Linoleum Market Overview: Types and technical specifications of flooring, properties of natural material, collections of foreign companies.

Moda (Tarkett)

With the protective layer of Extreme Protection and antibacterial layer Sanitized

Footprints from paints and markers on PVC coatings in a napkin are removed with a napkin moistened in alcohol, and then washed with water

Linoleum seams are sealed with welding: cold (using a liquid additive) or hot (fusion of PVC cord at 350c)

Plastics "

The surface of PVC coatings that mimic porcelain or stone is never cold. A cup that fell on such a floor is unlikely to break

Watened rooms, where water and other liquids often fall on the floor, it is advisable to install only anti-slip materials.

The quality of dyes determines the light resistance of PVC coatings. In love if they need to be protected from sunlight

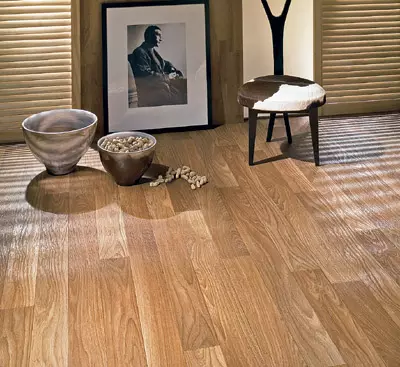

PVC linoleum design reproduces and classic piece parquet, and exotic bamboo floors

The harmonious combination of the floor with other elements of the interior is easy to achieve by choosing the coating of the desired shade in the collection

PVC linoleum classes 31, 32, used in offices and hotel rooms, denser and tougher residents. Little conditions on its surface are not formed dents from the feet of furniture. The service life of such materials is at least 10-20 years

The style of the room largely determines the choice of drawings of household linoleum: under the tree, marble, tile or special design for each room

Protective coating from mechanical effects, as well as ultraviolet radiation, protective film mastic - wax or polymer

The preferences of the Russians are as follows: 50% of buyers acquire linoleum for kitchens, 15% - for corridors, 5% - for living rooms IDR. All floors in the house cover them only 6% of respondents.

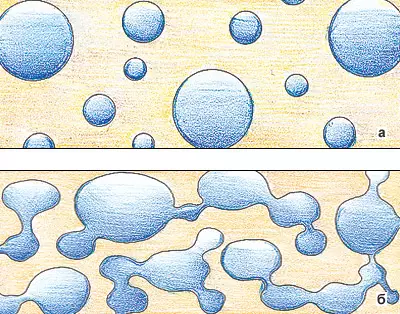

B - mechanically foamed PVC with reported air cavities

PVC coatings for wood reproduce natural beauty of colors and textures of wood, oak, beech, cherries

Many experts believe that regardless of the size of the linoleum room should be adopted to the floor

Bright colors of natural linoleum will not fade and after many years of intensive use

The wonderful properties of this material will certainly please the owners and do not disappoint the adherents of all natural in the house. It successfully imitates the textures of the tree, stone, ceramic tile, and people are creative attractive a variety of colors and original design.

To the question: "What is Linoleum?" - Anyone without a knockout will answer that it is inexpensive flooring, practical, waterproof, simple in caring, which even unprofessional cans. It is a long time for a long time - 5-15 years. Yet we decided to once again tell about modern linoleum and its useful qualities. After all, these knowledge will help make the house beautiful and comfortable.

PVC and others

There are other types of linoleums (although they are rarely used in residential buildings). For example, the glyphthalean is a cloth coated on one side by a layer of alkyd resins with filler, with another special anti-nipple. Compared to PVC coatings, this material is distinguished by the best heat and soundproof properties, high strength, but more fragile. From cellulose treated with a nitriding mixture, a colloquiline linoleum (nitrolinoleum) is produced. It has good moisture resistance and elasticity, but due to increased ignition, its use is limited. Rubber linoleum (Rural) consists of a mixture of synthetic rubbers applied to the rubber base, and an intermediate thermal insulating layer of porous rubber. The coating is firmly elastic, stalling to water. Fill it in industrial premises, cars, garages.

Of the total number of sales of all types of linoleum, 80% are accounted for by PVC coatings, widely represented on the Russian market. These are products of international concerns Armstrong DLW, Forbo and Tarkett, Gerflor (France), Juteks (Slovenia), Polyflor (United Kingdom), Upofloor (Finland), Domo (Belgium), Graboplast (Hungary), as well as MosstroyPlastmass, StroyPolymer "(Russia) IDR. There are no one dozen collections in short manufacturers, and the number of design types reaches 300.

In addition to use, all PVC coatings can be divided into several types:

household (for houses and apartments);

semi-commercial (for small offices, hotels);

Commercial (for premises with a more serious load on the floor).

They differ from each other with wear resistance, which shows what load is able to withstand linoleum without changing the initial properties. We are interested in household PVC coverage. Their cost (80-600 rub. For 1m2), according to specialists, is directly dependent on quality. The joy of the acquisition of a cheap material sometimes turns into large problems during its operation. So we turn to the prose of life ...

Do not believe our eyes

Old flooring usually replace new during repairs, which, as a rule, is carried out in the apartment once every 10-11 years. Naturally, throughout this time, I want to have a durable and beautiful floor. Money invested in floor covering can be considered investment. Avybor material should be started with finding out its wear resistance.However, marketing studies indicate a friend. Apparently, indestructible thrust for excellent forces our compatriots to make a purchase, focusing on the external attractiveness, and only then think about the durability of products. Some are fascinated by ridiculous low prices for separate species of PVC linoleum: 80-150 rubles. For 1m2. Scratching and the dirt, separated by the seams and the wavy surface of the floor probably overshadow the mood of such economical citizens before the onset of the next repair ...

Anatomy of coatings

According to its structure, PVC coatings are single-layer (homogeneous) and multilayer (heterogeneous).

The greatest variety of design is PVC coatings intended for home. Among them are traditional (150-300 rubles. For 1m2), improved domestic with various additional properties (300-500 rub. For 1m2). In addition, semi-dimensional coatings are sometimes laid in residential areas (300-600 rub. For 1m2). All of them, as a rule, have a multi-layered structure:

The working (wearing) layer of PVC will long protect the coating from scratches, breaks, protects the drawing from erasing;

The decorative layer of water-dispersion paint is responsible for aesthetics and design;

The carrier layer of foamed PVC is the basis for the drawing, and in addition, consumer properties depend on it;

The base layer of the glass cholester performs a reinforcing function, and its density determines the quality and scope of the coating;

Substrate (from foamed PVC, jute, felt, polyester, corks IT.D.) Provides additional sound and thermal insulation.

About "personal" qualities

The total thickness of the multilayer coating can be 1.5-4.5 mm. However, the most important parameter is the thickness of the working layer - 0.15-0.3 mm. Focusing on it, as well as on the abrasability and density of the material, it is assigned to the corresponding class of wear resistance: 21 (0.15-0.2mm), 22 (0.2-0.25mm) or 23 (0.25-0.3 mm) . The higher the class, the longer "lives" the coating and the more intense movement in the room it can withstand. Thus, PVC linoleum class 21 is intended only for bedrooms, and its service life is at least 5 years. It will not impact female shuffles on studs, constant movement of chairs and moving heavy items. For living rooms and children's class 22 (operating period - 10 years). However, the habitat of the younger generation can be attributed to the extreme zones of the apartment along with the kitchen and the corridor and to give preference to class 23 products or even 31, that is, semi-commercial, and the other will serve 10-15 years old.Such a characteristic of household PVC coatings, like the mass (1.25-2.5 kg / m2), it would seem, nothing tells about the potential buyer. But when comparing two such samples, it is important to know: the smaller the total thickness, but more mass, the higher the density, and therefore the strength and durability of the material. Now, time should not strive to acquire the coating with the limiting mass: after all, its increase makes the material more expensive, and the floor in our apartments is not subjected to such significant loads.

Another interesting parameter is the residual deformation. Will be visible after some time on the floor tracks from the legs of a move chal or not? To understand this, the coatings are tested with a flat stamp at a temperature of 23c and relative humidity of 50%, determining the residual depth of indulgence after 150 minutes of load and the same time without load. Residual deformation indicators are regulated. For household coatings, it should not exceed 1-1.2mm. For semi-commercial items, it is 0.25-0.35mm, and how it is less, the tougher PVC linoleum.

A very specific indicator is the flexibility of the material. It is possible to unprofessional to bend it only a couple of times: during the delivery from the store and in the process of laying. But, as practice shows, acquiring a coating with a width of 3 or 4m, buyers sometimes ask not to turn it into a roll, but folded fourly. We warn you: this is not possible to do this, otherwise you risk damage the basis of glass cholester or spoil the surface with ugly chances. Although the question is how to make a piece of 4m wide on any floor above the first, while it remains open ...

The water absorption of PVC linoleums is 1-1.5%. They practically do not absorb moisture. If the water is accidentally leaving under the coating, the substrate may afford it. The dense structure of the upper layers will not evaporate the liquid, and the result is an unpleasant shaft. That is why it is not recommended to lay stuff on a felt substrate in rooms with high humidity, for example in kitchens and bathrooms.

The PVC Linoleum's fireproof is close attention in its commercial use, that is, where there is a chance of mass destruction of people in the fire (in offices, stores IT.D.). Enhance the fire resistance of such materials helps special additives. ABSE Household coatings are distinguished by a high degree of flavoring (G4). At what temperature, they will start melting or ignite and what substances to allocate at the same time - indicated in the fire certificate of a particular material.

Good, warm and ... quiet

The thermal conductivity and sound absorption of PVC coatings deserve a separate conversation. After all, the sounds and noises surrounding a person affect its health and well-being. PVC linoleum muffles the shock noise or sounds arising when walking or falling items, 2-19DB, and also slightly reduces the level of air noise indoor. This effect is especially noticeable in comparison with laminate and parquet.

The thicker coating, the better it is sound-absorbing, as well as heat-insulating properties. Extremely significantly, they are manifested with a thickness of more than 3.4mm. According to the experienced specialists of the company "Old Man Hottabych," the material remains longer than these qualities on the substrate from mechanically foamed PVC. It is he is preferable to children's and bedrooms.

It is worth clarifying that the foam is obtained in two ways: chemical and mechanical. For the case, the structure of the substrate cells is obtained closed, and from long pressure of heavy items, air bubbles can burst and flatten. In second, air cavities communicate with each other, and under the influence of the load, the air moves from some cells to others, and when removing it is returned. But the "mechanical" foam is more expensive.

The thermal-loving fellow citizens will undoubtedly want to know: can I put PVC-coatings on the heated floors? Yes, but under one condition: the floor temperature should not exceed 28c.

Opinion of a specialist

Different materials use different materials as substrates of modern PVC coatings. The most common non-woven substrates from polyester or polyamide, externally resembling felt, as well as foamed by a chemical or mechanical method of PVC. By deputy of them there are pluses and cons. Thus, the coatings on a polyamide or polyester-based basis well tolerate temperature differences. They can be laid on glazed balconies and summer cottages, which are not heated in winter and freeze before -30c. Avot material on a foamed substrate resembling a sponge, is not the best choice for such premises. It has a porous structure and filled with air having a certain humidity. With repeated freezing and thawing the wall between air bubbles begin to collapse. Of course, the substrate will not crush after the first year of use, but its service life will be steadily reduced.

Now, the undoubted advantage of the coatings on the foam basis is low thermal conductivity. They are well insulates the floor surface from the cold tie cold. In addition, water practically does not absorb (especially the substrate foamed by the chemical method) and can be used in rooms with high humidity.

Tatyana Kuznetsova, director of marketing for household flooring "Tarkett Eastern Europe"

He stepped on a glacier and a sin ...

PVC coatings for kitchens and corridors - the areas where the floor is often wet, do not have slippery. According to insurance companies, accidents associated with the fall of slipped or stumbling people are the main cause of injuries. The most secure materials providing good clutch soles with a surface due to the embossed layer. It is created by a chemical method, adding special microparticles to the top layer, or by mechanical embossed. Anti-slip coatings are in the assortment of most companies. This is a collection of Sens and Magic (Juteks), Optic, Woodstar, H2O (Tarkett), as well as Novilon Fortuna Life (Forbo).Anti-slip PVC coatings, imitating the embossed texture of natural wood or stone look very impressive. True, vigilant housewives, looking at similar materials, be sure to ask: Is it easy to clean their original surface? After all, the dirt is usually entrusted to the smallest pores of the working layer. To this not happened, many companies are applied to cover additional protection from polyurethane. It completely seals all microscopic cracks and does not allow dust and dirt to penetrate inside, due to which cleaning becomes easy and pleasant occupation.

Killers for bacteria

As you know, the pathogenic bacteria feel comfortable in a humid environment and are capable of forming huge colonies in seconds. The dry and clean surface of PVC coatings does not contribute to this negative process. Nevertheless, the largest producers decided that the floor in children's, bedrooms and kitchens needed additional protection. Tarkett Concern uses a special antibacterial layer Sanitized in MODA and Welcome collections. This brand is well known for sports lovers on a unique thermal power with a similar impregnation that prevents the reproduction of bacteria. Juteks also has a special MEGA antimicrobial collection. DOMO (Belgium) has developed for PVC coatings Antibacterial MICROBAN substance. According to experts, its polymer molecules are able to damage the shell of bacteria cells. WHAT has a material with truly unique natural protection from microbes - natural linoleum.

Opinion of a specialist

Choosing outdoor PVC coatings for the house, first of all pay attention to their wear resistance and the degree of residual deformation. It is notable to ask the degree of antibacterial protection of the material, because many have small children who often sick. The product with antimicrobial properties will help reduce the number of diseases. Now special collections of PVC coatings appeared on the market, the processing of which prevents the appearance of bacteria. But over time, quality data is usually reduced. The best material in this plane is natural linoleum. Linen oil, which is part of its composition, is a natural antiseptic throughout the entire coverage service life. Apretecically inconspicuous evaporation of oils provide their-shaped inhalation, strengthening the immunity of everyone who is indoors.

Peter Gorshkov, Senior Sales Manager "Forbo Floring"

New- well forgotten old

Amazing fact: PVC coatings appeared more than 50 years ago, but are known to almost everyone. Anaturated linoleum whose industrial production has existed for more than 140 years, cannot boast so popular. This environmentally friendly material is made only from natural components. Coniferous resins (rosephole) and linen oil are used in the incidence of binding substances and linen oil. Due to them on linoleum, pathogenic bacteria will not be multiplied. It is not only completely safe for health, but also recommended to people with impaired respiratory system and allergic diseases.The material is extremely wearless: even the most thin varieties (2mm thick) will serve at home not one dozen years. By the way, over time, due to the gradual evaporation of linseed oil and reduce elasticity, this coating becomes only harder. Like his fellow in the class of linoleums, it is not afraid of water.

For modern kitchens saturated with electrical equipment, it is important that static electricity is not generated on the surface of the natural linoleum. Of course, it is unlikely to fail the household appliances, but it is quite capable of interference on the TV screen, extraneous noise in the radio or telephone, as well as periodic shocks when contact with metallic objects.

Valid dreams from PVC coatings on natural linoleum remains dark molten spots from hot ashes of cigarettes. Azhelny traces of tobacco resins It is easy to remove alcohol or a special cleaner.

Naturally, the material with such wonderful qualities can not cost cheaply. Price of natural linoleum Veneto (Tarkett), Marmoleum and Artoleum (Forbo) - 600-700 rub. For 1m2.

The coating does not have high plasticity and flexibility, so when it is transported and styling, sharp geeks should be avoided so that it does not cracked. The first 5-6 week after the flooring of the linoleum must be protected from large loads, since during this period it is especially sensitive to scratches.

Everything needs a snarling

We will not consider the process of flooring of PVC coatings and natural linoleum in detail. We only note that a common look at them as on materials that do not require special skills for laying is not quite faithful. This is evidenced by typical problems that could be avoided if you use the services of professionals. For example, bloating appears at the flooring on an insufficiently dry base, as well as due to applying a very thin (less than 0.5 mm) or, on the contrary, is overly thick (more than 2 mm) of the glue layer for fastening the coating. The insufficient time of "deployment" or acclimatization of the material leads to the formation of waves.

Do not save on surface preparation. It should be smooth and smooth. Since the domestic market shows many leveling mixtures, it is not difficult to do it. It is important to choose the properly chopping composition for absorbing or not absorbing the base water to which the linoleum will be laid.

Special knowledge and skills are required at the flooring on the old coating. In general, without the help of specialists not to do, especially since the cost of their works is small: 150-250rub. For 1m2. Only they will be able to guarantee a long life of the flawless surface of the new floor.

The editors thanks the representative offices of Concern Forbo, Tarkett, Mosstroyplastmass, "Opus", Old Man Hottabych for help in the preparation of the material.