Modern building windows: methods of sealing cameras, the use of low-emission, non-ferrous, safe and self-cleaning glasses.

Outdoor lining (a) and built-in laying (b, c) change the window stylistics.

Double-glazed windows must be blown in the window profile to protect the remote SP from the cold, without cutting the lighting

Photo A.reidalova

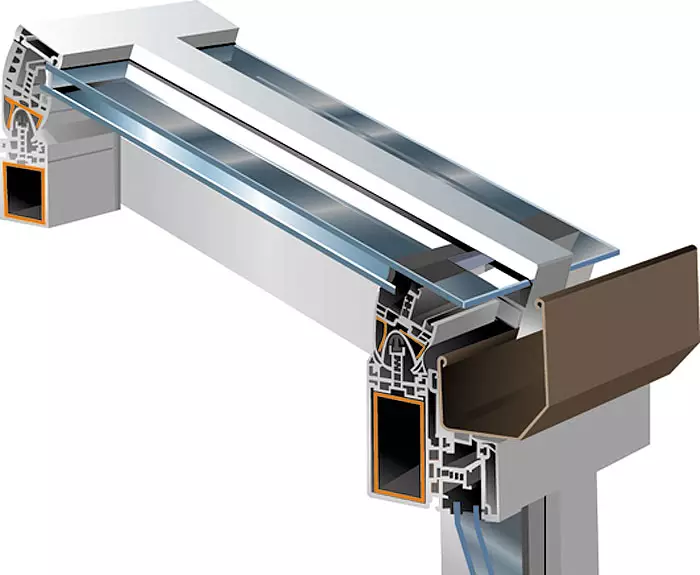

Bent (molded) joint ventures are used for winter gardens, but they have limitations in the size of glass sheets

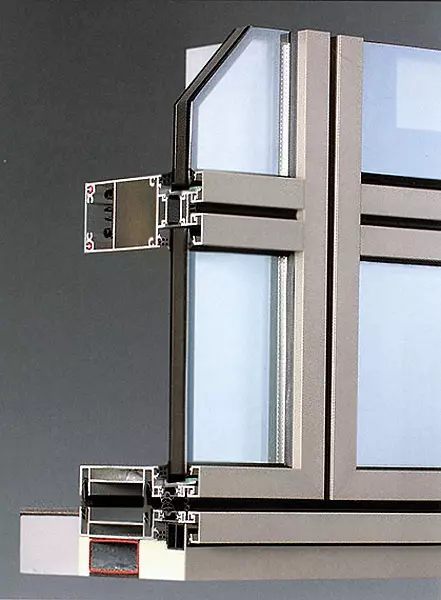

For facade glazing, double-glazed windows are used in conjunction with systems of carrier metal, plastic or wooden profiles

System "Favorite Lodzhik" for glazing loggias by sliding sash with single-chamber glass

Plans for replacing the old window are new, as a rule, are reduced to the selection of a system profile from which the window unit is made. At the same time, the fact that 70% of the window occupies the lighting opening, filled with hermetic construction windows, is often missed.

The market of windows has recently been filled with strange products. The efforts of negligent sellers, and after them journalists of a number of prints and even TV channels appeared plastic, wooden and aluminum double-glazed windows. Inesl you will hear the offer to buy cheaply or mount this, then know that it comes from an incompetent person, and therefore high-quality services can hardly be expected. In fact, we are talking about windows, the blockage of which is made of plastic, wooden or aluminum profiles, and its filling, of double-glazed windows (SP). Glass windows are used as translucent elements not only in windows or doors, but also in partitions, anti-aircraft lamps, for the construction of walls and roofs of winter gardens and glazing of the facades of multi-storey buildings.

Modern special technological product. Of course, inventive craftsmen are capable of making similar products and "on the knee". However, in this case, it is not necessary to count on its high technical and operational properties. Meanwhile, the quality of glazing largely determines the successful and long-term use of translucent design.

Design

Double-glazed windows are a kind of "puff pastry", in which space-chamber is left between the sheets of glasses. GOST 24866-99 "Glubber accesses glued construction purposes" divides products on one and two-chamber. Double and triple glass windows do not exist. By special order it is allowed to manufacture joint ventures from four (three-chamber) and more glass sheets. But such a production of products is carried out outside the regulatory framework.By type of medium in CP cameras divided into three groups: air, gas and vacuum. The overwhelming market share is occupied by air, and vacuum only begin to master.

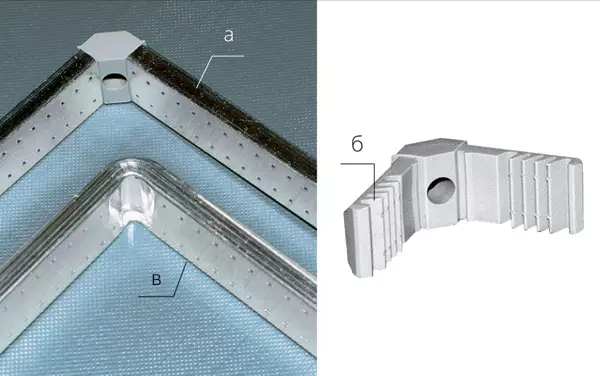

The unifying element of the joint venture is a remote frame (frame) from a hollow closed aluminum, steel or plastic profile - Helima (Germany), ProfilGlass (Italy). It has a perforation from the inside and is filled with moisture absorber (molecular sieve). It is more often a zeolite with a pore size of not more than 0.3 microns or imports of Degussa, Grace Davison (all Germany), CECA (France) IDR. Through the holes there is absorption (sorption) of water vapor from air in the chamber. One of the first dehyders is silichagel- absorbs moisture by 40% less, and therefore it is used less frequently, although it is cheaper.

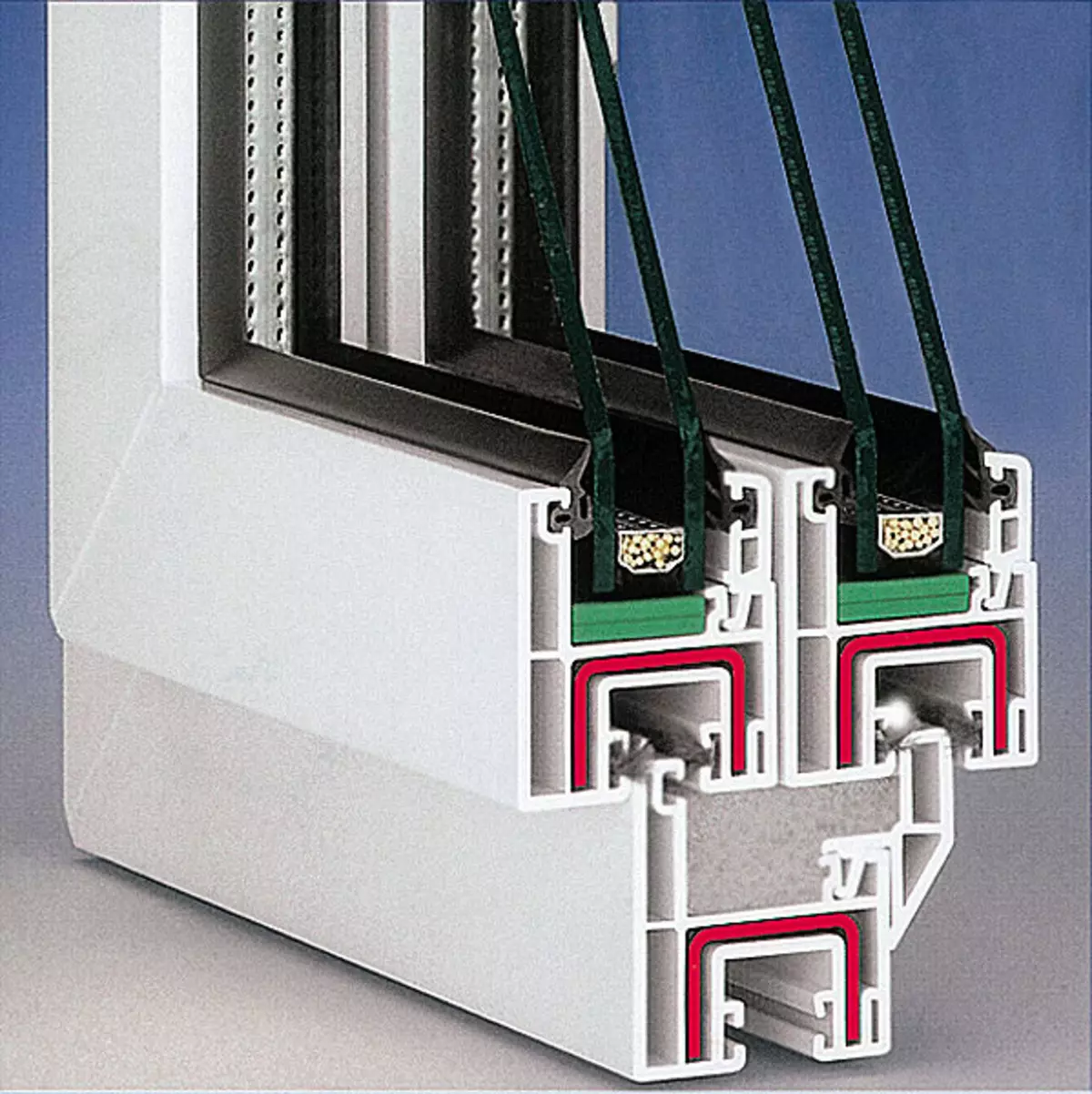

The tightness of the chambers decisively affects the stability of the properties of the joint venture. There are two layers of sealants for it. The first (based on Boutils) is applied to the frame, it compacts the places of its contact with the windows, is unreserved and serves as the main barrier on the way of penetration of moisture. The second (up to 5 mm deep) is imposed on the joint venture to bind the sheets and the frame with each other. After solidification, it gives the stiffness design, and also performs the function of insulation from dust, insects and partly from water. Silicone, polyurethane or thiocol (polysulfide) sealants are used here. Obviously, the efficacy and durability of double-glazed durability differ from the quality of both layers. The possibilities of molecular sieve are not limitless. If the moisture is actively penetrated into the chambers through the sealant, then the operation will soon lose operational properties. After all, the increased humidity in the chamber reduces the thermal insulating indicators of the package. But it is more unpleasant that at the same time a large temperature difference leads to condensate falling, that is, the glass inside the glass packs are stuffed, and in the winter indishes.

Meanwhile, even the most high-quality sealants are not able to solve the problem of the so-called edge zones. Together, the adjoining of the metal remote frame to the glass is high like the formation of cold bridges. Because of this, in the winter period, the double-glazed glass can be wrapped around the perimeter, as a result of which the window fishes, covered by frost and even when the room is found. No matter what trouble does not occur for such trouble, until the mercury column drops below -45 S.

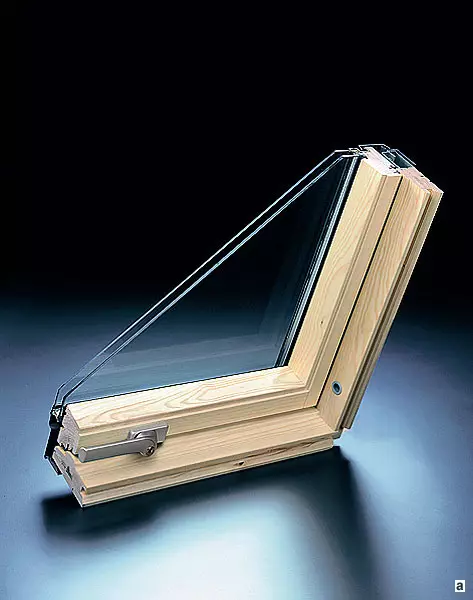

The problem of increasing frost resistance solve in different ways. Forward the queue it is necessary to provide a sufficiently deep landing (12-15mm) of the glass package in the sash profile, this allows the products of the largest companies producing profiles: Rehau, Kbe, Veka, Schco (all Germany) IDR. The same companies have their own branded recipes. Let's say in the attic windows of Velux (Denmark) single-chamber double-glazed windows with a steel remote frame (thermal conductivity have become more than 2 times lower than aluminum). To reduce the risk of freezing, remote frameworks with thermomosts are used (Pilkington, United Kingdom; Azon, USA) or thermal thermal keys (TGI, Germany). In the manufacture of similar products, heat efficient plastic reinforced with aluminum or stainless steel foil is used.

Another variant is the Swiggle Strip technology, which provides for the use of a special spacer sealing tape from thermoplastic polymers. Such a tape includes sealants, desiccant, reinforcing aluminum jumper.

Not so long ago, a new method of sealing double-glazed-tps was developed. The formation of a frame of thermoplastic (Thermo Plastic Spacer) with a desiccant inside occurs directly in the manufacture of products. Innovative technologies, in fact, create a warm contour around the perimeter of the glass package, which significantly increases the efficiency of window systems and their resistance to condensate formation.

It should be mentioned about glazing with electric heating. A metallized coating is applied to the glass surface, which is connected to a low-voltage current source. At low temperatures, the glazing is slightly heated (over the entire surface or in the edge zones). Thus, the probability of freezing and filling windows is completely excluded.

Basics of rigidity

Despite the amorphous structure, glass is quite hard material. However, it should be remembered that during operation the glazing is experiencing serious dynamic and static loads. In order for the glass package to serve as faithfully for many years, with its manufacture comply with certain rules and follow the guests. First of all, the ratio of the parties of the product should be more than 5: 1. There is also a clear dependence between glass thickness, glass area and a remote frame width. The selection of these parameters is made by special tables or by calculation. In other words, manufacture the facade double-glazed windows with dimensions of the sides 2 and 4m of the glasses with a thickness of 4mm at least dangerous. If the calculated stiffness of the glass pump is insufficient, then when it is formed, we use tempered glass, triplex or thick sheets of glass. Listening to non-standard big windows require show you these calculations: the manufacture of eyes is fraught with a mass of trouble.

True - in glass

For the production of double-glazed windows, float glass - Optifloat (Pilkington), Planibel Clear (Glaverbel, Belgium) Idre are used. Products received their name thanks to the technology, first introduced by Pilkington. Briefly can be described as follows. From the melting furnace, the glass tape is pulled out to the surface of the bath, filled with molten tin. The result is a glass with excellent optical characteristics (in particular, translucency of more than 90%), practically not in need of subsequent processing.

In construction, glasses 3, 4, 5, 6, 8, 10, 12 mm are used. Maximum dimensions of sheets - 63M (jumbo sheets). Flot glass serves as a basic material for the manufacture of special types of glasses and glassware (colorless, bibrous, energy-saving, sunscreen, impact-resistant, fire-resistant, noise absorbing IT.D.). The combination of different glasses in the composition of the glass package allows you to create translucent elements with predetermined properties.

Blinds in a glass cage

The fact that the shutters on the windows in budget expenditures give a lot of amenities, the fact is generally recognized. But here is the cleaning of their thin lamellas- case burdensome. The problem is removed if the blinds are built into the window. There are two options for this solution. The first is located inside the glass. For example, using Isolette Gruppe technology, horizontal lamellas are guided by aluminum edge inserted between two remote frames in a 14-27mm wide wide chamber. The maximum thickness of the air packet is 35mm, which is quite suitable for most four-chamber window profiles. Drive lamella-manual, cord. The disadvantage of low tightness of the injection site of the axis of the drive into the SP Camera and, as a result, condensate problems. Therefore, the design is more suitable for warm areas with a dry climate. It costs about 11 thousand rubles. For 1m2. According to the second embodiment, the blinds are mounted next to the glazing side of the room, and they are protected by an extra sheet of glass. Therefore, the joint venture can be gas-filled, and vacuum. The minimum sharp design thickness is about 40mm, which requires a wide profile for the frame. Plastic window based on Brilliant profile (REHAU) with vacuum glass costs about 12.9 thousand rubles. For 1m2.

Trappers for heat

The windows usually skip up to 40% of the inner heat of the building. There are many different reasons: the imperfection of the window design (frames, sash), installation defects, high thermal conductivity of glass IT.D. In the second half of XXV. The situation began to change rapidly for the better. Technologies have been developed to produce heat-saving profiles for the production of window blocks. Single glazing replaced hermetic double-glazed windows. Increasing the energy efficiency of the latter is achieved in various ways. You can increase the width of the aircases and their number. This path has technical and technological limitations (it is necessary to strengthen the frame and fitness). Another reception is to fill the chambers inert gases (argon, crypton, xenon). The resistance of heat transfer products changes slightly, but the soundproofing capacity of the glass unit rises by 2-3 times. For such windows, the distance frames are not collected from profile segments, and bend, resulting in only one joint. Thus, the number of microcellies is reduced through which the molecules of the inert gases are overlooked or the water pairs fall into the inside.Radically improves the properties of the joint venture vacuum environment in the chambers. After all, it eliminates the transfer of heat to the air convection and prevents the passage of noise, and the package itself is "losing weight." The problem is only in not allowing the glasses of the package to get into the outdoor air under pressure. Here manufacturers have their secrets. Thus, specialists from the company "Specokna" (Russia) between sheets have (with a step of 20mm) a plurality of tiny ceramic pads (0.4 mm diameter and a thickness of 0.1 mm). Outside, they are practically not visible. The perimeter of the chamber is sealed with glass above and pump air to the pressure of 510-3mm RT. Art. Vitoga is no deflection of even thin glasses (only 2mm); heat loss decreases at least 1.5 times; Soundproofing is 10-15 times higher than that of air; There is no problems with the edge bridges of the cold. Such double-glazed windows are released in size 1900700 and 1300900mm.

However, the main way to increase the heat engineering indicators today is the use of low-emission heat-saving glasses. It has been scientifically proven that the main proportion of heat loss falls on the radiation (radiative) component of thermal energy. Therefore, to keep heat, it needs to be reflected back inside the room. The task is solved by low-emission heat-saving products of two types: K- and and-glass (or E-LOW-glass). The first is produced by the pyrolytic method: the tape is coated with a thin metallized layer in the process of exiting melting oven. This is the so-called "solid" coating consisting mainly of tin compounds. It has high resistance to atmospheric and mechanical effects (can be used for single glazing), perfectly withstands high temperatures (easily transfers hardening). However, its heat transfer capacity is not enough to fulfill the current heat resistant standards. K-glass in the package usually put outdoor.

The "soft" e-low coating is applied to the ready-made glass by the method of magnetronic spraying. Conditions of deep vacuum on a glass surface are sprayed several layers of rare earth metals. "Soft" spraying requires a careful relationship. The glass with E-LOW coating is mounted in the package so that the heat-repeging film is facing the camera. Energy saving and-glass multiplies material with a "solid" coating (though, and the cost of such products is significantly higher). The resistance of the heat transfer of single-chamber double-glazed windows, equipped with sheets with a "soft" spraying, reaches 0.62m2c / W (when filling the chamber with inert gases, 0.68-0.7 m2c / W). At the same time, by SNOP II-3-79 * for windows of residential premises, this indicator should not be below 0.45-0.55m2c / W (MHSN, operating in the territory of the Moscow region, require not less than 0.55m2c / W).

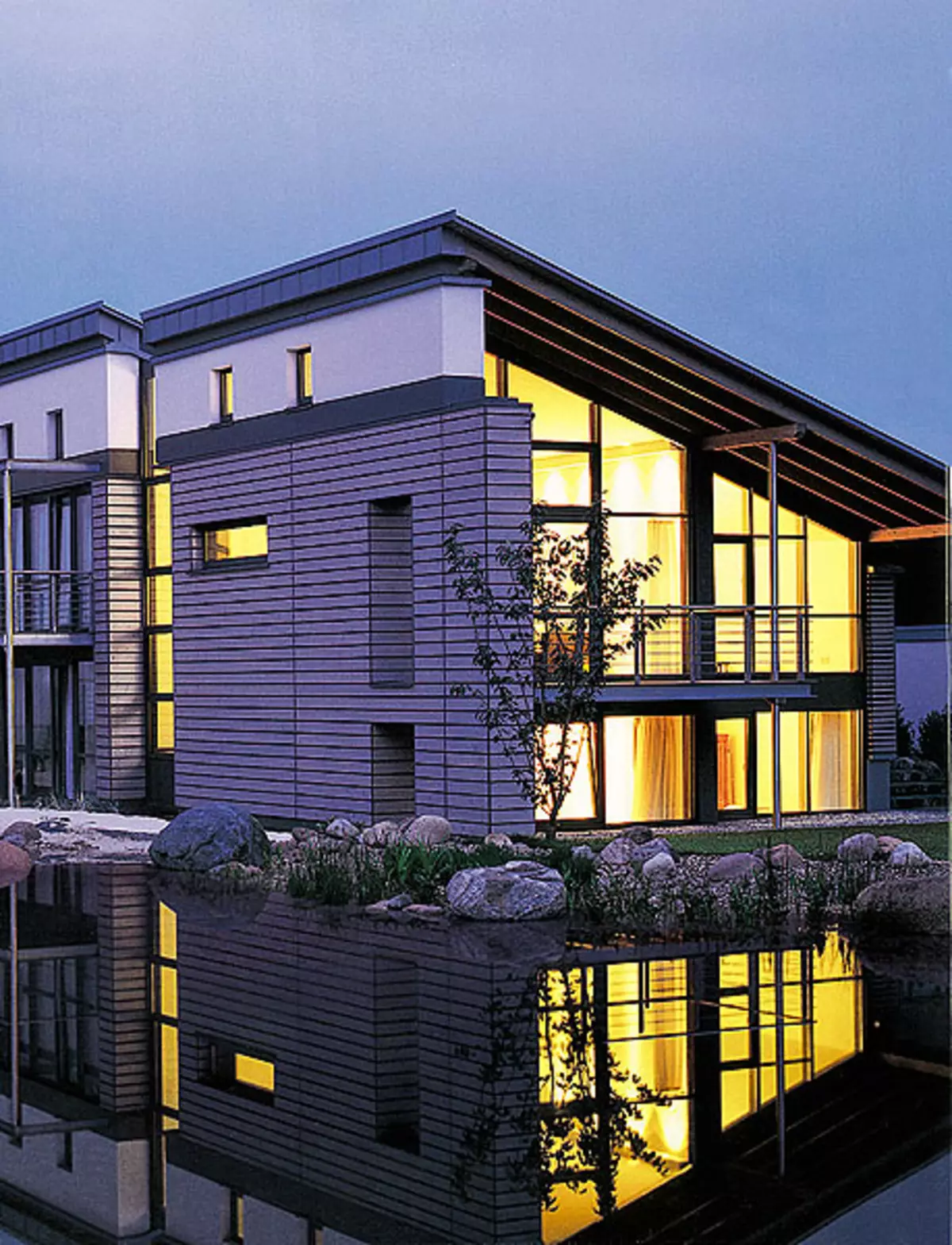

The use of progressive low-emission glasses allows 4 times to reduce losses due to heat emissions. At the same time, it is necessary to emphasize that the double-barker is only one of the components of the complex window system. In other words, if the profile from which the frame is made will not be warm or the mounting seam (the joint of the window block with the walls of the opening) is made without compliance with technological requirements, even the perfect glass package will not save the room from the cold.

"Quiet" glass

Increasing the level of sound insulation of double-glazed windows requires an integrated approach. First of all, combinations of glasses and cameras of various thicknesses are used. Thus, the effect of resonance is reduced. Improve the acoustic properties of double-glazed windows and inert gases that have the ability to reflect sound waves. Products with special laminated glasses, acoustic film, OptiLAM PHONE (Pilkington), Stratophone (Saint-Gobain Glass, France) Idre, deserve special attention. Such products due to high sound insulation ability protects the building from low-frequency outdoor noise. The same, unlike traditional double-glazed windows, combining glass and chambers of different thicknesses, acoustic laminated products do not have a critical frequency (that is, the frequency at which the sound insulation level is sharply insulation).

Cool in a hot day

The use of low-emission glasses causes another problem overheating of the internal space of the building (especially oriented-oriented). The heat introduced inside the room turns out to be "locked" by the heat-reflecting sprayed coating. As a result, a greenhouse effect occurs, at which the temperature can grow to 70 C.

It is possible to reduce degrees internal atmosphere at the expense of various shades: rolling shutters, marquis, IT.d.d. However, in this case, the reduction in window filling transmission is inevitably. Let's say, in the case of the application of the marquise (Roller from a special mesh material), this indicator is reduced by almost 70%.

Another variant in the mass of heat-absorbing glass: Arctic Blue (Pilkington), Planibel Coloured (Glaverbel), Parsol (Saint-Gobain Glass) Idre. Collect them by introducing metal oxide melt. Glass acquires not only the color (blue, gray, green, bronze, pink), but also special energy and optical properties. Thus, the proportion of the absorption of solar heat is 23-51%. At the same time, a low level of reflection is characterized for tinted glass, that is, such products almost do not glare. This positively affects the visual perception of buildings with panoramic and facade glazing. We add that toned glasses are characterized by a low level of bandwidth of ultraviolet radiation. By the way, thermal radiation, which ultimately dissipates into an external environment, can be used. There are solar collectors based on double-glazed windows.

At the same time, the use of colored glasses has both objective (for example, stylistic) and subjective (taste preferences of the hosts) restrictions. Not accidentally widespread neutral sunscreen glasses. Investing solar radiation control perfectly proven itself products with "solid" pyrolytic coating: Stopsol (GlaverBel), Antelio (Saint-Gobain Glass) Idre. There are glasses that combine reflective and energy-saving functions - SUNERGY (GlaverBel). True, similar products are recommended to combine with low-emission and glass.

A good effect provides multifunctional glasses with highly selective "soft" spraying - StopRay product line (GlaverBel). With a high level of heat saving, they completely eliminate the overheating of the rooms. We add that high-selective products are also produced based on tinted glass. Reflexing glass-SANGUARD, REFLECTASOL, COOL-Lite (Saint-Gobain Glass) IDR should be noted., On the external or inner surface of which the mirror layer is applied. In this case, glazing not only protects the inner space from the Sun, but also protects it from curious views in a dense urban building.

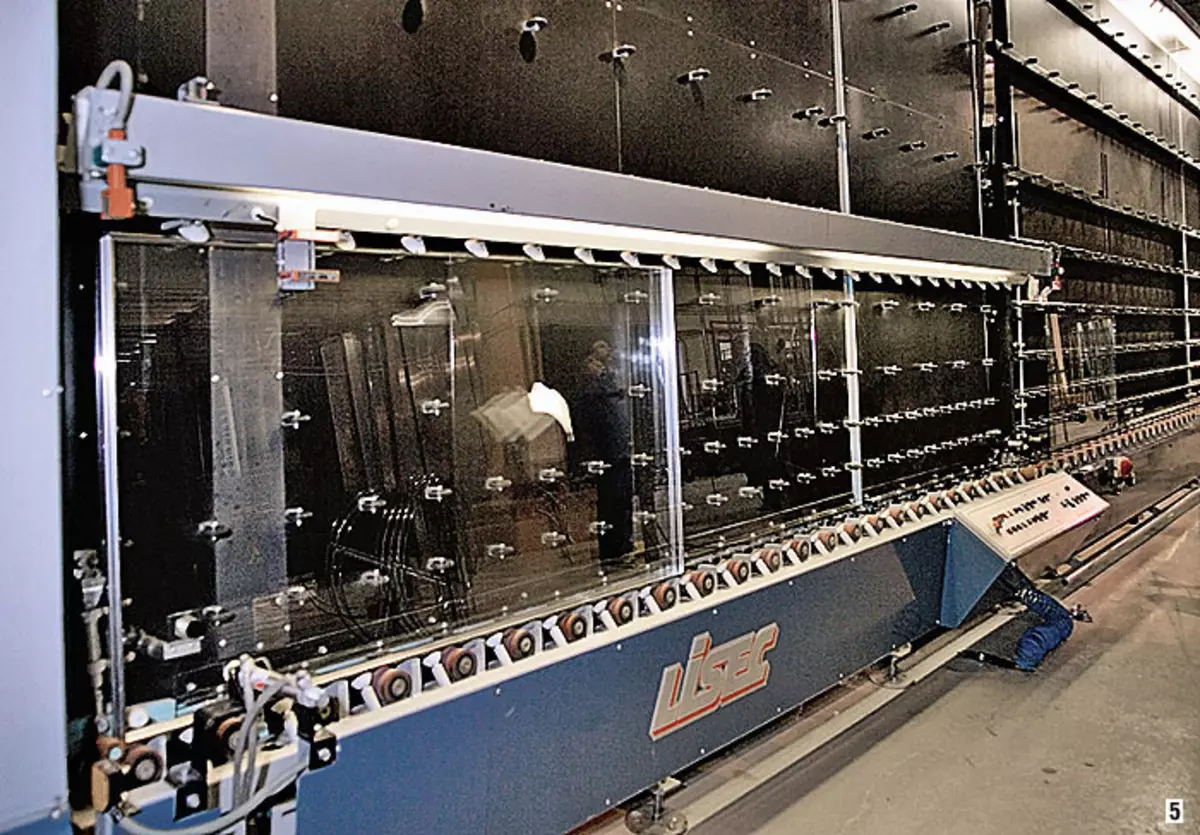

Quality on the stream (automated production joint venture)

|

|

|

Safe glazing

The fragility is almost the most serious lack of glass. When the glass canvases turn into different-caliber fragments that can cause irreparable harm to human health. Strengthening the ancient glazes were concerned. To increase the impact strength in the composition of the raw material (the mixture), magnesium oxide was administered. At first XXV. We developed the technology of thermal pre-stress of glass (by analogy with a metal hardening). The material is first warmed up to a temperature of 600 s, and then quickly cooled. At the same time, compressed outer layers cover an internal stretched layer. Vnashy days of this effect achieve chemicals using ion exchange. The hardening increases the shock strength of the glass 6 times, and thermal - 3 times. During the destruction, small and fairly innocuous fragments are formed.To the greatest degree quenching needed windows subjected to uneven heating. Let's say the tinted products on a sunny day in the light and in the shade absorb various amounts of heat, which causes substantial internal stresses of the material. Without hardening, such glazing threatens inevitable destruction (thermoshok). Meanwhile, tempered products have their own minuses. Such glasses can not be processed (cutting, drilling etc.). All mechanical operations must be performed before hardening. The same tempered glassware peculiar spontaneous self-destruction caused by residual stresses. Do not forget about flying small fragments, which can cause large trouble.

Sobility nature of destruction and high strength indicators are inherent in multilayer and laminated glasses (triplexes, polyplexes). The triplex consists of two glasses connected using a polyvinyl-cellular film and subjected to autoclave processing (temperature - 140-160 s, pressure of 12 atm). Also, the glasses for the triplex are poured with a polymer resin solidifying under the influence of UV rays. True, such products are considered less durable compared to products with film compound.

Triplexes can combine special-purpose glasses: energy-efficient, artistic (corrugated, patterned IDR), suveree, toned IT.d. As a result, compositions with universal properties are obtained. The inner layer also undergoes changes. Glasses are produced with adjustable transparency (electrochromic - when low voltage supply; photochromic- under the action of UV rays).

Multilayer structure have bulletproof glass. Safe double glass is a symbiosis of tempered glass and triplex. Initially, the first was placed on the part of the street, and the second - on the part of the room. However, this order is in itself a real threat to the health of passersby. Shakering glass fragments can cause serious injuries. A sprouting of selective glasses appeared the ability to "turn over" the glass package, that is, to install the triplex outside. Jumping with facade glazing These products have an additional advantage: almost complete absence of optical distortion.

The world is beautiful

The window is the most important attribute of the architectural appearance of the building. For the manufacture of window structures, double-glazed windows with decorative glasses are used (patterned, relief, matte, stained-in IT.D.). When assembling between glasses, the joint venture, you can insert layouts by changing the window of binding the window, or stained glass window. Their geometry, material and decor should be specified when ordering the product. For facade glazing, they produce a joint venture with unusual visual effects, say soft blue color, reflecting the clouds.

When erecting winter gardens and other translucent buildings use mlaroted windows. Such products have a lectal (curvilinear) form of various radius. In optical and heat engineering properties, they are not inferior to flat glass packages.

Recipe cleanliness

Washing is a tedious, time consuming, and in high-rise buildings there is also a very dangerous occupation.

Not so long ago, Pilkington offered an original and effective solution to this problem. Self-cleaning glass Pilkington Activ appeared on the market. The material has a special pyrolytic double-acting coating. It performs the function of the catalyst for the reaction of the decomposition of organic contaminants under the action of the sun. The same active layer gives glass hydrophilic properties. Debris products and mineral dirt (dust IT.D.) perfectly flushes rainwater without formation, divorce and spots. The process of self-purification occurs in daylight (regardless of the weather). The roofing option operates around the clock. The way "Dedovsky" will help the way: soap water and cloth.

Self-cleaning glass is combined with other types of glass products: energy-saving, reflective and other glasses.

The main characteristics of glass packs

| Type of glass package | Formula | Thickness, mm. | Heat transfer resistance, m2c / w | Soundproofing Index, DB | Price, rub. / M2 |

|---|---|---|---|---|---|

| Single-chamber | 4-12-4 | twenty | 0.37 | 25. | 3440. |

| Single-chamber | 4-16-4 | 24. | 0.39 | 27. | 3500. |

| Single-chamber, K-glass | 4-16-4K | 24. | 0.52. | 28. | - |

| Single-chamber, K + Argon | 4-16-4K, Ar. | 24. | 0.54. | 35. | - |

| Single-chamber, E-Low-glass | 4-16-4 E-LOW | 24. | 0.58. | 28. | - |

| Two-chamber | 4-8-4-8-4 | 28. | 0.50 | 39. | 3800. |

| Two-chamber | 4-10-4-10-4 | 32. | 0.55 | 39. | 3860. |

| Two-chamber | 4-12-4-12-4 | 36. | 0.58. | 39. | 3890. |

| Two-chamber | 4-12-4-6-4 | thirty | 0.49. | 33. | - |

| Two-chamber, E-Low-glass | 6-4-6-6-4I | 36. | 0.60 | 39. | - |

The editors thanks the company Scytter, "Isoolux", "Dekenink Rus", "Window Hobbit", "Eurowokna", "Specokna", "Pilkington Glass", Kbe, Polonia, Rehau, Schco, Velux for help in preparing the material.