Methods and methods of cutting vinyl siding. Testing Tools, Practical Recommendations, Manufacturers Tips and Expert Conclusions

As was promised in the article "

There was a cottage "(" IVD ", 2008, №9), today we answer for many readers of the magazine and visitors of the site www.ivd.ru the question of the methods of cutting vinyl siding.It is clear that when choosing a finish for the exterior walls of a newly built or restored house, you want it to be not too expensive (this applies to both the price of material and labor costs). But at the same time, the facing should look good and do not need careful care. All specified requirements for the maximum extent correspond to siding, primarily vinyl. Perhaps it is precisely this that explains it not only not weakening, but also ever growing popularity.

Increasing demand, as you know, gives rise to an increase in supply. As a result, only in the last 2 years, the number of siding manufacturers presented on the Russian market has increased (we think that it's not too mistaken) in 1.5-2ruses, and the number of firms taken for its installation (and far from all of them relate to high-end professionals), - in 3-4rd. Well, how many private owners are self-sided with siding walls of their own homes and cottages, we do not even predict. But for sure (this is confirmed by the personal experience of numerous trips to construction sites) we can say that all of them face problems when installing) when they don't pick it up) when cutting panels. The source of these difficulties is single-thought-out and frankly weak instructions on the installation, which is not surprising. Any major western manufacturer firmly confidently, siding must and will mount professionals who are on this, as they say, a dog ate. Is there any specialists in detailed instructions? And the fact that somewhere in Russia siding will be personally to sow the walls of the houses of his owner or the brigade of migrant workers, seeing this very siding (as, however, the owner) for the first time in life, he never comes to mind. The domestic manufacturers take an example from Western, they do not publish detailed instructions, and we have nothing ...

|

|

|

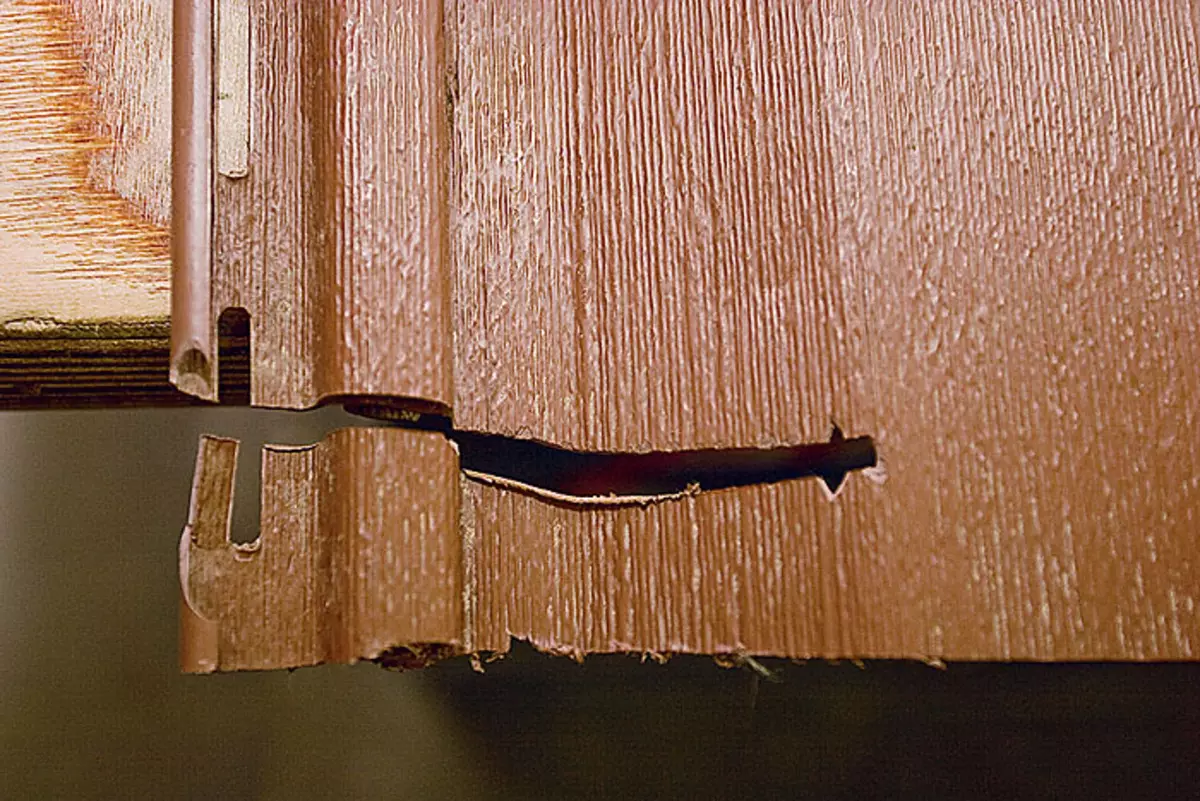

Cutouts on the ends of the panels for connecting them in length: in the upper (1) and lower (2) parts. Difficulties in obtaining the first of them creates a multi-layer hook of the castle

To help understand what is better to cut siding, we did not ask for any of the firms producing it, but decided to refer to the manufacturers of cutting power tools that dismantled in various methods and methods of cutting (as they say, and cards in hand). Companies specializing in power tools in the Russian market are presented in abundance: AEG, Bosch, Kress, Metabo (all Germany), Black Decker, DeWalt, Skil (All United States), Hilti (Liechtenstein), Hitachi, Makita (Oban, ), "Bykovsky ElectroCretory Plant", "Izhevsky Mechanical Plant", "Interskol" (all- Russia) and many others. The editors stopped their choice on Bosch, manufacturing the widest range of power tools. The reason is simple: a group of so-called demonstrators has been operating in the representation of this company, whose duties are just entering the virtuoso possession of any instruments manufactured and visual display of their capabilities to buyers of any category, including professionals. We decided to attract these specialists as independent experts.

They brought sample samples and on a specific example explained that it was necessary to cut and what result should turn out. In addition, they provided them with excerpts from installation instructions from several manufacturers, and then offered to try to fulfill the requirements of these guidelines. Of course, along the way, they had to choose the most suitable tool for cutting.

What and where to cut?Made of polyvinyl chloride by extrusion of the panel can have a length of the 2-6m- single standard here does not exist. The gentle part of each panel is a lock-latch, in the upper-perforated edge for mounting to the wall with nails or self-tapping screws and the response part of the latch lock. On the side ends of the panels and from above, and from the bottom at the factory there are a certain form of cutouts, thanks to which the panels when connecting an inch with an adhesive enter each other and due to this are held together.

Therefore, you can create a section of any length, but the multiple length of the panel. If the length of the wall is not coincided with this step, the extreme panel of the section is cut across the desired size. AESLI is trimmed at the house, it is not just across, but at an angle corresponding to the corner of the tilt of the roof of the roof. Together with the cut part, the panel is deprived of both end cuts that have to play on a new end. In this case, the neckline is easier to create in the lower part, in the upper due to the multi-layerness, more complicated.

Cut siding is also in the situation when the width of the panel is too large, - when connecting the side wall with the sink of the roof and under the windows. Moreover, in the first case, the panel is simply cut along, and in the second, it is necessary to make "drank" in it in the width of the window. For this make two transverse cuts and one longitudinal.

So, there are three tasks: cut the panel across or across the angle, restore end cuts and cut along.

|

|

|

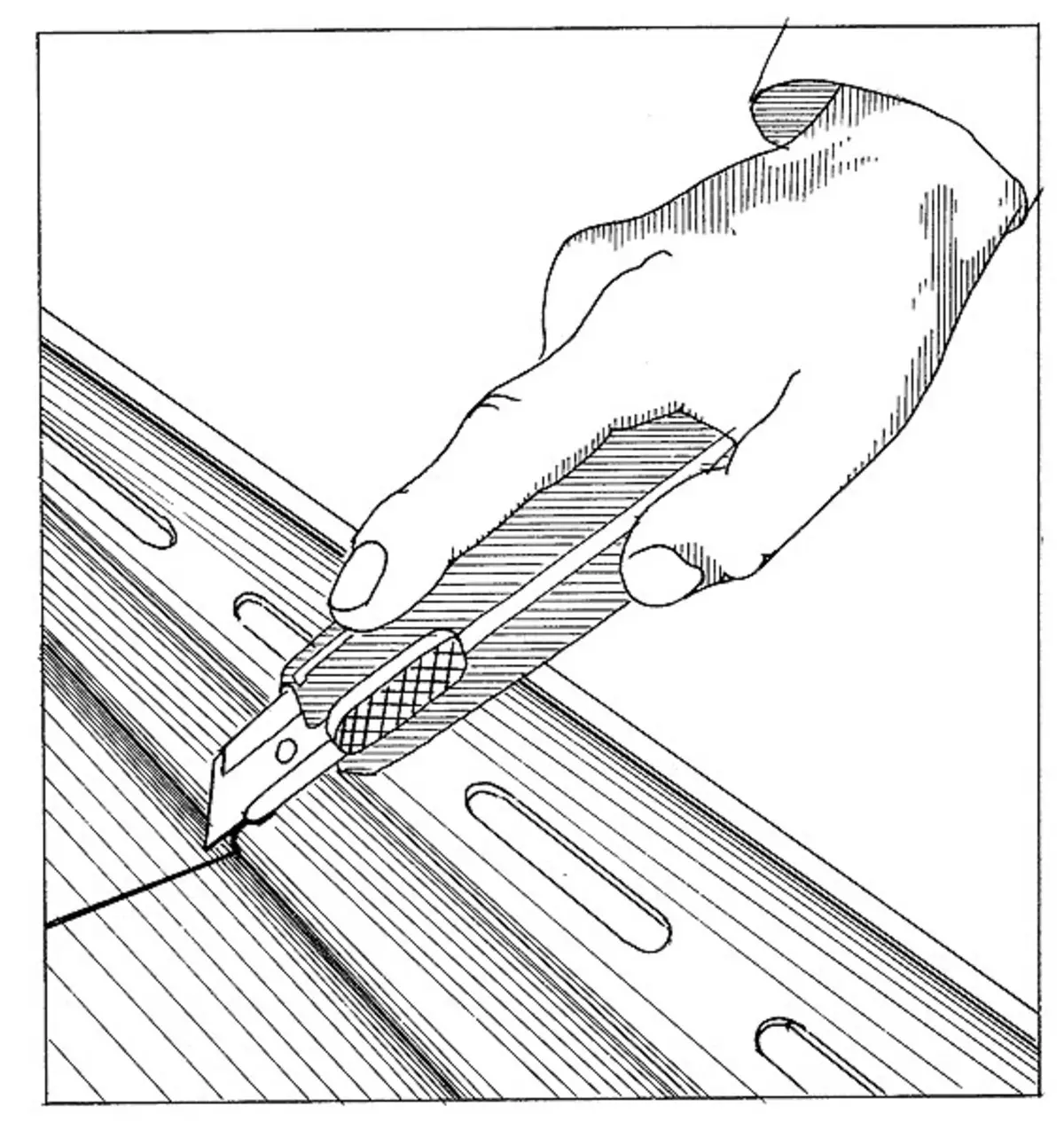

Use for cutting of vinyl panels of the saber saw (3) Even when applying clamps (4), success did not bring. With the help of electric scissors for metal (5) the result turned out to be a little better

How to cut?Let's start this section by quoting one of the instructions: "To install siding, you will need the most common hand tools, such as hammer, square, chalk, level and roulette. For eye protection, we recommend special glasses. For cutting panels, you can use: an electric saw or a jigsaw, a hacksaw for metal, scissors for metal, knife. "

Well, let's try to deal with each of the tools in the order of enumerations in the instructions.

Photo 6. |

Photo 7. |

|

Applied for edging windows (6) and angles (7) Special profiles can be cut in the same tool as the wall panels

FantasyHaving at hand in abundance, various tools, neither we nor the experts could deny themselves in pleasure to fantasize and test equipment for cutting panels that are not listed in any of the instructions. For example, a saber saw and electrical scissors for metal.

Sabelnaya saw, even equipped with a special plastic blade, cut siding is difficult, as it is necessary for this that its playground be restricted into a hard surface, for which it was necessary to attach a sample of the slab panel to the surface of the table. Terms of construction sites create such conditions can not always.

The electoral helps were very convenient to make longitudinal and even curly cuts. But as soon as the cutting edges of the tool fall on a curved surface, it becomes impossible to work, because it is not always possible to put the scissors parallel to the surface. Well, about cutting the multi-layer top of the panel lock, do not even say.

Electric saw. And immediately, two quotes from instructions from different manufacturers.

1. "Stationary or manual radial electric saw can accelerate the cutting of siding. A panel with thin teeth is suitable for cutting (from 12 to 16-tiping 2.5 cm), while the cloth must be installed in the opposite direction."

2. "When working with a circular saw, install a cloth with thin teeth (for plywood) in the opposite direction so that the cutting is softer and cleaner ... cut slowly."

Lobzik. And this tool for cutting siding is applicable only in part, in which they were unanimous and we, and experts. For normal operation, at least under part platform, the tool must have a solid and preferably even support. It is not enough that the siding panel itself is neither solid, nor a flat support is not, and under the zone of embedding the teeth in the hook loop, it does not relieve anything, and when cutting off a small part, it hangs in the air.

Metal hacksaw. According to general recognition, a hacksaw is a universal tool that can be boldly to cut siding and in the heat and in the cold. This help it is easy to create end drank, but ... provided that you are not in a hurry. The processing of each end takes 5-6min, and during this time you have to turn the panel at least twice.

Scissors for metal. Suitable for cutting siding only in warm weather. It is not recommended to use them into the cold - in the place of closure of the ends of the blades in the cold, the crack will definitely appear. By the way, with a certain thickness of the cutting parts (the design of the scissors there are different) such a crack may occur both in the warmth. In the installation instructions on this issue there are, for example, such instructions:

"When cutting panels with scissors for metal ... Avoid a complete closure of cutting edges of scissors." "... Use scissors blades only on 3/4 of their lengths so that the cutting is more accurate and clean. Start cut off the panel from the top, fastener."

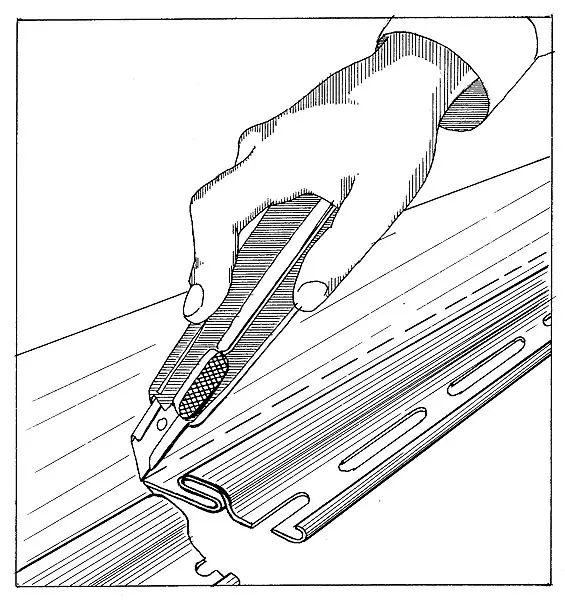

Knife (Photo 14). And again, let's start with the quote: "Using a knife cutter, spend a deep furrow on the panel, then bend a few times / break the panel, until it breaks on the planned line." Written valid only with the unusted cutting of a smooth area of the material. For example, two transverse cuts are made to obtain under the window opening (Fig. 1), apply a ruler and the knife is performed on the panel long incision, and then flex a cut side to the side opposite to the cut. A click is distributed, and the cut part drops to the ground.

The transverse cutting panels, as shown in Figure 2, taken from one instruction, should not even try to perform with a knife. How not to use it and to create end cuts.

|

|

|

A corner car, simply speaking, Bulgarian. This tool is also mentioned in many manuals, but very peculiar. The reinforcement is written about the following. It is not recommended for cutting vinyl siding (in some cases it is categorical, "prohibited") to use the grinder, since the cutting circle places the edges of the cut, which causes their embrittlement and as a result, the appearance of cracks. I found my phrase in one instruction in one instruction: "For cutting of vinyl siding, you can use hacksaw for metal ... and a grinder (at low speed)."

The tool proposed by experts approached as it is impossible. If you set a thin (thickness of about 1.5 mm) the cutting disk with a diameter of 125 mm and select the appropriate speed of rotation, you can cut the panel and along, and across. Some problems arise except when performing end cuts. It is necessary to perform an operation while holding the panel on the weight, besides it is difficult to cut off the "hook" -napper in the upper part of the panel: a little glanced, and the panel canvas turned out to be cut, and the part is hopelessly spoiled. And in general, work with a grinder on weight (and this tool is quite voluminous and heavy) - the matter is unsafe.

If the Dremel operations are suitable for the listed operations, then for the longitudinal and transverse cutting of the panels, it is necessary to prefer the usual grinder on these operations, it has a performance above.

What did the experts solve?At the request to comment on the work with the tools used by our experts reacted very peculiar. Long silent, and then the head of the group somewhat offendedly stated: "After all, you knew in advance that Bulgarian is the best tool for cutting! So you are so much time ... read the instructions? " I had to honestly admit: "Yes, knew! Because, contrary to the instructions tried it in practice. But after all, personal experience can sometimes be biased. So we decided to reinforce his opinion of experts and only after that publish the results so that our readers had no experimental experiments. "

The editors thanks Bosch's company for help in preparing the material.