Errors in the design and construction of houses from a rounded log: causes of cracks, problems when installing windows.

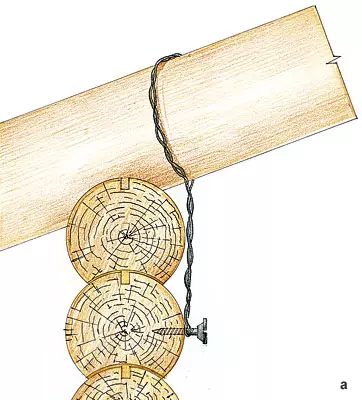

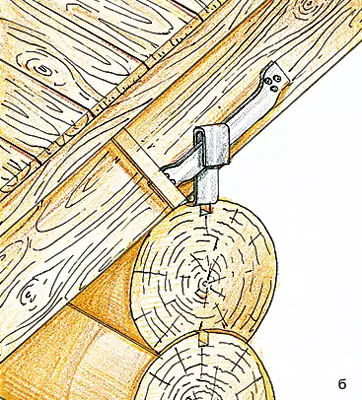

A- Wire screed. "hugs" a rafter foot and reliably attracts it to the top log of the wall. The flexibility of the wire allows the rafter to move for a short distance when shrinking at home;

B - special node consisting of a bracket and hook. The bracket is fixed along the rapid leg. The hook is passed between the bracket and rafting. It covers it from above, attracting a wall to a log. Self-fasteners

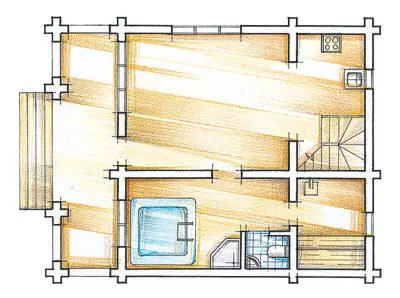

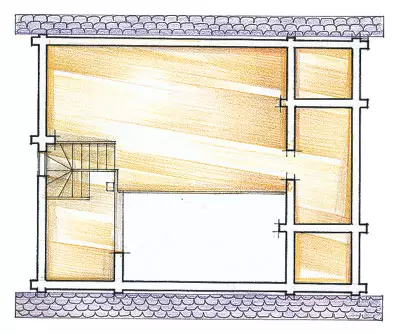

A- at the request of the hosts expanded the doorway, but at the same time did not provide for the upper crowns, tightening the facade walls;

Blocks balcony beams are based only on the lower, weakened log. Top log is not involved

A- bottom;

B-Upper

In recent years, the volume of construction of country houses from a rounded log of natural humidity grew by about 4 times. Alas, the seeming simplicity of working with the galindoint and the beauty of such buildings causes the desire to join them even with builders who do not have the necessary experience. Father, what it often leads to, and tells our article.

Rounded (or calibrated) log - Material Beautiful: Clean, Light, Smooth. The houses from it are obtained, just a look. It would seem to work with him, seemingly simply bringing a complete set of details sliced in moderate and even with connecting cups. Of them, as from bricks, a few weeks build a house. Everything happens quickly and simple.

This is a deceptive impression of simplicity, unfortunately, it arises not only from the owners of the future at home, but also from the house of the builders's grief. Isto such confidence is based on the absence of experience. Erecting from the α-tent of the houses-cans in size from 66 to 108m, the starting construction company decides that she is now all over the shoulder. House 1210m- easily! The attic floor is not frame, but from the log, to be more beautiful? No problem! Builds, rents and quietly goes to another object. In a year (and more often in two or three), the owners find it in their new home, from which it is not wonderful to test a real shock. Andasy to call builders. Athe answer: "When we handed you the house, it was like a candy! Even a year later, after the end of construction, you did not contact us, it means everything was in order. Who knows that you have done with the house for 2 years? We are in what happened Absolutely not to blame. Innen call more. "

The outcome of such a dispute usually solves the court. But to file the claim, the owner requires a document certified by experts, in which all detected flaws should be recorded and the reasons for their appearance are indicated. Then the hosts and recall that there are independent experts, whose task is to protect the customer from the negligent builder. It is they who will have to make the necessary conclusion.

Together with the technical director of the company "Independent examination of construction quality" (Russia) we visited two objects, one of which was already built long ago, and work on the second is at the final stage. What we saw there and formed the basis of this article.

|

|

|

|

|

|

The thick layer of ice on the roof (a) and the icicles hanging on the attic windows (b) indicate that the ventilation guide did not perform its functions. The cause is the absence of air inlet holes on the oats of the roof and the outlet in the skate (g, e). To make sure that it was necessary to "open" the roofing "pie" (B) on one of the roofs of the roof. Since pairs from the gap through the insulation are not deleted, the wooden doon is shown. |

Object First

This two-storey house (without basement) with an area of 270m2 was built from a rounded larch log and put holders about 3 years ago. For the first year after the construction of the box, the owners did not fit into him, waited until the building gives shrinkage. Then they started finishing, which lasted for quite a long time. After that, it began to import the necessary engineering equipment for the boiler room, sauna, a small IT pool. Forward the queue acquired and the heating equipment was installed by the beginning of winter. Akak only it began to work, it turned out that on the roof of the house there was a thick layer ... ice! When it feels, the droplets begins, water flows from the roofs of the waterproofs and sinks of the roof.

Then the owners of the house for the first time and called an expert. He recorded seen on the film and issued the owners a conclusion: most likely, construction technology was broken. This led to the fact that the ventilation clearance in the roof is scored or closed, so there is no ventilation of the underpantle. Household owners in the middle of winter did not do anything, but simply took note of the information. In the spring, they came close to the technical equipment of the building. Everything you needed was able to purchase only by the end of the one, they were brought, lay on the first floor and gathered to mock. Hevdrug found that the attic floor falls apart. The call to the building built house did not give a positive result, after which the expert was again invited. He was horrified and suggested that it was not too late to call specialists who would save the situation. Therefore, when we first hit the object in the company's society, there was a brigade of Montolith (Russia) employees, trying to figure out what happened.

Below every criticism. What we saw has nothing to do with the normal quality of construction. Inside the house, the gaps were increased between the crowns in the area adjacent to the ceiling, as well as throughout the height of the nurse's walls. Both long facade walls were somewhat curved in the side of the street, as evidenced by a rather wide horizontal gap between the first flooring floor and plinth (the wall moved to the distance exceeding the width of the plinth). Paul, naturally, twisted. The inner partitions almost crumbled into separate logs, from this they held them anywhere where wooden braided. Freed from the load, some logs twisted corkscrew. Workers under the guidance of the Proba broke the plinths and platbands, disassembled the door boxes and the deformed frame walls - until the troubles had happened, it was necessary to take action as soon as possible. We deeply planned the owners.

Technical side of the issue. It is no secret that shrinkage of a wooden house from the material of natural humidity (which is often 30-40%, while lowering admits no more than 25%) occurs for two reasons. The first-drying and shrinkage of logs (the magnitude of the latter is 5-8%, depending on the initial moisture of wood). For example, a log diameter of 240mm (it is such rounded logs that are used in this case) by the end of the shrinkage may have a diameter of 220-230 mm. Second-ground logs under the weight of the load and the disclosure of cracks (shrinkage comes to 2%). Thus, the total shrinkage value is equal to 6-10%, that is, at the initial height of 3m to the end of this process, the walls are sometimes lowered by 15-20 cm.

Now about shrinkage deadlines. It is believed that it is maximum in the first year after the construction of the house, and in the future its magnitude can be neglected. As practice shows, this is not quite the process of shrinkage of the house of the wood of natural humidity can last up to 7-8 years. Dates depend not only when the tree is cut (winter or summer wood), and from the initial moisture content of the material, but also from the design features of the cut, and most importantly, on the conditions of its drying.

As a result of the fact that the inner walls dried significantly faster than the outer (and therefore faster gave a complete shrinkage), they freed from the load created by roofing design. The result is huge slots in the upper zone.

It is generally accepted that a year after the construction of the box, the heating system and other engineering communications are mounted, perform an external and internal finish, after which they are aligned. Live and drown a house. Juda if the owners laid down a housewarming, they drown in all the power so that the wood dried faster. But just how does it happen? The inner walls are dry primarily (heat surrounds them from all sides), the exterior is much later (and the southern faster, north slower). It has such drying to uneven deformation of the structure as a whole.

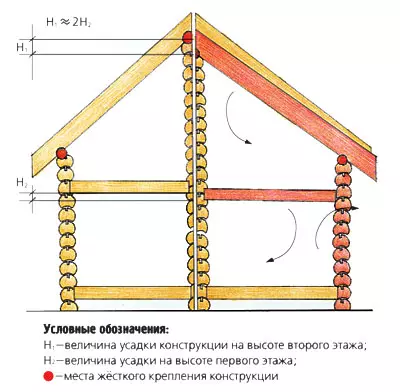

This is especially brightly manifested in houses with a sphere rafter system, where the walls, frontoths, and the main-partitioned partition of the attic floor are made of otlindering (it was the house that we visited the house in which we visited). The design and so stands unevenly, and here there are still frontal and inner walls are significantly higher than the outer (the higher the wall, the greater the total value of its shrinkage). If the rolling rafters, which are based on one end on the log walls, and the second line of the skiing bar, are rigidly connected and with the other, the misfortunes are not avoid. The attic floor will begin to fall apart. The laws of geometry will work: dropping together with the skate bar, resting on the frontaths and the inner walls, the rafter legs will be put forward towards the street (their length does not change) and, being rigidly connected with the walls, pull them on. As a result, the outer logs collected on the impudent walls (they are relatively moving structures) will be arched at all height towards the street. Following the angle of inclination of the roof of the roof, the greater will bend. All this is dangerous than the fact that the beams of overlappings are usually firmly attached to the inner walls, stretch out of their nests in the exterior walls. Inesl the length of their supporting platform on the wall is less than the magnitude of the progress in the connection site, the overlap can simply collapse.

The described phenomena is possible in homes not only from the rounded log, but also from the usual (darling), as well as dried under production conditions, but not brought to humidity 18-20%, and, moreover, from a natural humidity bar (provided that FRONTONONES AND HIGH INTERNAL WALLS Folded from the array). There are also other scenario of the behavior of the revolving rafting system (the truth, no less sad). Beams can either break away from the wall or skate bar, or crack, and then break.

A vanalogic situation The use of hanging rafters does not lead to such dramatic consequences. Even if such rafters are torn away from the walls or skate, while the outer walls are not "breaking out" - it will not give a tightening horizontal beam (tightening). Well, a monsard of a frame design at all is not threatened: as it is known, the tree of the longitudinal shrinkage practically does not give, only transverse.

Apparently, the logs began to get out to each in their direction even during the period of construction, which forced the grief-carpenters to bore the ends of some log cabins. The fact that the logs will continue to get out, the electricians were not suspected at all and calmly laid in the longitudinal grooves on the ends of the electrocabel's logs. Miraculously this cable has not passed anywhere.

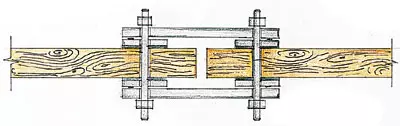

As the situation saved. The lip cover was revealed, the rusty nails were removed with a length of 250mm connecting the rafters, and installed a simple hinge element from metal plates (all its parts are galvanized). With a further shrinkage of the house, the hinge will allow you to change the geometry of the connection of the rafter feet in the zone of the skate, without breaking away from it. Together the joint of the raftered with the wall set the sliding elements. It can use a wide variety of designs that are considered to be a good firms, so they do not like to show them. But no secret, nor special technical difficulties in such an element. The easiest case is a wire screed that "hugs" a rafter foot from above and attracts it to a crutch, driven into a walled wall with two crowns below. A more complex variant is a combination of a bracket and hook (both elements are made of sheet steel with a thickness of at least 4mm): the bracket is installed in the connection zone along the rapid leg, the hook covers the bracket from above and attached to the upper crown.

After installing the sliding elements, the corners were removed, rigidly fastened rafting legs with an upper crown. When the design "let go", she immediately began to sit under his own weight. A results of the trim legs have come out to approximately 5 cm. The outer walls at the same time began to straighten up. The process was brought to the end with a steel cable and a powerful winch.

Further, as they say, the case of technology: the insulation was put in place, they restored moisture and vapor barrier and roofing in the area of the skate. The threshold zone created a hole for the air outlet from the ventilation gap, which was previously absent (about what the violations lead to the Ventzazor device, we will tell a little later).

This installation of windows is nothing in common with GOST 30971-2002, regulating this issue, has no. What are there three-layer structures from outdoor waterproofing, foam insulation and internal vapor barrier! Window boxes are dugged (a), the gaps are laid down with boards (b) and shut down pacles (B). Moreover, they also placed the electrocabolic.

At this place, we will break our story about the first object and we will tell the reader, which was the second home (so that the mistakes could be generalized).

Opinion of a specialist

How many times caught? Those who decided to build a wooden house should be completed with the idea that the post-witty repair will not be avoided. The cracks will appear in any case, the question is only in their quantities and sizes.

The experience of our company shows that the house should be caught at least 3 times. First, during construction, when the sealant is laid in interventic seams and connecting cups. The second is after the main shrinkage (after 1-2, sometimes 3 years). The third, final, - after another 5 years. The second and third core must be capital when the appeals appeared. But it is impossible to allow this process to cause the so-called lift lift due to an increase in interventical seams. It is better to carry out re-cauldation using materials such as Chesna Flax or Red Moss.

How to "dry" the house? The house built from the material of natural humidity must be gradually bringing to the norm. The wation of the first year should occur natural drying. A year later, you can turn on the heating, but in gentle mode so that the temperature in the rooms is 5-8C. With this mode, the tree dries slowly and long. Ito is good - less will be deformation of the structure and the number of cracks in the logs. It is impossible to live in a house at a similar temperature, so it is necessary to accept in advance with the fact that you are in 2 years in it.

The problem of complex roofs. Even the bartal roofing design may behave on a large house inadequate. If the roof is a four-tie or, as is now fashionable, a multi-level complex shape, then its behavior at shrinkage is almost unpredictable. Such a roof is generally better not to install the house at least 1-1.5 years, as long as the main shrinkage occurs, stands under a temporary coating (for which it is used, for example, rubberoid). Tomple after this, thoroughly examining the rafting system, you can mount the roofing material.

Vyacheslav Kuletlav, director of the company "Monolith"

Object two

This house is built from a pinned pine log of natural humidity and is located in one of the near Moscow cottage settlements. The object entered the stage of completion of the building of the building of the building: there are walls and roofs, but there are no windows and doors, the internal and external finish is not performed. At this stage, the owner decided to say goodbye to the previous builders, and the remaining volume of work to instruct another company. To evaluate the quality of the work already performed, and the expert was called.The first thing we drew attention to, entering the house, - drums on the walls and a specific smell. It turned out that literally before the arrival of the owner, the builders began to lighten the walls with the help of a chlorine-containing bleach (he was a source of smell). But why?

Probably, the antiseptic processing of the logs, of which the log house is assembled, before that they have never been carried out (in violation of the requirements of SNiP "Wooden structures"). As a result, a lot of dark points appeared on the surface of the tree, which tried to remove builders. In easily accessible surfaces, it was possible to do this, but in the joints of the crowns, on the ends of the logs, as well as where the walls are connected to the roofing structure, the dark spots remained (the position was complicated by the fact that the upper parts of the logs were covered already installed steam barrier).

When should the antiseptation be carried out so that the tree is not infected with mold and rot? The first time the wood is treated even in factory conditions or before transportation, since it is not insured during this operation during this operation. The second time when storing logs on the plot. At the same time, they must be laid in a stack on gaskets, otherwise the tree will not be ventilated. The third antiseptation queue occurs when the house is assembled and covered the roof. These places and nodes, access to which will be impossible, processed during the assembly.

Now that we talked about the individual features of each object, consider typical errors made in design and construction.

Project miscalculations

Typical error N 1- No ventilation of the attic space. In practice, the attic to the entire height of the rare construction is rarely elevated. Significantly creating a cutting part of the attic space of a warmed ceiling. Thus, over the house there is a mini-attack 3-3.5 width and a height of 1-1,5m. The trouble is only that the project is forgotten to lay the device of its ventilation. For 2-3 years, a pair of moisture overlooking its space in its space will cover the rafter and Konk rot ... The output is one: to make ventilation holes in log films and cover them with decorative lattices. It is even better to cut the auditory window: then the ability to control the state of the part of the rafter system in the attic will appear.

Error N 2- Lack of input and outlet air holes. It should rise along the roof slide one or two ventilation gaps, carrying out a pair of moisture coming from the premises through the insulation. At the same time, the Ventzor himself can be arranged in all the rules, but there is no benefit from it: on the project of the sink of the roof tightly sewn with clapboard, there are no graduation cracks for the air of the roof. Over time, the same thing will happen as on an uninterrupted attic: the roof doom will rot, and for the neutropyl and the horse. This was the first object: when at one of the slopes of the attic, the inner trim and the roofing "pie" (vaporizolation, insulation, moisture insulation) opened, were found under them the crate for 3 years. If the defeat is a strong, the roof is to immediately disassemble. But it is better not to bring to such a condition and demand at the stage of construction or acceptance of the house to install ventilation grilles in the sinks. Even more reasonably- replace the trim lining, for example, perforated siding.

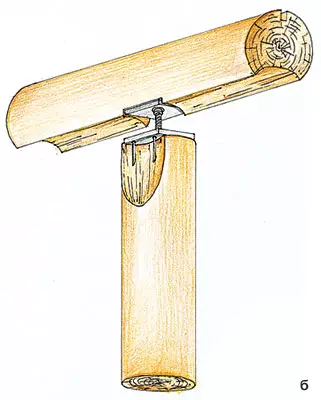

Of course, here are not all errors in the design, only typical for both houses considered and the most significant. Avoid them is quite a lot. For example, on the second object in two transverse internal partitions, doorways at the request of the host have significantly expanded to visually combine the premises. True, at the same time cut off the top crowns, which should "pull" the facade walls. Such "ties" will have to restore. There, we saw a balcony with a length of the entire side facade, the beams of the flooring of which were based on the one side on the wall, on the other, on a log, which lies on the console supports. Together, the logs of the beams are weakened, and over time it will come. However, over a weakened log lies the second, the whole, and not involved in the design. In order to avoid trouble, it is better to pull it with the lower bolts.

Why appear slots?

In the log walls often arise wide gaps between the crowns. The reasons for their appearance are several.

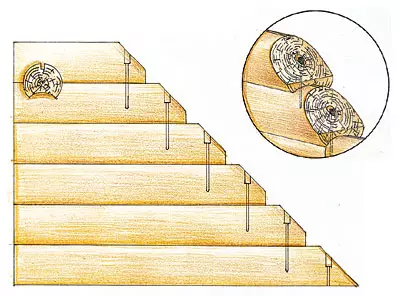

First Waving logs on the brave. Professionals advise to collect logs only with the help of wooden brands, but in no case are not metallic (they certainly rushes), the more not to use the logs made from the reinforcement (on their corrugated surface the log necessarily freezes). Holes under the camps need to drill strictly vertically. Everyone's wooden brazers must be non-round, and square: they have less contact area with the surface of the hole in the log (therefore, less friction force preventing shrinkage). It is necessary to have them in a checkerboard in the height of the wall at a distance of no more than 1.5 m from each other. Babe braided with a wooden threshing with a small force.

For copiers, it is necessary to use more durable than log, material: for example, if the logs are pine, then the heat-birch or oak. Their humidity should be the same as the moisture content of the wood, - when drying, is simultaneously compressed and the heel, and the hole.

The second reason- Insufficient load on the logs. Especially often the gaps appear between the logs of the frontones, which is explained: above these areas there are no multi-meter walls (as above the crowns of the walls of the first floor) and the bottom of the roof will not press the weight (if it is not sophisticated). How to be?

The logs, from which the fronttones are folded, can be "loading" using special devices resembling spring valves of the automotive engine. They consist of a screw running on the springs and two washers. Install such "valves" in advance drilled on both ends log logs. Compressed when installing the spring of the device in all conditions will press the top log to the bottom, reducing the likelihood of the appearance of the gap. The details of the "valve" must be made of stainless steel or galvanized.

The third reason Drinking logs. It is to blame for this so-called swordness of wood, and simply put, the twisted of its fibers on the helix. The magnitude of this twisting depends on the place where the tree grew is in more often the forest or on the edge. For the first reason, the probability of the appearance of swovels is less, in second, more. During drying, especially as a result of a sharp inclusion of the heating system, thousands of logs, mainly low-loaded and not bonded by naked, will definitely begin to get out. Then, on the one hand, the walls of the gap between the crowns can practically disappear, but on the other it can expand greatly. It will not be possible to correct the twisted log in place. The output one is carefully to cross the gaps. Of course, the interventic seams will not be less from this, but the appearance of the wall will improve significantly.

Fourth reason Not spent on time adjustment of jacks - shrinkage compensators. These mechanisms installed on vertical column supports have long entered the practice of wooden house-building. It is quite convenient and simple: twisted the nut on the device- and the reference site shifted in height by magnitude equal to the shrinkage of the log wall. Often regulate the compensator is necessary in the first 3 years (period of intensive shrinkage). Avoobacope, as practice shows, it has to do for 5-8 years. For the compensator to work all this time all this time, it should be made of stainless steel or have galvanized parts.

The attempt to clean the cut with a bleach was only a partly in part in the easy-to-access surfaces, black spots disappeared, then in places closed with vapor insulation (a), on the joints of the crowns (b) and the ends of the logs (B) remained.

Problems of installation of windows

In order for the walls at home, the walls do not dispel the window and door boxes, two receptions are used. The first: in the ends of the logs overlooking the window (and the door) of the opening, they make a groove with a cross section of 5050mm, which invests the so-called casual lump. He prevents the bushing of the logs, and it is for him that the window frame is attached. The second method is technically more complex: on the ends of the logs are cut out a longitudinal spike, which is worn by a timber (cluster) with a corresponding groove. Above the box and lump leaves a gap that exceeds the value of the expected shrinkage, and lay it elastic insulation.The window or door frame should be attached only to the platform (casing) with nails or self-tapping screws, the length of which does not exceed the total thickness of the frame and the cluster (casing).

Be carefull!

Probably, you have already understood that the construction of a house of solid sizes even from such a simple material on the type of material, as a rounded log of natural humidity, it is advisable to trust exclusively by professionals. During construction, they use technical techniques described in detail, and their own know-how. Keep in mind that all mentioned seemingly simple methods and details in aggregate can somewhat increase the cost of construction. However, it is worth it to go, then not to face a lot of trouble, and most importantly, with additional expenses.

Opinion of a specialist

On warranty obligations. At home "Houses residential one-headed" There is a rather unusual point: "At the request of the developer in the composition of the house documentation, a heat-power passport should be provided and the instruction manual of the house ... Instructions ... must contain the data necessary for the home owner to ensure safety during operation. In the number of information about the main designs, engineering systems, the location of the hidden elements of the frame, hidden wiring and engineering networks, as well as the limit values of the loads on the elements of the house and its electrose. "

Agree, the item is wonderful. It is a pity that this wonderful point almost no one performs. Amezhdu, such an instruction would help the owners of the first object described in the article, where there was no proper control over the shrinkage of the building from the performers, to avoid many troubles. At least they would know what work and in what time frames should be held, and in time reminded of this builders.

To oblige construction workers to perform during the warranty period, the necessary operations can only be able to include the appropriate paragraph in the "Warranty Obligations" section of the contract concluded between the customer and the Contractor. If this was not done in a timely manner, then an additional agreement should be compiled to the agreement mentioned.

Transmission guarantees. In accordance with the law of the Russian Federation "On the Protection of Consumer Rights" after the construction of the construction, the Contractor must give the owner a guarantee for a constructed building, which should be reflected in the contract mentioned above. What should be the term of this warranty?

In art. 29 (PP. 3, 6) of this law - "Consumer Rights When detecting the shortcomings of the work performed (service provided)," it is said: "The consumer has the right to make requirements ... within ... five years Regarding shortcomings in the structure and other real estate.

... if this requirement is not satisfied for twenty days from the date of its presentation of the consumer or the detected disadvantage is unrelated, the consumer for its choice has the right to demand (meaning through the court): relevant reducing the price for the work performed (provided); Reimbursement of expenses incurred by them to eliminate the shortcomings of the work performed (service provided) on their own or third parties. "

Sergey Zelensky, Technical Director of the company

"Independent examination of quality of construction"

The editors thank the ABS-Stroy, Monolith and the "independent examination of the quality of construction" for help in preparing the material.

The enlarged calculation of the cost * building a house-bath with a total area of 99.4m2, similar to the submitted

| Name of works | Number of | price, rub. | Cost, rub. |

|---|---|---|---|

| Foundation work | |||

| Layout, development and garment | 108m2. | 107. | 11 556. |

| Dump removal of dumplings | 28m3. | 520. | 14 560. |

| Device of the foundations of ribbon reinforced concrete | 13,5m3 | 1800. | 24 300. |

| The device of retaining walls from concrete blocks (base) | 6.5m3 | 900. | 5850. |

| Horizontal waterproofing | 18m2 | 45. | 810. |

| TOTAL | 57080. | ||

| Applied materials on the section | |||

| Concrete heavy | 14m3 | 3100. | 43 400. |

| Block concrete 400200200mm | 450 pcs. | 45. | 20 250. |

| Masonry heavy solution | 1,7m3 | 1490. | 2533. |

| Hydrosteclozol, Bituminous Mastic | 18m2 | - | 940. |

| Armature, Formwork Shields and Other Materials | set | - | 25 420. |

| TOTAL | 92540. | ||

| Walls, partitions, overlap, roofing | |||

| Preparatory work, installation and dismantling of scaffolding | set | - | 11 000 |

| Cutting walls and partitions from logs | 48,5m3 | 2700. | 130 950. |

| Assembling overlaps with laying beams, with floors | 67,2m2 | 382. | 25 670. |

| Cabinet Terrace | set | 10 010. | |

| Assembling roof elements with crate device | 128m2. | 319. | 40 832. |

| Isolation of walls, overlap and coatings insulation | 24m3. | 280. | 6720. |

| Hydro, vaporizolation device | 195m2. | 76,3 | 14 879. |

| Soft roof coating device | 128m2. | 240. | 30 720. |

| Filling opening windows and door blocks | 14m2. | - | 33 490. |

| Flooring device, ceilings, finishing and other work | - | - | 203 590. |

| Antiseptation ready-made solutions | 1740m2. | thirty | 52 200. |

| TOTAL | 560060. | ||

| Applied materials on the section | |||

| Log construction | 48,5m3 | 6000. | 291,000 |

| Sawn timber | 18m3. | 4200. | 75 600. |

| Paro-, wind-, hydraulic films | 195m2. | - | 13 964. |

| Mineral wool insulation | 24m3. | - | 49 600. |

| Poland boards | 6.1m3 | - | 60 690. |

| Interwidden insulation, bent, fasteners | set | - | 36 035. |

| Roof coating "Top Single" and decorative elements | 128m2. | 460. | 58 880. |

| Window and Door Blocks | 14m2. | - | 101 510 |

| Neck-protecting compositions | 867kg | 36. | 31 212. |

| Finishing and other materials | set | - | 202 390. |

| TOTAL | 920880. | ||

| * -Contacts completed without accounting of overhead, transport and other expenses |