Overview of the floor gas boilers: types of devices, a description of the basic components involved in the heating process of the coolant

Outdoor gas boiler-tested by time, a device for heating and hot water supply of a country house. It is advisable to apply such an aggregate at large needs of the house in warm and hot water.

As a fuel for heating a country house, stone coal, firewood, peatcrippers, diesel engines, electricity, propane-butane and natural gas can serve. The last now is the cheapest fuel in our country, the interruptions of which is quite rare. Supporting the efficiency of the modern gas boiler (at least 90%) for the heat obtained with it, you will pay at about 13 times less than the heating of the house with electricity (at 2nd for 1 kWh). For the same amount, if not more expensive, heating will cost the use of diesel fuel, and when using import gas (propane-butane), you overpay for heating by about 8 times compared with the main gas (if the price is 1l propane-butane-10 rubles.). Well, at least 2-3 times more expensive than gas is heating with purchased birch firewood. That is why the presence of a gas highway next to the house, to which you can connect, makes the choice of a modern floor gas boiler as the main source of heat is quite justified.

Gas boilers include high heat transfer and efficiency, the ability to work automatically. Correctly mounted and connected gas boilers are safe, reliable and durable.

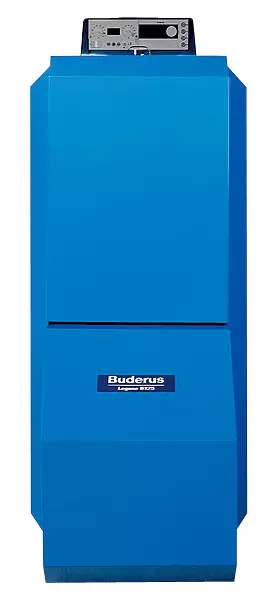

Buderus. |

Vaillant. |

Fondital. |

Fondital. |

1-2.The modern highly efficient boilers Logano GE (Buderus) (1) and Atmovit (Vaillant) (2)

3-4. Poly gas boilers ELBA Dual (3) and Scudo (4) (Fondital) are designed to work with fan burners. Watch devices used Multiple cast iron heat exchangers

Of course, the connection of the boiler to the village gas network is quite expensive (from dozens to several hundred thousand rubles). For connecting, installation and maintenance will have to attract certified and licensed contracting organizations. But the investment "GAZ" significantly increase the liquidity of suburban real estate. Therefore, developers usually do not stop the complexity of the preparatory stage.

Choosing an outdoor gas boiler, you should contact the specialists. They will help to determine the heat generator, get all the documents to connect it to the gas network, will perform installation and commissioning work, and then warranty and service maintenance of the mounted unit will be carried out. But it is necessary to resort to the help of professionals in advance, at the stage of designing a country house. Since it is necessary to make fundamental decisions regarding the equipment on the technology, it is required before going to a particular company, to obtain a general idea of the main stages of choice and the most important structural elements of modern floor gas boilers.

Housing for the boiler

The boiler room is often equipped on the first floor of the house, for example, next to the garage. Another good option is to place the boiler and his "environment" outside the housing, in a lowered or separately worthwhile building. The size of the boiler room is chosen in accordance with the regulatory documents and the planned layout of the equipment.

So, when installing heat units with a total capacity of up to 150 kW in a separate room located on any floor of a residential building, this room must meet the following requirements:

The height of the ceiling is not less than 2.5m2;

volume is not less than 15m3;

The room must be separated from the arms-adjacent rooms with the enclosing walls, the limit of the fire resistance is at least 0.75h;

Natural lighting - at the rate of 0.03m2 glazing on 1m3 room volume;

Be sure to be provided for the supply and exhaust ventilation;

If the room is located on the first, in the basement or basement floor, it should have a way out directly out;

In buildings, equipped with autonomous systems of water and heat supply, there must be grounding contours. Input to the building of the underground gas pipeline should pass through an insulating flange;

The room must be equipped with a sewer or drain veil with a pumping pump;

For a gas floor boiler, it is necessary to provide a podium with a height of at least 25 cm.

A ready-made project of the boiler room should be coordinated with the district architect, sanitary-index authorities, fire inspection IT.D. Installation of equipment starts when the podium has been built to install the boiler, the gas pipe is performed, the gas meter is installed, and the electrical wiring was carried out to power the system of automation and other electrical equipment and cold water, sewer taps were made. Walls should be plastered or tiled. Well, the floors and the ceiling can be finished after installing and connecting the heat generator.

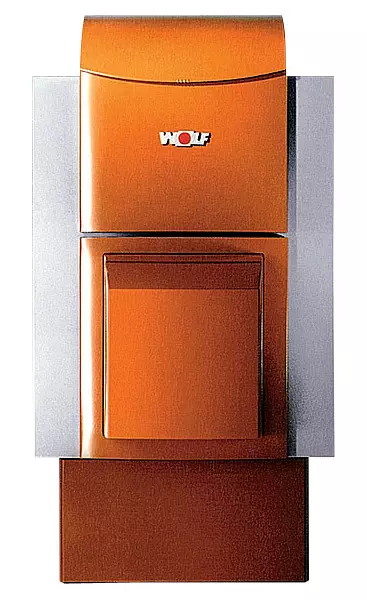

Orange

The selection of heat generating equipment for the heat supply system Specialist-designer begins with the fact that it determines the required boiler power. At this stage, errors often arise, as a result of which the consumer sells significantly more powerful (sometimes 50-100 kW) than necessary for heating and DHW of the country house, and therefore an unjustifiably expensive device. There are such annoying missiles in the calculations from our vendors of the boiler equipment quite often, as this profitable transactions bring more profits. Azoskchechyr is forced to exploit excessively powerful equipment, which even in the most severe frost works with minimal load and low efficiency, worsens the ecology of the site, is premature fails due to breakdowns caused by non-optimal operating mode. Meanwhile, the powerful boiler consumes gas in very significant volumes, so the owner has to overpay a round sum monthly. Buying an excessively powerful boiler can be economically justified only if the owner of the country housing in the next 1-2 years plans to connect new buildings to it (for example, a garage or bathhouse, guest house).

Wolf. |

Buderus. |

Buderus. |

Vaillant. |

5.Topone TNG-B (WOLF) with gas atmospheric burner

6-7. In the consoles of automatic control systems Buderus Logomatic, convenient keys and control knobs are used to "scroll". Graphic displays displaying information about the state of the boiler and the heating system, for easy reading, equipped with background backlight

8. In proven by the time of water heaters VIH (Vaillant), the steel reservoir (a) and the heat exchanger serpent (b) coated with corrosive enamel, for additional protection there is a magnesium anode (B). The boiler is thermally insulated polyurethane foam (g). Maximum pressure for tank - 10 bar

Accurate calculation of the power of the boiler - the multifactoric task. For effective and economical heating at home, it is necessary that the thermal power of the floor gas boiler ensure the compensation of all without exception of thermal losses in the rooms at an outdoor temperature in the heating period, equal to the average temperature of the most cold five days in this village. For example, for Moscow, this temperature is -26c, and for Zlatoust is -34c. Do not allow the designer to be mistaken several times possible, if you independently determine the desired power at least in the first approximation. When calculating the most important parameters to which it should be relying, the area of heated premises (S) and the specific capacity of the 10m2 boiler (Wood), which is installed, taking into account the amendments to the climatic conditions of the region, the heat loss and the type of building.

There are evaluated values of specific power for different climatic zones:

for the areas of the Moscow region Wood = 1-1.5 kW;

for the northern regions Wood = 1.3-2 kW;

For southern regions Wood = 0.6-0.9 kW.

Calculation of the power of the boiler (WKOT) is produced by the formula:

WKOT = SWD / 10.

For example, if the heated area of the house in the suburbs is 200m2, you need a power boiler at least 20 kW. The critical value should be added another 15-20% - this is a stock that will allow to pay off the unintended heat loss. Such a rough calculation is suitable for a brick house (in two bricks) with small heat lines (the height of the ceilings in the rooms is not more than 3m, windows with double-glazed windows and a warm attic).

Baxi. |

Reflex. |

|

|

9. Rapid boilers with a cast-iron heat exchanger Crysalis Xenium (BAXI) Complete the control panels of ECOControl various types

10.Beers of the S (Reflex) series with a capacity of 150-500l with colored metal casing

Wuttomatics of most modern boilers are provided by the function of the priority of the DHW, and select the gas boiler with an excessive capacity for cooking hot water is not necessary. Although at the time of the preparation of hot water, all power is used for the DHW, it practically does not affect the microclimate of the country house: the thermal inertia, which has any building, will not allow a sharp decrease in the air temperature in the premises even during a long-term water intake. In practice, the work of the boiler in the DHW mode wears periodic and short-term. It is not worth increasing the power and if you are going to warm the water using autonomous, non-boiler-based boiler-type boiler with an integrated gas burner. Avot If it is planned to connect additional contours that consume heat from the heating boiler (for example, water heated in the pool), it should be done to the minimum necessary heating power of the boiler in the size of the maximum power of these circuits.

And further. You can read regular booklets or instructions about the heat capacities of the boilers, which they are able to develop only at the pressure of natural gas, which make up 13-20mbar, although the real pressure in Russian gas networks can be 10 membar and less. Often, due to a reduction in pressure in the gas highway, the boiler (for example, with a capacity of 60kvt) loses 1/3 of its capabilities and is able to warm the house with an area of no more than 400m2 instead of the calculated 500-600m2. A possible drop in pressure must be compensated by choosing a boiler more powerful by about 30% than the calculation is obtained.

Stripping from the necessary power, the parameters of the boiler room and some of some characteristics, the designer's specialist chooses the boiler on the catalogs of manufacturers, then looks like other equipment required for the boiler room. At this stage, the designer must take into account all the wishes of the house owner regarding the boiler, in particular by the method of heating hot water, the type of heat exchanger, burners and automation.

Wolf. |

Viessmann. |

Buderus. |

Vaillant. |

11-13.The modern gas boilers with cast iron heat exchangers ComfortLine (Wolf) (11), Vitola 200 (Viessmann) (12) and Logano S125T (Buderus) (13)

14.Wanguaded burner Boilers Atmovit Exclusiv (Vaillant)

How much water flowed ...

According to the method of heating hot water, the boilers are divided into one- and dual-circuit. There are no "hydraulic elements" of the DHW system, there is no "hydraulic elements" of the DHW system, so it is cheaper than a dual-circuit. But to supply the house with hot water to the feed and return highways of a single-circuit boiler coolant (the contour of radiators, warm floors of the IT.P.) are connected to the water heat exchanger of the outlet boiler. The latter is a capacity of 50-1000l, which is specifically designed for cooking and storing hot water. The cost of boiler (especially 800 or 1000l) is often comparable to the attendance of a single-circuit boiler or even exceeds it.

The same, despite the fairly high cost, it is this technical solution (one-connecting boiler with a remote boiler), in our opinion, most preferably for the organization of the GWS of a large country house.

Vioxcinular gas boilers, the elements of the GVS system are laid in the design. Plush heat generators are placed either built-in boiler with a capacity of up to 120-160l with the necessary elements of the strapping, or a heat exchanger in which hot water is heated in the flow mode. Through it, the pumps simultaneously pump the coolant, then departing into the cottage heating system, and the water heated for the needs.

The advantages of a two-kilt boiler before single-mounted compactness, the minimum installation time, the smaller value of the bundle "boiler plus equipment for the preparation of hot water." Kednostats can be attributed to the DHW capacity limit and the boiler capacity is not more than 160l, which is unlikely enough for a family of three or four people, if they all want to wash in turn. If the built-in boiler fails, for the period of its repair, the house will remain not only without hot water, but also without heat. In addition, the two-round outdoor boiler usually has no power no more than 40-50kW. Two-killets with lamellar heat exchangers There are restrictions on the second consumption of hot water - they are able to supply no more than two water consumption points at the same time. Such heat exchangers over time overgrow (especially if the water consumed in the house is rigid, that is, rich in calcium salts).

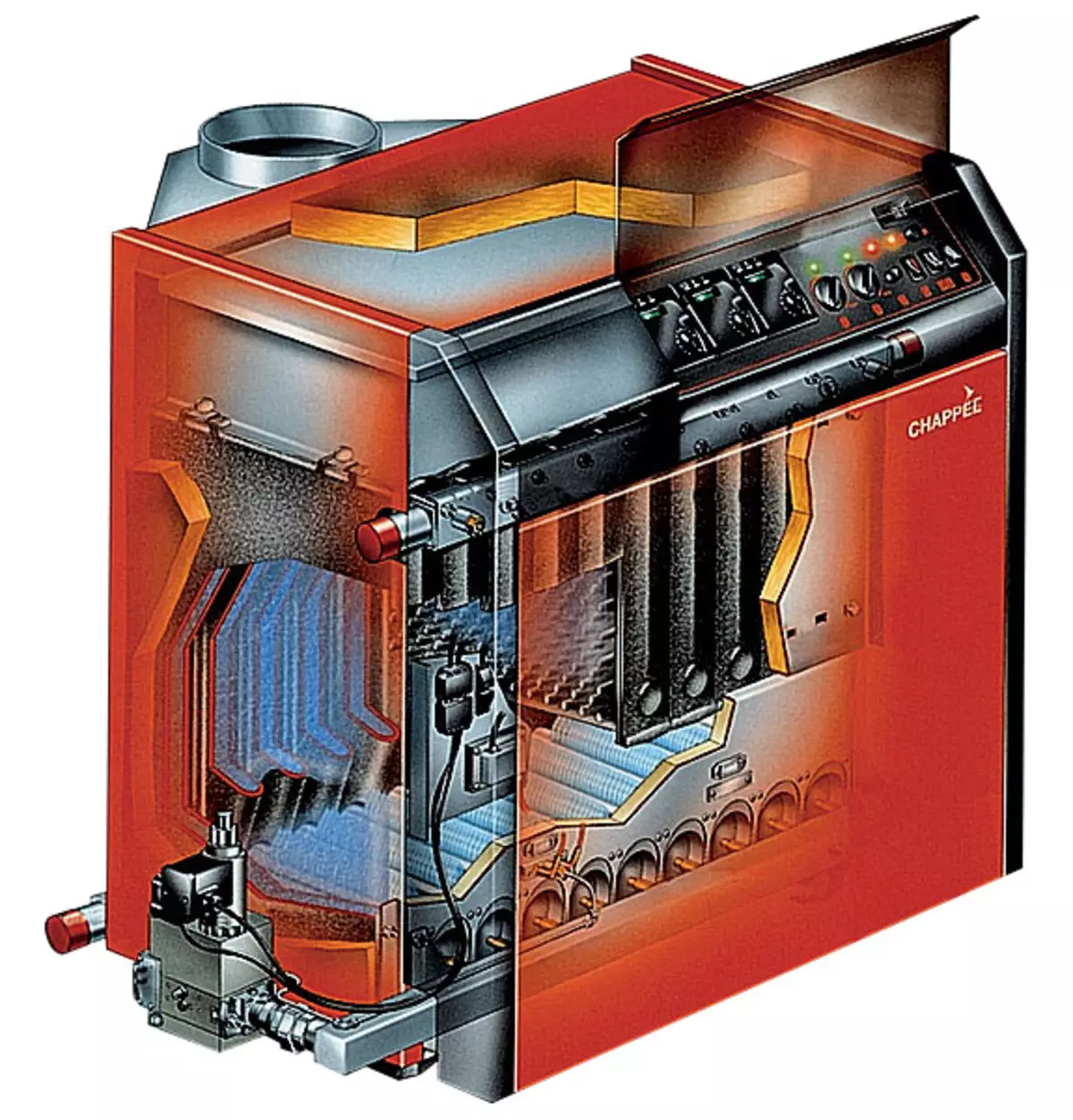

Chappee. |

Lamborghini. |

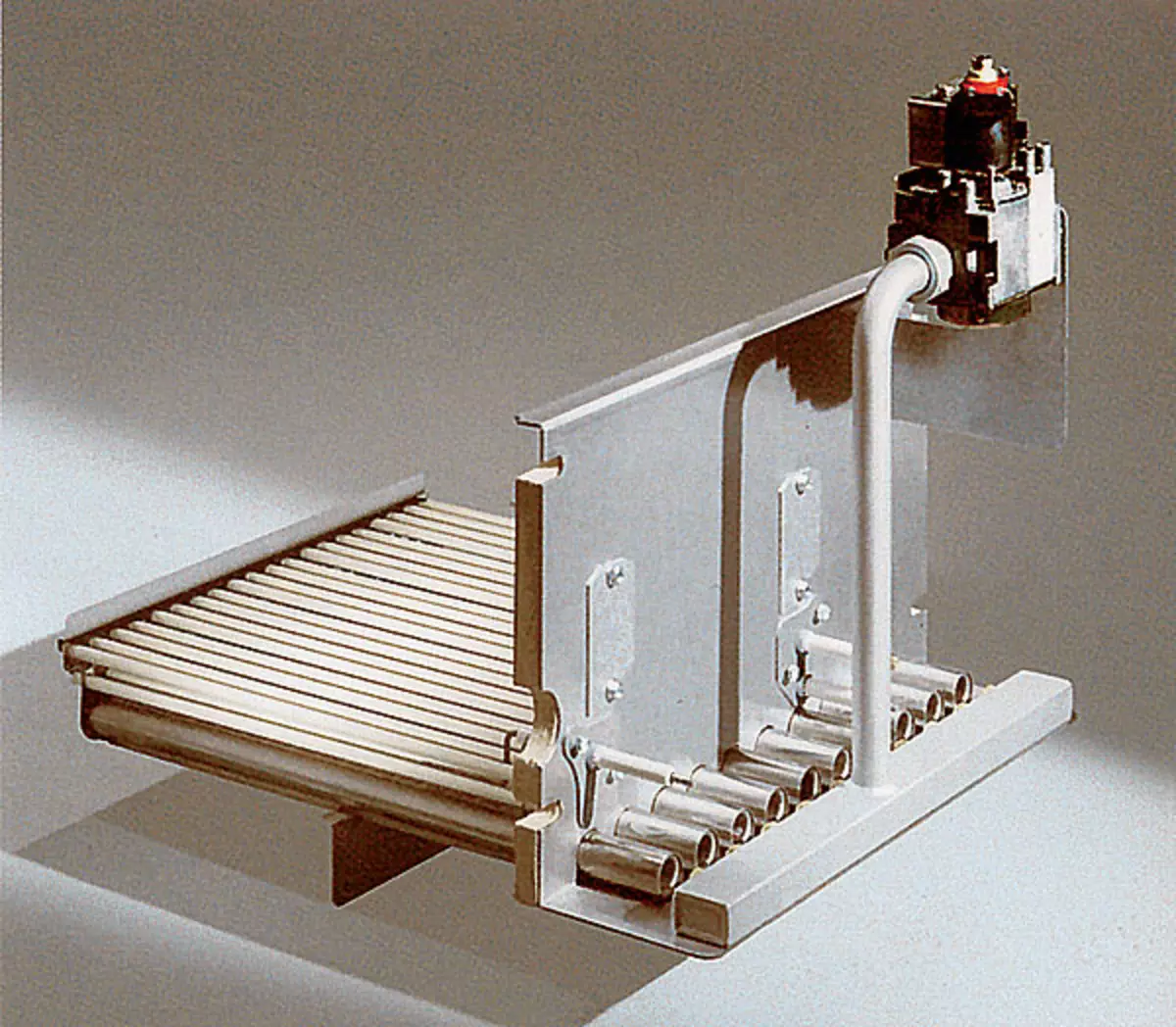

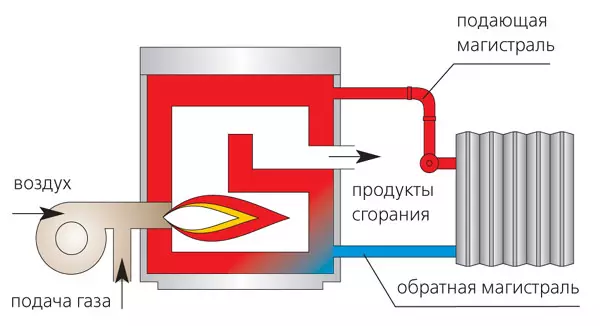

Scheme of boiler with atmospheric burner |

Scheme of a boiler with a fan burner |

15-16. The power of the "Eden3" series boilers (CHAPPEE) (15) with a cast iron heat exchanger- 65-344kW. MEGA Prex (Lamborghini) (16), equipped with high-grade heat exchanger, maximum power can be 80-3500kW

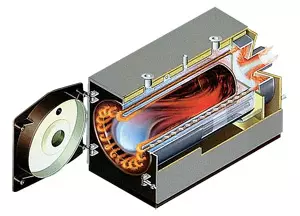

17-18. Right gas boilers with atmospheric burner (17) and heat generators with fan burner (18)

Aza design

Now briefly reflect the basic components of the floor gas boiler involved in the heating process of the coolant.

Heat exchanger. From the material from which the heat exchanger is made, the term of "life" and the economy of gas boilers depend. The most durable (up to 25-50 years of operation) boilers with cast-iron sectional heat exchangers. For convenience of transportation, such heat generators can be ordered in the assembled, and disassembled, especially if you need to enter the unit into the boiler room through a close corridor. Increase the power of the boiler When the new heat consumer appears, you can, buying and installing additional sections of the heat exchanger. Some experts argue that there are particularly good in the work of cast-iron heat exchangers of floor gas boilers from the so-called eutectic cast iron used in de Dietrich products (France), Viessmann (Germany), CTC (Sweden) IDR. Extremely high quality and durable cast-iron heat exchangers are equipped with Vaillant boilers (Germany).

Calculated the deficiencies of cast-iron boilers It should be noted their increased sensitivity to a large heat transfer temperature in the feed and return highways - in case of failures in the operation of automatics, the cast iron case of the device can crack. It is easily collapsed from random mechanical damage, blows, drops that are difficult to avoid during the transportation of equipment.

If you choose an outdoor gas boiler with a cast iron heat exchanger for your country house (we would stop on such a device), when you purchase, compare weight aggregates. The solid weight is one of the indicators of the reliability and durability of their heat exchangers. Help boilers are usually small internal sections, insufficient fins of the walls of the combustion chamber and smoke channels, which move hot products of combustion of the gas-air mixture. This leads to a decrease in the efficiency of equipment, as well as to overheating of individual sections of the heat exchange surface and the appearance of significant temperature stresses in the metal of the heat exchanger and the furnaces, which is why boilers are premature.

The resource of boilers with steel heat exchangers (among them there are quite a few models of domestic producers) usually does not exceed 10-20 years. But they are cheaper than cast iron. The plastic steel used in the boilers does not crack from a random strike, which allows you to deliver boilers with steel heat exchangers for considerable distances without damage. The heat exchanger made of steel withstands large temperature differences in the feed and return highways. But the combustion chamber in such boilers is faster corroded due to acid condensate. The cause of its appearance is admitted to the boiler on the return highway from the heat carrier heating system, having a temperature below the one to which the unit is designed.

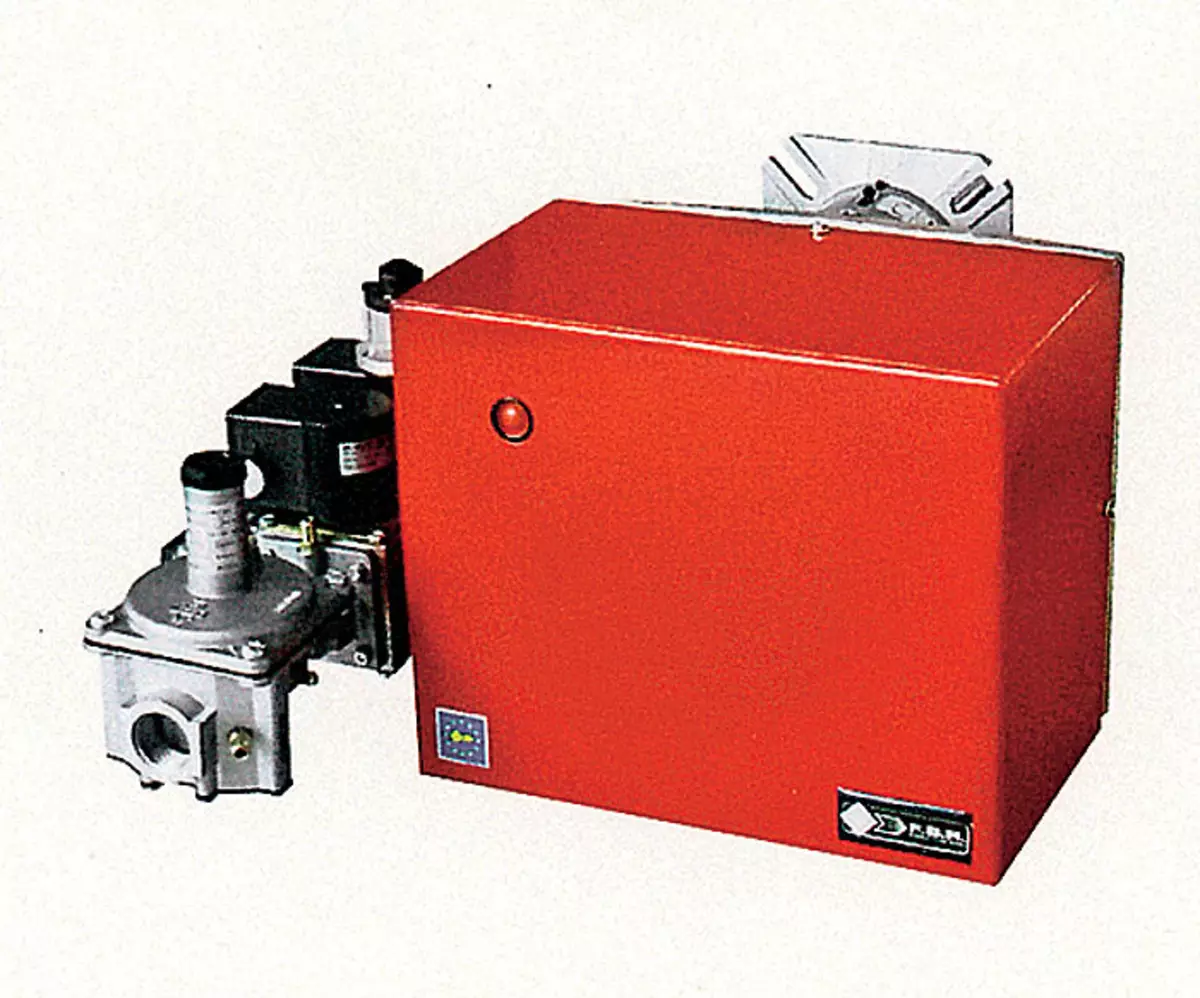

Weishaupt. |

F.B.R. |

Energosbyt |

|

19-20. The fighter burners retain performance and lowering the gas pressure to 5 mebar

21. It allows you to protect the heating system from defrosting even with long-term electricity shutdowns. But such a liquid "on the larger" not all the boilers

22. The modern circulation pumps for GVS Logafix Buz15 (Buderus) systems provide uninterrupted hot water supply to any point of the private country house

Stretch boilers with the same parameters (power, efficiency of IDR) can be found heat exchangers with walls with a thickness of 2.5-3 or 4mm. Ukhotlov with thin walls service life is less. Only in the most expensive models to increase the resource are used corrosion-resistant steel. Such boilers are successfully competing with cast iron.

In addition to cast-iron and steel on sale there are and very interesting models of boilers with so-called bitmarthy heat exchangers. For example, in the Vitola 200 model (Viessmann) there is a special cylindrical heat exchanger consisting of two layers, one of which is cast-iron, and the other. This design allows to reduce the intensity of condensate formation in the furnace and increase the service life of the boiler.

Burner. Efficiency, noise level, the content of harmful emissions in fuel combustion products depend on the burner devices used. Signs of high-quality burner are fullness of gas use, the manufacturability of installation, durability, safety, the absence of strong noise and vibration.

Outdoor gas boilers are most often supplied with gas atmospheric (injection) burners. The power of floor gas boilers with an atmospheric burner, as a rule, does not exceed 70kW (but there are firms producing and more powerful boilers of this type - so, Vaillant releases models up to 154 kW). Atmospheric burners work almost silently and have many other positive qualities, but not flawed. One of the unstable burning at a low gas pressure on the network, which, as already noted, can fall in winter to 5 mb. With a low gas pressure, the flame tongues are too close to the holes in the hollow rods of the atmospheric burner, feeding the gas-air mixture into the combustion chamber, because of which the rods are combined and prematurely fail.

Wolf. |

|

"Forsterm" |

23.Energos saving system of heat supply at home based on two boilers and solar collectors (WOLF)

24.Module GEFFEN collector system

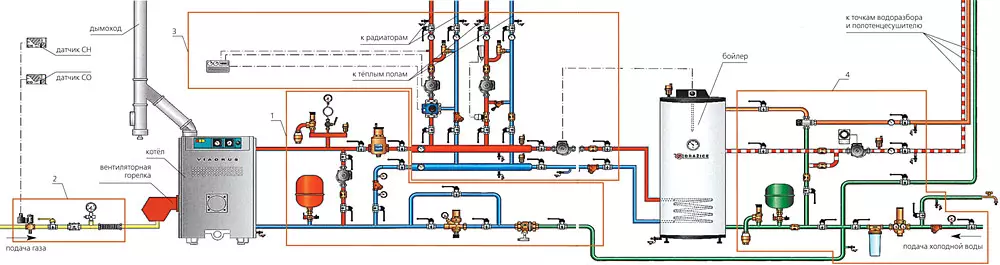

25. To the maximum use of the gas boiler capabilities, it must be properly installed in the boiler room and combine with the distribution network of heating and the DHW system to the general system, that is, make the strapping of the boiler room. The breakpoints include a variety of components and parts that can be consolidated to boiler fittings (1), elements of the "gas line" (2), a node of regulation of radiator heating and warm floors (3), as well as elements of a cold and hot water system (4 ). For the strapping, the boiler room should use only the highest quality reinforcement and aggregates. In the opposqu one, the main equipment can work incorrectly or even prematurely fail

If the gas pressure in the village network regularly falls below 13 MBAR, it is best to buy a boiler for use with a fan (superior, blowing) burner. The latter will have to be purchased in addition for a fee, and it should be compatible with your boiler and is recommended for the application of the Federal Service for Environmental, Technological and Nuclear Supervision (former Gosgortkhnadzor).

Fan burners retain performance when the gas pressure is dropped to 5-6bbar. They may have 1-2 power steps or smoothly changing power (modulating burners). At the full capacity of the boilers are included on the automatic team only when heat requires a lot (for example, if there is sharply cold or all the points of water separation are sharply cold). Usually one level of the burner is functioning. The result is possible to significantly save fuel, increase the boiler resource. Restrictions on maximum power for boilers with fan burners practically do not exist - they can give thousands of kilowatt heat! But when equipped with a boiler with a blower burner, it is necessary to provide good sound insulation in the boiler room, as the working burner device in terms of noise is comparable to the vacuum cleaner.

Just in case

Modern gas heating boilers are equipped with control and automation systems that require a stable voltage value (220V 1-5%) and uninterrupted power supply. If the supply voltage goes beyond the limits set by the manufacturer, these systems give failures in the work or simply break (often this happens with control blocks and gas burners).

If you do not disable electricity, and only the problem of stabilization of the voltage occurs (it can be much lower or higher than 220V), it suffices to install a low power voltage stabilizer. In one case, if you often occur unexpected power outages, you can install an uninterrupted power supply (UPS). It is best not to regret money and acquire a UPS with a double transformation that will provide a sinusoidal output voltage and stabilizes the power supply. Another possibility is to install a gasoline or diesel generator with an automatic start-up system in energy supply.

Attractions of components of the boiler room there are various approaches. With reliable gas supply, the most common of which is the installation of two boilers instead of one. Such systems have great reliability and flexibility in ensuring thermal comfort. As a rule, they take two boilers with the same power. At the same time, according to experts, the boilers are combined into a system of either the so-called Tichelman loop with two drives with an electric drive (on each "rating"), or through the hydraulic arrow with two pumps of the boiler circuit. As for control and regulation devices, it is necessary to consider a specific case, but usually put the lead and driven automation and the strategic module (embedded) for cascading boilers. For a two-celent installation, it is better to use one boiler sufficiently large volume.

If gas supply interruptions happen often, the system includes a solid fuel or electric boiler, which will be responsible for maintaining a positive temperature in the building. At the same time, a sufficient fuel supply should be provided for the operation of a solid fuel boiler. The use of an electric boiler is possible if a powerful electrocabolic is connected to the building and it is uninterrupted with electricity.

Automation. "Standard" Automation involves manual control of the boiler (it is equipped with almost all floor boilers in the basic configuration). It only controls the burner, takes signals from the boiler security devices, and also supports the desired coolant temperature. At the same time, the user must constantly regulate the temperature depending on the need for heat. When cooling the power of the boiler must be increased, and when it is warm on the street, it is for what every time you have to go to the boiler room. For the entire heating season, the total time of these trips will be several days and nights. Of course, this method of regulation due to the thermal inertia of the heating system and the building itself will not allow achieving a modern level of temperature comfort and economical use of fuel.

Most developers want no need to go to the boiler room for temperature control. Thanks to modern automation, the floor gas boiler can be operated in a country house. True, such regulatory systems are supplied only with boilers in the "top" configuration.

If financial capabilities allow us, we recommend purchasing together with the boiler or purchase a modern weather-dependent microprocessor automation to the already acquired unit. It will keep the desired temperature in the house depending on the meteo conditions. At the same time, to participate in the process of regulating the temperature of the coolant households will not be required. Adjusting the temperature of the coolant boiler with such automation will be carried out, without waiting for the temperature of the air temperature in the rooms, and this, despite the thermal inertia of the building and the heating itself, will allow creating a comfortable microclimate in the premises even with sharp weather changes.

Low-temperature solution

In Russia, the heating systems are popular, in which the temperature line temperature is 90c, and the reverse-70c. High temperature "Feed" allows you to install low-size heating devices (radiators). However, it requires a significant fuel consumption. When touched to strongly heated radiators, you can burn. The release of the heating system is usually low-temperature: the supply line is 50-70c, inverse, 30-50c. But at the same time, it is necessary to increase the area of heat exchange of radiators or arrange warm floors. The use of low-temperature heating systems allows to reduce fuel consumption and the number of harmful emissions. However, during operation in low-temperature mode, the risk of corrosion of the boilers is increasing, especially in models with a steel heat exchanger. However, boiler manufacturers have long learned to fight this danger. Leading boilers are used in the manufacture of their products, various technologies protecting the furnace. The simplest solution that allows to operate almost any energy-dependent gas boiler in low-temperature mode, assumes the installation between the supply and return highways of the coolant of the bypass branch (lintels) with the pump, which is included with the temperature in the reverse highway below 35c.

Orynke

Choosing outdoor gas boilers, the first thing to pay attention to the products of firms with a global reputation, such as Bosch junkers, Buderus, Wolf (all Germany), Ferroli (Italy), De Dietrich, Vaillant, Viessmann. Good technique release Biasi (Italy) and CTC. It is impossible not to note Roca (Spain), as well as ACV (Belgium), Protherm (Slovakia). The cost of 20kW imported boilers with atmospheric burner and simplest automation is an average of 40-80 thousand rubles. Energy-dependent gas boilers with atmospheric burners are manufactured in Russia: it can be recommended, for example, the products of the Kirov Plant, sold in the retail network at a well competitive price. The boilers under the fan burner more often fall into our country from abroad: the German 52kW power model will cost about 60-90 thousand rubles, about 35-50 thousand rubles will be required for the modulating burner.The burner service life is often in 3-4 times lower than the boiler, therefore, as it is exploited, demand occurs both on fan and atmospheric burners - instead of supplied with heat generators. The burner devices are released and delivered to Russia Dreizcher, Giersch, Krting, MHG (all Germany), Bentone (Sweden), ELCO (Switzerland), Cuenod (France), Oilon (Finland), Baltur, Ecoflame, FBR, Lamborghini, Riello ( All Italy), Olympia (Korea), de Dietrich. Among the Russian manufacturers can be noted the company "Red Banner" in the Commonwealth with "Russian", "Belogorier" and some other firms. The price of atmospheric burner is from several thousand (domestic equipment) to several tens of thousand rubles (foreign prototypes). A good imported fan burner is always significantly more expensive - for a capacity of 70kW. The modulating burner is worth 60-100 thousand rubles.

Advanced automation for boilers are delivered to Russia mainly from abroad- for example, manufacturers such as Bosch-Junkers, Buderus, CTC, de Dietrich, Vaillant, Viessmann, Wolf Idre. Experts in the field of heating also recommend management and regulation devices from Komextherm (Czech Republic), Kromschroder, Siemens, Coster (Italy), Honeywell (USA), Roca. The cost of good equipment can be approximately 15-50 thousand rubles. Domestic devices usually cost significantly cheaper.

Instead of epiloga

Of course, in a limited volume material, you can only list the most important items that you need to pay attention to when choosing a boiler for a modern country house. Any model should have a valid certificate of compliance of the Federal Agency for Technical Regulation and Metrology (Former Gosstandart of the Russian Federation) and the resolution of the Federal Service for Environmental, Technological and Nuclear Supervision for use (for the boiler under the fan burner, separately on the unit and the burner unit). An important point is the availability of documentation in Russian. The firm offering the boiler is obliged to provide you with the details of its service center for the service of the unit, which you purchased. It is necessary that she has licenses of the Federal Service for Environmental, Technological and Nuclear Supervision for the right to carry out activities for the construction and operation of gas facilities.

If in the catalog of the equipment sold by the company, you found boilers of two dozen domestic and foreign manufacturers, which means that the reseller firm is bought by the goods from the general dealers and only earns their interest on the resale of technology. Its opportunities to carry out technical advice, to carry out service and warranty service are often minimal. If the company is already purposefully engaged in one or two brands of equipment, this is a seller working at producer prices, thoroughly studied the strengths and weaknesses of the proposed technique and responsible for its further work.

The editors thanks the representative offices of Buderus, Vaillant, Viessmann, Riello, the company Kirov Plant for help in preparing the material.