The main types of carpets. Features of the tuffing method for the manufacture of carpeting: a variety of textures. Specialist comment.

Main types of carpet floors:

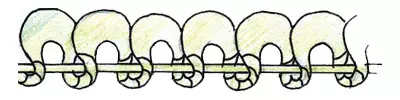

A-cutting pile: coatings are comfortable, easily clean, suitable for rooms with a small load on the floor;

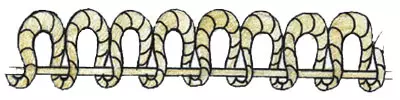

B - loop: Elastic, better restored after crushing

Diverse textures of carpet coatings with intriguing names "Berber", "Scroll", "Saxon" or "Frieze" are formed from loops, cutting pile or combinations thereof.

Modern carpet covers inherited from their aesthetic appeal, tactile comfort, as well as very important heat and sound insulation properties for home. Progressive technologies for the production of natural fibers, artificial threads and their combinations make it possible to make the material not only beautiful, but also practical. As a result, when choosing a carpet cover, you can pay more attention to its decorative properties, that is, the color, drawing, texture, thanks to which the unpretentious floor will turn into a vivid expressive element of the interior. They will talk and talk.

Opinion of a specialist

The consumer properties of carpet coatings are influenced by a whole complex of factors: a pile material, its "density", view and special processing methods (antistatic, anti-infection IT.D.). Each of these factors is important, but only their optimal combination is capable of providing the required result.

IMATING VORS All clearly: the better the quality fiber is applied in the manufacture of carpeted coating, the better results we have the right to expect.

The "density" of the pile in the domestic understanding should be considered as a combination of a number of technical characteristics of the carpet covering: the number of stitches per unit area, height of the pile and its specific gravity. These characteristics are interrelated. So, a carpet with a smaller number of stitches per unit area, but with a higher pile, it can have a greater specific weight of the pile than a carpet with a flax number of stitches, but a lower pile.

Different types of pile look differently, it is differently perceived by the load and resist to it, in different extent susceptible to abrasion and contamination. Choosing a carpet, keep in mind that in addition to aesthetic preferences you need to decide that it is more important for you, comfort or wear resistance.

Sergey Khomyakov, Leading Specialist of Carpet HOUSE

Why taftting?

There are several methods for the production of carpets and carpets. The oldest of them- woven, in which the pile is intertwined with the bases of the base. The most economical, needed, when the mass of unrelated pieces of fibers is based on special needles with jar, turning in a homogeneous material that resembles felt. However, most modern carpet coatings are made by a tuffing way. This technology developed in the middle of the XXV., Making a real breakthrough in the carpet industry, allowing to produce hundreds of meters of the canvas per day.

The main principle of tafting is the firmware of the woven or nonwoven base with patent threads. The process looks like this: the needles make the thread through the foundation, and the hinge obtained from the reverse side picks up special hooks. The vitog is formed a coating with a loop pile. Hooks can be supplied with a blade that cuts the loops, turning them into a cut-out pile. Changing the distance between the needles and the number of stitches per unit area, obtain coatings of different density. To fix the hinges and give the carpet strength, the reinforcing material (jute fabric, synthetic grid, felt foamed) is glued to it with the help of various latex compositions.

Types of pile of tuffing carpets

| Non-level loop. Coatings of this type consist of loops of the same height. Different with high wear resistance. |

| Loop multi-level (structural). It turns out as a result of combining loops of different height, due to which a volumetric pattern is formed on the surface. |

| "Berber", or a large loop. Very beautiful, elegant coating. It consists of different hinges, which, in addition, may vary in color or shade, which enhances the "sculptural" effect. |

| "Scroll", or a cut-off loop pile. Created by haircut looped multi-level coating. The cutting part forms pile areas, and low loops remain uncut. The coating looks elegant than the usual loop, but it is easier to crush. |

| Rezanny pile. It occurs after cutting the loops with the subsequent haircut. Less wearless than looping, but softer and more pleasant to the touch. In the height of the cutting pile of coating are divided into short-ski (3-5mm), stretch (6-10mm) and high-voltage (more than 10mm). |

| "Velours". Dense low cutting pile of non-executed threads flipped after a haircut. Traces of steps and pollution are well noticeable on monophonic velor coatings. |

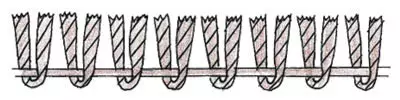

| "Saxony." A cutting pile of twisted and sharpened, like a pencil, a thermofixed thread. The surface of the coating acquires a "grain" texture on which there is no trace. Twisted thread has a springs effect and high focus resistance. |

| "Frize." Rezanny pile from a strongly twisted thermofixed thread. It has high focus resistance, capable of recovering (rising) after load. |

| SHEG (chips). Very long cutting pile, the fibers of which fall under the weight of its own weight. Coatings with such a pile provide comfort, good heat and sound insulation, but are complex in care. There are many yarn on their production, which makes the material quite expensive. |

| Rezanny loop pile. It is a combination of a cut and loop pile of different (less often one) height. Allows you to get interesting textures and bulk graphic patterns. |