Modern household solid fuel boilers: models with enlarged load, devices with built-in tenn, units with advanced combustion schemes, Pellet boilers

The boiler is not a luxury, but a heating. Inesl for you a trunk gas - very foggy or too expensive perspective, and the cost of diesel fuel (which has already been practically equal to the price of gasoline of the brand 95), as well as the cost of electricity costs seem exorbitant, the output is one- as a source of energy for heating its own home Use solid fuel.

So, choose a solid fuel boiler. Today, the market presents a wide variety of their types. They work on firewood, coal (brown, stone, anthracite, coke), as well as on peat, wooden, coal and other briquettes. Such a boiler operates according to a completely understandable classic scheme, in which everything is thought out, except for one: the fuel tab bursts for 2-4. It means that if from the evening flood it, among the nights you have to get up and go to the boiler room to add fuels, otherwise there is a risk to the morning to freeze. Agree, the prospect is unpleasant: in three rose, to five with difficulty fell asleep again, the alarm clock rang at seven, urging again to go to the boiler room. AB Middle of the working day Who will throw a firewood? It's time to hire an extract ...

Protherm |

Dakon. |

Buderus. |

ViaDrus. |

Opop. |

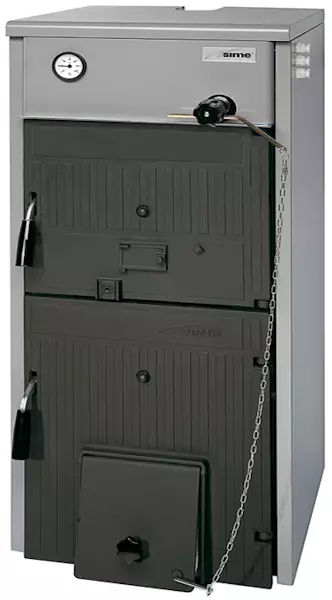

SIME. |

1. Once another two or three years ago, due to the wide gasification of the villages, wood boilers began to be considered outdated and ineffective. But after many manufacturers have finalized the design of products produced, boilers on firewood again turned out to be in demand.

2-6. FB (Dakon) (2), U22 (ViaDrus) (3) and Solida (SIME) (4) (3) and Solida (4) (4) and SOLIDA (4) are loaded through a wide door on the frontal plane, and in boilers Logano S111 (Buderus) (5) and H412 (OPOP) (6) - through the "Luke" located on top.

But still the output exists. Manufacturers of boiler equipment now provide their products with increased loading chambers, electric tanks, improved combustion schemes, and also offer automatic boilers operating in the new form of fuel pellets. Let us try to figure out what each of the listed types of devices is and how helping to solve the problem called.

Increase the download

Modern household solid fuel boilers have absorbed the advantages of their predecessors. The main one: the heating system does not require power. (True, recently the boilers began to equip the smokers that require 50-150W electrical power.) And now boilers can automatically maintain the specified coolant temperature. This happens as follows: the sensor follows the temperature behind the heat carrier temperature on the boiler; If it exceeds the installed, the device covers the damper and burning slows down. If the temperature drops below the specified value, the damper opens. The most important thing is in modern boilers, the volume of the loading or flue chamber is increased (and in some cases, the size of the door leading to these cameras). As a result of the combustion duration of one fuel load increased by 1.5-2 times and reached 8h (the maximum number declared by the manufacturers, which we managed to find when preparing this article). Many manufacturers equipped the combustion chambers of their boilers with adjustable secondary air supply systems used for flue gases - it increases the efficiency efficiency. Now it is possible to adjust the amount of combustion products leaving through the chimney, which allows you to provide optimal traction. The accuracy of the boilers provides additional protection against overheating - a special cooling circuit. Thanks to him, it is possible to quickly reduce the temperature of the coolant as manually (opening and closing the valve) and automatically (the thermostat gives the valve command).

Solid fuel boilers again in fashion

Nowadays, the popularity of solid fuel boilers increases both on the European boiler equipment market and in neighboring countries. Forward, this is due to the desire of consumers not depend on gas and oil supplies from states with an unstable political situation. The idea of "Gas Independence" in the minds of Europeans sped a long time ago, but to actively embody it in life began only after a memorable conflict between Russia and Ukraine in early 2009. The Ukrainian side blocked pipelines for which Russian gas was transit to Europe. The second reason is clean economic. After all, firewood, coal or pellelee, an inexpensive alternative to oil and gas. (For reference: Heat obtained from firewood is cheaper than from coal, about 1.5-2 times; compared with heat from the diesel engine, 5-8 times, and from electricity - 12-17 times.) Burning Sawdust, chip, sunflower husk, as well as briquettes and granules manufactured from them, you can at the same time to dispose of woodworking waste and agricultural production. In the early time, interest in solid fuel boilers is growing in Russia. There are several reasons for this: in some regions, gas has not yet been supplied to the housing, and where it has already been done, it is quite expensive to connect it. Only the house connection to the gas highway is sometimes worth 500-800 thousand rubles., And if the house is just on the fee - even more. The government again promises to increase gas tariffs by 27%. If automatic (i.e., almost not requiring interference in its work, like a gas) pellet boiler, along with the installation will cost 300-400 thousand rubles, you will most likely give my sympathy to him. You can buy so many pellets for saved money that they are enough for a boiler for 10 years.

The range of solid-fuel boilers with increased loading is quite varied: Russian and imported, steel and cast-iron, working only in one form of fuel and on several, for systems with natural or forced circulation. Western and price range - from several thousand to hundreds of thousand rubles. Releases of their companies atmos, Dakon, Oror, Rojek, Viadrus (all Czech), Protherm (Slovakia), Buderus, Olymp (both Germany), Roca (Spain), CTC (Sweden), Jama (Finland), Wirbel (Austria ), Demir Dokum (Turkey), Hajdu (Hungary), Sime (Italy), NMZ, "Flame", "Stanov", "Evan" (all- Russia). Most of the listed firms have been working for quite a long time in the domestic market. AVOT ATMOS, HAJDU, OROR and WIRBEL appeared on it relatively recently, but has already managed to gain popularity. Ito is quite natural - in the design of boilers of these firms used original technical solutions.

Zota. |

Zota. |

Zota. |

Zota. |

Wirbel. |

"Evan" |

7-12. Solid fuel boilers with built-in Tan differ in additional functions: MIX (ZOTA) (7-9) can be equipped with a gas burner, thus turning into multi-fuel; On the top plate of Aots 18 (Zota) there is a comfortable, which is convenient to prepare food (10); Eco-EL (Wirbel) (11) is equipped with a bench control unit, it is installed on the unit of the unit from above; Warmos-TT ("Evan") (12) allows you to burn fuel with humidity up to 70%.

Not all solid fuel boilers "omnivores"

"Omnivore" boilers of increased loading, allowing to use any kind of solid fuel, not so much in our market. These are mostly cast iron units: Solida (SIME), Logano, G211 (Buderus), Opop H (Opop), "Beaver" (Protherm), Hercules U 26 (ViaDrus), as well as boilers from the Solitech Basic series (Demir Dokum). Choosing a boiler, keep in mind that some manufacturers have models with prescribed (basic) and backup types of solid fuel. For example, basic fueling; Reserve - brown coal, briquettes, coke. Or vice versa: prescribed fuel - brown coal; Backups. If the consumer does not know this and the boiler constantly works instead of basic fuel on the backup, its efficiency (and therefore thermal power) can decrease by 5-10%. Result Fuel consumption will increase. Courtic fuel boilers, for which the prescribed fuel are firewood (Woody IT.P.), include DOR D (Dakon), Logano G211 D and Logano S111 D (both - Buderus), U22 D (ViaDrus). Coal (stone, brown, anthracite, coke IT.D.) is the prescribed fuel for boilers like Dor (Dakon), Logano S111 (Buderus), AC 25S (ATMOS) and U22 C (ViaDrus).

Consider EKO equipment (Wirbel). These are steel water heating solid fuel boilers with a capacity of 14-80 kW. Cox, coal, firewood (Length Length - 600mm) and Thor-Fiana Briquettes are used for inclusive fuel. If necessary, they can be transferred to gas, diesel fuel or pellets - in the bottom door of the boiler there is a hole to install the corresponding burner. The furnace chamber is made of 5mm thick steel, which ensures the service life of the boiler at least 15 years.

Steel and cast iron heat exchangers

Solid fuel boilers can be equipped with steel and cast-iron heat exchangers. Each type of these devices has its advantages and disadvantages. Heat exchangers made of iron resistant to corrosion than steel (cast iron and in itself less prone to corrosion, and, moreover, the cast iron heat exchanger has a greater thickness). The cast iron has a higher heat capacity, so the heat exchanger from it is heated long, but slowly cools. But since the cast iron is more fragile than steel, during the operation of cast iron heat exchangers, the problem of the so-called temperature shock (thermal shrink) arises, due to which the sections of the device can crack. The reason for this is a significant difference in the temperature of the water in the feed line and the "returns" (manufacturers are not in vain indicate in the instrument passport the minimum temperature in the return highway). Some firms (for example, Sime and Wirbel) use design solutions to avoid dangerous for iron drops inside the heat exchanger. Steel heat exchangers are lighter and impact-resistant, which is important when transporting, loading and unloading (microcracks may occur in the cast iron). In addition, such devices from steel are less sensitive to temperature drops. Finally, it is important that boilers with steel heat exchangers are cheaper. But ... these devices are subject to corrosion caused by condensate, formed when the heat exchanger temperature decreases below the dew point. The service life of the steel heat exchanger depends on the quality of steel, its thickness and operating conditions.

A feature of the rojek boilers is a water-cooled grille from heat-resistant steel. This allows not only to increase the heat transfer, but also to start in the boiler inverse water with a temperature of 40 s (although usually this indicator should be no less than 60 s). Under the grille there is a comb, with which you can clean it without opening the door of the boiler. Water-cooled earrings equip their boilers and the company HAJDU, but they are not made of round, and from a square pipe with a cross section of 5050mm.

Other manufacturers are improving other manufacturers. For example, Dakon equips his boilers with a patented system of rotary graters, complemented by a folding grate - it leads to a special lever, which is bred on the body of the boiler. There is a similar device in Buderus boilers.

Boilers with built-in ten

Some hard fuel boilers are equipped (or offered to make it to order) built-in ten. A similar idea is not equipped with so-called multi-fuel boilers, capable of working on four main types of fuel: solid, liquid, gaseous and electricity. They are issued by CTC, Jama, Zio-Sab (model "Ziosab-45") and "META" (Flame boilers) (both- Russia).The stated and real level of burning

Choosing a solid fuel boiler, the consumer primarily draws attention to the burnt duration of one full fuel laying by the manufacturer. This value is certainly important, however, to the numbers indicated by the manufacturer should be treated with caution. For example, in the boilers of the upper combustion of BKTT (SZOS, Belarus), according to laboratory tests, the full tab in the minimum mode goes for 31.5 hours, and to the maximum for 61h. Moreover, the manufacturer honestly warns that these are indicative data, since the duration of burning one fuel laying depends on its quality, external and internal temperature, the heat-saving ability of the Idr building. So, firewood, the humidity of which exceeds 30%, are grown unstable and do not provide the proper temperature of the coolant. A similar phenomenon is possible with insufficient thrust, even if the firewood is dry.

It should be noted that solid fuel boilers are additionally equipped with a somewhat different purpose than multi-fuel. Ten Here is intended only to maintain the desired temperature of the coolant in the interruptions between the intimidation. It turns on only when the hard fuel will feed and the temperature of the coolant will decrease to a specified limit (it, as well as the inclusion and disconnection of the Tan controls the special control unit). Thus, the TEN here is the very element that eliminates the consumer from the need to rise in the middle to throw firewood into the boiler.

Such boilers spend not a lot of electricity: the power of the Tan, which install them, is obviously lower than necessary for home heating. After all, they only heat the coolant, and for this heat is needed significantly less.

In our market, the boilers with built-in tenan are not too wide. Among the common models, it is worth mentioning EKO-EL (Wirbel) having a water-cooled grille and designed for use as the main fuel of coal, frameworks of IDR; Warmos-TT boiler ("Evan"), as well as "smoke" and MIX ("plant of heating equipment and automation" - Zota, Russia).

Boilers upper burning

To increase the burning duration of one wood laying, manufacturers change the usual fuel burning scheme and in connection with this almost completely transform the design of the boiler. Especially succeeded here Lithuanian manufacturers. They are literally in need of boilers, in which firewood burns not according to the classic scheme - bottom, and from top to bottom. Ignore much longer! For example, in the strapuva boilers (Lithuania), according to the manufacturer, the DRA tab is burning about 1 day, and the coal laying is 5-7 days.

|

|

|

|

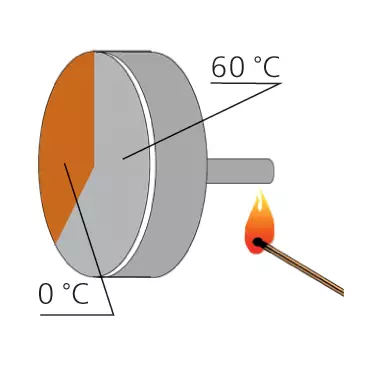

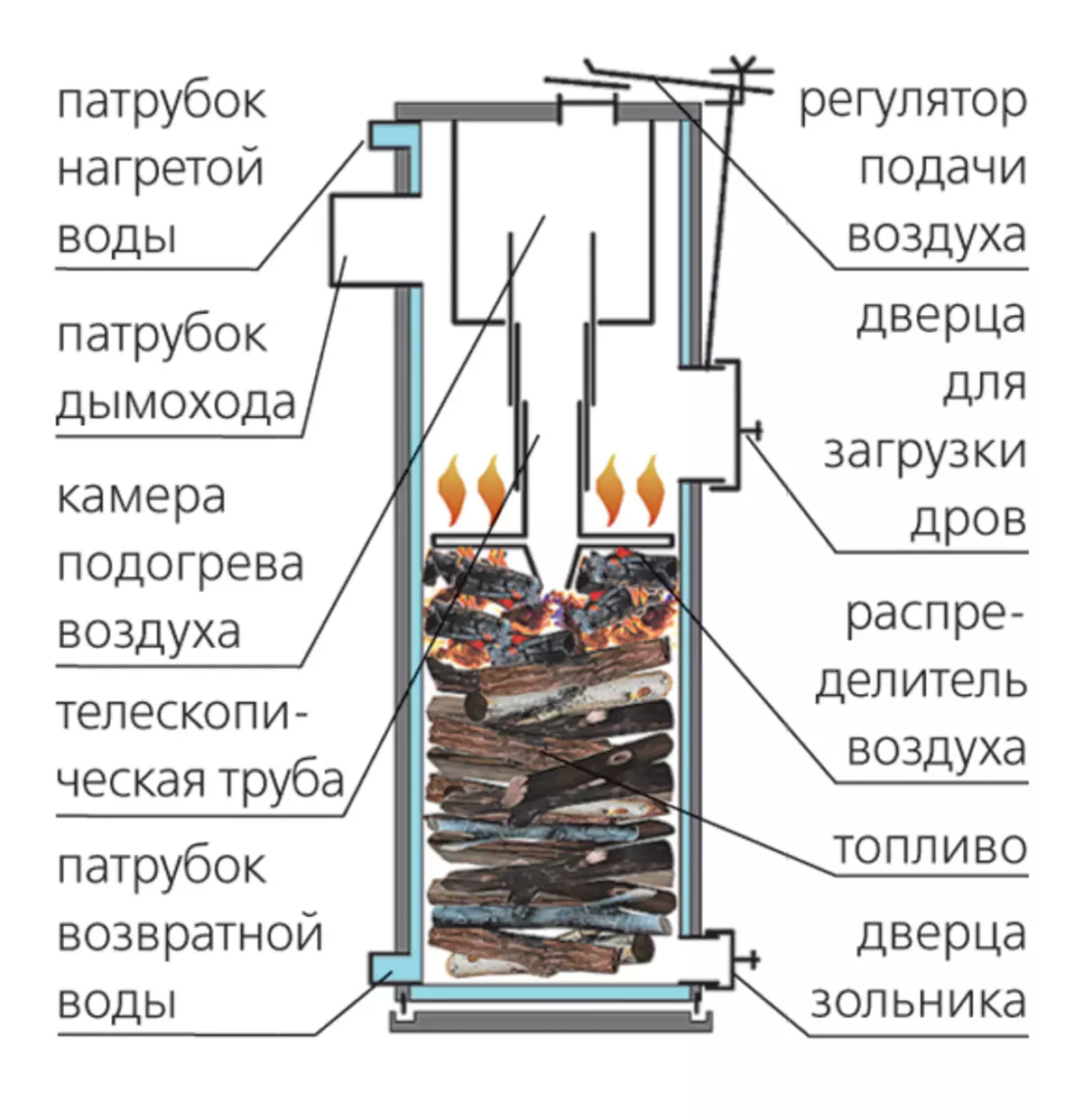

13-14. Principle of vertical combustion:

13- The match in the horizontal position will burn 30-40 s and heat the thermometer to the maximum up to 60 s; 14 - Match in a vertical position (head up) will burn 60-80 s and can heat the thermometer to a temperature of about 120 C.

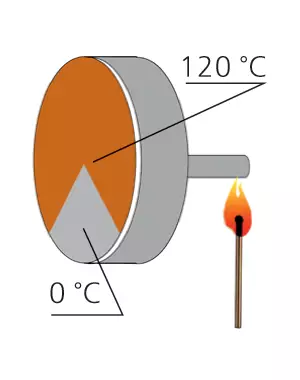

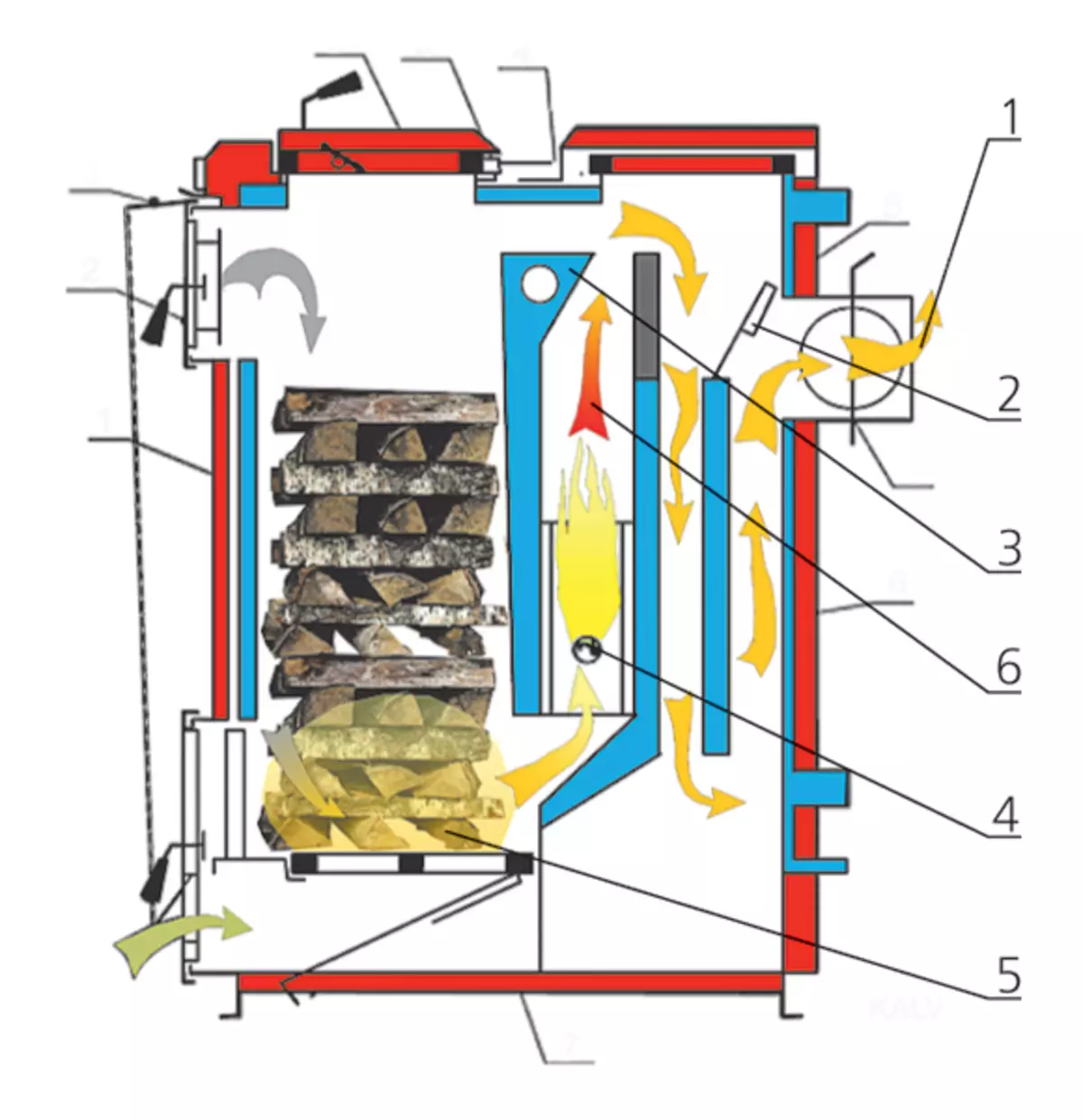

15-16. Circuit diagrams of gas generator boilers with lower (15) and side (16) location of the pyrolysis gas burning chamber:

1- chimney nozzle; 2-ignition schieber; 3- heat exchangers; 4-nozzle; 5-chamber of pyrolysis combustion; 6 - Pyrolysis gas burning chamber.

How is such a boiler? It consists of two steel cylinders (one inside the other), and in the space between them there is a heated coolant. A small diameter latch is placed in the fuel loaded through the door on the housing. The air supplied for combustion enters the heatpace from above (while it is heated due to the heat of the outgoing gases) and is sent to the burning center using the air distributor. The latter is a telescopic tube, at the end of which the device is attached, in shape resembling an umbrella. The bottom edges, this umbrella rests on the fuel located at the walls of the furnace (in this zone, the burning occurs is not so intense as in the center). Air is supplied to the furnace with such a calculation to stimulate the burning of only the upper layer of firewood with a thickness of 15-20 cm. The underlying layers of the boiler keeps about the supply, as if a hamster behind the cheek. As the top layer bursts, the umbrella is lowered below, but always keeps on the fuel at the level of burning line. The ash practically does not prevent burning, it is enough to clean 2-3 times insteps.

What are the advantages of upper burning boilers? In their round in cross section, the furnace is equally well burning both firewood and briquettes of wood sawdust and peat. Despite the considerable height, such aggregates occupy a very small area in the boiler room. Finally, since only the top layer of fuel is lit in the boiler, even when the coolant circulation is turned off, its temperature is increased only by 12-16 C.

In our opinion, the main disadvantage of such devices is that it is not possible to exhaust fuel into a burning boiler. Why is that bad? Imagine: Early morning, it's time for you to work, and on the street frost under 30 C. According to your calculations, the fuel in the boiler is left for 1C, and you will return home only in 9-10 h. There are three ways to solve the problem: do not go to work; come home to a lunch break; Having hoped that until the evening the pipe would not have time to freeze. Another minus the upper burning boilers are more expensive than traditional 1.5-2 times.

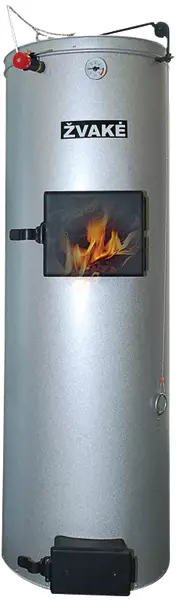

For the Russian market, such boilers are supplied by Aremikas (Lithuania, Candle and Zvake boilers) and Stropuva, as well as the Smorgon Optic Stank Tank Plant (SZOS).

Gas-generator boilers

The basis of the operation of the gas generator (pyrolysis) boiler Pyrolysis burning (dry sublimation) of fuel. The essence of the method is as follows. Under the action of high temperature (270-800 C) and in conditions of lack of oxygen, dry wood decomposes on a volatile component (the so-called pyrolysis gas) and a solid residue (charcoal). This is exactly what the design features of pyrolysis boilers are due: they have not one combustion chamber, but two and upper. The normal fuel burning first occurs (in this mode, the boiler is incites), and after switching to long-burning mode (for this, it is necessary to manually cover the flaps on the path of air supply and flue gases) - pyrolysis and burning coal. Due to the heat allocated, the heat carrier is not only heated, but the air that goes into the upper chamber is heated (it is customary to be called secondary), which is necessary for burning pyrolysis gas. The latter enters the combustion chamber through a special nozzle and forms a light yellow or almost white flame. Its burning can be automatically controlled, as well as burning natural gas or liquid fuel. But the main thing is, with the burning of pyrolysis gas, much more heat is distinguished than when burning firewood.

If there will still be gas in the house ...

In order not to pay the money first for a solid fuel boiler, and then for an aggregate working on the long-awaited blue fuel, specialists offer an original solution. Similar to many producers of solid fuel boilers have combined models, which, after installing the corresponding burner, can be translated from firewood. There are also boilers with two fireboxes: one of them works on solid fuel, and a second-gas or diesel fuel. Moreover, such a device is replicated without effort from one type of fuel to another. Solid fuel combined boilers with two firefoots on the Russian market are offered by Dakon (FB D series), ROCA (P-30 series), ATMOS (DC and EP / SP series), Wirbel (EKO-CK and EKO-CK PLUS series) IDR.

What is the difference between the traditional and gas generator boiler? When operating a conventional solid fuel boiler, the fuel is layered once in 3-4 hours, and in pyrolysis time between loads increases in 2 or more times. The result complex of pyrolysis combustion The flue gases at the outlet of the boiler practically do not contain harmful impurities and are a mixture of carbon dioxide and water vapor. But at the same time, such an aggregate will be thrown into the atmosphere 3 times less CO2 than the traditional wood level. With pyrolyzny burning, a minimum amount of soot and ash is formed, so the boiler needs cleaning less often than the usual one. Isaoy main, pyrolysis boilers have a high efficiency (about 85%) and make it possible to automatically adjust the power in the range of 30-100% of the nominal.

One of the minuses of pyrolysis boiler - high cost (they are 1.5- 2 times more expensive classic similar power). The same for the operation of the fans used for the superior air to the combustion chamber of pyrolysis gas or to remove the exhaust gases, it is necessary to power. But for the sake of justice, we note that not all manufacturers use fans in the design of boilers, and pyrolysis aggregates are electrically dependent. Such devices are equipped with a diffuse type burner (it resembles a perforated tube of a special design that provides a natural current of gases) and mechanical opening / closing controllers of dampers through which the primary and secondary air comes into the pyrolysis boiler.

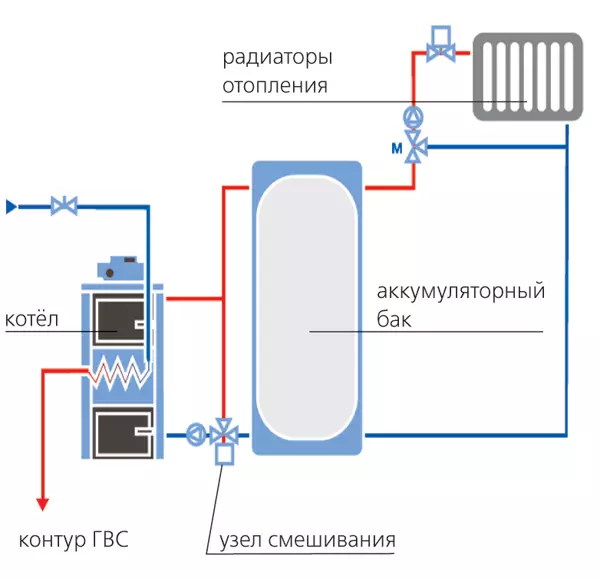

Alternative solution to the problem is to establish a tank drive

The heating for pyrolysis boilers should be talking in more detail. Almost all manufacturers offer to use any kinds of wood, as well as woodworking industry and special wood briquettes whose humidity does not exceed 20%. Only strict adherence to this requirement ensures the operation of the boiler with maximum power and long service life. It is worth downloading raw firewood into the boiler - and you will receive a complete set of trouble: from the pipe will begin to pour strong smoke; In the room where the unit is installed, an unpleasant smell will appear, and the single-layer steel chimney will "decorate" the drums of soot and tar. At the same time, the efficiency of the boiler will decrease and the service life is significantly reduced not only the device itself, but also the chimney.

Some manufacturers, applying two-stage burning, provide an opportunity to use alternative fuels in their boilers: brown and stone coal, coal briquettes, coke. Of course, at the same time, no matter what pyrolysis of speech does not go, the boiler will work in the mode of ordinary burning. But such an option may be very useful if the firewood is completed.

Aremikas. |

Aremikas. |

Viessmann. |

Viessmann. |

17-18. The uniqueness of the solid fuel boilers of vertical burning is that in the absence of complex mechanical fuel supply systems in the burning zone, one loading is lit down depending on the type of fuel from 7 to 34.

19-20. The vitoligno 100-S boiler firebox (Viessmann) is made of steel sheets with a thickness of 8mm, which ensures long service life.

In our market, pyrolysis boilers with the top arrangement of the gas burning chamber offer Opop and Wirbel, as well as "Bourges-K" and "Uralenerk" (both- Russia).

One of the technological innovations of modern gas generator boilers is the system of lower combustion. From the already described it differs in the way that the magizer of the pyrolysis gas is placed not above the furnace, but under it. Firewood is smolder at the bottom of the firing - at the grate, and the released pyrolysis gas is surrounded in the chamber under the grate. Thanks to such a diagram, the firewood is burning evenly and longer, and the heat of flue gases can be used more fully, since their path within the boiler is extended. The market also presents units, in which the gas burning chamber is not under the furnace, and on the side of it. At the same time, the pyrolysis gas highlighted by the wood, burning in the lower zone of the furnace, is not allowed, respectively, and Block. Yves volume and in another case, for the efficient operation of the system is better to use forced traction.

Do not trust advertising allegations of trading firms that even wet firewood can go in such boilers (allegedly they will dry out in anticipation of access to the combustion zone). Such statements are not supported by manufacturers data. As forbid, as for the other pyrolysis boilers, it is allowed to use only dry firewood.

Pyrolysis boilers with a lower combustion system in the domestic market quite a lot. These are Kalvis products (Lithuania), Viessmann (Germany), Atmos, Buderus, Dakon, Opop, Rojek. Most manufacturers offer on one series of such pyrolysis aggregates, and ATMOS and BUDERUS- two. For example, ATMOS releases ATMOS DC boilers with one or more fireboxs, as well as devices with ATMOS D semicapping without fan. Buderus presents a series of S121 and S121WT boilers equipped with smokemosos, and the latter are also equipped with a protective cooling circuit. Installation of the smoke instead of the injection fan is an additional security measure: The smoke creates a small vacuum in the combustion chamber, which prevents the emission of flue gases into the boiler room when the boiler door is opened.

A curious constructive solution is used in the Viessmann boilers: heated water, rising through the pipes, rushes to the rear wall of the boiler and mixes to cold water reverse. This allows you to increase the temperature of the reverse water and prevent the occurrence of low-temperature corrosion.

Pellet boilers

Pellets are used as fuel in these devices. These are wood granules made on a special pore of chips, sawdust and other waste of the woodworking industry without the use of chemical additives. When pressing a particle "glues" lignin contained in the wood. The diameter of the granules is 4-10mm, the length is 5-30 mm (1 T pellets occupies a volume of 1.5 m3). Pellets sell in convenient for transportation and storage of packages.

"Burzhuy-K" |

"Wonderful furnaces" |

Atmos. |

21-23. It may seem to someone that the domestic models "Burzhuy-K" (21) and the "miracle furnaces" -KW (22) have not yet become a miracle of designer and technical thought, but they are 2 times cheaper than foreign, such as ATMOS boilers ( 23).

These granules are environmentally friendly and very calorie fuels (calorific value is 4500 kcal / kg). Other their advantage thanks to the small size of their submission to the pellet boiler can be automated.

Europe is struggling for independence. From whom and what?

Denmark has practically no energy resources, the gas was found a few years ago on the shelf of the North Sea. Idatchan one of the first in Europe was understood that depend on imported oil and gas is unsafe. At the end of the 90s, gghh century. Here we accepted a special program that encourages the transition to biological grades of fuel for heating buildings, and above all on granulated fuel-pellets. Of course, changes took place very difficult and not too fast. Only in 2006 Pellet boilers won not only popularity, but also the title of products of the year. Denia followed the rest of European countries. For example, in Germany already in 2007. More than 70 thousand boilers were working on granules, and 1.8 million tons were produced for them. Doves The demand for pellet boilers is growing not only in Europe, but also in Russia. It is, first of all, due to the fact that domestic pellets producers (they appeared immediately, as soon as in European countries there was an interest in this product) Finally realized that it was not so profitable to sell granules abroad because of the huge transportation costs And pellets can be supplied to the domestic market. Secondly, releasing pellets began new enterprises (now they are already more than 200). Competition arose, with the result that pellets stopped being a deficit. In the meantime, Europeans in the struggle for "gas independence" seems to be stopped not going, and today this movement develops into the struggle for "fuel independence". So 3 years ago at the SHK exhibition in Frankfurt am Main were presented with granules made of the so-called poor coal of the long-abandoned ruro coal basin, which can be successfully used instead of pellets. Therefore, it is quite possible that in the coming years, residents of Europe will begin to gradually refuse not only from gas, but also from pellets supplied from Russia.

A special burner is built into the gesture of the bracket. More pellets come on a screw conveyor from a small fuel feeder burner. The inner granules fall from the storage bunker located near the boiler or in the adjacent room, and there is another screw conveyor in the nearby room, which controls the photo seensor built into the feeder, it monitors the feeder with granules, including / shutting down the outer auger. The separation of the conveyor feeding pellets into two parts increases fire safety: if even the flame breaks out of the burner, then it does not spread.

Cases use the bulk type burner (it resembles a saucepan of heat-resistant steel, cast iron IT.P.). Pellets are served in this device depending on the design of the boiler in two ways: they are poured into the burner from above either through the hole in its bottom.

How to choose good pellets?

The operation of the boiler and supplying fuel mechanisms "manages" a special electronic unit. Control the operation of the unit using the control panel on which you specify all the necessary settings, including the desired temperature, daily and even weekly cycle of the boiler. For safety in the design of the boiler, an emergency thermostat that burst the electrical circuit is provided if the device is overheated. The rotors are equipped with boiler doors. It is clear that such a "stitched" electronics of the boiler in Russian conditions is recommended to connect to the network only through the voltage stabilizer.

|

Wirbel. |

ViaDrus. |

SIME |

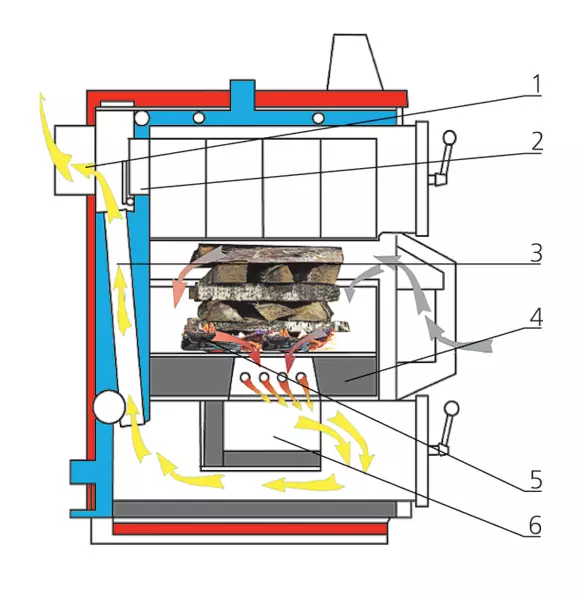

24. Scheme of boiler vertical burning.

25. Steel boiler EKO-CK Plus (Wirbel) with two fireboxes: left - for burning solid fuel (firewood, coal), right- for diesel fuel or gas. Power - 25, 35, 50 kW. The unit has only one chimney. These boilers can be both single and double-circuit.

26. The boiler Hercules Eco (ViaDrus) has a number of advantages: time-tested cast iron heat exchanger, protection of the combustion chamber of ceramic plates, eco-friendly and comfortable fuel-pellets, as well as modern automation. According to the manufacturer, the unit distinguishes ease of maintenance.

27. The SOLIDA 8 PL model was created on the basis of the SOLIDA boiler 8. Turbulizers that improve heat exchange and increasing the efficiency of the unit are installed by the removal channels of the device. It is complemented by Kit Pellet, which includes a burner with a conveyor and a ignition system, a screw conveyor, a tank for pellets, control panel.

After receiving the "Start" command, the conveyor begins to push the pellets into the nozzle burner. Mounted under the last fan in the meantime, air is supplied to it, and the incandescent spiral facing the granules (there is another method of ignite, with a hot jet of air generated by the fan heater). When they trim, the control system itself will select the feed mode of the pellet corresponding to the specified power, and will support it until the coolant in the system does not warm up to the required temperature. After that, the feeding of new portions of the fuel will stop, and the pellets remaining in the nozzle burner will slowly go. If they do not have time to fully fire until the next inclusion of the system, the new portion of the granules will light from the old one. Aesley will have time - not scary: the boiler will simply repeat the whole cycle.

The use of a cumulative bunker allows domestic pellet boilers to operate on one bookmark the granules several days. For example, a 24 kW unit with a capacity of 240l, with full loading, it is capable of autonomously operating about 7 days. By increasing the volume of the cumulative bunker or adapting the adjacent storage room with the boiler room for storing pellets, it will be possible to increase the continuous operation of the boiler almost as much as you wish. It will only be necessary to periodically fill the accumulative pellet bunker and remove ash from the ash box, and this can be done only once a week. Pellet value fluctuates in the range of 2-5 thousand rubles. For 1 t, which is quite comparable to the price of firewood (from 1200 rub. for 1m3). Agree, these are good arguments in favor of a pellet boiler.

Such boilers are convenient in transportation, since the design is divided into the heat exchanger, the conveyor for the granules, the bunker and the pellet burner. Another advantage of these aggregates is that they have a relatively compact combustion chamber and, on the contrary, a large multi-part convective part, which absorbs the resulting heat (the temperature of the outgoing gases does not exceed 120-130 C). If necessary, the burner can be removed or close with a special lid and then stir the boiler with conventional lanes. Some manufacturers equip their aggregates with an additional circuit for the DHW system (hot water supply).

Now about the shortcomings. In our opinion, the pellet type boilers are two. The first is more expensive than classic 3-5 times (the price includes the price of the required additional equipment: bunker, conveyor IDR.). The second is how the boiler work depends entirely on the incoming electricity from the outside, for its uninterrupted operation, you should create an emergency nutrition system.

The domestic market contains pellet boilers such foreign firms, like Kunzel (Germany), Attack (Slovakia), Jaspi (Finland), Verner (Czech Republic), Biomaster, D'Alessandro, Faci, Ferroli, Sime (All Italy), Atmos, Kalvis, Opop (Woody, BOIK), Protherm, Viadrus (Hercules Duo) IDR. Russian producers are much smaller: "Alt-A", "Stunkonstrument" and "Automatic-Forest".

"Thermo-World" |

|

|

28-30. The operation of pellet boilers Biomaster (28) is controlled using a small console (29). S-shaped three-axis heat exchanger guarantees efficiency up to 88%. The burner of volumetric type (30) is made of cast iron and allows you to burn pellets with high bark content and even the inclusions of quartz.

When choosing a pellet boiler, professionals advise pay attention to the degree of demanding aggregates to the quality of the granules. According to experts, German boilers are particularly capricious. Aitalian, such as Biomaster, thanks to the special design of the burner, on the contrary, very unpretentious. These boilers and other advantages are: S-shaped three-axis heat exchanger, providing efficiency to 88%; A reinforced fuel supply mechanism that allows you to add to the pellets to 50% of any crushed dry biomass, IT.P.

Some firms produce special equipment kits when installed which you can translate solid fuel boilers manufactured by this company to pellets. For example, Wirbel launches PELET-SET kits, designed for mounting both new and long-working boilers EKO-CK and EKO-CKBT series. The host includes a pellet burner (it consists of a fan, dispenser and automatic ignition system), a digital remote, the bottom door of the boiler, the bunker for the granules by 330l and the screw conveyor. The price of recruits - from 107 thousand rubles. Sime offers a similar set.

What is the result?

Our article shows that the main problem of working with a solid fuel boiler (it consists in increasing the time between the fuel bookmarks) can be solved. Well, the selection of a solid propelled aggregate-traditional (classic), pyrolysis, pellet or boiler of the upper burning is yours.Some characteristics of solid fuel boilers

| Characteristics | With increased combustion chamber | |||||||

|---|---|---|---|---|---|---|---|---|

| Manufacturer | SIME | Wirbel. | Wirbel. | Dakon. | Dakon. | Dakon. | Protherm | Buderus. |

| Mark Kotla | SOLIDA (F)) | EKO (C1)) | EKO-CK (C) | DOR (C) | DOR D (C) | FB D (h) | "Beaver" (h) | Logano G211 D (H) |

| Number of models, pcs. | 6. | nine | nine | five | 2. | five | five | five |

| Model | SOLIDA 3-SOLIDA 8 (H) | EKO 14-EKO 80 | EKO-CK 20-EKO-CK 110 | DOR 12-DOR 32 | 32D-45D. | FB 20 D-FB 42 D | 20 DLO-60 DLO | G211 20D-G211 42D |

| Thermal power, kW | 40. | 20-80 | 20-110 | 12-32. | 28-45 | 17-38 | 19-48 | 20-42. |

| Prescribed fuel | Any solid fuel | Brown coal | Firewood, coal | Brown coal 2-3cm | Firewood | Firewood | Coal, firewood | Stone coal, firewood, briquettes |

| Efficiency,% | 75-80 | N / d2) | N / D. | 78-84 | 75-82 | N / D. | 90.2 | 78-82 |

| Backup fuel | Pellets | Divine, Gas, Pellets | Divine, Gas, Pellets | Stone coal, briquettes, firewood | Brown coal, briquettes, coke | Coal | Any solid fuel | Gas, Dressing, Briquettes |

| Height, mm. | 1082. | 900-1250 | 1200-1300. | 920-1040. | 1040-1045 | 1035. | 935. | 1033. |

| Width, mm. | 469. | 600-860 | 450-700 | 600-700 | 700-750 | 500. | 440. | 490. |

| Depth, mm. | 355-855 | 960-1150 | 526-776 | 730-830 | 770-830 | 840-1240. | 570-1170 | 840-1240. |

| The volume of the furnace, l | 17-60 | 62-392. | N / D. | 26-61 | 63-115 | 22.5-59.5 | N / D. | 25.5-59.5 |

| Length is full, see | 60. | 55-60 | 50-55 | N / D. | N / D. | 29-69 | 32-68 | Up to 68. |

| Mass of the boiler without water, kg | 175-350 | 175-382. | 253-451 | 158-240 | 240-320. | 210-350 | 230-455 | 210-350 |

| Water volume in the boiler, l | 23-43 | 33-100 | 76-214 | 47-64. | 64-73 | 27-43 | 19,9-39.8. | 27-43 |

| Water pressure bar | 6. | 2.5 | N / D. | N / D. | N / D. | four | four | four |

| Energy consumption, W | Not | Not | Not | Not | Not | Not | Not | N / D. |

| Chimney diameter, mm | 147. | 133-180 | 150-200 | 145. | 180. | N / D. | 130-150 | 150. |

| Chimney thrust, mbar | N / D. | 0.14-0.28 | 0.16-0.32 | 0.12-0.22 | 0.22-0.26 | 0.20-0.28. | 0.20-0.32 | 0.10-0.28 |

| Price, thousand rubles. | 40-60 | 30-76 | 52-124 | 29-39 | 44-56 | 45-64 | 40-70 | 48-68 |

| Characteristics | With increased combustion chamber | |||||

|---|---|---|---|---|---|---|

| Manufacturer | Buderus. | Hajdu. | ViaDrus. | ViaDrus. | Opop. | Atmos. |

| Mark Kotla | Loganos111 (c) | HVK (C) | Hercules U-26 (H) | Hercules U-22 (H) | Opop H (C) | AC 25S (C) |

| Number of models, pcs. | sixteen | 3. | eight | 7. | 6. | five |

| Model | 12-32 / 32D-45D | HVK20-HVK40. | 3D-10d. | U22 D-4-U22 D-10 | H412-H650 | C 18S-C 50S |

| Thermal power, kW | 12-32 / 32-45 | 20-40 | 12-66 | 12-58 | 12-50 | 18-50 |

| Prescribed fuel | Brown coal, firewood | Coal, firewood | Coal, coke, briquettes, firewood | Coal, tree | Any solid fuel | Brown coal, firewood |

| Efficiency,% | 78-84 | 80. | 80. | 71-78 | 75-80 | 81-88 |

| Backup fuel | Stone coal, sawdust | Briquettes, gas, solard | Not | Briquettes, pellets | Not | Not |

| Height, mm. | 920-1060 | 1344-1462. | 1128. | 974. | 865-1524 | 1120-1360 |

| Width, mm. | 424-688 | 426-526. | 544. | 520. | 386-534 | 590. |

| Depth, mm. | 730-980 | 528. | 383-1153 | 750-1130 | 465-727 | 845-1105. |

| The volume of the furnace, l | 25.5-59.5 | N / D. | N / D. | N / D. | 35-97 | 66-150 |

| Length is full, see | N / D. | N / D. | 18-95 | N / D. | N / D. | 33-53 |

| Mass of the boiler without water, kg | 158-320. | 189-246. | 215-526. | 257-485 | 150-390. | 225-415 |

| Water volume in the boiler, l | 46-73 | N / D. | 27-67 | N / D. | 25-110 | N / D. |

| Water pressure bar | 2.5 | N / D. | N / D. | N / D. | 2. | N / D. |

| Energy consumption, W | N / D. | N / D. | N / D. | N / D. | Not | N / D. |

| Chimney diameter, mm | 150-180 | N / D. | 156-176. | 156-176 | 130-159 | 152. |

| Chimney thrust, mbar | 0.12-0.36 | N / D. | N / D. | N / D. | 0.18-0.27 | 0.22-0.28 |

| Price, thousand rubles. | 30-64 | 38-42. | 33-61 | 44-61 | 28-62 | 100-203. |

| Characteristics | With built-in ten | |||

|---|---|---|---|---|

| Manufacturer | Wirbel. | "Evan" | Zota. | Zota. |

| Mark Kotla | EKO-EL (C) | Warmos-TT (C) | "Smoky" (h) | MIX (C) |

| Number of models, pcs. | nine | 2. | 3. | four |

| Model | EKO-EL 14/6 --EKO-EL 80/24 | TT-18 K, TT-25 K | AOTT-18 -POT-25 | KST-20 -KST-50 |

| Thermal power, kW | 14-80 | 18-25 | 18-25 | 20- 50. |

| Prescribed fuel | Brown coal, firewood | Coal, firewood | Coal, firewood | Coal, firewood |

| Efficiency,% | N / D. | 65-75 | N / D. | N / D. |

| Backup fuel | Solar, Gas. | Not | Not | Gas |

| Height, mm. | 900-1250 | 1100. | 700-880 | 1050-1175 |

| Width, mm. | 600-860 | 500. | 540-610 | 430-480 |

| Depth, mm. | 960-1150 | 740-820 | 690-760 | 550-750 |

| The volume of the furnace, l | 62-392. | 50-60 | 70-90. | 35-79 |

| Length is full, see | 55. | 55. | 45. | 30-50 |

| Mass of the boiler without water, kg | 175-382. | 91-101 | 110-160 | 135-207 |

| Water volume in the boiler, l | 29-100 | 42-45 | 52-95 | 50-140. |

| Water pressure bar | 2.5 | 2.5 | 2. | 2.5 |

| Energy consumption, W | 6000-24 000 | 2000-6000 | 1000-6000 | 1000-9000 |

| Chimney diameter, mm | 133-180 | 159. | 200-2543) | 160-180 |

| Chimney thrust, mbar | 0.14-0.28 | 0.1-0.3 | 0.12-0,16 | 0.2-0.3 |

| Price, thousand rubles. | 38-101 | 26-31 | 21-28. | 30-45 |

1) heat exchanger material: C iron, C - steel; 2) N / D - no data; 3) the manufacturer recommended by the producer of the smoke section of the chimney, cm2. (For reference: Chimney area with a cross section in one brick (2613cm) - 338 cm2.)

| Characteristics | Gasomerates with upper pyrolysis gas burning chamber | Gas generator with a lower pyrolysis gas burning chamber | ||||||

|---|---|---|---|---|---|---|---|---|

| Manufacturer | Opop. | "Burzhuy-K" | "URALENERK" | Wirbel. | Dakon. | Dakon. | Atmos. | Viessmann. |

| Mark Kotla | H730 PYRO (C1)) | "Burzhuy-K" (Ch1)) | "Wonderful furnaces" (c) | Bio-Tec (C) | Damat Pyro (H) | Kp Pyro (C) | DC (C) | Vitoligno 100-S (C) |

| Number of models in the line | one | five | 6. | eight | five | four | fourteen | five |

| Model | H730 Pyro. | T-10- T-100 | KW-12- kW-60 | BIO-TEC 18- BIO-TEC 80 | 20 g- 36 g | KP 18- KP 38 | DC 15E- DC 100 | 100-S. |

| Thermal power, kW | thirty | 10-100 | 8-60 | 18-80 | 20-36. | 21-40 | 15-99 | 25-80 |

| Prescribed fuel | Firewood | Firewood | Firewood | Firewood | Firewood | Firewood | Firewood | Firewood |

| Efficiency,% | 86. | 85. | 75-80 | 91. | 80-85 | 85. | 81-88 | 88. |

| Backup fuel | Brown coal | Coal any brand | Any solid fuel | Not | Not | Not | Not | Not |

| Height, mm. | 1010. | 760-1610 | 950-1350 | 1085-1735 | 1165. | 1188-1250 | 1180-1590 | 1015-1389 |

| Width, mm. | 480. | 380-780 | 500-900 | 570-820 | 670. | 626-686 | 590-980 | 618-841 |

| Depth, mm. | 1110. | 610-1100 | 1000-1500 | 1245-1545 | 690-1090. | 995-1085 | 845-1180 | 1190-1885. |

| The volume of the combustion chamber, l | 72. | 55-570 | 50-200. | 87-393. | 48-115 | 66-138 | 66-180 | 100-300 |

| Length is full, mm | N / d2) | 450-950 | 39-88 | 550-930 | 280-680 | 430-580 | N / D. | 500. |

| Mass of the boiler without water, kg | 355. | 100-1400. | 150-450 | 435-735 | 405-640 | 240-300 | 273-780 | 390. |

| Water volume in the boiler, l | 48. | 18-65 | 70-480 | 81-271 | 68-100 | 76-124. | 45-171 | 100-350 |

| Water pressure bar | 2. | 4.5 | 2. | 2.5 | four | 2. | 2. | 3. |

| Energy consumption, W | Not | Not | Not | Not | 85. | 55. | N / D. | 60. |

| Chimney diameter, mm | 160. | 130-250 | 159-219 | 150-200. | 150. | 150. | N / D. | 150-200 |

| Chimney thrust, mbar | N / D. | N / D. | 0.20-0.30 | N / D. | 0.20-0.29 | 0.20 / 0.28. | N / D. | 0.10-0.20 |

| Price, thousand rubles. | 77. | 37-161 | 18-69 | 109-283 | 70-82. | 73-125 | 84-417 | 95-264. |

| Characteristics | Gas generator with a lower pyrolysis gas burning chamber | Upper burning | Pellette | |||||

|---|---|---|---|---|---|---|---|---|

| Manufacturer | Buderus. | Opop. | Rojek. | Aremikas. | SIME. | Opop. | Atmos. | Biomaster |

| Mark Kotla | S121, S121WT (C) | Ecomax (C) | KTP (C) | Candle (C) | SOLIDA 8PL (H) | Woody (C) | D (c) | VM (C) |

| Number of models in the line | eight | 3. | five | 3. | one | five | four | twenty |

| Model | 18-38 | Ecomax 25- ECOMAX 42 | KTP 20- KTP 50 | Candle M-20 / Candle 20 / Candle 35 | SOLIDA 8PL | Woody 16- Woody 80 | D 15 P- D 45 | BM-15-BM-1400 |

| Thermal power, kW | 18-38. | 25-42. | 20-50 | 20/20/35 | 26. | 16-80 | 15-45 | 15-1400 |

| Prescribed fuel | Firewood | Firewood | Firewood | Coal, firewood, briquettes | Pellets | Pellets | Pellets | Pellets |

| Efficiency,% | 78-85 | 83-79 | 75. | 85. | 86-92. | 90-94 | 91-92 | 87-92 |

| Backup fuel | Wood waste | Any solid fuel | Brown and stone coal, briquettes, coke | Not | Firewood | Firewood | Firewood | Firewood |

| Height, mm. | 1250-1315 | 1200-1475 | 605-745 | 1550/2070/2070 | 1082. | 1307-1272. | 1405. | 1100-3300 |

| Width, mm. | 626-686 | 612-712 | 495-800 | 570/570/7006) | 856-1230 | 515-743 | 606. | 500-1500. |

| Depth, mm. | 935-1085 | 850-1120 | 1165-1260 | - | 1050. | 750-1009 | 470-870 | 450-2390. |

| The volume of the combustion chamber, l | 66-138 | 120-200 | 90-166. | 195/260/400 | 200, 300, 5003) | 2203) | 250, 500, 10003) | 2503) |

| Length is full, mm | 430-580 | 370-570 | 300-600 | 350-550 | 600. | N / D. | N / D. | N / D. |

| Mass of the boiler without water, kg | 310-410 | 270-455 | 235-420 | 210/250/300 | 350. | 290-510 | 259-430 | 200-5000 |

| Water volume in the boiler, l | 76-124. | 60-78 | 98-165 | 30/45/53 | 43. | 50-125 | 65-117 | 40-2300 |

| Water pressure bar | 2. | 2. | N / D. | 1.5 | four | 2. | N / D. | 2.5 |

| Energy consumption, W | fifty | 21-50 | Not | Not | 3004) / 505) | 350-6504) / 50-1255) | 535-11704) / 120-1355) | 700-35004) / n / d |

| Chimney diameter, mm | 150. | 160. | 159-219 | 160. | 147. | 130-180 | 152. | 160-500 |

| Chimney thrust, mbar | N / D. | 0.25. | 0.10-0.12. | 0.15 / 0.15 / 0.21 | N / D. | N / D. | N / D. | N / D. |

| Price, thousand rubles. | 86-104 | 126-134. | 87 100-145 900. | 84-97 | 260-307 | 161-200 | 116-186 | 253-330 |

1) heat exchanger material: C iron, C - steel; 2) N / D - no data; 3) the volume of the pellet bunker; 4) electric power consumption at the start (during ignition); 5) electric power consumption in working mode; 6) The diameter of the boiler, mm.

The editors thanks the company Buderus, Sime, Protherm, Viadrus, Burzhuy-K, "Plant of heating equipment and automation" - Zota, "Comfort-Eco", "Heatarket", "Thermo-World", "Miracle Furnaces", " Evan "For help in preparing the material.