

Overall

In the apartment, the conditions for facing surfaces with decorative stone can be considered ideal: permanent microclimate, lack of aggressive external influences. When the facades are optimal, the ambient temperature is considered in the range of 10-25C. It is undesirable to mount the stone in the rain and straight solar rays, since excess moisture or rapid drying of the solution reduce the strength of the masonry. The best time for finishing (especially for grouting seams) are morning and evening.

At air temperature to -10 C use special "winter" glue. True, there is one condition: while the masonry solution does not drop 70% strength, the air temperature should not fall below the value indicated on the glue package, otherwise the strength characteristics and the durability of the composition will decrease. With even lower temperatures, the separated area surrounds the so-called warmth, reminiscent of film greenhouses, heat the air inside it and the stone is mounted. At the end of the work, this temperature is maintained for another 3 days.

Editorial Thanks White Hills, Kamrock, Chelsea Stone

For help in preparing the material.