Overview of automatic pumping stations for cottages: Types of pumps, restricters of re-short-term inclusions, principles of installation.

Photoxpress.ru.

ARM 100/25 on the basis of a self-priming pump with a remote ejector raises water from the depth to 35m

Redcover.com.

Weak water pressure? Using the pumping station, ensure the necessary pressure easier in the water supply

The water treatment system in the cottage has a high hydraulic resistance, to overcome which automatic pumping stations are often put at the entrance

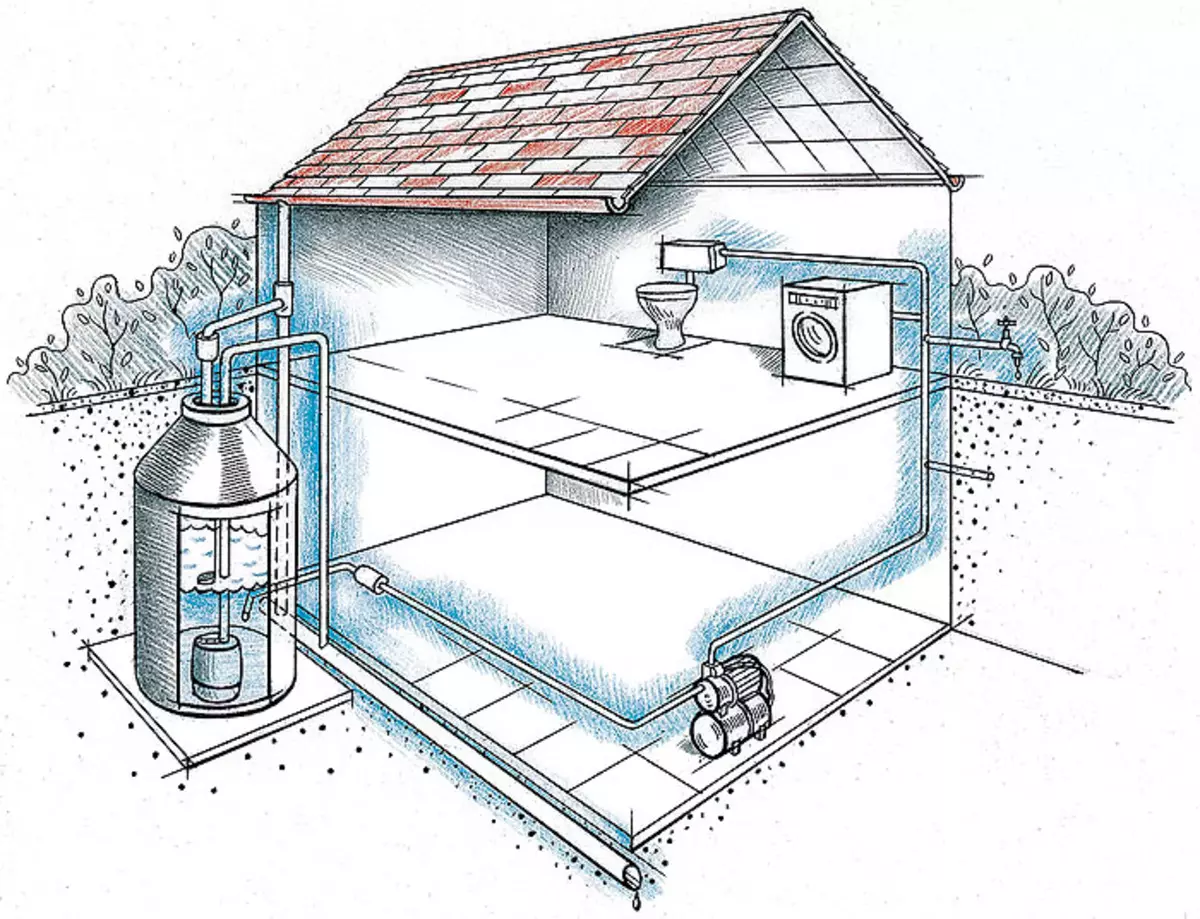

Water supply system based on automatic pumping station and cumulative tank

Pear-shaped membrane for hydroaccumulator

Cartridge filters with replaceable filtering elements (most often used "coils" from polypropylene filament) are installed on the pressure pipeline

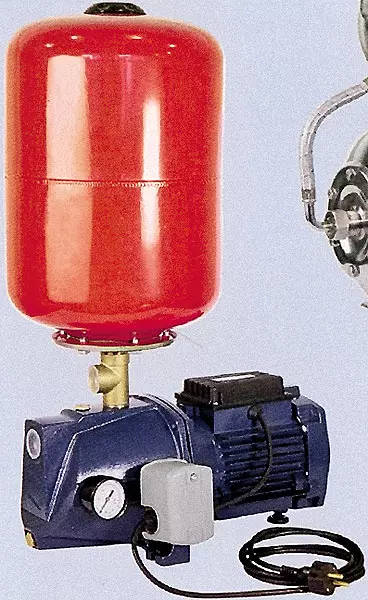

Saer Station with a hydraulicular and self-priming stainless steel pump

Automatic pumping stations consisting of a surface pump with an electric motor, a hydro-accumulating tank with a capacity of up to 60 liters, a pressure switch, as well as a connecting hose and an electric cable with a fork (in such a layout, such devices can be seized on sale at any store specializing in the sale of goods for the garden and the garden ), Ideal are suitable for domestic water supply of a country house. The station holder can be to become commonplace with a relatively small amount - from 3-4 thousand rubles. For a model made in China, which is "enough" for one or two seasons, to 10-17 thousand rubles. For the device of the Danish, German or Italian assembly, the service life of which can be 3-10 years or more.

Just and availableAutomatic pumping stations can supply water from wells, wells, open sources of water intake. Wriegions with a hot climate they are injected into the house water pipe bridge drinking water from tanks; With their help elementary organize watering the garden. The stations are permissible to apply not only in the country, but also in the city dwelling, if the water pressure in the main water supply is not enough and it is necessary to increase the pressure in the water supply system. The main thing is that in the pumped moisture there were no abrasive particles (sand, etc.) and long-fiber inclusions - all kinds of sticks, blades with linear dimensions more than 2mm. The total number of mechanical impurities should not exceed 100g / m3. The most powerful "family representatives" is supplied to the house and for a household plot to 3.5-8m3 moisture per hour, maintaining an overpressure in 2-3bar in the water supply network, and sometimes higher. Due to this, in addition to traditional points of water treatment, such as cranes in the kitchen, bathroom and plums in the bathroom, water heaters, gas speakers, washing and dishwashers, automated irrigation systems and irrigation systems are connected to the network.

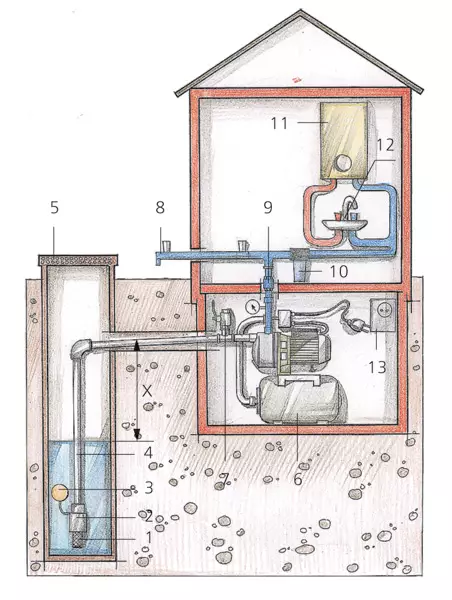

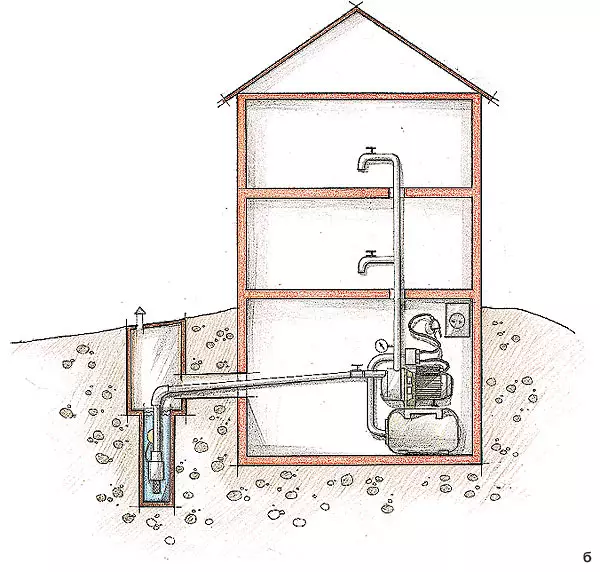

The scheme of the year-round water supply system of the cottage from a mine well (x - suction depth):

1- Mesh filter;

2-check valve;

3-float switch;

4- suction piping;

5- warmed lid;

6- pumping station;

7 - filling crane;

8- crane for watering;

9-check valve on the pressure pipeline;

10- cartridge filter;

11- Electric water heater;

12th mixer;

13- Stabilizer for 220V

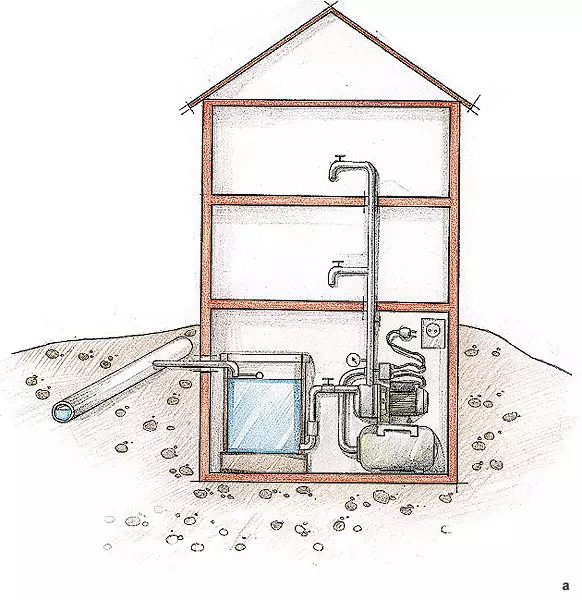

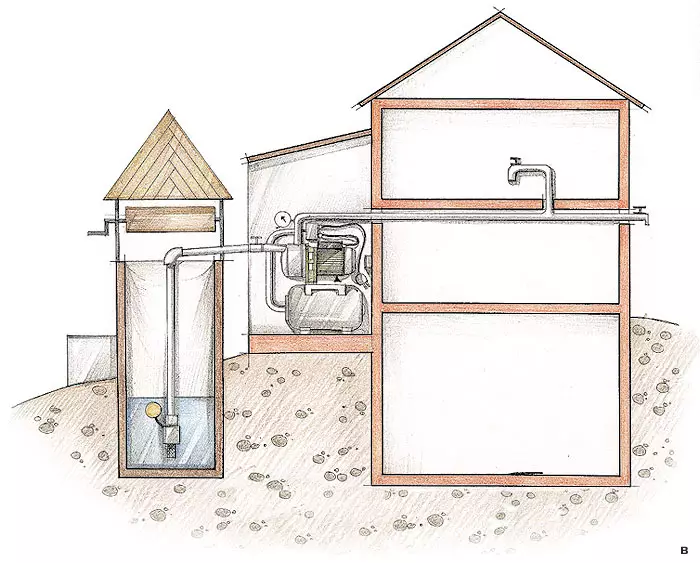

The pumping station is placed in the house or abroad, the main thing so that the suction ability, pressure and the performance of its pump is enough to provide housing with water. If you are going to use the device only during the warm season, for example, to supply the water of one crane in the kitchen and filling the small pond, install equipment easier simple- can be stirred in 1 second. It is enough to pave a special water hose from the well to the station (on this segment, the water should rise up at least under the slope of 1, while the horizontal sites and the absorption tubes are unacceptable). Next, you need to connect the feed pump to the water supply pipe, connect the station to the electrical network and perform some other non-slip guidelines for the manufacturer on the launch of the equipment.

Installation of a pumping station, which is prepared all year round, most likely will be delayed for several days. It can be installed in the heated area of the cottage or in a warmed caisson next to the well, and the highway from the well or well to the house to be paved in the ground below the level of freezing (at least 1.5-1.8m). The well should be closed with a warmed lid. When choosing a place to install a pumping station, it is important to remember that as it removes it from the well or well, the allowable distance vertically from the water mirror to the suction pipe of the pump is reduced: if the station to the source is 5m- about 5-15%, 10m- by 10 -35% of passport values of the maximum suction depth, depending on the diameter of the suction hose, its material, the number of turns (specified by calculation). If between the well and house more than 10-15m or before the water in the well, more than 6-7m, the station is better to put next to it, and to the house to stretch the pipe from the pressure pipe of its pump.

The automatic pumping stations are working independently, a matter of time, without human participation; The main thing is that the water in the source is plenty and electricity has not turned off. The plumbing network to which the automatic station is connected, is under pressure generated by the hydroaccumulator (membrane pressure hydrobacom). If you open a crane in the kitchen, water rushes out of it with a cheerful jet, while the hydroaccumulator will begin to empty, and the pressure in the system is slowly decreasing. When it falls below the set minimum (usually about 2-2,2bar), the pressure switch will automatically turn on the pump, and it compensates for water consumption. After closing the crane, the pump will work for some time. It will fill the hydroaccumulator until the pressure in the system does not increase until the initial (approximately 3bar), after which, due to the relay there will be automatic shutdown of the pump. The upper and lower pressure switches of the pressure switch are installed at the factory, but if necessary (for example, to increase the pressure in the system), they can be changed.

Average daily water consumption| Type of water supply system | Norm of average daily water consumption per person, l / day |

|---|---|

| House with water consumption of street water treatment columns and wells | 30-50 |

| House with internal water supply and sewage without bath | 125-160 |

| Same + Baths and Local Water Heaters | 160-230 |

Head and flow

Before buying a station, it is necessary to determine whether the pressure developed by it and consumption is enough to meet the "water" needs of your home and the site. In contrast, the purchase of expensive, but not able to cope with its direct responsibilities of the technical device is quite likely. The maximum cost of the station ideally should be equal to the amount of expenses of all simultaneously included pointing points in the house. The subposition of the station necessary to ensure consumption through all points of the water-based, consists of three components. First of all, it is necessary to know how many meters vertically you need to raise water from the source water mirror to the highest point of the water pipeline in the house. Then it is necessary to take into account the working pressure in the plumbing equal to at least 2bar (which corresponds to the 20m pressure), - such pressure is required for the normal operation of household appliances. The third component of the pressure along the entire length of the water pipeline, on the suction and supply sections.

For a specialist gives you competent recommendations, do not be lazy to spend some measurements on your site. Determine the distance from the installation site of the station to the well, the actual distance from the water intake nozzle to the water mirror in the well either the well or excessive pressure in the water supply, type and diameter of the IT strapping pipes. It is also desirable to have a plan of the house with the location of water-based points. You should not spend time looking for the necessary reference information on the roughness of pipes, hydraulic resistance of the shaped elements IT.D.- In any decent company, such data will find the manager-consultant or designer. It will calculate the required performance, and water consumption and will select the station for your particular case, and also recommends installers that can be quickly and efficiently installed.

Lead elementStation is a very profitable purchase if only because they mounted it at the factory. The equipment set is fully tested by the manufacturer, which means that the problems associated with the poor quality assembly of the installation can not be afraid. If the station fails, it can be repaired in a warranty workshop or replace a new one. However, the conscious choice of a particular model is impossible to disregard its basic components.

Automatic pumping stations are equipped with pumps with plastic, cast iron and stainless steel housings; The electric motor leads to them. Pumps with plastic enclosures cheaper, from cast iron and stainless steel - more and more durable. However, judging the real service life of pumps and engines in the composition of automatic stations is difficult. Data on resource testing, failure statistics and other interesting information about the manufactured technique none of the manufacturers, alas, does not advertise. From the launched information when choosing a pumping station, the data on the type of pump can be greatest for the user, it depends on which depth the station will be able to "tighten" water to the house, how convenient will its operation IT.P.

Most often, automatic pumping stations are performed on the basis of inkjet-centrifugal self-priming pumps with built-in ejectors. They have a noticeable advantage over the pumps of other types due to the high pressure (from 40m) and the depth of suction (accurately vacuum absorption height) to 7-8m, low sensitivity to the air presence in the system. This means that when the pump is started, it is enough to fill with water only its housing, for which it is necessary to unscrew the plug of the fuel hole, pour water into the pump until it sticks through the edge, then spin the plug. The suction pipe from the pump to the well water can not be filled. The pump, first pumping the air, will begin to feed water into the house (excess air from the highway is poured using the valve on the pump housing or opening any crane). This feature of a self-priming pump with a built-in ejector is particularly useful if the source of water supply is the so-called needle tube, scored to the ground to the aquifer. But in any case, not to experience discomfort when using the station, on the suction pipe, it is recommended to install a check valve with a mesh filter, otherwise it is not possible that before each start of the pump will have to wait a long time (3-10 minutes, and sometimes longer) while water Rises into the pump from the well.

Among the wide range of stations, we will note "Jambo" ("Djelex", Russia), Banu BSTCC ("Ukrelectromash", Ukraine), Hydrojet and MQ (Grundfos, Denmark), Wilo-Jet Hwj (Wilo, Germany), PKM (Pedrollo), Waterpress Inox (NoCCHI), Aquajet INOX (DAB), self (marina) (all of italy).

Another type of stations aggregates also with inkjet-centrifugal pumps, but with remote ejectors. They are used to pump water from deep (up to 20-45m) wells and wells. Such a station is placed on the surface, and the ejector (small block) attached to two pipes are lowered into the well. One of the pipes is used to supply water down, ejector, and creating a suction jet there, and the second is for lifting water partially returned to the ejector, and partially directed to the house water pipe. Music stations of this type should be attributed to the fact that they are sensitive to the air, sand, have a small efficiency. At the same time, just such a station can be placed on the heated cottage area, if the well is located far from home (up to 20-40m). Example Equipment - ARM100 / 25 (Marina).

Sometimes you can find automatic pumping stations with single, two-time and multistage normally suction centrifugal pumps - Wilo-Multipress HMP (WILO), seams (LOWARA, ITALY - USA). Use them mainly to increase pressure, but some can lift water from a depth of 3-5m, sometimes more. However, before starting operation, it is necessary to fill with water water hose and the working part of the pump. If this is not done, the latter fails. In order to increase the pressure, automatic stations based on vortex pumps are used, which are very sensitive to the presence of impurities in water (sand), but "indifferent" to air traffic jams in the water supply. When working, the vortex pump is tangible noise. Plus device compactness. Example Station model Art (Calpeda, Italy).

|

|

|

Automatic pumping stations can be supplied to the house water from different sources, for example, from a storage capacity, into which the moisture comes from the water pipeline (A), or directly from the finely breeded well (b). For the summer, the station is sometimes installed under a small canopy near the house (B).

Useful volumePerformance (consumption) of the pump of the automatic pumping station often significantly exceeds the needs of the country house in the water, as a result of which the pump can operate in frequent / disable / discs. Some surface pumps of automatic stations allow the rapid frequency of launches than submersible (up to 30-100 times per hour). But in any case, frequent starts and stops strongly reduce the service life of the electric motor and launchers. That is why manufacturers of pumping stations seek to ensure their protection against premature development of the resource of components as a result of frequent use.

The main limiter of the number of re-short-term inclusions of the pump with a slight water treatment or leaks in the system is a hydroaccumulator. It is usually a hollow steel vessel with a capacity of 8, 20, 24, 25, 50 or 60l, inside of which there is an elastic membrane. It is most often made of natural rubber or butyl (when buying a station it is desirable to check the hygienic certificate) and has the shape of the flask. The neck of the membrane is hermetically sealed with a tank throat through a flange connection. The flange has a threaded fitting for connecting to the water supply system. The space between the membrane and the inner cavity of the vessel is filled with air under pressure, which can be adjusted via the car nipple, which is at the top (the pressure in the tank periodically must be checked, for example, using a bus pressure gauge, if necessary, pump up to the required 1,5thm). Since the water contacts only with the membrane, the possibility of corrosion of the inner surface of the tank is excluded. Sometimes instead of the pear-like membrane, a flat, separating tank into two parts is used - in such hydroaccumulators, the inner surface has a protective polymer coating. From atmospheric moisture, low carbon steel tank protects the enamel coating (but it is still better for the street with stainless steel tanks).

Hydroaccumulators with a capacity of 20-24l are often used in conjunction with superficial pumps with a capacity of up to 1.2kw, and for pumps up to 2 kW, hydrobars are recommended by 50-60l. Theoretically, according to the classical methods of selection, this volume of hydroaccumulators is clearly not enough to reliably protect the pumps from frequent launches (you need at least 80-150l). However, practice shows that it is not. Many stations with 24-liter tanks, installed in country houses 5-7 years ago, despite daily use, work reliable and so on. Avota An increase in the volume of the hydroaccumulator to 100-200l and more often leads to a decrease in the comfort of using the water supply. Opening a crane or turning on the shower, a person is forced several minutes to put up with a smooth reduction in the system in the system, until the pump and the jet from the tap does not find enough power.

A large hydroaccumulator is useful for storing water supply in the house under pressure in the case of short-term interruptions in power supply. It will provide several tens of liters to the water disposal points even with a non-working pump. If necessary, you can always connect an additional hydroaccumulator to the plumbing highway of any volume you need.

In addition to the hydrobook, protection against re-short-term inclusions provides modern automation of pumping stations. Most pumps are equipped with protective thermal relays, so a re-short-term mode usually does not lead to their destruction, but only reduces the resource. A mechanical pressure switch that automates the operation of the electric pump, including it when the pressure in the water supply system is lower below the set limit and turning off when the upper installed limit is reached, sometimes replaced with the electronic relay. For example, at W. P. Superinox 1500 P E (Flotec, Italy) is one of the functions of such an electronic time-timer of time inclusions, significantly increasing the durability of the pump by limiting the number of its launches per hour.

Practically not afraid of frequent starts automatic pumping stations with water-cooled engines, such as MQ (Grundfos). The installation is a complete system, including a pump, an electric motor, a pressure sensor and flow sensor, a check valve and a membrane pressure tank with a capacity of only 0.18l. The system automatically starts the pump at the beginning of the water-based and automatically stops when the water consumption is stopped. The automation turns off the pump in the event of a dry stroke or overheating caused by, for example, clogging or overload, thereby preventing the winding of the electric motor windings. The miniature pressure tank included in the pump station reduces the number of cycles of re-short-term inclusions in the event of leaks in the water supply system, which reduces the degree of wear of the pump parts, and also protects the water pipe from the hydrowarders.

How do pumps work?

Centrifugal. The principle of operation of the surface centrifugal pump is as follows: The impeller rotating on the drive shaft is directly opposite the suction pipe placed on the pump housing. The design of the impeller provides with minimal hydraulic losses the radial movement of water from the center to the periphery, during which the radial blades inside the channel of the impeller transmits the energy of the infamous fluid in the form of both pressure and increase the flow rate. At the outlet of the impeller, the water rushes into a spiral, due to both it, and the conic diffuser, part of the kinetic energy is converted into the energy of the pressure.

Inkjet-centrifugal. One of the types of centrifugal pumps. The effect of self-examination in them most often contributes to the ejector (special form nozzle) installed inside the case. Purchased liquid is only partially fed to the discharge nozzle. The remaining part recycle due to the ejector connected to the absorption chamber, due to which it creates the discharge required for water absorption. Sometimes the effect of self-priming in the inkjet-centrifugal pumps provide an ejector and a suction chamber, made in a separate unit, which is lowered into the well and fasten with the pump body with two pipes.

Vortex. These pumps work like this: on the periphery of their impeller, the set of radial blades transmitting the energy of the infamous water. The special profile of the blades provides radial recycling of the fluid flowing into the pump between the blades of the impeller and the double channel located on its both parties. Since each of the numerous blades is involved in energy transmission, water pressure gradually increases during its transition from suction to the discharge nozzle, in this way, on the one hand, an acceptable uniformity of the flow, and on the other, high output pressure.

How to put and stickInstalling a pumping station is necessary in strict accordance with the instruction manual. As a rule, it is written in detail in detail the installation procedure - the deviation is fraught with premature output of equipment or even accidents. It is better, of course, to invite to install experienced company specialists with which you are going to purchase a station. But with certain skills, you can rely on your strength.

The plumbing to which the pumping station will be connected, it is beneficial in the country house with lower wiring. At the same time, its main plot connected directly to the autonomous water supply station is placed in the basement or underground (between the piston and rough floors), with a slope of 0.002-0.005 in the direction of the pump. The riser, raising water on the floors, is closer to the places of installation of watershed reinforcement pipes from the riser to the plumbing devices must be minimal length. To avoid headlows, mount the water supply should be mounted without sharp bends and turns. Compounds of pipelines must be absolutely sealed, it will avoid leaks and pressure losses.

If the power grid and the socket, to which the pump will be connected, have a valid grounding device, then the earthing of the automatic station pump should be carried out through the contacts located on the plug of its cord and in the outlet. In contrast, the pump housing is autonomously.

All equipment supplied from abroad corresponds primarily to the industrial standards of the producer. Thus, for automatic pumping stations of the production of Germany, the allowable deviation of the voltage in the electrical network from the nominal is 6-10%. Despite the embedded protection systems, "drawdors" and voltage jumps negatively affect the resource of the electric motor. Therefore, in addition to the station, a fairly powerful voltage stabilizer must be purchased.

|

|

|

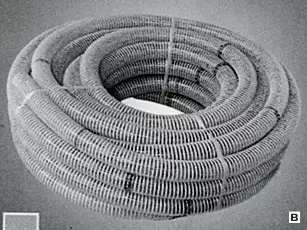

The mesh filter (A) and the check valve (b) are mounted on the end of the pressure-vacuum hose in the rigid spiral braid (B)

The editorial board thanks Grundfos, Wilo, "Avan" and "Heatimport" for help in the preparation of the article and the provided photographic materials.