Greenhouse operation: Conditions for the location of greenhouse structures on the site, Materials for frame and coating, comparative table

Modern greenhouses - durable and durable, well preserve heat and serve as a dacket for many years

Optimally designed greenhouse designs allow you to grow a variety of cultures - from garlic to tomatoes

Some gardeners are successfully growing flowers in greenhouses, and they do it almost year-round. It is important to equip the greenhouse with heating and provide ventilation

The greenhouse is often put next to before. The building will protect the design from the winds. The territory must be with a smooth surface, well drained. If the ground is clay, it is pre-made a pillow of gravel and sand

Arched structures are very popular with gardeners. The frames of such a form are covered with a cellular polycarbonate or film

The buyer can independently design the greenhouse, and the firms engaged in their production will return this project into life. The main thing is to choose the shape of a frame and underfloor material

Gardeners take care not only about the appearance of greenhouses, but also about their inner decoration, breaking neat beds

The cultivation of different cultures in the greenhouse sometimes requires its separation into zones. This can be done with partitions

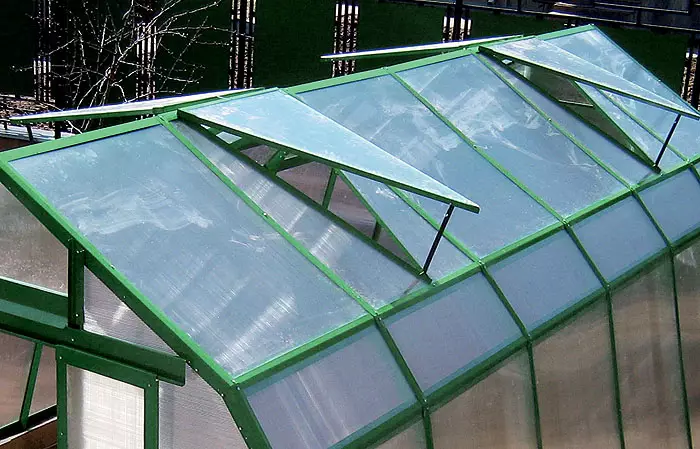

Greenhouse structures require mandatory ventilation. It is necessary not only for the optimal growth of all plants, but also to pollinate some crops. Ventilation is carried out using several vents and doors

The greenhouse will serve many longer if it is installed on the foundation. For example, constructions with a ribbon foundation 1M depth of 1M save up to 10% heat

Modern greenhouses can be lengthened by installing additional sections. The atrektal shape of the frame in winter prevents snow from entering inside

In order for the soil in the winter "breathing", it is worth removing greenhouse for a while. Light will fall inside

The greenhouse doors can be both ordinary, on loops and "coupe." Guided aesthetic requirements, the dacnik usually decides which one to give preference

The greenhouse was always the main assistant of the dacket, dreaming of collecting environmentally friendly and vitamin harvest. These garden structures are popular and now.

Typically, the greenhouse takes the relay at the greenhouse, in which the gardeners traditionally grow seedlings of tomatoes, cucumbers, peppers, cabbage or colors. Greenhouses, as a rule, do not differ in large sizes, do not require special lighting and do not always need heating using technical means. Sometimes the greenhouse fit in general on the windowsill in the apartment. Well, then the "future harvest" changes the place of residence, moving in a greenhouse.

The greenhouse will help the gardener to start landing work earlier than this will allow nature, - already at the beginning of April, and complete them later than usual, in early November. These designs produce many firms in which it is possible not only to choose the appropriate option, but also to order a greenhouse on its own project-desires and design. For the most simple models will have to pay at least 6 thousand rubles, and the cost of the most upgraded often reaches 30 thousand rubles. and more. Watering systems, heating and ventilation, of course, require additional investment of funds.

A place under the sun

To accommodate the greenhouse, optimal is a well-drained area with a smooth surface. When installing glazed heated structures, it is important that the subfield below the fertile soil layer was sandy: in this case there will not be a water and harvest loss. If the plot is clay, before the start of work, a pillow should be made of gravel (bottom layer of subsoil) and sand (upper layer of subsoil). Groundwater should be located no closer to 1.2-1.5m from the soil surface in the garden. By the current case around the greenhouse you can break through drainage grooves.The most correct location of the greenhouse is such: the longitudinal axis of its frame is directed from the north to south with a deviation to the West at about 15-20 (that is, greenhouses are oriented to the West and East). It is with this placement that the sunlight evenly warms all the surfaces and is ensured by a softer thermal mode during the period of possible overheating. You can take care and that the greenhouse is protected from the winds with garden trees or other buildings. Azbui heat loss from the north will help with white oil paint reflective screens, which are installed outside at a distance of 1-2m from the "Houses for Plants". They are designed to create an additional backlit of the structure due to the reflected sunlight.

What will be born in the greenhouse?

One of the obvious advantages of growing vegetables in the greenhouse is the possibility for one season to collect several crops of cucumbers, tomatoes, cabbage IT.D. But only a greenhouse does not guarantee good fruiting by the plant, the gardener will still have to take care of them and take into account the peculiarities of the growth of certain cultures.

So, cucumbers are very picky about soil, it should be extremely fertile. Therefore, it is important to remember feeding both when preparing the soil to landing and after, in the process of growing culture. Seeds by tradition are lowered to a depth of 3-4 cm, and when sections appear, you need to do soil looser. This is a plant, therefore, therefore, the greenhouse should prepare the appropriate supports.

Early tomatoes are very demanding of temperature conditions, especially if we are talking about early March, when it is recommended to engage them. Experienced dacities before the appearance of shoots with good solar lighting are maintained in the greenhouse daytime temperature 16-20s, and the night-10-12 ° C (the heater will help).

Cauliflower needs a few feeders, otherwise the heads (shoots with the incarnations of inflorescences) will not be delicious. The agronomists advise the first time to feed it 12 days after the landing, the second - after 10-15 days, the third one will noticeably, which is formed by the head.

Sweet pepper is actively growing at a temperature of 22-30s. If it starts to rise or decrease, the likelihood is great that the process of fertilization will violate. Pepper self-escasive culture. True, experts still advise you to isolate the sweet "option" from acute to achieve maximum purity of the variety: semi-sweet, and sometimes bitter fruits are obtained. For garlic, it is not recommended to apply humid or fresh manure as a fertilizer. At that, this plant loves frequent and abundant watering. However, 2 weeks before harvesting should be stopped.

Fundamental basis

The greenhouse can be deepened in the ground at 80-90cm, in other words, to build it in a pre-dug-off rectangular kitty for the necessary dimensions. This improves the thermal regime, especially in winter, and in the summer it allows to align the temperature inside the greenhouse. Below the construction is not recommended, since many low-spirited plants will be in the shade.

Most modern designs also require a foundation. It is necessary, first, in order to serve as a support for the frame and the coating material (for example, withstand the weight of the glass), and secondly, to remove the rainwater. In addition, it was established that greenhouses with a ribbon foundation 1M depth to 10% of the heat are saved.

If the tools are limited, the foundation is made lightweight lying on the surface (superficial). It can be impregnated with antiseptic timing by a cross section of 100 100 or 150150mm, concrete fill, metal corner, channel, bricks. The bar is less durable, but in such a kind of foundation there is a need if the owners plan to transfer greenhouse from place to place. By the way, it is useful to periodically do and so that the soil rested from permanent use. Between the frame and the foundation, it is necessary to provide an additional "gasket", which will extend the service life of the greenhouse, protecting it from rotting and corrosion. Suppose you can apply a bitumen layer or apply silicone maize.

Some manufacturers (for example, "will" produce greenhouses, fixed on the ground using special T-shaped frame endings. The foundation is not required. You can call the models "DAKA-2DOM" (for cellular polycarbonate, area-12m2, the price with a coating - 13 700rub.), "DAKA-2D" (under the film, area - 16,2m2, the price is 5300 rubles). The greenhouses "Droplet", also not needed the foundation, produces "Teplagia" (area - from 11.2m2, coating price, from 24 thousand rubles.).

There is no stronger

The frame in the greenhouse plays the role of a kind of "skeleton" - keeps the coating. It may have the shape of the arch or tunnel ("Will", "Contact", Glass House), a double house ("Agrisovgaz", "Adventory Kit"), a three-tent tent ("Teplagia") IT.D. The gardener is under the power and independently design the framework, and the manufacturer will embody his sketch into life (for example, will gather the frame in the form of a yurt).All manufacturers provide services for building the length of the greenhouses - for this it is necessary to purchase additional frames of the frame. Excess meter costs 15-20% of the price of the base model.

Typically, the doors are sold (such as "coupe" or on loops), the number of which depends on the product model (one or two). You can buy an additional partition for installation inside the greenhouse, if you are going to grow vegetables that require different temperature modes and non-interpretation.

Specialists advise paying special attention to the material from which supporting structures are made. First of all, it should be durable to withstand and wind strength, and snow pressure. Keep in mind: the frames must be mounted in the side walls and on the roof so that there are no cracks and gaps between them and the supporting structures, which will allow to minimize the loss of heat. It is mistaken to think that these gaps facilitate the ventilation of the structure - these functions are performed by the versions and doors. The air, "unorganized" penetrating into the greenhouse from the slots, can be dangerous for plants - they risk suffered from drafts.

Many dachas as a carcass material prefer aluminum (agrissogaz products). His advantage - durability, ease, fire safety. Often aluminum performs in a tandem with a steel galvanized profile, from which the base of the greenhouse is made. True, the aluminum profile is considered quite expensive material, besides, as a non-ferrous metal represents the value for thieves. Therefore, a number of manufacturers offer cold-rolled galvanized steel frames, relatively inexpensive and easy to use ("Advantage Kit", "Will", "Contact", "Teplade", Glass House Idr.). The frame is also made from steel profile, square pipe IT.D. In all cases, it is necessary to provide anti-corrosion processing of its elements. Frames made of wood gradually move into the background as less reliable.

With proper operation, the design can "work" an average of up to 30 years. Note: In order for the frame to serve for a long time, the main thing is to avoid contact with the soil, otherwise the chemical corrosion of "eating" after a few years.

Opinion of a specialist

The framework of the square pipe from the galvanized leaf manufacturers can be painted with powder paints, after which the metal structure is sent to the roasting furnace. Teplik Vitoga will find a very attractive view that will remain for many years.

The greenhouse is the decoration of your household plot. It should harmoniously fit into the landscape.

As for the acquisition of the greenhouse, we all remember the saying: "Preparing Sani in the summer ...". It is more profitable to buy it in the fall or in winter - it is not necessary to stand in line for the manufacture and installation of the design, besides, many companies declare seasonal discounts.

In order not to lose time and money, it is better to contact the manufacturing company, it will be possible to purchase a greenhouse at the price of the manufacturer, without overpayment for mediation, with a guarantee for all products (the production time will be minimal possible).

Anna Shilkin,

Sales Manager

Plastic, glass or film?

As a coating, film, glass or cellular polycarbonate are chosen. Most greenhouse manufacturers represent all three options to buyers, negative the pros and cons of one or another coating. One of the cheapest is the film. So, a model from a galvanized profile area of 18.6 m2 with one door costs about 5 thousand rubles. ("Advantage Kit"). You can generally purchase one framework, the model "cucumber" ("Will") with an area of 4.8m2 (1.5 thousand rubles), which is then easily covered with a film. Most often, the film is attached to the arched frame, and sometimes it replaces the doors- for example, the model "Perchina" for 2300 rubles. ("Will"). Autumn film is removed from the frame and stored indoors. If necessary, next year, the framework can be moved to another place.

True, the film is not very durable: on average, it uses 2-3 seasons. To protect this coating from ultraviolet radiation, a special stabilizing processing is carried out. Another disadvantage of film is a small heat-insulating ability: the day of plants is hot, and the greenhouse should be ventilated.

Alternative coating - glass. It is in great demand in gardeners, as many times fast film, passes up to 90% of light, does not require special care and can serve dozens of years. But such models of greenhouses are more expensive than film. For example, for the 0,200 adventant set) model ("adventant set") 2,5m with a 2,5m height of 2.5m from 24 thousand rubles, and the three-tie greenhouse "Sadovaya" ("Teplands") 3m and 2,4 m high from 23 thousand rubles. For construction, greenhouses traditionally use window glass, but the best results gives float glass. For safety reasons, glass thinner 3mm in the greenhouses do not put. To improve thermal insulation, you should use double glazing, that is, install double frames. It is necessary to envisage the ability to dismantle the inner glass for cleaning. To seal the seams between the outer glass and the frame, the T-shaped rubber profile is used, and for the ends and the guide blocks and silicone sealant.

It is extremely popular today and such a greenhouse coating as cellular (cellular) polycarbonate. This is two- or three-layer light-up panels with cavities inside (thickness 4, 6, 8, 10mm and up to 40 mm). The greenhouses of temporary use are covered with a polycarbonate with a thickness of 4mm, and large-6 or 8mm. The advantages of this material have a lot. It is easier glass 20 times and is well bended, although it is very durable (it is not even smashed (it is not even a hammer), has a relative-friendly spectrum of the transmitted light. The transitability of polycarbonate is about 90%, besides, it is frozen - not afraid of even temperature -50 OS (that is, there is no need to remove coverage for the winter). The agolate machine will save the heat almost like double windows.

Traditionally, polycarbonate is laid on the frame of large sheets. In practice, its service life is over 20 years. There are deficiencies in the coating, but they do not lead to critical consequences. So, in the morning cold, moisture can be condensed in the cavities of the panels, which is close to the lower edges of the sheets where water flows, microalgae crosses or insects are covered in search of food. But the sealant layer on the ends of the sheets helps to cope with these problems.

Polycarbonate uses many firms, including "adventant kit", "Will", "Contact", "Teplade", Glass House Idre. The cost of the material is not too different from the price of glass coating. For example, for the construction of the stationary greenhouse "Sadovaya" ("Teplanda") with a length of 4m will need to buy a glass thickness of 4mm in the amount of 6810 rub. Aesley to cover the arched model of similar sizes by cellular polycarbonate, the value of the material of the same thickness will be 6430 rubles.

Opinion of a specialist

Concrete fill, channel, bars foundation take longer. The buyer can find out the size of the future model in advance and prepare everything without a rush.

Most often, dacms, having a small land of Earth, pay attention to typical designs with a width of 2.5 or 3m, 4-12m long, with 2m increments. The folding flaps are of size 21m, and for the winter it is desirable to shoot them so that snow and rain and the ground "breathe" fall into the ground. Arched structures are most popular, but it is worth noting that the buyer may come up with a greenhouse model, and designers and collectors will prove the project to life.

Tube knuckles install doors. Partitions inside the greenhouse to create a different microclimate in separate parts are acquired additionally. All parts are connected to each other bolts (not welded), so any gardener can easily disassemble the greenhouse if necessary. Some buyers, using the instructions, and successfully collect acquired models.

Pavel Kovalovnikov,

Head of the Sales Department of the Firm "Contact"

Greenhouse accessories

When growing vegetables in a closed ground, determine how you will aircap the greenhouse, heat it (if there is a need for this) and water the plants. Think also that it will serve as a guarantee of a good microclimate.To ventilate the greenhouse allow the vehicles placed on the roof of the facilities and the doors in the ends. For natural ventilation, it is advisable to use the upper part of the design. It is important to know that ventilating is also responsible for pollination of crops, and in addition, smoothes the temperature differences, mixing air flows. However, not all dacms can once again go to the site to open greenhouse vents, say on the working day. In order for the ventilation to be regular in the absence of the host, the device for automatic ventilation is used. It works without electricity, using only the power of an adjustable hydraulic mechanism containing a special working fluid. With increasing temperature, the liquid heats up, expands and pushes the rod that opens the window. Such a mechanism is acquired additionally, and it costs about 1200 rubles. ("Contact").

Watering plants can also be carried out through mini-systems of irrigation, such as the Polywaki watering system worth about 300 rubles. ("Will"). A special adapter is connected to the water supply, and it works at a pressure of at least 0.2 atm. (from the tank on the roof).

If you are going to care for plants in heated greenhouse, the most convenient way to heat the design is connected to the house system of water heating. Disposal pipes should be insulated and buried to the ground. The same greenhouse needs them, on the contrary, "set" to the surface. According to experts, the heat generator ("thermal gun") should be purchased for greenhouses with an area of more than 10m2. The cheapest such devices are about 5 thousand rubles. Many greenhouse manufacturers simultaneously specialize in the installation of the named equipment.

General characteristics of greenhouse structures

| Parameter | View of the coatings | ||

|---|---|---|---|

| Film | Cellular polycarbonate | Glass | |

| Foundation | Usually not required | Concrete Pouring, Metal Corner, Schweller, Idr Bricks. | Concrete Pouring, Metal Corner, Schweller, Idr Bricks. |

| Frame | Cink Steel | Steel corner, galvanized profile pipe 4020,2020mm | Steel corner, laminated 32323mm or curved 1.2mm |

| Heat transfer (in quiet weather) | 13W / (M2C) | 3.9W / (M2C) | 8W / (m2c) |

| Sealant | Not required | Silicone | Rubber compressor |

| Foreign safety | Blood Material | Empty material, self-fighting | Failed material |

| Svetopropuska,% | Not less than 80. | From 86. | More than 90. |

| Service life | Until 3 | Up to 15 | Up to 20. |

| Cost 1m2, rub. | From 500. | From 900. | from 1500. |

The editorial board thanks the company "Agrisovgaz", "Advantage Kit", "Will", "Contact", "Teplade", Glass House for help in the preparation of material.