Floor screed device: Material for the base of floor covering, specifications of leveling mixtures, styling technology.

Photo by D.Minkina

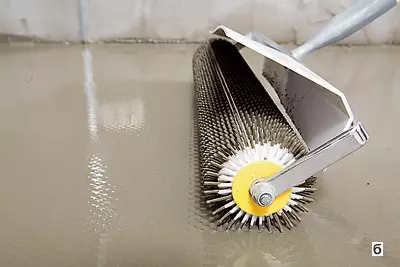

Summer mass should be slightly helped to host the floor area. This is done with the help of Rakly (a) or comb. To displacing air bubbles from the layer, it is recommended to go through the surface with a needle roller (b)

Properties are not more than 20.

Opening the instructions for laying any floor covering, you will definitely read the phrase: "The basis should be even, durable, dry and clean." How to get a covered horizontal surface if the initially floor is far from the ideal?

Paul-parquet, ceramic or anyone else is a multi-layered design. One of the layers, as a rule, is a screed. It serves to align the underlying slabs of overlapping (carrier structures) and is the basis for laying the finishing floor covering.

Preference is given to concrete

Due to the adhesion (bonding contacting surfaces), the screed forms a single integer with the supporting structures. Durable monolith not only closes irregularities, but also tightens the cracks, eliminating the likelihood of mud propagation, the propagation of insects, rodents, seeding water, which is its advantage in comparison with the floor on lags that do not form a solid base.

Two technologies of the "wet" screed are used to enter. The traditional technology implies the use of cement with sand and reinforcing mesh, evenly distributing the voltage arising in the screed, and a greater durability of the concrete layer. The new technology has emerged with the advent of special building mixtures, developed directly for the device of the smooth base of the floor. The selection of components in such a mixture and the homogeneity of their distribution makes it possible to obtain a monolithic layer with the desired improved properties, with the required strength throughout the volume without the use of the reinforcing grid.

Universal problems

It must be said that the construction teams forced to work with cement and sand exist their tricks to improve the properties of the working mixture. Thus, cement is added to the solution for greater strength to the solution, for the best plasticity of PVA or synthetic additives-plasticizers. However, these measures do not guarantee the result. After all, it is difficult to achieve a good homogeneity in the manufacture of a working solution by manual dosing and kneading, and the likelihood that improving properties will occur only in some places.

Narrow specialization

Modern technology is based on the use of special modified mixtures, designed specifically for the screed device. The main advantage and difference of new high-tech mixtures is the selection of components and homogeneity of their distribution throughout the volume, which guarantees stable specified properties on any section of the layer. In addition to the binder (portland cement and polymeric components), fillers (sands of various fractions) in their composition include modifying additives, improving the properties of both directly screed and working solutions. Some components are normalized by shrinkage, the speed of hardening, others simplify the knee, the third displaces the air, the fourth increase strength, the fifth reduce the drying time, the sixth improves the "fluidity" of the solution. Recall that the reinforcing grid is not required in this case. In addition, the amount of water required for the preparation of the solution from the mixture bag, as well as its consumption is shown on the package.

mixtures forming the flowing solution with water, well distributed

The tie high drops are made in two stages along the entire surface at large differences. Pre-floor is roughly aligned with the help of so-called leveling mixtures. The mixture is embeded with water, distributed over the surface and aligned with a rules. About a day, the layer solidifies and dries. Such a screed is no longer required for several days to make water, it herself regulates its drying. At this stage, great irregularities and differences are cleaned. Such a mixture is cheaper than the finishing self-leveling, therefore allows you to save money. However, without certain labor and skills, it will not be possible to get an ideal horizontal surface.

At the second stage, the finishing alignment is made using a different type of mixing, self-leveling. It is also bred by water, and the resulting solution, which is reminded by ripples, poured into the floor, helping the fluid to host the vaccine surface and a special needle roller. The raised and frozen mixture will make the surface perfectly horizontal. Depending on the initial leveling of the base and the results of coarse alignment, two types of mixture for the "Finish" can be used: thin layer (thickness from 2 to 5-7 mm) or a thick-layer (5-30 mm).

Accuracy according to the laws of physics

By the way, the standard of quality of construction work is allowed to the height of the finished floor not more than 5mm on 2 p. m floor length. The roughness of the black floor in the apartment located in the new building is not normalized in general, and according to the side of the stove of inter overlap must be aligned additionally.

Traditional technology

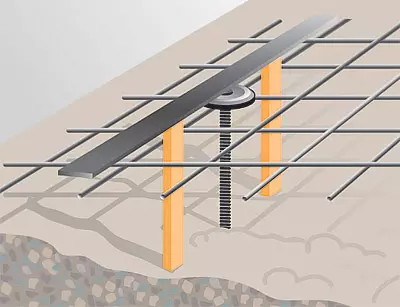

To obtain an ideal horizontal line on which the beacon profiles can be laid, on the same level with a screw of the self-hardening construction mixture in one row with a self-tapping screw building two supports. The reinforcing grid is placed on the floor. So that the grid does not come into contact with the floor and was inside the layer of the screed, the pieces of ceramic tiles are put under it. On tags arranged from screws screwed into the floor and additional supports, the light air profiles are installed on top, which form the boundaries of the space poured by a solution. Light profiles are firmly attached using a fast-rigging mixture. The space between them is filled with the working solution, and then aligned with the rules.

How to calculate the consumption of materials

When using packaged mixtures, calculations are simplified. Thus, a bag of universal building mixture weighing 50kg will be required for a layer device with a thickness of 10mm on an area of 5m2. Remaining manufacturers of special mixtures Consumption is specified on the package, and, as a rule, for a layer of 1mm thick on Square 1M2, 1.5-1.8 kg of dry mixture is required. After conducting preliminary calculations, you can purchase and bring all the necessary materials (and once, not twice).

Doubtful savings

Due to the homogeneity of the composition, the presence of modifying additives, special mixtures are more expensive than universal. Plopobeton bag price 50kg is about 100 rubles. Today, for the device, the tie on traditional technology is often used by sand-concrete-domestic building mixtures, containing as a filler in addition to the sand fraction of small rubble (pebbles), partially playing the role of fittings and prevent cracking.The cost of special mixtures for the screed device is 4 times more. But in this case, it will not be necessary to buy a reinforcing grid (about 100 rubles. For 1 mm), lighthouse profiles (30 rubles. For a product with a length of 3m), the work of work will be simplified, the time of preparation and processing will significantly decrease, it will not be necessary to water the surface with water days. Asaable main - high quality screed will be guaranteed.

Alignment mixtures for the base floor base device

| Manufacturer | Name | Purpose | Packaging, kg. | Approximate value, rub. |

|---|---|---|---|---|

| "Saint-goben Weber Rus" | Weber.niv.trm. | Mix for alignment of interior floors from 10 to 70mm | 25. | 180. |

| Weber.niv FS30. | Self-leveling mixture from 5 to 30mm | 25. | 520. | |

| "Maxit Group" | "Old 5000" | Mix for alignment of concrete bases from 3 to 80mm | 25. | 360. |

| "Old 3000" | Self-leveling mixture from 0 to 5mm | 25. | 500. | |

| "Mirage" | IVSIL-TIE-ROD-IV | Self-evaporation, fast-hardening mixture for flooring from 2 to 100mm | twenty | 240. |

| IVSIL-TIE-ROD-II | Blend for final surface alignment from 2 to 10mm | 25. | 290. | |

| "STROYMONTAZH MS" | "Bests T-41" | For the production of high strength and even base from 30 to 150mm | fifty | 123. |

| "Best T-42" | Self-leveling floor to create a smooth surface from 3 to 30mm | 25. | 226. |

The editorial board thanks the company "Saint-Goben Weber Rus" and "Dilemma-Stroy" for help in the preparation of the material.