Overview of the plasterboard market: features of production and dignity of material, types of drywall, GOST requirements, rules for transportation and working with GCL

This material is indispensable in the device of stitched ceilings, aligning the walls and the erection of light interior partitions. Knowing people attract his amazing ability to become plastic in a wet state and restore the initial hardness after drying. Meet: Plasterboard!

E. Kirillov

O. Koppinets

E. merchants

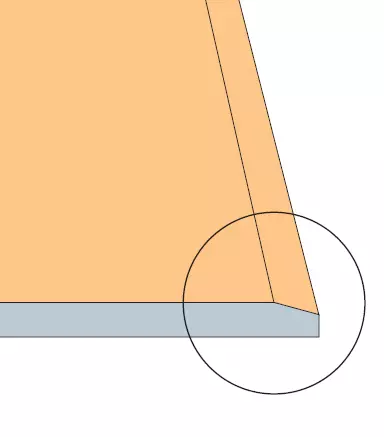

Photo K. Manko Sheet of Gypsum Carton (GLC) is a rectangular flat building element. Its foundation forms a gypsum layer (core), on both sides lined with a solid cardboard. Reliable clutch of the latter with the core provide adhesive additives. The longitudinal edges of the GLC are roasted by cardboard, and the end is open, but smoothly cropped. It is not necessary to confuse GLC with a dry-fiber sheet (GWL), which has a similar design, but its gypsum layer includes fibers of flocculation waste, evenly distributed throughout the volume.

Plasterboard does not contain harmful ingredients, as pure plaster, water and cardboard serve as the main raw material for its production. It does not smell, does not allocate allergens and other substances dangerous to humans. Due to the high porosity, the facing of GKK has the ability to "breathe". This material takes the excessive moisture from the air, accumulates it, and with a decrease in relative humidity, gives it to, thus, to maintain a comfortable microclimate indoor.

"Saint-Goben Construction Products Rus" |

"Saint-Goben Construction Products Rus" |

"Knauf" |

1. The covering of the multi-level ceiling and walls in the nursery is made of GLC. This is the most economical version of the preparation of far from the perfection of the surfaces of the old house under painting. The walls of the rooms bordering the neighboring apartments, soundly insulated with stained wool plates, which were laid between the metal frame racks.

2. Works on the facing of the GLC ceiling and walls are more convenient and more reliable (in terms of cutting sheets, arrangement of sound insulation) start from the walls, and then go to the ceiling.

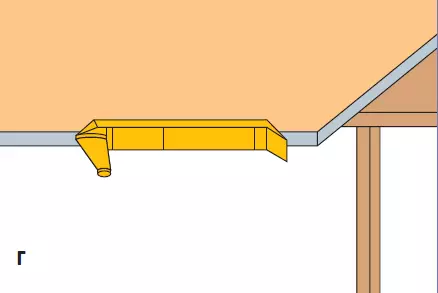

3. Metal profile barrier for drywall will help quickly install a frame for a tail ceiling.

Optimal density

One of the high quality indicators is the il- optimal density of the core. The average weight of 1M2 drywall is 9-10kg, and the standard leaf of 2500120012.5mm weighs 27-29 kg. It would be preferable to a large plaster density: the sheet is stronger, it is not broken during transportation, it has better size stability. But it is very difficult to attach it to the metal profile. Saws cannot be sold the core and cut the carving in the metal, which, as a rule, leads to the destruction of the gypsum and the damage of the profile. Such a material is not at the expense of installers, too much alterations are required. Excessively porous gypsum reduces the weight of HCL, it becomes easier to work with it and the screw easily passes through it, but the core will usually crumble, and the sheet adjacent to the profile is not tight enough, while the self-tapping screws should be tightly entering drywall at a right angle and go beyond the profile For a length of at least 10mm.

When the GCL cut, the core of which contains domestic pores, is usually an uneven edge that requires subsequent processing. To exclude a similar effect, many companies change the recipes of drywall and use new pores. The result of the leaf breaks exactly along the line, with the formation of an even end.

Photo by D. Minkin |

Photo by D. Minkin |

Graphics I. Emelin |

4-6. When lining the walls of plasterboard sheets, a frame of metal profiles is usually used: ceiling and rack (4) guides (6). GLCs are fixed to the frame of self-drawing. The joints of the sheets with drunken edges (5) put sand using the reinforcing tape to provide the necessary storage strength.

The most common sheet sizes: thickness - 9.5 and 12.5 mm, width - 600 and 1200 mm, length - 2500 and 3000mm. However, these parameters can be changed when making to order: the thickness of the product - in the range of 6.5-24mm, length is 2000-4000mm (with 50mm increments).

Among the largest producers whose products are widely represented on the Russian market, we note the company "Khaauf" (Russia- Germany), Saint-Goben Construction Products Rus "(Brand Gyproc, Russia - Czech)," VOLMA "," YUTAHIPS "(both - Russia), "Belgips" (Belarus).

Love is not for no reason

The reason for the inexhaustible love of builders and finishers to the material described by us is its numerous advantages. Judge for yourself: the use of GLC instead of brick or concrete to build partitions 7-9 times reducing the load on the bearing elements of the building. This allows you to reduce costs when booking the foundation, increase the flooding of the house, reduce the total construction costs. Equally relevant light designs when repairing buildings built 100 years ago and earlier.

Plasterboard sheets help to do without most unpleasant "wet" and "dirty" processes during decoration. As a result, the labor productivity of the finishes increases markedly. But most importantly, it is possible to realize any ideas and multivariate architectural solutions, including creating decorative curvilinear surfaces.

"Knauf" |

"Knauf" |

"Knauf" |

"Knauf" |

"Knauf" |

"Saint-Goben Construction Products Rus" |

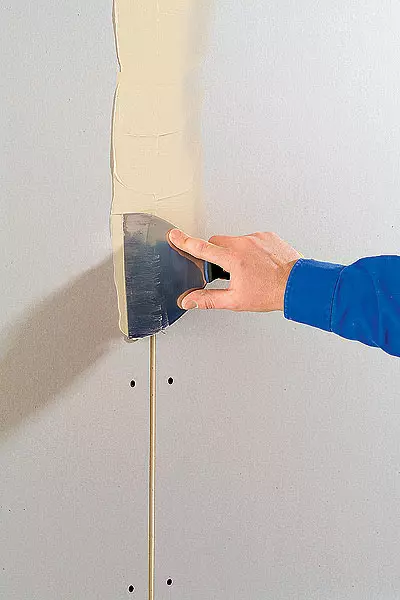

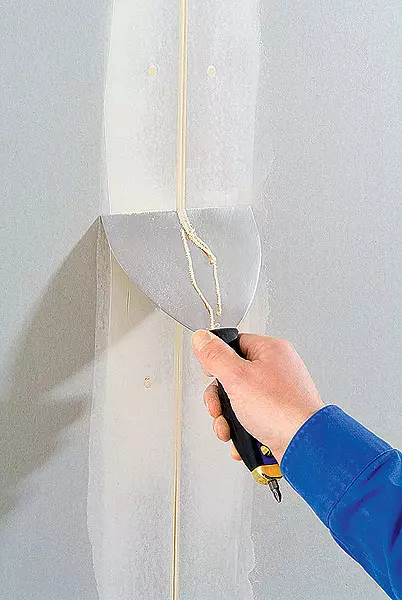

7-11. Operations on the seaming of the seams between GLC begin with applying putty (7), fill it with its seams and the entire zone of the thinning (8), remove the excess solution (9), impose a reinforcing tape, pressing it with a spatula (10), leave up to dry (12-24 h ), after which the finishing layer of putty (11) is applied.

12. Reinforcing paper tape Marco ("Saint-Goben Construction Products Rus") for sealing joints between GLK. Her ribbed surface provides good grip with putty. The longitudinal perforation of the tape eliminates the formation of air bubbles, and the sold central groove facilitates the treatment of corners.

It is worth noting that the GLC increases the fire safety of the premises. Therefore, it is used as flame retardant coatings for various designs. After all, the plaster itself is a non-combustible and fire-resistant, and the gypsum base contains approximately 20% of crystallized water. B1M2 sheet thickness of 12.5mm. Its volume is about 2l.

.Frequency resistance

Manufacturers produce plasterboard of different types, but when redeveloping and finishing apartments, two are most often used by two: ordinary (GLC) and moisture resistant (GCCV). The first is used in rooms with dry and normal humidity modes, simply speaking, in residential rooms and corridors, where relative humidity does not exceed 60%. The use of moisture-resistant drywall and kitchens, as well as window slopes. The core has been added substances that reduce moisture absorption, and it is not afraid of a periodic increase in humidity up to 70%. However, these premises, in accordance with the requirements of SNiP 23-02-2003, "thermal protection of buildings" must be necessarily equipped with exhaust ventilation, and the facial surface is leaf protected by waterproofing, moisture resistant paint, ceramic tiles IT.D. Moisture-proof material from ordinary is very simple: both European, and domestic manufacturers tinted a layer of facing cardboard with green pigment. The price of 1M2 of the usual GCL (250012009.5 / 12.5 mm) is 60-75 rubles, moisture-resistant, slightly above: 85-95 rubles.

Ready forms

NMC. |

NMC. |

NMC. |

NMC. |

13-16. Pressing polyurethane forms are used to embody original design solutions, corners, as well as embedding systems of lighting.

Fire-resistant plasterboard (GKLO) has an increased resistance to exposure to open fire. It is 2 times higher by this parameter than that of the usual GCC, since the GKLO core is reinforced with mineral fibers and special additives. Glit rooms fire-resistant material apply not as often as in public. The cost is 1M2 GKLO - from 75 rub.

Quality criteria

All plasterboard coming on sale in Russia, regardless of the country and the manufacturer's company must meet the requirements of GOST 6266-97 "Sheets of plasterboard". However, in life, we are often forced to deal with poor-quality materials. There are two questions: what to navigate when choosing GLK and whether a potential buyer can determine, good plasterboard before him or not?The concept of "quality" involves a certain set of consumer properties. What is the most significant for the user? First of all, the density of the plaster core should not be too high or too low. VGPS of normal density can be easily screwed off: it enters the effort, but it takes off without destroying the material. It is necessary that when cutting the GLCs on the edge there were no torn edges, and the cardboard was not peeled from the core. Qualitative material is cleaned strictly along the cut line, which was knocked. It is easy to check: it is enough to take a sheet, cut it and carefully inspect the breakfast area. If the core is not homogeneous enough, the edges will be torn and they will have to additionally process them.

Opinion of a specialist

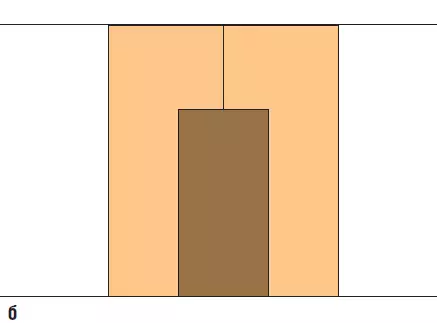

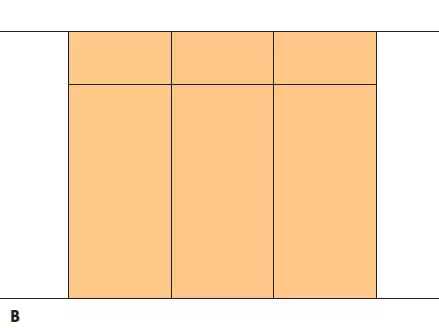

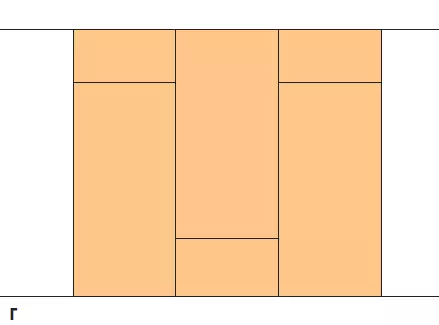

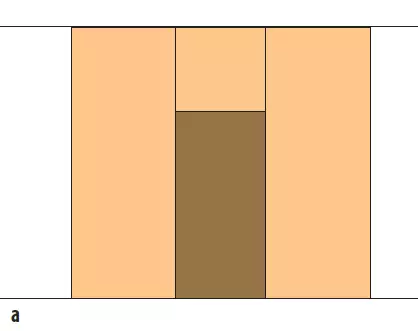

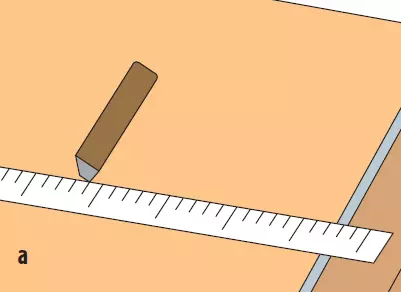

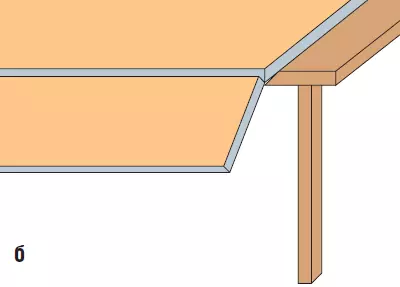

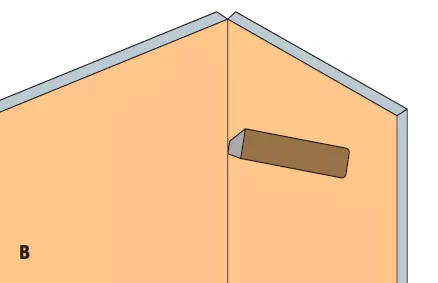

The most common error of the installation of GLC, leading to the appearance of cracks in the joints of sheets, is the incorrect design of doorways. Often, whole sheets are installed on the left and right of the door, and the area over the opening is sewn carved in size (a). In this case, even if the seams are embellished correctly, after several strong cotton, the door grid appears on them. With the proper design of the doorway, the sheets of GLCs are trimmed so that their joints are above its middle (b). If the height of the room is greater than the length of the GLC, along with whole sheets use good. Often, the first, second, third whole sheets are fixed to the frame racks, and on top - the missing quantity (B). It is impossible to do this: due to the formation of a long pass-through seam, cracks may occur. The design will be more stable if there are no more sustained sheets that from above, then below (g). When installing two-layer partitions, the joints of the external and internal sheets should not coincide.

Konstantin Novitsky, manager of Knauf

Graphics I. Emelin |

Graphics I. Emelin |

Graphics I. Emelin |

Graphics I. Emelin |

a, b. Wrong.

B, G. Right.

When repairing residential premises, GLCs with refinement on the front side in the direction of the edge are most often used. After putty using the reinforcing tapes of such sheets, such sheets are completely invisible. The width of the refinement in poor quality drywall varies: for example, at the top of the sheet-2cm, and below, 4cm. In this case, the edge of the reinforcing tape can go beyond the limits of the reinforcement and on the surface of the sheet it is formed by a hill. Pension GLC width of thinning is the same over the entire length of the edge of the sheet.

Simple rules

"Knauf" |

"Knauf" |

"Knauf" |

"Knauf" |

"Knauf" |

Architectural and construction company "Studio-A" Photo of S. Morgunova |

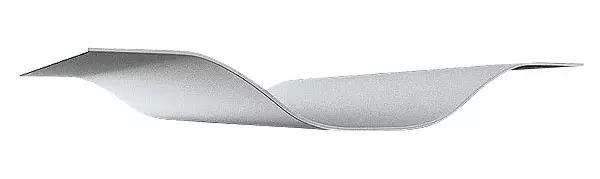

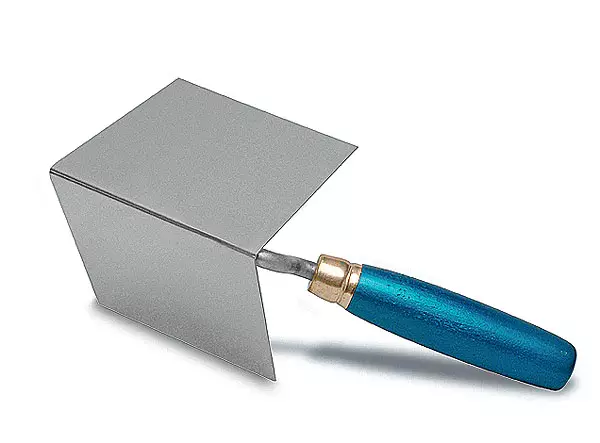

17-21. Special tools make work with GLC easier and more convenient. The edge plans (17, 19) plasters the edges of the sheet at a certain angle. Plastic grout (18) removes burrs. A spatula for internal angles (20) helps to get a perfectly smooth junction. The screwdriver (21) has double-use.

22. The covering of the multi-level ceiling and walls in the nursery is made of GLC. This is the most economical version of the preparation of far from the perfection of the surfaces of the old house under painting. The walls of the rooms bordering the neighboring apartments, soundly insulated with stained wool plates, which were laid between the metal frame racks.

Mount GLC is best in conditions as close as possible to operational. Do not do it immediately after transportation, as they say from the wheels. Sheets should lie down some time, acclimatize, and not just on the floor, but on the pallet or waterproof gasket. The adaptation period depends on storage conditions. If the material was in the covered hangar at temperatures above 0 s, it is enough 24h. At the acclimatization of sheets lying on an open area with adverse atmospheric conditions, it will take about 2 days. The main thing is not to put them vertically, but to store only in a horizontal position so that GLC has not led.

Forget about all his cracks ...

The main problem of surfaces from drywall is the appearance of cracks at the joints of individual sheets. Manufacturers assure that in the overwhelming majority of cases, the causes of this are non-compliance with the installation technology and poor operating conditions. For example, bought GLCs stored in the air, brought immediately attached with self-drawing and quickly sawed joints. The owner is very pleased. But after a couple of days, an excess moisture was left of the sheet, it decreased in size, and cracks were formed on the seams.

"Saint-Goben Construction Products Rus" |

Design Bureau "Evim" Photo D. Minkin |

"ArNT" |

"ArNT" |

23-25. The design of the staircase ceiling is a steel frame attached to the overlap and the room-covered by one or two layers of plasterboard. The ceiling improves the heat and sound insulation of residential premises and at the same time very decorative.

26. The design of the ceiling with plasterboard successfully masks electrical wiring and other engineering equipment, and the use of GKLO increases the fire resistance of the room.

Opinion of a specialist

A typical suspension ceiling construction includes suspension, ceiling profiles and GKL. According to the installation technology, the suspensions are attached to the bearing plates anchor wedges capable of withstanding colossal loads. The most common error in the arrangement of the ceilings is the use of a dowel-nail instead of ancker-wing, despite the fact that this type of fastener is designed for walls and other vertical surfaces and is not able to withstand the severity of the suspension design. A results of the ceiling can be saved or even collapsed. Metal guides, suspensions and rack profiles, adjacent to walls, floors and ceilings, must be installed on a damping polyurethane or rubberized tape. It sounds the framework and protects the inhabitants of the apartment from the spread of unnecessary sound waves and shock noises. Otherwise, the ceiling and walls will work as acoustic membranes.

Timur Abramov, Director for the Production of ArnT

Another situation: workers hard attached plasterboard sheets to the walls and ceiling, finished the finish and said goodbye. After that, the owners of housing staged a winter garden in the room: they grow lemons, oranges, dates, care about them, do not spare water for watering. Humidity in the room is high, the gypsum absorbs moisture, expands, but there is nowhere to go. The result of the sheets are strung out and crack in the joints of the joint. There are a lot of such cases. To avoid this, it is necessary to invite highly qualified finishes, which strictly follow the rules for working with HCL, and subsequently maintain the normal temperature and humidity regime in the room.

"Eurasia" |

"Eurasia" |

"Eurasia" |

"Eurasia" |

"Eurasia" |

"Eurasia" |

"Eurasia" |

"Eurasia" |

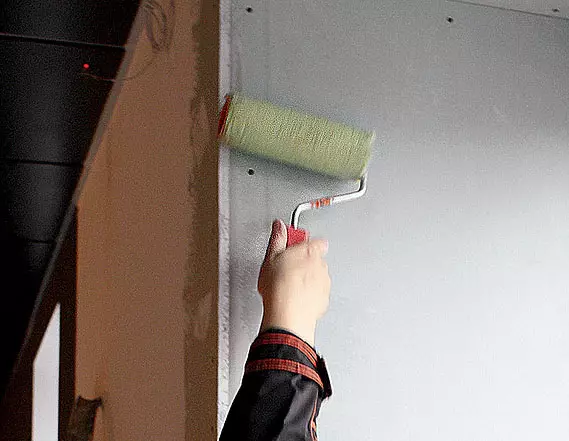

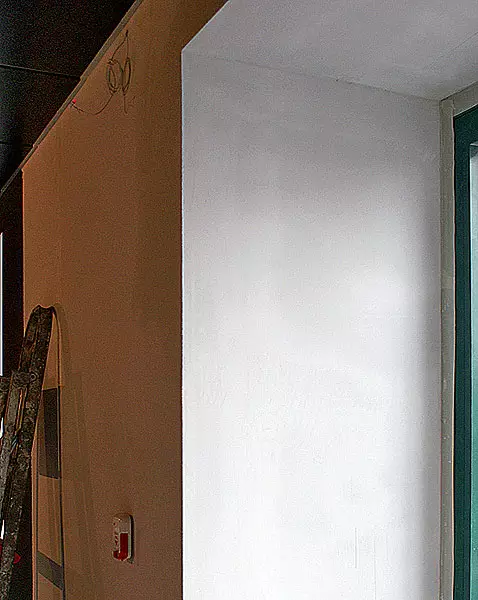

27-34. When finishing the window slopes, it is desirable to use moisture-resistant GKC. They are fixed with self-drawers or glued. It will later, it is important that the walls in contact with glue are not impaired, that is, the correct thermal insulation is necessary, the absence of cracks and tightness in the places of the window adjoining the window to the Obra. The order of the discovery is as follows: the window frame is protected by adhesive tape (27), the drywall is coated with ground (28), the joints of individual sheets are reinforced with sickle (29), the surface of the surface (30-31) is carefully placed; metal corners (32) are installed on the outer angles Twitter again (33). Sunshine is ready (34).

Change minus on plus

Those who have already used GLCs to align the walls and ceilings or is only going to do this, most likely indicate one of the most obvious drawbacks ... not the material itself, but the method of its installation. The fact is that the design of the crate to which sheets fasten, reduces the size of the room. The new surface of the wall is from the basic at least 4cm, and the loss of the area for the room, the metro station is 20m2, will be about 0.5 m2.

How to turn this minus in plus? Easy: Frame cavity to use wiring for mounting. In the case, the process is much easier and takes less time than a long and tedious standing of the walls (by the way, it is allowed to do not far in all houses), laying wires and close the cavities. In addition, the air layer inside the septum together with the sheets of drywall extinguishes the energy of the sound due to the forced oscillation of the elastic lining. If you fill out the free space of insulating material, the soundproof effect will noticeably increase.

"Knauf" |

"Knauf" |

"Saint-Goben Construction Products Rus" |

Graphics I. Emelin |

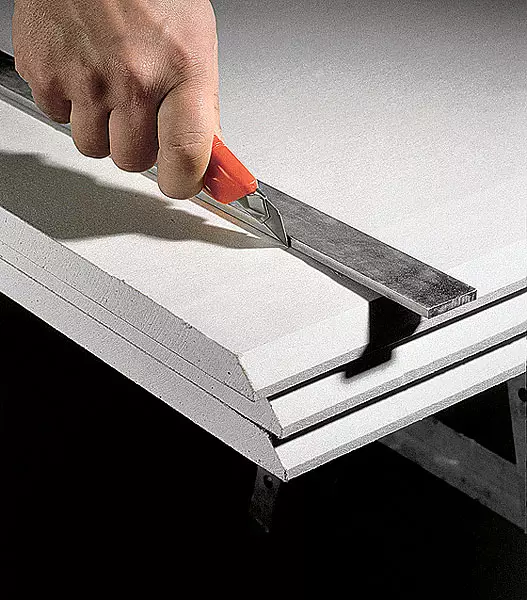

35-36. A good GLC breaks exactly along the door line, while a smooth end is formed.

37. The spacing solution was embedded - the grooves from the self-tapping screws, the seams between the GLK, the joints between the walls and the ceiling. Works are carried out at stable temperatures (not lower than 5 seconds) and humidity. Under the subsequent painting, a solid shtpocking of the surface of the finish line should be made.

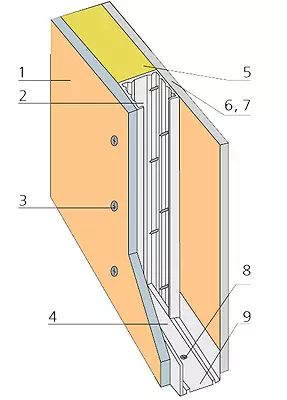

38. Partition with single-layer trim:

1 - GLC;

2, 4 - profiles;

3 - self-tapping screw;

5 - isolation;

6, 7 - spacure and ribbon reinforcing;

8 - dowel;

9 - Ribbon Soundproofing

Another obvious complexity: on the wall or partition from GLCs with a frame design it is difficult to hang a wardrobe, attach the shelf or TV if you did not determine the exact place of their mounting and did not strengthen this section to the mortgage element. The permissible load on the 1m2 two-layer partition from Hlk is not more than 65kg. The fastening is performed using universal dowels, special dowels like "Butterfly", "Driva", "Molly", dowels for hollow materials or spring anchors. Restrictions are serious, but there is a way out.

When aligning the walls, you can apply the modern installation of the GCL mounting on special gypsum glue. It is applied directly on the brickwork with a solid layer with a thickness of 10-15mm. It fills all the irregularities, and the hard sheet of drywall provides a smooth surface. Advantages are obvious: you do not lose useful centimeters of the square; The alignment thickness is approximately the same as the standard plaster layer - 15-20mm. Embossed does not remain emptiness attractive for insects, and in country houses - for rodents. Work is faster. Isaoy main thing - you can use the bearing capacity of the wall. But practice shows that most masters do not hurry to master this technology, since the framework work is more familiar and easier.

Enviable flexibility

Plasterboard - a real find for lovers of complex architectural structures and curved walls and ceilings. It sounds a bit snacks, and in moist, it becomes even greater flexibility. The sequence of actions is as follows: the side of the sheet, which will later bend, ride with a metal roller with spikes. This tool makes deep punctures and open the pores of the core. Then the sheet is placed with a plane-treated up and with a sponge or brush, soaked with water to full saturation until the plaster stops it. It is necessary to do it neatly: if the water falls on the opposite side of the cardboard, it can be in a flexion. Further, the material is given the right shape, fix and leave until it is completely dry. Finally, the affected curvilinear element is mounted.

Graphics I. Emelin |

Graphics I. Emelin |

Graphics I. Emelin |

Graphics I. Emelin |

39-42. To cut the GCC, it should be put on a flat surface, exactly the line with a knife with the front side of the cardboard layer and part of the gypsum core (39), move the sheet to the edge of the table and donate it along the end line (40), after which cut cardboard on the back The side of the sheet (41), if necessary, to process the edge to be treated with a ridestrouse, so that it becomes smooth, without bellows (42).

In principle, any plasterboard is capable of bend, but within certain limits. Thus, the bending radius of a sheet of 9.5mm thick in a wet state is 500mm, and a thickness of 12.5 mm is 1000mm. Company "KNAUF" in 2010 It began to produce a special bending drywall with a thickness of 6.5 mm, designed to create arched and other curvilinear surfaces. You can work with a sam, without spending time for punctures and additional moisturizing. Radius of bend wet sheet - 300mm, dry-1000mm.

On the finish line are direct

After mounting the ceilings or partitions or wall cladding, the surface of the drywall is prepared for finishing finish: staining or plastering, sticking wallpaper. First, the joints are close: they are putty, they are paving the reinforcing tape and put another layer of putty. The external angles of walls, door and window openings are protected by angular metal profiles that are installed on putty.

Recompute with technical requirements provides for the following limit deviations of the walls of the walls and the ceilings vertically and horizontally: 1mm to 1m, but not more than 5mm for the entire height of the room or the length of the ceiling plane. Deviations of window and door slopes should be no more than 1mm on 1m height or length and no more than 3mm on the window or door. The final finish depends on the type of decorative coating. Especially carefully preparing the basis for painting: it is important to ensure not only the absence of sinks (voids), fuses, spacing of a spike solution, but also the inconspicable eye transition from acruming junctions to the main surface. This is achieved with the help of full finish shtlocking walls and ceilings. Excellent result will be guaranteed if you charge all the work of highly qualified finishing craftsmen.

The material is prepared according to the results of the survey of readers on the site "Create new ideas"

The editors thanks the company ARNET, "VOLMA", "Eurasia", "Knauf", "Saint-Goben Construction Products Rus", NMC for help in the preparation of material.