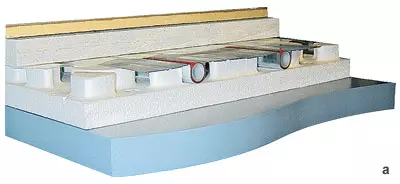

Stacking technologies for the undertensional floor heating system for heating the upper floors of houses and rooms in buildings with "weak" overlaps.

Photo E.Lichina

Photo by A.MEDVEDEV

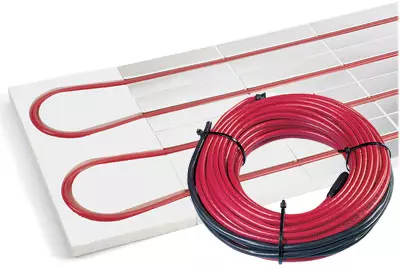

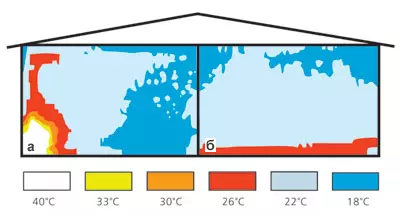

Components of "dry" systems of outdoor heating

As a heat generator heatsing the coolant, highly efficient thermal pumps are increasingly used in recently

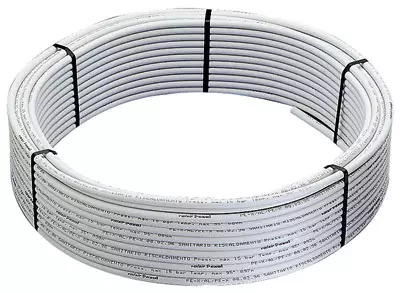

Metal-polymer pipes for systems of warm floors

Heating the upper floors of wooden country houses or other rooms in buildings with "weak" overlaps, as a rule, is carried out using radiator heating. However, it is possible to warm them in a different way, for example, with the help of a lightweight system of warm floors. About this small approach to the arrangement of outdoor heating in Russia, we will tell.

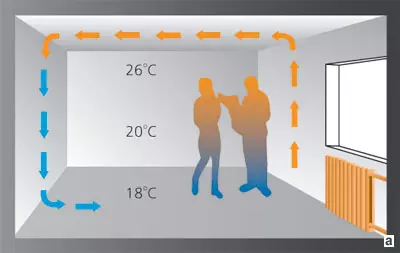

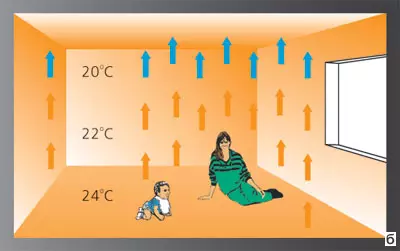

Alternative to alternative

We must immediately say that the warm floor uses popularity is quite deserved. After all, with this method of heating the room, the surface free from the furniture under the legs radiates heat. Obones the most favorable ratio of temperatures in the height of the room. For example, in residential rooms it is 24-26c at the floor and 20-22c at the head level. Such a temperature regime is perhaps unable to maintain any traditional heating devices. Yes, in contrast to conventional systems, the warm floor does not initiate convection circulation air, therefore, the air is not saturated with dust. It is noted that outdoor heating is very favorable on the health of the elderly and children, especially suffering from various allergic diseases.However, quite often developers have to abandon use in their dwellings outdoor heating. The reason is the insufficient carrier ability of overlaps, especially on the floors above the first. Indeed, traditionally used in construction and often imposed by the customer as the only possible, "wet" system of outdoor heating is quite an insidious. When it is created on top of a thick layer of thermal insulation (50-200mm), the leveling screed is usually poured, and then, another layer of concrete, inside of which the heat-emitting circuit is hidden. Next, the vapor barrier and the finishing floor covering (tile, parquet IT.P.). The total thickness of such a "cake" reaches 150-300mm, it loads overlap weighing 250-300kg / m2, and sometimes more. This weight is applied only in buildings, where the floors are made of concrete slabs with a bearing capacity of over 500-600kg / m2. Askage, wooden or other similar designs withstand such a significant load is often simply unable.

In addition, the "wet" system not only overlaps the overlap, but in some cases noticeably "eats" the height of the rooms. This is especially noticeable in the reconstructed buildings of the construction of the 70-80s. last century. As for country houses, in the case of cosmetic repairs, not all owners are ready to wait for the whole month, while you can use the heating system (since the time required for the complete drying of the concrete screed is 29 days).

Alas, few of our developers know that along with the "wet" system of outdoor heating there is also "dry", or fearless. It is delivered from the shortcomings of its heavy colleague. Instead of a concrete screed in this case, special metal plates or foil are used, distributing heat from the pipe or heating cable or on the substrate, or directly on the floor coating. The main difference between the "dry" system from "wet" is to reduce the load on overlap (for example, in wooden buildings it is about 30kg / m2, which is almost 10 times less than in the case of a concrete tie). Having laid a "dry" option at the stage of designing a country house, you can noticeably reduce the general capacity, refusing unnecessarous structures. Do not do without a "dry" system and, if necessary, reduce the thickness of the floor "cake". Its minimum height with this method of heating ranges from 13 to 50-60mm. The lack of "wet" process significantly reduces the installation time. And immediately after its completion, the system is ready for operation.

The "dry" system due to the features of its design (thermal power, which can be transmitted to the 1M2 premises heated surface, usually does not reach 100W) is most often used for additional heating. It makes rooms more cozy, heating floor to physiologically comfortable temperature. However, in the regions with a mild climate, a fearless option is used and as the main heating system (satisfying the need for the warmth of all rooms of the apartment or country house). Mounted such equipment can be mounted in a children's, office, living room, bedroom, corridor and other rooms.

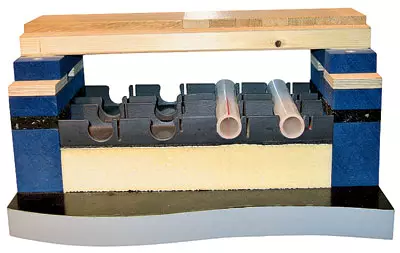

Recommended Time Mounting technologies are used directly in wooden floors on lags, as well as technologies applicable to all types of existing floors with a solid flat base (concrete slab, adjustable floor from plywood IT.P.). Latest constructions are called the ranks. It and others can be created both based on polymer pipes (with a coolant supply) and using heating cables. Next, we will talk about some recipes for the manufacture of "dry" undertensional systems of outdoor heating.

Anatomy of heating

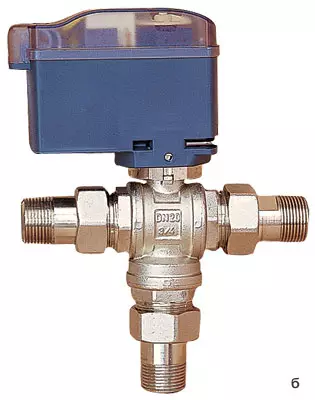

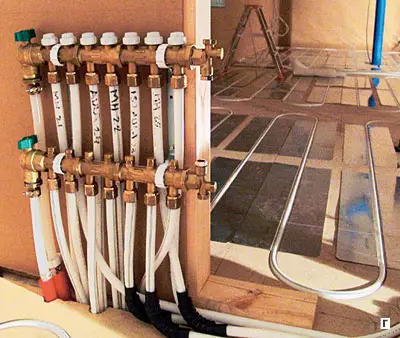

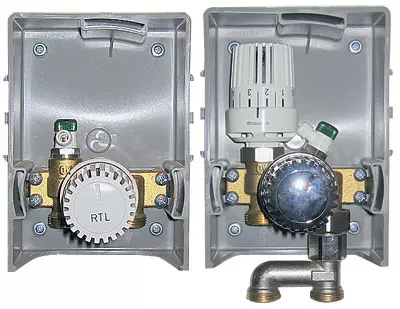

For "nutrition" of water-free systems in the cottage, a boiler should be provided, a collector, circulation pumps (for each heating circuit), an expansion tank, as well as a control system. In general, the main executive node of the warm floor is the thermostat (mixing unit). It affects the water temperature in the circuit, mixing water from the boiler or other heating source (temperature to 90C) in the desired proportions (temperature to 90C) and returning from a warm floor system ("reverse"). Create a contour in the room where hot water is already connected from the boiler, with the reconstruction of the room, you can, for example, using a special device for installing OVENTROP.

Over warm water

The scope of "dry" warm floors with a supply of coolant-private houses equipped with water heating systems with forced circulation. The main heat transfer elements are durable and easy-to-install polymer pipes from stitched polyethylene or metal flux (metal plane), and a source of energy-heated coolant (most often water), which, passing along the pipes laid in the floor, gives heat to a finite coating or substrate.

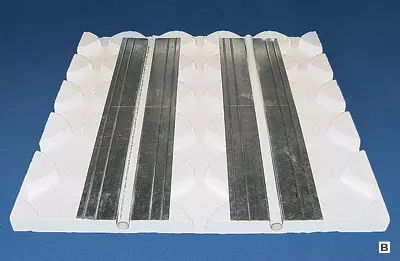

The main component of most "dry" systems with a pipe coolant-metal (aluminum, galvanized) plates with a groove for a dense coverage of the pipe. They are covered with 70-90% of the heated floor area (the plates are located under the finish coating or under the substrate). In essence, they replace concrete, providing a uniform distribution of heat from pipes with hot water over the entire surface. Plates can be divided into parts, customized along the length of the room. In effectly from the manufacturer, they either have perforation for quick installation, or elementary cut into pieces with a fitter's instrument (hacksaw, scissors for Metal IT.P.). With proper laying, aluminum plates exclude the probability of appearance on the floor of the heat zebra (alternation of the bands with increased and reduced temperatures), as well as zones of local overheating, resulting in a damage of the coating (milking parquet or geepboard).

"Dry" systems are characterized by environmental friendliness (no emission) and economy. The heating costs of the coolant are usually small, especially when used in a cottage, a natural gas boiler, or a thermal pump. However, the initial costs of building such installations are usually quite and very significant. So, the creation of a water-minded system in one room with an area of 10m2 is often accounted for at 21500-40500 rubles. and more. However, if the heated is arranged in several rooms of the country house, the costs are significantly reduced: you can do the amount of 215-940 rubles. For 1m2 area. In addition, using a water-minded system, it is difficult to obtain a specific power exceeding 60-80W / m2.

To illustrate installation technology "Dry" system with a coolant supply in the wooden floor on the lags Consider the Wirsbo system (Uponor, Finland). It can be used in the case when the distance between the lag axes does not exceed 600 mm.

Initially, it is necessary to put insulation between lags, most often this mineral wool. Next to the lags nourish boards with a cross section of 9522mm with moisture content of no more than 10%. There should be a gap between the boards (at least 25mm, the specific value is determined when designing the entire system). On the length of the board, it is necessary to cut over 30cm from the transverse walls to leave the free space for turning the pipes in the opposite direction (when laying the contour). On the floor-free lags, located near the walls of the room, to align the floor, it is necessary to navigate the boards with a cross section of 9522mm.

After completion of these operations, the lags are formed for the installation of aluminum heat distribution plates. They should be placed according to the scheme of laying pipes, ranging from the outer wall, and fasten with nails so that the grooves for the pipes are immersed in the gaps between the boards and are coaxially located. Next, mount the Wirsbo-Pepex pipe with a diameter of 20mm. Then, on a layer of vaporiozolation layer, pupil 2mm thick plates are placed (in the original technology, special tape plates are used) or the plates from GWL (this material is often used in Russia, if it is not possible to purchase original chipboard). The layer of plates lay across the boards by sections of 600mm wide (equal to the turn of the lag) and fix with screws, tongs and grooves are glued. Punching floor covering can be used by a sex board, parquet, tile.

|

|

|

|

|

|

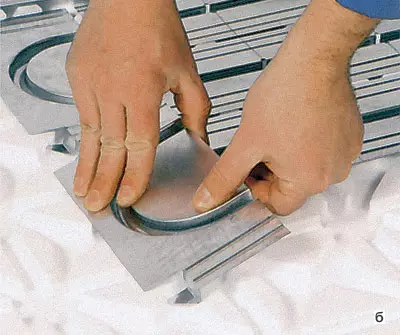

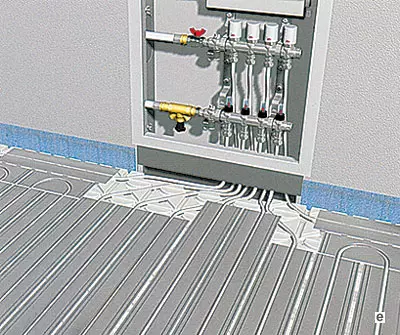

Polystyrene system (OVENTROP): Installation of heat distribution plates on mats with a thickness of 25mm (A); Installation of reversal plates (b); Laying the metal-plastic pipe Cupipe (B, D); Pipe passage through a hole in the wall (D); The heating circuits are laid and connected to collectors (E). |

A variety of described technology allows laying of a laminated parquet directly to closed with vapor insulation aluminum plates, without chipboard. At the same time there will be a small win in the height of the room, but the base design must be enhanced. The cross section of the applicable boards is not less than 7028mm. In length, they must overlap the entire room (from the wall to the wall) and be nailed to all lags, except for the end. During the installation of pipes, the ends of the boards rise, the loops of the pipes are pushed under the boards, after which the ends are nailed to lags with nails. Laminated parquet stacked across the boards.

Typical Nonstil polystyrene system Offers the company THERMOTECH (Sweden). The equipment is mounted on a smooth, clean and dry base. If necessary (in rooms with high humidity or when laying on the foundation), the floor is covered with a layer of vapor insulation from 80-100 mkm thick-resistant polyethylene. Top plates special polystyrene plates with the strength of the 200kpa. In addition to the heat loss of the floor, their thickness can be 30, 50 or 70mm. Flusted grooves for aluminum plates with a step of 150mm (dimensions of the plate - 12001450,5mm) or 300mm (12002700,5mm).

The plates are placed in the grooves of polystyrene slabs without gluing. Slage-eyed plates with a slight press pressed the thermotech pipe from stitched polyethylene 172mm (here and further: the diametral wall of the wall). It has a special coating that prevents the screens that could occur during operation due to friction surfaces. Normal or laminated parquet, as well as a parquet board with a thickness of at least 9mm mounted directly on aluminum plates through a thin laying of cardboard or foamed polyethylene. When using a linoleum, ceramic tile or PVC coating, it follows to aluminum plates first put the bidding of GVL sheets (according to the technology, the sheets of production of Knauf, Germany are recommended) - two layers of 10mm.

The variation of the thermotech's filling polystyrene system is the so-called Fortation system (updates) . Twin are used polystyrene plates with a thickness of only 20mm with already glued aluminum plates. You can choose this option, for example, during the reconstruction of the cottage, when installing heating to the old floor (say, coated with ceramic tiles).

Of course, components for flooring polystyrene systems of floor heating produces not only thermotech. A very interesting technical solution offers Giacomini (Italy). Its system allows you to lay a tile without applying chipboard or GWL. Instead of them after installing polystyrene plates, heat distribution plates from galvanized, pipe layouts (from cross-linked polyethylene PE-X161,5mm or 162mm metal plates) The sheets of galvanized steel 500250 or 500500mm are placed on vaporizolation. They create a monolithic metal screen on the floor, providing a very uniform distribution of heat and almost no thickness of the "cake". The finish coating is fastened with a special tile glue. Undoubtedly, polystyrene flooring systems of companies Uponor, Roth, Oventrop, Rehau (all Germany), Henco (Belgium) IDR are deserved. We can talk from these models in more detail, and we will definitely do it in the future.

In addition to the above described above, there are other options for arrangement of occupational flooring systems. For example, polystyrene is often replaced by special chipboard, in which grooves are cut to styling heat-distributing plates. It turns out Flooring wooden system . The shorter of its dry team screed includes one layer of GVL sheets with a thickness of about 10mm. Accessories for wooden flooring systems are produced by Uponor, Thermotech IDR.

Very easy to install Hypotocarton Flooring System (Such technology was presented on the Russian market a few years ago by PEXEP, Finland). On flat (this is fundamentally!) The dry surface is placed in moisture resistant drywall (if necessary, steam barrier) and the pipe laying route is applied. Further, there are strips of plasterboard. They are screwed using self-tapping screws to the first layer of HCCV so that the grooves for PET pipe with a diameter of 12mm are formed. The heating circuit unfolds, fixing the pipe with plastic ribbon segments and screws. Next, the groove with the tube is closed with a gypsum solution. After drying it, another layer of moisture-resistant drywall sheets are placed, and then steamproofing and finishing coating (for example, laminate).

Parquet without caprises

The surface temperature of the heated parquet floor should not exceed 27c (including under carpets). If there is no more than 15-20% of the area in the room, then for the preservation of the wooden flooring, it is worth maintaining the temperature of 23c on free surfaces, which will provide the air temperature about 21c.

According to the law Ohm

The heat source in the electrical undertensional floor heating system is most often a resistive heating cable located in the floor design. The system is powered by a voltage of 220V / 50Hz. It is used to achieve the highest comfort in rooms with cold floors, on the first floors of buildings, as well as in any other residential and non-residential zones. For example, in the kitchen, children's, living room or library. Use electrical businessless systems both in country houses and in urban apartments.

The toes of such equipment include sufficiently high thermal power (up to 100W / m2) and low purchasing cost. Indeed, the electric heating system for the surface of 1m2 will cost the customer in 2700-4050 rubles, while on the area of 10m2 you can put in 675-810. / M2. If the cable laying area is measured with tens and hundreds of square meters, the initial costs are even more decreasing. But the total cost of the electrical system throughout its service is likely to be noticeably higher than the cost of water, due to the high cost of electricity.

Electrical system in wooden floors on lags. The power of the heating cable should not exceed 10W / m (60-80W / m2), otherwise the risk of ignition increases. Punch base for laying the heating cable In such systems, a metal fastening grid was used, placed above thermal insulation between lags. The size of the mesh cell is not more than 5050mm, the diameter of the wire is not less than 2mm. Important condition: unacceptable contact of the heating cable with thermal insulation and wooden structures. The distance from the cable fixed on the grid (fixation - every 30cm) to lag should be at least 30mm, and to coating at least 50mm. Together crossing the cable and lag, it is necessary to proceed in them (the width is 30 mm, the depth of 25 mm) and is mandatory to protect it with an aluminum foil or other non-aggravated material. A water slot can take place no more than one thread of the heating cable.

It is necessary to take care of the electrical safety. When laying the heating cable directly on the metal grid, the latter should be connected either to the potential equalization system, or to a zero protective conductor (in accordance with the requirements of GL.1.7Pue).

To control the system mounted in a wooden floor on lags, the thermostators are most suitable, which are equipped with a built-in room temperature sensor indoor and connected to the floor temperature sensor. Such a sensor is located in the floor design and measures the air temperature between the lags. The connection of the sensor with the thermostat should be carried out only with a copper wire laid in a metal or plastic corrugated protective tube with a diameter of 10-16mm (depending on the type of sensor). The thermostat is recommended to be installed in a heated room at an altitude of 0.5-1.5 m from the floor surface. Punching of the finishing coating is suitable for a packer parquet, a tipped floor board of solid wood, multilayer plywood with subsequent laying of laminate IT.P.

Among the manufacturers of equipment kits, which can be used for mounting a warm floor in wooden floors on the lags, it is necessary to highlight ENSTO (Finland); It makes sense to pay attention to the devi technique (Denmark), Ceilhit (Spain), Kima, Thermo (Obvlenium) IDR.

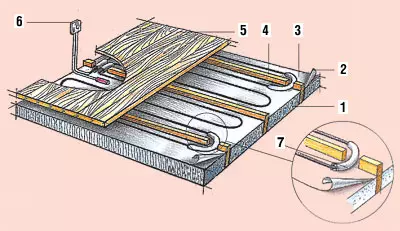

Wood floor electric heating on lags (ensto):

1- thermal insulation;

2- aluminum foil (optional);

3-fastening grid;

4- heating cable;

5-floor flooring;

6-thermostat;

7- Passage of Lagi.

On smooth floors of various types can be applied. Floor heating electrical system . This installation, suitable not only for cottages, but also for city apartments, offers on the Russian market Devi. Special Devicell Dry mounting sheets allow you to locate the cable system of the warm floor of Devi under a laminate or parquet and start using it on the same day. Maximum installed capacity - 100W / m2.

When creating a warm floor, it is necessary to prepare the basis for which it is carefully processed by a vacuum cleaner. After that, you need to decompose the installation sheets of Devicell Dry on a heated area in accordance with the diagram prepared in advance. Mounting sheets (100050013mm) are made of extruded polystyrene foam, resistant to deformation under load up to 3670 kg / m2, and equipped with a profiled aluminum coating. They need to be combined with each other with plastic latches (included in the package). Sheets are laid in one direction to coincide the grooves for their compound. If necessary (for example, with a complex room form), they can be cut by an electroll q or another tool, giving them the desired outlines.

Deviflex Heating Cable (DTIP-10 and DTIE-10) Light Pressing is stacked in grooves made on sheets with 100mm increments. Together, the installation of the floor temperature sensor must be made in the mounting sheet of the cutout and with the help of aluminum scotch fix the corrugated tube and the heating cable coupling. In those areas where mounting sheets and heating cable will not be mounted, there are moisture-resistant gypsum solid sheets or plywood sheets (for floor alignment).

At the next stage, check the performance of the system and electrical connections according to PUE and instructions for installing a heating cable and thermostat. The assembly of the wooden floor should be made in accordance with the manufacturer's instructions (let's say, spread the substrate from foamed polyethylene and lay the laminate). The system can be used with virtually all types of wooden flooring.

Subtle solution

In addition to occupyless systems based on heating cable, a film floor heater can be used. This special material (no more than 1 mm thick) is produced in the form of a roll. The roll is rolled off, the film is fixed to the floor of the tape, and on top of any floor covering (carpet, linoleum IDR). On the installation of the heater, a few minutes are leaving. The thickness of the floor does not increase. The system runs from the electrical network. The desired temperature is set using the thermostat. If desired, the heater can be quickly transferred to a new place.

The editorial board thanks Devi, Ensto, Henco, Oventrop, Rainbow, Rehau, Uponor and Heatlightport for the provided photographic materials and help in the preparation of the article.