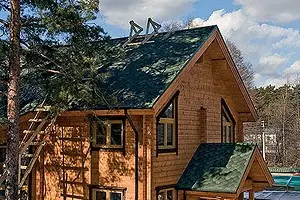

Erecting the attic roof in the house of glued timber: the rafter system, the design of the underpants "cake", the material for the roof, ventilation

Of course, a good roof can decorate the house, so the name "Fifth facade" was fixed behind it. But at the same time, reliability and durability and durability are also the main criteria for assessing its quality, that is, the ability to carry out carriers, hydro- and heat-insulating functions for many years. On how to build a beautiful and durable roof, and our article will tell.

Of all the constructive schemes of the building system known to date, allowing not only to save at the construction stage, but also to reduce the cost of home or cottage costs, perhaps the most accessible and therefore is popular for the construction of an attic floor. It is she who provides an opportunity to get a serious increase in the useful area while reducing costs.

However, for Russia, the construction of an attic is a relatively new and, in our opinion, extremely poorly regulated by the existing construction documentation: GOST, SNIPI, TP IDR. That is why, during the construction of houses with attic, much is done, as they are called at the level of intuition (and it is known to have, and who also has ...) or on the recommendations of manufacturers of materials for the roof. Then it begins the "trouble". Mixed materials, and appropriate recommendations for each company. Plus, even those who have never been engaged in the construction of such materials that have never been engaged in the construction boom for the production of such materials. A dilettanic approach often flourishes almost at all stages, ranging from the design and ending with the realization of conceived. A results of about 30% of the roofs (terrible statistics!) On the attic floors you have to redo the first winter. Apparently, therefore, readers and visitors of the journal site www.ivd.ru have accumulated a lot of questions. Today we will tell about how the attic roof in the country house from the glued bar, made on the project "Western" Finnish company Rovaniemi (see No. 5 "IVD" for 2008, article "Western" in Finnish "). At the same time we will try to answer some questions of readers and give practical recommendations.

Athenium roof

The longevity of the attic roof provides its correctly performed components. First, the carrying frame, which should be competently "tied" to the design of the house itself. Secondly, a guide "pie", which includes vapor barrier, insulation, ventilation gaps and waterproofing. Yves-third, roofing carpet itself. Moreover, there is a rigid relationship between the roof selected by the developer and the roof structural circuit. But we will not immediately complicate, let's go about everything in order.Power frame

In our case under consideration, for the construction of the rafter system, beams made of dried wood (22048mm), which entered the construction site complete with the house were used. It must be said that such wood is one of the best materials for creating a rafter system: the tree is dried in advance (humidity - 12-15%), and therefore nor shrinkage nor deformation is practically subject to.

Promotable practice for rafting elements is usually used by lumber of natural humidity. It should be remembered that according to the requirements of SPEPOV, the residual moisture content of the materials used should not exceed 18%. What threatens the use of more wet wood? Made from it rafters will begin to change in size over time, and the roof will be, as experts say, "walk". How to deal with it? It is necessary to fold the entire batch of wood on the stacking stacks and defending against the rain canopy, to withstand for 1.5-2 months. During this period, the wood-blowing wood will dry up to the required humidity. So a single important question. What a tree is neither useful or natural humidity, it is even before installation in the design you need to handle protective compositions: antisepting and protecting against fire. The last operation is necessary to make wood by the foolishness, and even better by the favorable material. It is such a protective processing that is recommended by the bottom.

In this case, the processing was carried out by two compositions: first the antiseptic "Mikout", and then the antipiren "Diaphos R-50". However, other impregnations can be applied. In the modern Russian market there is a large number of protective compounds, including combined firebio-protective, allowing to reduce the complexity of processing. When choosing, it should be remembered that most of them provide wood only a second protective efficiency group. The first group is only units, for example, the composition on a water basis "Phenylaks" (NPP "Rogunda"), as well as "Sezhnezh Firebio Prof" (NGO "Tsorozhetsky") (both firms - Russia).

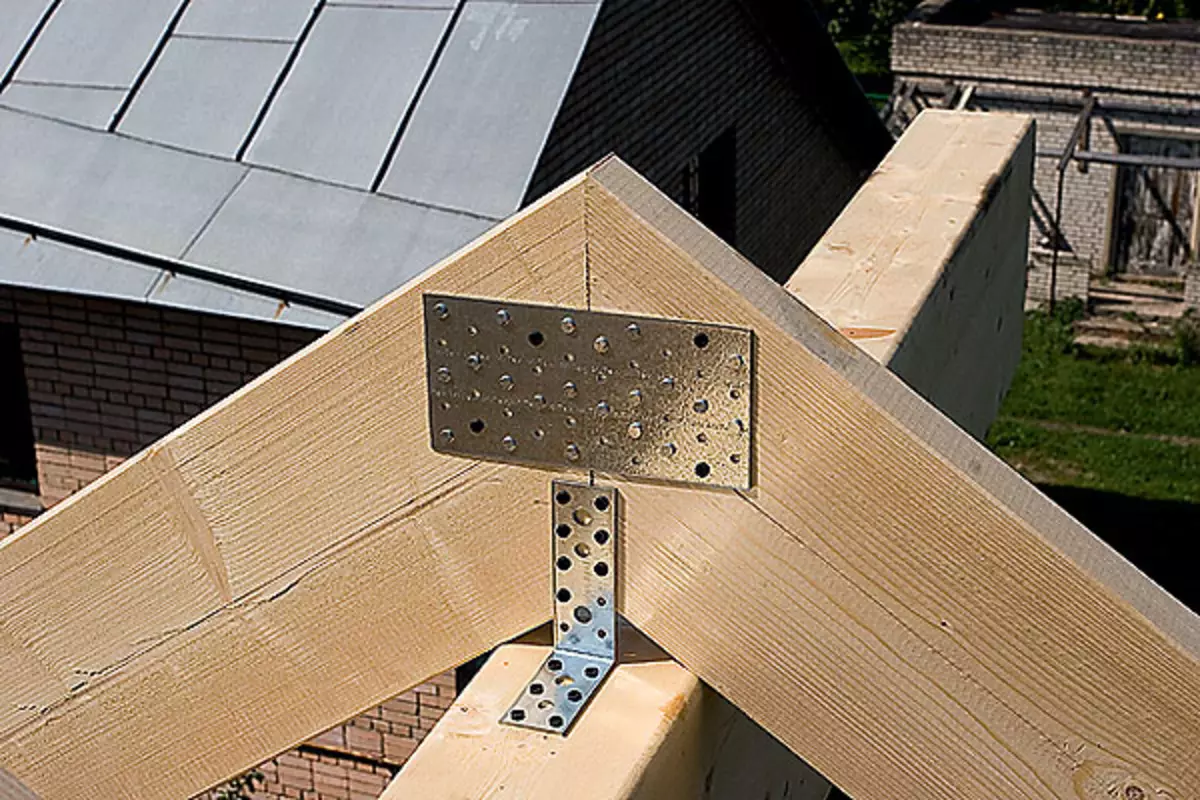

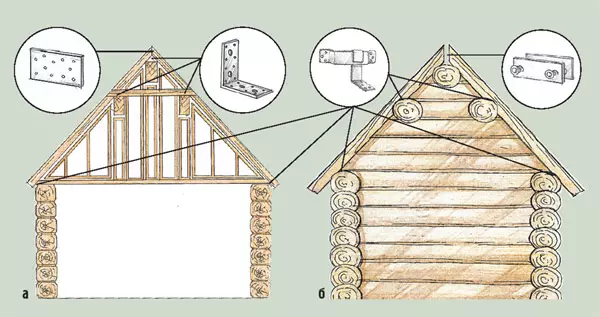

Now about attaching rafters. If the skate beam, the rafter legs were hung hard, then they were connected to the top bar of the log cabin (Mauerlat) with a special rolling element consisting of a flat bracket and a hook of galvanized steel 2mm thick. The hook was fucked by self-drawing to the top timber chamfer (it was made still at the factory), the face of which is parallel to the roof slope. Next, the bracket hooked behind the hook, installed parallel to the edge of the rafter foot and attached to it with self-draws. Such a connection, under no circumstances, will not give the rafter to tear away from the upper crown, but at the same time will not let it move with the shrinkage of the brusade wall. Yes Yes! Do not be surprised! The walls collected from the glued profiled timber are also subject to shrinkage, as well as created from natural humidity (log IDR). Is that the magnitude of this shrinkage will not be so significant - 1-3%.

A- for a brusal or log house with a skeleton mansard;

B - for a log house with log-made male frontones and log inside walls of the second (indarrent) floors

Next, they mounted so-called delay-horizontal elements that convert stripped legs into a triangular farm. They were attached to the rapid legs with steel bolts, and to the auxiliary skate beams of metal corners. It should be warned that the described attachment scheme of the rafter is applicable only to the houses from a bar or logs with a skeleton mansard. For example, for log houses with male frontones, it is somewhat different, and the moving elements in it is much larger.

Crucial "Pie"

In the attic roof, the undercase "pie" performs two important functions at once: heat and moisture insulating. Thermal performance of the components of this "cake" is largely dependent on both the comfort of indoors and the stability of the technical and aesthetic characteristics of the roof, and even the duration of its service without repair.

It is known that the thermal insulation properties of the insulation are significantly reduced by increasing its humidity. Therefore, one of the most important tasks of the design of the underpants "cake" is to ensure its effective protection against moisturizing both pairs from premises and atmospheric precipitation and condensate, generated under certain conditions on the lower side of the roofing coating.

How to prevent the rafted freezing?

The ratio of the coefficient of thermal conductivity and the thickness of the insulation layer

| The thermal conductivity coefficient of insulation, W / (MS) | The minimum thickness of the insulation layer (according to the requirements of SNiP II-3-79 for the middle strip, RO = 4.7M2C / W), mm |

|---|---|

| 0.035 | 160. |

| 0.04. | 180. |

| 0.044. | 200. |

| 0.045 | 205. |

| 0,046. | 210. |

| 0.047. | 215. |

| 0.05 | 225. |

| Knowing the thermal conductivity coefficient of the selected insulation, it is easy to calculate the required thickness of its layer, and then dial it, summing the thickness of the plates available in the assortment |

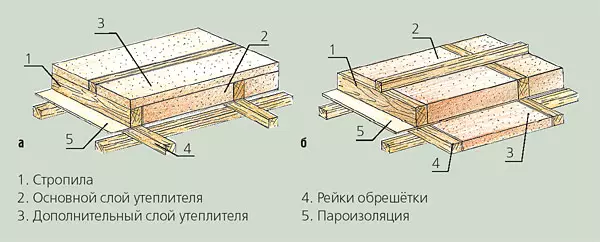

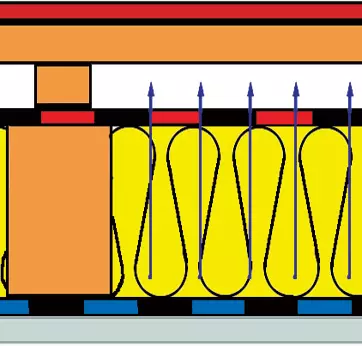

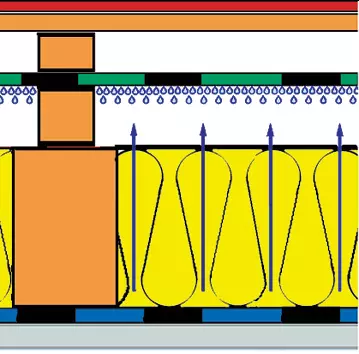

In this case, the creation of a subframe "cake" began with the fact that in terms of the premises, the Fibrotek Master vapor insulation film was pulled by the Fibrotek Master (Lensacks, Russia) - her panels were mounted across the slope from top to bottom, and in the forefrenched zone glued a special scotch. On top of the vaporizolation, the domestic crate, creating a structure, which will continue to perceive the load from the insulation and the inner skin.

Then between the rafters were laid in several layers of hydrophobized heat-insulating plates from mineral wool based on rocks of the Rocklayt Basalt Group ("Tekhno Plant", Russia). Why did you choose hard stoves? Specialists strongly recommend using soft insulation in rolls in the warring systems in the insulation systems. Such a material is gradually lungs, and also slides at the slope of the skate, forming "cold bridges".

Roofing material and construction of the underpants "cake"

When choosing, it should be noted that superdiffusion membranes are recommended to be used only in a pair with roofing materials that are not afraid of moisture impact on the reverse (back) side, for example, to use them in combination with ceramic, cement-sand and bitumen tiles. Avot with metal tile (with the exception of such that has an alumonic coating, for example, MetroBond, Belgium) or wavy bitumen sheets (the so-called euroshorter) should not be combined.

They are presented in our market, such as products of such firms as Eltete (Finland) and Juta, "Lenshas", "Megazol", "Stroyism". Diffusion waterproofing membranes are used in a pair with the same roofing materials as superdiffusion, with such a reverse side of which moisture is not afraid.

The described work scheme can be implemented only if there are two ventilation air spots - the lower and top. A pair of insulation will be outlined, and then deleted. Thanks to the top, the reverse side of the roofing material will be ventilated. The cost of anti-condensate waterproofing films is about 15-20 rubles / m2. Offer them in our market such firms such as Juta- Jutakon, Eltete- Elkatek Extra Idr.

Is it worth applying only the mentioned insulation? The modern market of insulation is extensive and diverse. You can choose any fibrous material you like. Just learn from the seller the coefficient of its thermal conductivity, and after that, using the table we offered, determine what the effective thickness of its layer should be, and to type it from the plates of a certain thickness available in the assortment. Check how typical of the thickness of the insulation layer corresponds to the height of the rafted. If the first value is less than the second, there will be no problems. If the opposite is also not scary. There is a simple and effective technique, allowing the insulation thickness to increase, and prevent the rafted freezing. After laying the insulation (200mmm) between the rafters perpendicularly, the bars of 5050mm are styled with a pitch of 600 mm and put mineral wool slabs with a thickness of 50 mm between them. It is possible to lay the same layer of insulation from the inside of the house, between the rails of the inner crate. This is exactly what the builders were accepted when the roof device over the "Western".

Practical recommendations on the device under construction ventilation

The area of supply and exhaust holes should be calculated taking into account certain parameters (volume and concentration of removed watches IT.D.), which in practice it is possible to do not always. Therefore, more often use empirical developments.

1. The value of the ventilation gap between the insulation and the base of the roof should be at least 5 cm. It depends on the length and angle of inclination of the roof rod and is determined by the table below.

2. Summary section of the supply input ventilation holes per 1 p. Cornis also depends on the length and angle of inclination of the roof of the roof and is determined by the table. Air flow can be organized both along the entire eaves, and locally - with the help of ventilation grids embedded into the binder of the cornice sv, IT.D.

3. Summary area of exhaust ventilation holes, which should be arranged in the highest point of the roof, for each slope there must be no less than the area of the supply holes. Pulling exhaust devices can use ventilation skates, ventilation caps for tent roofs, roofing aerators IT.D. It is permissible to apply both ready-made (purchased) devices and manufactured by the construction method.

| Skate length, m | Slope slope, hail | ||||

|---|---|---|---|---|---|

| 10 | fifteen | twenty | 25. | thirty | |

| five | five | five | five | five | five |

| 10 | eight | 6. | five | five | five |

| fifteen | 10 | eight | 6. | five | five |

| twenty | 10 | 10 | eight | 6. | five |

| 25. | 10 | 10 | 10 | eight | 6. |

| Skate length, m | Slope slope, hail | ||||

|---|---|---|---|---|---|

| 10 | fifteen | twenty | 25. | thirty | |

| five | fifty | 49. | 48. | 46. | 42. |

| 10 | 100 | 98. | 96. | 92. | 84. |

| fifteen | 150. | 147. | 144. | 138. | 126. |

| twenty | 200. | 196. | 192. | 184. | 168. |

| 25. | 250. | 245. | 240. | 230. | 210. |

From the album "Technologies of Roofing Systems" of TEGOLA

After the insulation was laid, started assembling a vapor-permeable waterproofing membrane. Why is it needed? The main enemy of any roof is not so much rain moisture, how much condensate formed on the back of the roofing coating. Izadach Slonnel waterproofing - protect the insulation and supporting structures and on the other.

The subsystems of the pitched roofs as a subcoase waterproofing use super-diffusion and diffusion membranes and anti-condensate films. What to apply, decide on the basis of which roofing is chosen, and material opportunities. In the case, a vapor-permeable superdiffusion membrane Tyvek (DuPont) was laid close to the insulation. Material canvases rolled across the skate starting from below. Fasting of the canvas was at least 100mm. The result was a solid coating: fallen, for example, from the skate of the condensate drop, as a hill, rolls along to the sink of the roof.

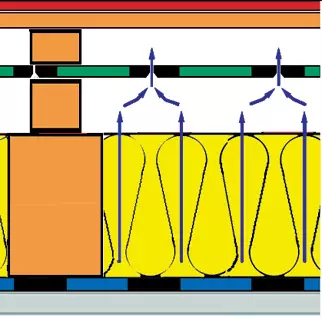

Ready Ventilation Kind: Simple solution to a complex problem

Devices for air output from the ventilation gap are two types: point and continuous. The point is more often called roofing fans, they are installed in separate parts of the roof closer to the skate. They, as a rule, have a migratory shape, and sometimes equipped with a built-in fan. Examples of the Vilpe Vent Finnish company SK Toute. The second is continuously mounted along the entire length of the ridge of the roof, providing the best ventilation. Until recently, such ventilation skates were manufactured exclusively to a construction method (schematic device, see "IVD" No. 2 for 2008. in the article "Caution," closer "!). One bad thing: the creation of such a skate requires from builders not only high qualifications, but And a certain experience. Otherwise, the risk that under the horse in the winter time will be clogged with snow, which, hitting the gap between the skates, will certainly find out, and then forgive, forgive the underlining ventilation, and hello, icicles.

About a year ago, the situation changed: ready-made ventilation skates at least two well-known firms appeared: Ridge Master Plus (Mid America) and Shinglevent II (CERTAINTEED) (vale). This cost this, as it turned out, is already released for more than a dozen years (in general, as always, it turned out that the bike has long been invented). Products are able to operate in the temperature range -50 ... + 60c, and both the guarantees of both companies give a lot of 40 years. (True, there is no confidence that the same warranty period will give domestic sellers.)

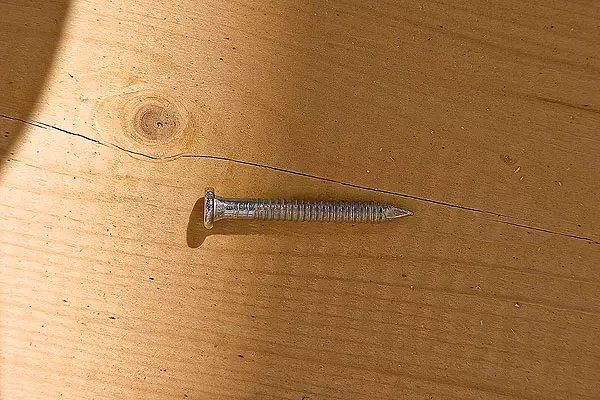

Chosen in this case, the KUNDGE MASTER PLUS ( but ) - Made from stainless aging and UV radiation, is equipped with labyrinth seals that are simultaneously rebours of rigidity, due to which it is capable of withstanding human weight, which is important when installing. The design is equipped with a built-in spongy filter ( in ), not passing insects, as well as excluding snow or rain, excluding the snow at the wind speed to 30m / s. Installation is easy to limit: the elements of the skate length 1220mm and the width of 290 mm are fixed to the base of the roof with corrugated roofing nails or self-drawing ( B. ) For which they have a markup on the housing. Between themselves, the sections are connected by locks ( D. ). From above, the mounted bitch is covered with bitumen tiles ( G. ). It is worth adding that the horse itself is rather low and is almost not noticeable on the roof. If you consider the relatively low cost of one element, it is perhaps the best solution today.

|

|

|

|

|

Cruising ventilation

It should be borne in mind that even the presence of a completely reliable parobacker does not eliminate the likelihood of steam penetration into the insulation. Therefore, special attention was paid to the problem of ventilation of the undercase.

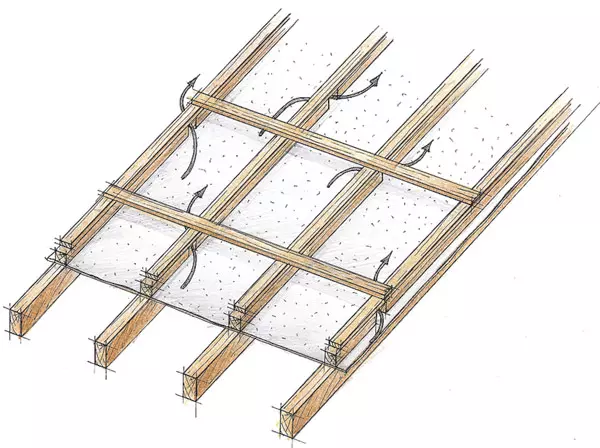

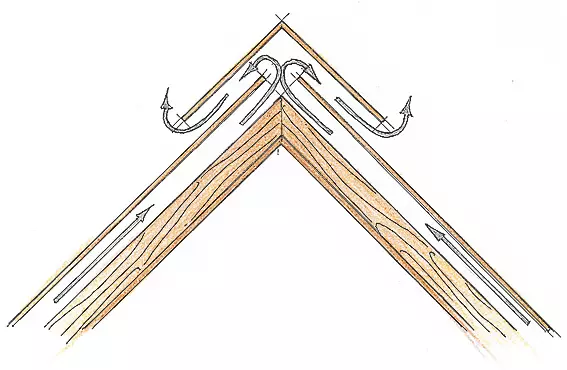

To create a ventilation gap on the rafter along the bars of the brucks of the cross section of 5050mm. And between the bars after 1-1,5m, the gaps of 50-100mm were made so that the air flow could flow from one channel to another. Such technological admission makes it possible to eliminate the formation in the roofing structure of the so-called stagnation zone around windows, in endowers IT.D. What are dangerous stagnant zones? It is in them that the insulation will begin to saturate moisture. Western insulation, wait for a complete set of trouble: snowdrifts on the roof and icicles on the atmosphers, increase the cost of heating and ... overhaul of the roof.

On bars "perforated", the counter tests were bequeatted (already without breaking) Rake 5020mm, thus bringing the height of the ventilation gap to the required 70mm (this value depends on the length and angle of the slope, select it on the table). Further, the crate of 5030mm bars have knocked out a cross section of 5030mm with a step of 400mm, and on top of them, using self-tapping screws, created solid flooring from the oriented strokes with a thickness of 9mm.

On top of this flooring subsequently elevated the soft bitumen tile kerabit (Lemminka..nen, Finland). We will not dwell on this issue in detail, but will continue the conversation about the underpox ventilation. So that it normally functioned, having ensured the long life of the roof as a whole, there should be a unhindered passage of the air flow from the eaves to the skate in all points of the roof (which builders have achieved, creating "perforation" in the counterclaim). The height of the ventilation gap should be such that the drying effect can be achieved. Calculate it in complex formulas, but you can be guided by the data given in the table.

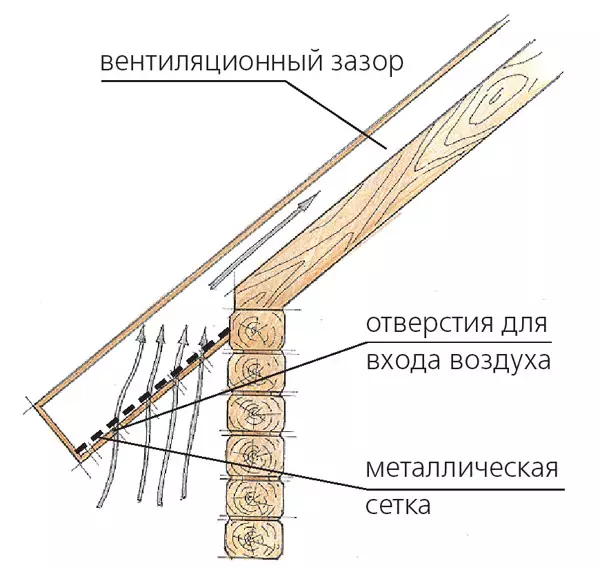

Curious arrangement of the input and outlet openings of the ventilation gap. The first are located in the sink of the roof and almost continuous throughout its length. The entrance cover the bang-born binder board, under which the grid-barrier for insects is laid.

Ventilation Konk decided not to create a constructive way, but took the ready-Ridge Master Plus (Mid America). It and the quality of ventilation provides proper, and insects are protected, and in assets it is easier. Yes, and it costs no more expensive: the cost of one element is about 1,2m- approximately 800 rubles. As they say simple, but a wise decision.

Opinion of a specialist

The most commonly encountered the following errors in the device of the attic roofs: 1- Insufficient insulation of the undergraduate space (for example, for the Moscow region, the thickness of the insulation must be at least 200mm); 2- complete absence or insufficiency of the undercase ventilation of the mineral wool insulation; 3- confusion of vapor and waterproofing membranes; 4- laying of membranes not the same side (confused by the outer and inner surfaces of the cloth); 5- low-quality or incorrect installation of individual nodes and structures in general. How to avoid all these errors?

Three outputs. First- control the process yourself. True, then you may have to quit your favorite job and devote all of the released time to study the instructions. The second - to hire a technical supervision engineer and instruct him to observe the quality and correctness of construction. (It is the engineer, not a construction expert. The latter exist mainly to determine who is right or builders?) And finally, the third- to make it do ... the builders themselves. It is useful to know that the construction of a consistent acceptance of works is applied during construction, for both parties periodically make up and sign "acts of acceptance of hidden work", thereby giving permission for further actions. For this, the process of erection of an individual house is divided into consecutive stages and establish the deadlines for each of them in the contract, as well as the payment procedure. In one case, when the quality of work does not comply with the criteria provided for by the terms of the contract, the parties are the so-called "defective act", which lists the identified defects and lowers and determine the timing of their elimination. The new stage of construction work should begin only after eliminating the defects specified in the act, and signing the act of acceptance acceptance.

So what is the novelty of the idea? Everything is simple. To sign the act, you will definitely leave for an object (this will naturally require time), and the builders themselves first show you instructions or recommendations on how to lay one or another material or perform a specific node, and then demonstrate the embodiment of the shown "on nature" - On the very object, photographs made during the work, IT.D. (By the way, the advanced leaders of construction firms in this way take works.) And until you make sure that everything is completed correctly, do not sign any acts. Let it be about where to get the necessary documents (connectors, recommendations, instructions of the manufacturer of IT.D.) and how to prove its rightness, the head hurts from builders. But not you.

Sergey Zelensky, Director of the company "Independent expertise of construction quality"

The editorial board thanks the company Petrostil (Rovaniemi trademark), "independent examination of quality of construction", as well as personally A. Tadzhiev and A. Kharkovsky for help in the preparation of material.