Current constructions for winter garden: aluminum, wood-aluminum and plastic profile systems, Options for translucent filling

Until recently, winter gardens in private homes were rare. Owners of suburban real estate doubted whether the "work" such a transparent structure will work in the conditions of our harsh winter, whether snow loads will withstand. Yes, and the cost of warm large-format glazing was very high. Based on the effective and affordable new technologies of doubt developers began to dissipate.

Photo by K.MagnoSilyating the phrase "Winter Garden", someone will present a full exotic plants with a greenhouse on the roof of the mansion (remember the Niro Wolfe and his orchids?). A small cozy room with a panoramic view of the forest, a miniature fountain and wicker furniture arises before the thought of another. For the construction of the garden-gardener, winter garden is something like a greenhouse attached to the house. Amnogie from us is a semi-drying-half-sized name of this proud named their glazed loggia, or even just a window sill, on which several pots with onions and evergreen tomatoes are banging. Well, what is a winter garden from a technical point of view?

Behind the sun next

Construction "Dynasty"

Photo by A.MEDVEDEVADLA architect and builder Winter garden is a separate one-story building, an extension to the house or its upper floor, having a significant area of glazing, heated and adapted for year-round vegetation of plants. Aspercylist in translucent designs will call in the winter garden any small structure with glass walls and roof. It is not at the same time not necessarily that there are trees and flowers, for example, it can perform the function of the porch-hall, gallery, turn to the pool, gym and even a garage, the main use of a special type of construction during the construction of the construction. Oni, we basically we will talk in the article.

The popularity of winter gardens is growing: developers are also attracted by the originality of the architectural solution, and the comparative ease, and the speed of assembling the design, and those special feelings that the owner promises the opportunity to admire the blizzard or thunderstorm through the transparent walls and the roof (they say only during these moments and you understand - Indeed, what is homemade comfort). However, it should be borne in mind that the entirely glazed building, especially if it is heated, requires constant attention, and its maintenance costs are quite high, because, by strength and thermal insulation, the translucent fence cannot be compared with the traditional materials made of traditional materials.

In order for the winter garden for many years he gave joy, and did not turn into a burden, a competent project is needed, the right choice of translucent filling and frame profiles. As for the latter, it is necessary to take, perhaps the most responsible decision.

What is all holding

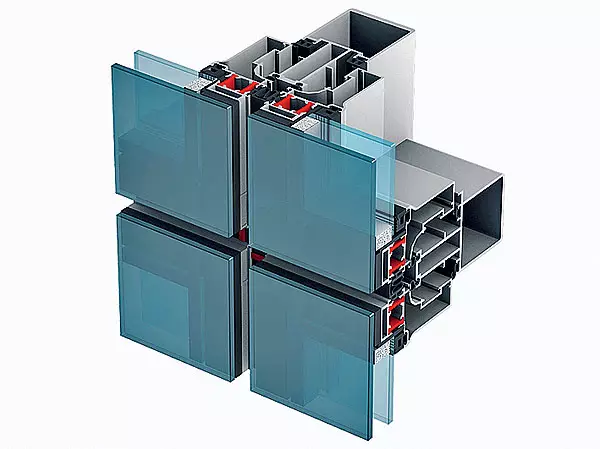

Oddly enough, in our country there are widespread in the construction of winter gardens Facade systems of aluminum profiles, Initially designed for glazing high-rise buildings, mainly business centers and elite new buildings. Production of AgrisovGaz (AGS 150), BCMPO (FS-55), Glavstroy Mosmek (ALUMAX trademark "(SPL-06 trademark, SPL-10," Grand ")," Tatprof "( TP 50300) (all- Russia), Aluk (SL-60), Newtec (NT 150) (Obaitaly), Reynaers (CW 50) (Belgium), Schco (FW 50+ and FW 60+) (Germany) iDR . The cost of 1M2 fence made using domestic profiles is an average of 4600-4900 thousand rubles, that is, the price of 1m2 of the total area of one-story building (excluding the foundation) - about 19 thousand rubles. The profiles of Western producers are 1.6-2.2 times more expensive; Accordingly, the cost of the winter garden will increase by 20-80%. At the same time, as many experts believe, the difference in quality (among other things, it concerns the durability of seals and paintwork) the first and second today is small.

"Bavarian House" |

Raico Bautechnik. |

Raico Bautechnik. |

Raico Bautechnik. |

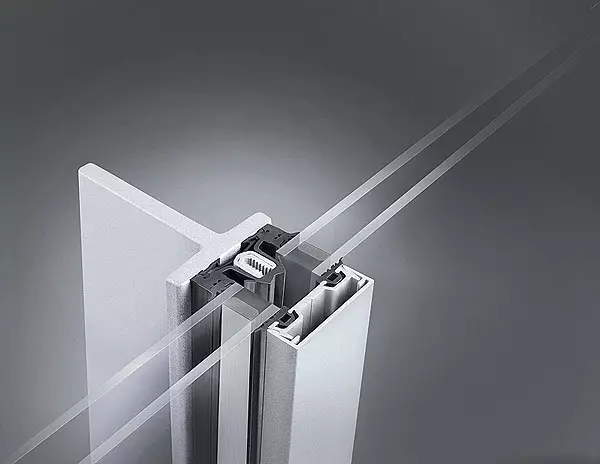

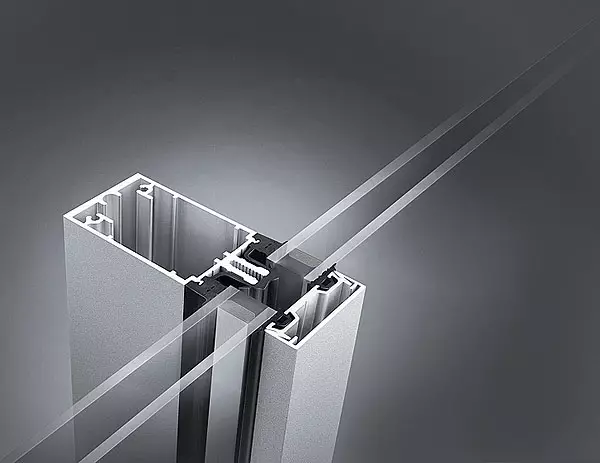

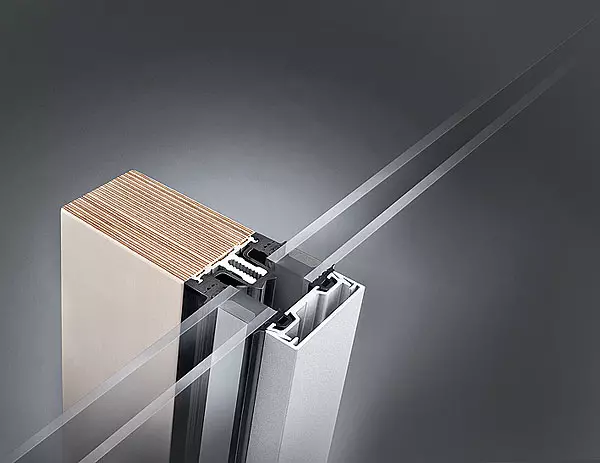

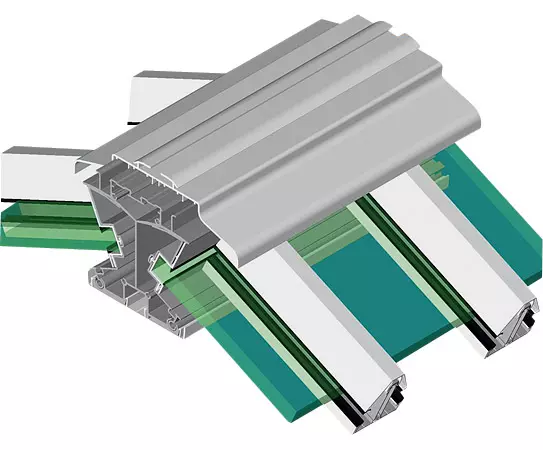

1-4. Whole Western European firms produce so-called multivariate facade systems, providing for several types of carrier frames, for example, from the aluminum pipe of the rectangular section (1.3), the steel brand (2) or a glued timber (4).

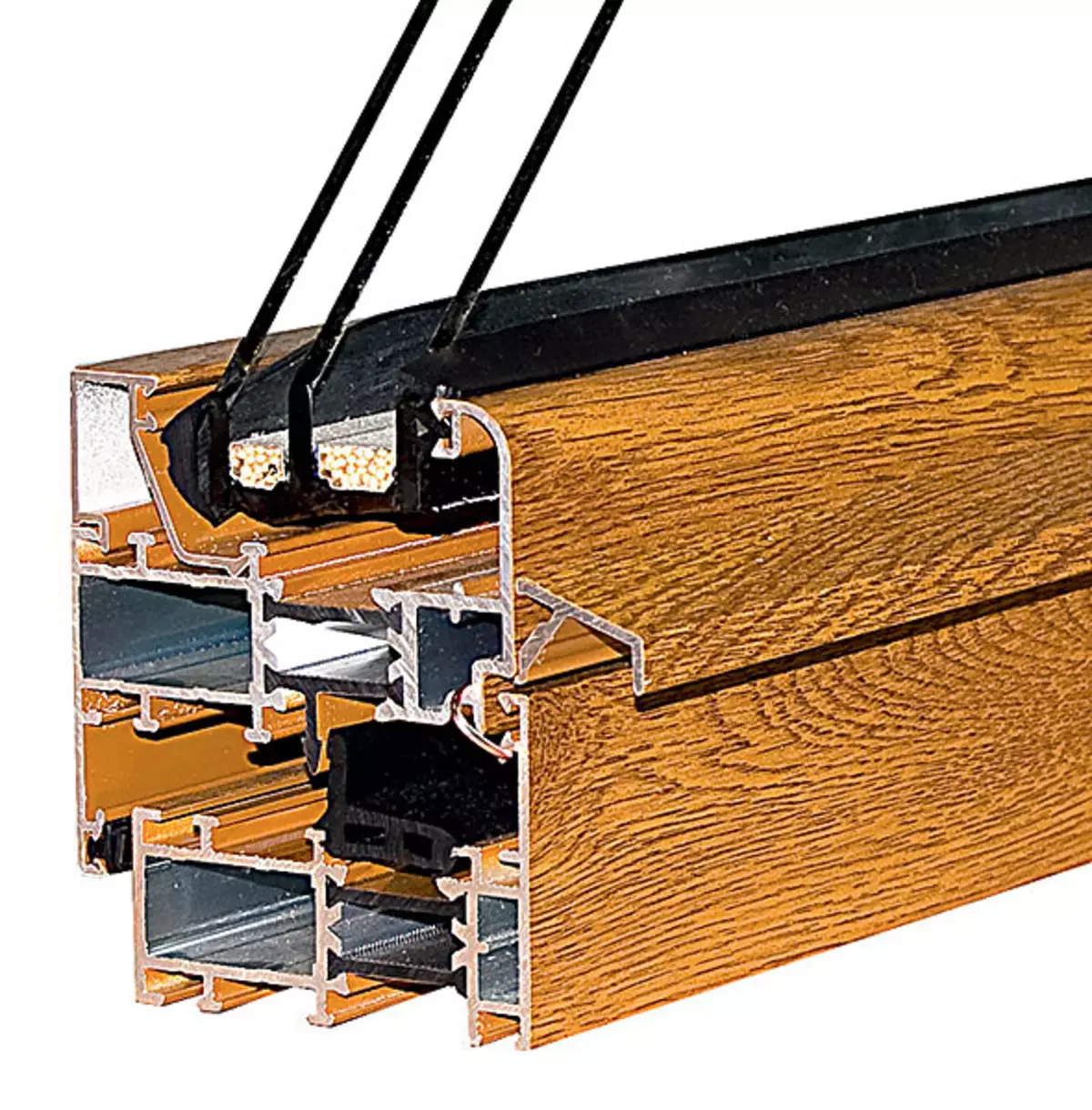

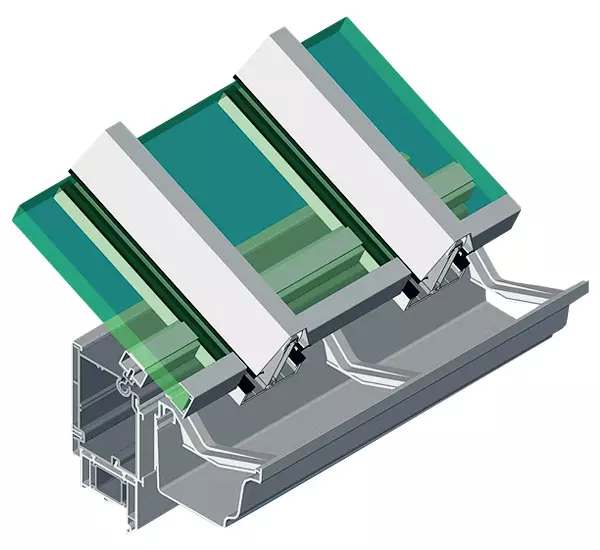

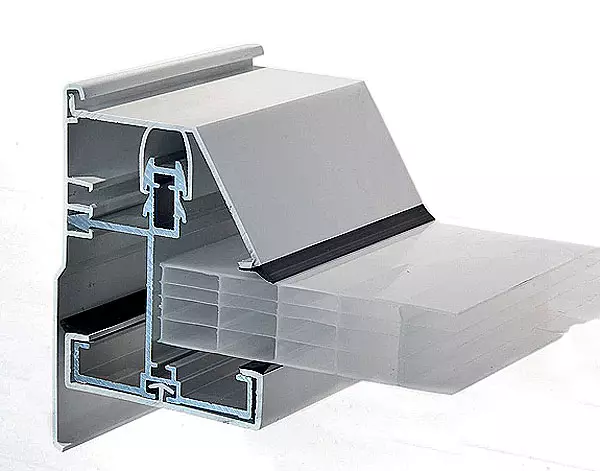

Facade systems are universal: for walls and roofs are provided by the same set of racks, riggers (horizontal jumpers) and angular elements (they are also suitable for skates and endands) made from hollow profiles with a cross section of 5030-18060mm. From them collect the framework, to which the windshop will then fasten the windshields by means of clamping slats. Thanks to the seals from the frost-resistant material (EPDM-synthetic rubber), all the joints "Profile / double-glazing" are obtained absolutely hermetic and do not let moisture. The clamping strips are "rushing" or screwed to special fastening elements available on carrier profiles. These elements made of reinforced plastic play the role of thermal explosions and improve the thermal insulation characteristics of the profiles. Despite this, the heat transfer resistance (RPD) of the latter is relatively small: 0.35-0.45m2c / W.

Opinion of a specialist

Sergey Elnikov, Head of Veka Rus Marketing Department

Modern double-glazed windows with low-emission glass and cameras filled with inert gas allow manufacturers even when using comparatively "cold" frames to fulfill the requirements of SNiP 23-02-03 "Thermal protection of buildings". According to this document, resistance to the heat transfer windows of residential buildings in the middle lane of Russia should be at least 0.51-0.55m2c / W. However, practice shows that condensate is formed in frost on frames from facade aluminum profiles, as a result of which the life of the structure is somewhat short. Yes, and the cost of heating "Aluminum" winter garden is higher than expected. Note that in SNUP, there are norms relating to the windows, and after all, the calculated area is about 10% of the area of the room. The winter garden has completely glazed walls and a roof, and therefore to translucent designs here it is necessary to present higher demands.

Yucco |

Yucco |

Rehau. |

Architects D.NOSOV, V. Cherry Photo R.Shelomentsev |

5-6. AGSO profiles AGS from "warm" aluminum: 5-laminated; 6- painted.

7. For the natural ventilation of a small winter garden, it is enough to install several winding windows in the "cells" of the walls (at least 20% of the fencing area).

8.Technical documentation of each profile system there are norms that determine the maximum length of the rafted, their step, the maximum distance between the rigels. The values of these parameters should not be exceeded when designing a winter garden; Otherwise, the design may not withstand operational loads.

The stroks of the thermal insulation is undoubtedly a more winble version of wood-aluminum structures, which are also effectively looking in the interior of the winter garden. They are produced mainly by individual projects, the company "Bavarian House", "Window shipyard", Yucco (all- Russia) IDR. A tree (glued timber from northern pine) is used in the manufacture of a carrier construction frame. Aluminum makes only light overhead frames, using intended-designed system of overhead profiles with a thermal survey, for example, Therm + (Raico Bautechnik, Germany).

Translucent structures from wood-aluminum practically do not differ from the most facade aluminum profiles of European manufacturers. But if in the winter garden it is assumed to settle tropical plants, which require increased air humidity (85-90%), wooden structures will have to be not easy, and without regular processing with special protective compositions they will serve not more than 10-12 years.

Transparent High Tech

You can enter a winter garden to the architectural appearance of the building built in a modern style, using a special type of glazing - the so-called structural on the roof (or in the entire design). For this, special aluminum profiles and non-standard double-glazed windows (their outer glass is more internal, thereby applying a protrusion closing the frame profile). Double-glazed windows are mounted using only a frost-resistant sealant, going around without clamping slats. The result is obtained by a smooth glass surface, which is distinguished by the original appearance and has one indisputable advantage: snowflakes and raindrop drops are easily rolling.

In the West in private house-building for winter gardens is used mainly Specialized profile systems. They are manufactured from both "warm" aluminum and from plastic. The domestic market includes aluminum profiles Four Seasons Solar Products (USA); Park Lane, Ultraframe (Breeding); Reynaers- System for CR120 Winter Gardens; SchCo- systems for roofs and walls Wi60 and WA60 IDR. The product nomenclature here is quite wide and includes a variety of decorative elements: curly skates, complex eaves, lighting layout, as well as drainage gutters and pipes. All this helps to create relatively small and light buildings of the original architecture, they already have nothing to do with a greenhouse greenhouse. One of the possible solutions for the roof is the outer (above glazing) the arrangement of the rafter, emphasizing the design of the structure, as, for example, in most English systems.

"Bavarian House" |

"Window shipyard" |

"Britton" |

9. Aluminum profiles of facade systems, like steel drains, cover the powder enamel. Using the universal RAL scale, it is easy to order products of the same color.

10-11. Details of the wooden frame are covered with colorless or tinting compositions (10); Facing PVC profiles are separated by an atmospheric-resistant film under the tree (11).

The vasserine of manufacturers such as Deceuninck (Belgium), Rehau (Germany), a relatively recently appeared PVC systems for winter gardens, although it is possible to call them plastic only with some stretch. The basis of the design is the framework, the parts of which are racks, the riglels, rafted are bent profiles from galvanized sheet steel (at Rehau some elements, such as angular racks, are made of "warm" aluminum). From PVC (special T-shaped profiles), only framework designs for glazing are made - they are fixed to the framework on the latches. UdeCeUnInck Kit complement external aluminum lining, locking glass. AeuroCell and Heywood Williams (British) in the roof design use aluminum profiles of complex sections equipped with plastic lining.

For strength and thermal insulation capacity, such products are practically no different from aluminum. The difference is only in the appearance of the design: according to the visible PVC-profile width, as a rule, somewhat larger, so the whole building looks massive and, perhaps, it is better combined with the houses of classical architecture.

"Britton" |

"Britton" |

SPM |

12-13.Specialized systems include special cornese (12) and skate (13) elements that provide removal of rain and melt water from structural joints.

14. System for structural glazing Rost Systems.

Alas, the heat insulation specialized systems- both plastic and aluminum- almost do not exceed the facade. Therefore, most professionals recommend the following solution: Specialized systems use only when the roof of the winter garden is erected (that is, where an increased bending strength is required from profiles), and the framework of the walls of the walls are made from ordinary five-chamber (mounting depth - 70mm) PVC profiles of the most popular Systems: Brilliant-Design (Rehau), Expert (KBE), Softline, Topline (Veka), Innonova (TRocal) (all Germany) IDR. In addition to improving the thermal insulation characteristics of the fence, this reduces the cost of winter garden by 10-15%. The required strength of the walls is not difficult to give with special aluminum connectors, as well as reinforced with thick-walled steel liners with plates, which allow you to poison window and door box at an angle of 60-180. The only problem arises with the adjuncing of the roof to the wall, because different systems are not compatible with each other, and the waterproof of the roof and walls is difficult to achieve. Therefore, the roof should necessarily have a sweat of at least 150mm.

Glass and its competitor

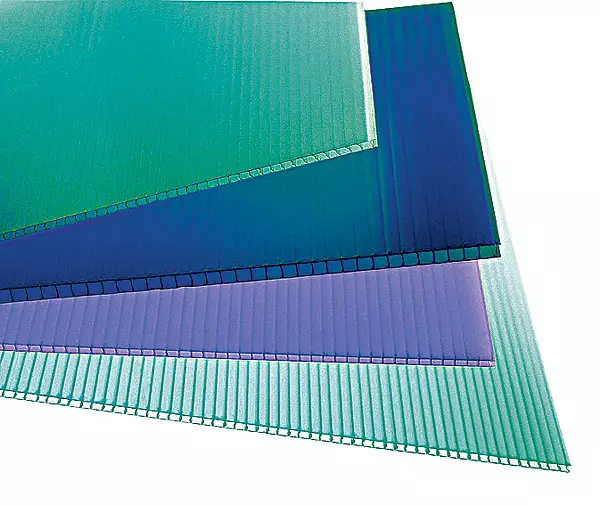

As a translucent filling of the wall and roof races of the winter garden, the windows are used mainly in the windows: for wall-two-chamber with wide chambers and energy-saving glass (for example, 4-16-4-16-4i, with heat transfer resistance 0.72m2c / W), for roofs - Only one-chamber with low-emission glass (so as not to increase the load on the frame). To ensure safety, the roof windows need to be manufactured not from conventional glass, but from triplex (internal) and hardened (external). The cost of the roof will increase by almost 2 times: if the price of 1m2 of the energy-saving package with I-glass is about 3500 rubles, then 1m2 of safe glazing will cost at least 4500-6000 rubles. Therefore, when erecting the roof, the cellular (cellular) polycarbonate is increasingly choosing. (For his walls, alas, it is impossible to use due to insufficient transparency, and the monolithic plexiglass, even with a thickness of 12 mm, cannot provide the necessary thermal insulation.)

Polycarbonate today is well known to most subtle (4-6mm) sheets of this material perfectly suitable for the construction of greenhouses. For the winter gardens, panels are used with a thickness of 25, 32, 35 and 40mm; You can use 16-millimeter sheets with thickened walls, for example, "Titan" (Polygal, Israel). Such a decision will reduce the cost of the whole building by 30-40%: the polycarbonate itself is 3-5 times cheaper than glass, besides, it is much easier, which makes it possible to reduce the cross section of carrier profiles and facilitates installation. However, it is necessary to remember that the service life is limited: over time, its microstructure varies yellow and embrittleing, and after 8-10 years there will be serious roof repair work. But from polycarbonate It is not difficult to make curly modules; In addition, the panels can be bent (with a thickness of 25mm, the minimum bending radius is 4.4 m) and thus create a variety of vaulted structures. Molded (curved) windows will cost almost 10 times more expensive (their cost is from 7500 rubles. For 1m2).

Veka. |

"PROFIN RUS" |

Politex Trade. |

"Britton" |

15. For the exit to the street from the winter garden you can use a sealed lifting door.

16. Self-cleaning pyrolytic glass will help to confine the time on the washing of windows.

17. The roofs are sometimes installed non-ferrous polycarbonate sheets. At the same time, the room is heated slightly less on hot days, but in winter you can feel the shortage of sunlight.

18. The lists of polycarbonate are mounted in the frame as well as the glass unit: with the help of presser staps. If the latter are equipped with seals, no additional sealing is required.

Panels from cellular polycarbonate frost resistant and very durable. With a thickness of more than 16mm, they do not even divide them with a sledgehammer. True, when installing should be taken into account that the thermal expansion coefficient of the material is approximately 3.5rd higher than aluminum alloys from which frames are made. Therefore, the sheets are cut so as to install them in the frame with a gap of 5-8mm around the perimeter.

Polycarbonate produce different colors; In the assortment of some firms to 30ton. This makes it possible to better enter the winter garden into the architectural appearance of the house, pose a successful combination with facades or roof (though, to the detriment of light source). Cellular polycarbonate is produced by Safplast (Russia), Lexan (Austria), Marlon (United Kingdom), Plastilux, Polygal (Obrael) Idre.

Opinion of a specialist

Our company's experience shows that the most reliable framework systems for winter gardens, made of steel galvanized closed sections profiles. This is evidenced by the case that occurred a few years ago in the suburbs, when a wet spring snow with ice boulders came up from the roof of the cottage to the winter garden. Specialists estimate that 1m2 of the transparent roof had a static load of 1430 kgf. The cords of the owners of the mansion, the design almost did not flinch: only one rapid-hinge connector was alone, which was subsequently replaced. Ahetheeva was convinced of the correctness of the system selection.

Mikhail Dmitriev, Product Manager of Dekenink Rus

It is important to remember that in hot sunny weather, the translucent roof turns into an extremely powerful "heater", and if you do not provide ventilation and dimming, use the winter garden as a living room or a rest room you can not. To protect against overheating, you may be inserted into the roof frames double-glazed windows with tinted or photochromic glass or polycarbonate with an IR filter (this material reflects infrared rays). However, the optimal variation of the winter gardens is recognized by outer marquises (rolled curtains with a web of the weather-resistant material) and roller blinds. The cost of the first - from 5 thousand rubles. For 1m2, rolling shutters are about twice as expensive.

From theory to practice

You can build a winter garden by contacting a specialized company that carries out the assembly of turnkey designs both individually and by typical projects. This is the easiest way, however, we still have such firms, and the cost of their services is relatively high. Another option is to purchase a project in the architectural bureau, after which you order the necessary structures from the manufacturer of the windows (we note that only major manufacturers take such orders), and the installation work is entrusted with the team of experienced builders. Finally, you can buy a ready-made set-designer, they produce some English and American firms, and collect it on their own. The only question is whether the typical design will fit into the architectural appearance of the house and the landscape of the plot.

"Britton" |

Veka. |

"PROFIN RUS" |

19-20.In the roof of a winter garden with an area of more than 16m2, opening hatches should be embedded (19). It is necessary for the effective outflow of overheated air in the summer heat. Achloba transparent walls did not fill in the cold, in the floor, inserts in the floor convectors (20), which ensure that by blowing glasses with warm air.

21. It is one of the ways to combat overheating of the room in the scene of the construction of the south side by the crowns of trees. True, if the forest hardened on your site, you will have to wait until new landings are growing.

The winter garden, like any other overhaul, is required. On bunched soils (clays, loams IT.D.) build a columnar-rigal (woodworking) or pile-scoring, with the embedding in the depth of freezing, or the "floating" (tape, slab) foundation. If the winter garden is attached to the ready-made home, the main task is to avoid the mutual movement of the building and an extension due to shrinkage and under the influence of frosty powder forces. The depth of the foundations, as a rule, make the same. They must be tied up with each other anchor bonds. At the same time, the design of a small-breeding foundation is useful to supplement the screw adjustable supports necessary to eliminate shrinkage blocks. This method is good "works" on any soils, except for the most "problematic" - water-saturated bubbly and weakness (dust-orstand IDR). On top of the foundation, waterproofing is necessarily placed on top of the two layers of the roll material (rubberoid, IT.P. glasses), glued on bitumen mastic.

Start a construction assembly, as a rule, from the wall of the house, to which an anchor bolts are attracted with a step of 600-1000mm starting profile (one of the corners are collected first by separate buildings). Inside the mounting racks, there are 10-20mm thick remote dies; Subsequently, the clearance is filled with mounting foam (sometimes-mineral wool); Outside, the insulation is waterproof, it is insoluated, and then close from two sides with naschelniki.

Striple!

When designing a winter garden, it is necessary to think over in advance how you will fight snow and found out on the roof. You can use the heated glass and pave the heating cable in the gutters and drain pipes. However, this is quite an expensive solution. Possible alternative - increase the angle of inclination of the roof to 30 or more; At the same time, in any case, the design should withstand snow loads at least 140kgs / m2. It is worth noting that the biases of the roof towards the house, so often found in the Western European projects of winter gardens, in the conditions of our climate are unacceptable. In winter, snow will definitely accumulate snow, and when his melting is inevitable leaks.

The same design has the adjuncing frame frame to the foundation, in one exception: the supporting dies here replaces the narrow coaching profile here, and instead of an external nickname, the withdrawal of painted galvanized steel is mounted. Racks and riggers of facade aluminum systems bond with each other through the mortars of "superstars", the wooden frame is collected with the help of corners and self-tapping screws; Specialized systems provide bolted, screw and latch connections. Make sure that there are no integrated rubber seals, the joints necessarily seal with silicone or other composition.

Top to the walls are fixed with a strapping (a kind of mauerylalate) from an aluminum or steel profile, which serves as a support for rafters. The joke of the roof with a wall of the house insulate the mounting foam. Its waterproofability is provided by different ways, most often, gluing on the polymer mastic or silicone sealant of the roofing material.

Characteristics of translucent filling

| Glazing option | Svetopropuska,% | Heat transfer resistance, m2c / w | Mass, kg. | Soundproofing, DB | Price 1m2, rub. |

|---|---|---|---|---|---|

| Glass windows 4-16-4I | 81. | 0,68. | twenty | 27. | From 3400. |

| Glass windows 4-16-7 (triplex) | 72. | 0.55 | thirty | 32. | From 4550. |

| Cellular polycarbonate transparent, 25mm | 55. | 0.58. | 3.5 | 21. | From 720. |

| Cellular polycarbonate transparent, 32mm | fifty | 0.71 | 3.8. | 23. | From 740. |

| Cellular polycarbonate color, 25mm | 35. | 0.58. | 3.5 | 21. | From 820. |

The editors thanks Veka Rus, "Dekenink Rus", "Profin Rus", "Britton", "Window shipyard", "Window Factory", Yucco, Veka, Four Seasons Solar Products, Rehau for help in the preparation of material.