Overview of the market for the construction of wooden houses: wood varieties, advantages and disadvantages of the construction of walls from a log and timber.

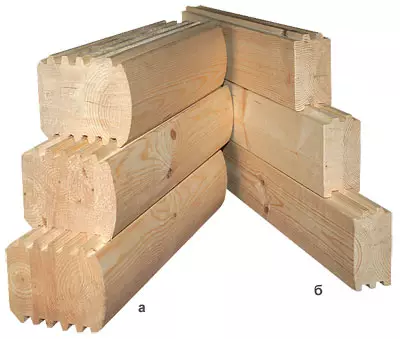

A- conjugation of the outer and inner walls by a word;

B-corner connection turning to a native spike

A- due to the wall profile are not blocked and do not require caulking;

B, the passing and cutting of "cups" can be held both in place and at the factory, which is much accelerating the installation

A- logs are cleaned from the bark with a manual bra hand;

B - To rally the logs with each other by vertical (this prevents twisting and disintegrating each log separately), it is necessary to use wooden brazed;

The log house collected from the logs of manual tesse, in appearance, is little less inferior to the collected from the otling

The launching of a new cut (adhesive) to the already existing problem is not a simple, but executing. To do this, you can use the Wide "Semi-Survene"

(in the form of halves of a swallow tail)

Walls from the boiler:

A- "Norwegian Castle" provides a dense angular connection;

B, the lathes successfully combines the quality of the logs and timber;

Glocked in the opening window is designed to install a vertical cluster

A- adjustable threaded nodes make it easy to compensate for the shrinkage of the wooden structure;

B - between the crowns laid two layers of the jute canvase;

Powerful walls are able to withstand the snow load, and considerable weight of roofing material, such as natural tiles

A- externally similar to collected from the profiled timber;

B - the place of the timber comes ready for installation;

Pages and ridges are hardly fixed with bars among themselves;

Glantsy the crowns by hairpins

The modern market offers a great many species of materials for the construction of walls of wooden houses. How to understand all this abundance?

Nevertheless, along with the advantages of the tree there are disadvantages. It burns, does not like moisture (moisturized wood is exposed to the action of fungi, bacteria, mold IT.D., that it is forced to observe the rule: a tree should not mock up to the requirements of SNiP on the heat resistance for the middle strip (RO = 3.2M2C / W) walls From the logs of any diameter or bar without additional insulation do not reach. The playgrounds from the wood of natural humidity are subject to shrinkage deformation, which is especially large in the first year after the construction of the construction (in more detail this can be found in the "Cottage" article in the expiration. Shrinkage The finished box of the house should "stand out" six months-year (and sometimes more), which does not always like to customers and builders. Get rid of long-lasting waiting allows the use of a profiled or glued timber dried by artificially to residual humidity 8-12%.

We will conduct a brief analysis of the merits and disadvantages of the wooden walls, which are erected from all the semi-finished products listed above. Let's start with the materials of natural humidity.

How to distinguish winter forest from summer

It is worth purchasing the winter forest, it is more dry. From the summer it can be distinguished independently according to the following indirect signs:

on season when you buy it;

The ends of the Winter Forest logs are lighter (with the autumn rains they darken);

Footprints of dirt on the crust speak of a summer forest;

Winter forest is easier to cut, saws very smoothly, as a result, longitudinal sleeps do not have a wavy characteristic for summer forest.

There is a fairly simple chemical method: the core of the winter forest contains more starch, and if iodine drops on it, the stain will acquire a blue tint. Is the same with a 100% probability to determine the summer or winter in front of you, it is quite difficult, since the listed features of the full guarantee do not give. For sure, only specialists after laboratory analysis are capable of answering this question.

Conventional rectangular timber

You can find the timing of the next sections: 100100, 120120, 140140, 150100, 150150, 180180, 200150, 200200mm. The most beneficial use of a timber section of 150150mm (price, from 3150 rubles / m3). Thirdly (200200mm IT.P.) and costs more (from 3700 rubles / m3), and the market is less likely, since it is made of selected rounding. The smaller bar (about 100100mm) is considered unprofitable at once in four reasons. First, the wall thickness of 100mm is much colder than 150 mm, and it has to be insulated. Secondly, the complexity of construction increases, since the number of crowns stacked on the wall (and therefore the interventical seams, which must be supplied by the seal, and the VPO consequence to cross) in 1.5rd more. Thirdly, the length of the outer wall that does not require a dressing with the wall of the inner (this forms the so-called rigidity edges) is only 4m. In other words, it is impossible to create a room with an area of more than 44m, which is acceptable only for homes up to 86m. For timber sections 150150mm This value is 6m. ASSO, the maximum size of the room is 66m, which is suitable for any area houses. Fourth, the thin bar leads more than it has a smaller supporting surface.

Method for connecting corners

Is it worth choosing a timber with a cross section of 200200mm and more, as they say, Master's business. The heat resistance of the wall thickness 200mm (RO = 2M2C / W) although exceeds a similar wall indicator of 150mm, but it is still far to the requirements of SNiP. WHATS The same certain advantages have a thick bar. First, it has a greater rigidity, which is very good for houses of 1510m and more. Secondly, the walls of a thick bar look more beautiful (fewer interventic seams).

In love, the case of 6m long lumber is delivered to the construction site, and its cutting, as a rule, is already on the site of the assembly of the walls. During construction, you can use the lining and sexual board of natural humidity (from 3400 rubles / m3) - during the posting, they are dried (to the use of the use of a gender board of natural humidity in the article "House from Bruus").

Constiversities of a natural humidity vehicle can be attributed to the relatively low cost of 1m2 walls and ease of work. The shortcomings are somewhat larger. Moreover, the main needy "standings" of the box (the bar gives shrink to 6% in the transverse direction). This hprocession can last depending on the size of the bar and at home itself from six months to a year. The second drawback is the mandatory exterior decoration of the walls after the end of construction (more on the options for finishing our magazine wrote in the article "House from Bruus"). The fact is that the scar of the natural humidity goes with the tolerance of 0.5 cm in thickness. So, under the outer decoration it is necessary to organize a crate levevating irregularities. The exception to this rule is a timing of 200200mm and more than the walls, as a rule, first plane, and then polished and coated with colorless or toning biolalect composition.

Meannest seals

As an interventovation seal of walls, erected from an unpainted timber or logs, moss, palable, felt, hemp and flax fabric can be used. If any of the listed materials is suitable for the log, then for walls from a bar, it is better to use a flask linen that absorbs moisture. This is explained by the fact that when docking the bars "seam" between them, it turns out horizontal and flat, unlike the arc-shaped "seam" in a log cabin. It is clear that in the rain the horizontal "seam" rises much stronger. That is why horizontal junctions of the bar require more attention. If the bar walls are in the future it is not assumed to be something like something, on the upper outer edge of each bar, it should be made to the assembly in size from 1010 to 2020mm with an angle of 45. This will improve the outflow of water from the "seams".

Profiled bar

(central grooves on top and bottom with nested in the upper bar) and two-circuit seals (flax cords) This is usually the same lamination of natural humidity, as in the previous case, only on its upper and lower surfaces for a more dense connection, spikes and groove. With a simple case (with a small timer's width), it may be one spike above and the groove under it below, in a more complex - 3-5 spikes and grooves. What their more, the better, between the elements of the structure, an unproduced labyrinth seal occurs. The typical section of the bar is 150145mm (cost- 4800rub. / M3), but you can meet both more (210200mm) and less (145100mm).

The advantages of this material are as follows. First, in the manufacture, it is passed through the planer, and at least one of his side (and both both) is quite smooth. Jesl, you decided in advance that on the one hand (external or internal) wall will not be separated, it is precisely such a timber (the lower price of a conventional timber is leveled during its planing and grinding). Secondly, the profile minimizes the magnitude of the slots that appear between the bars during the shrinkage. Thirdly, this material has a strictest geometry than an ordinary timber: the value of the tolerance in width and height is 1-1.5mm- if it turns out more, the grooves and spikes will not sit down on each other. Kednostats, inherent to all houses from the wood of natural humidity, in this case, another is added: when dried on the front side of the profiled bar, cracks appear, sometimes significant. True, not all consumers believe that this spoils the appearance of the wall, "many claim that it is the cracks that give the structure a kind of charm.

Dry profiled timber. It is now offered by very few manufacturers, with an artificial drying, the timber leads a lot (with natural drying, it also leads it, but less). The advantages of this material are the same as the previous one. Sytom, you can enter the house immediately after the end of the construction. Disadvantages more, and the main one is the increase in the cost of construction. First, the timber itself is more expensive (about 6000 rubles / m3), which gives a tangible increase to the total cost (for orientation: 35m3 wood is needed to the house 88m). Secondly, the crowns are not bonded by vertical vertically or nails, and they are tightened with steel studs (depending on the length, material and protective coating, they cost 400-1000 rubles. / Bim.m). Punching of interventic seals use fine-layer foamed materials similar to those stacked under the laminate (more about this - in the article "Achto under laminate?"). When finishing, only dry lining and sex board should be used, the cost of which reaches 8000 rubles / m3.

Special profiled timber. We are talking about a puzzle profiled timber (cross section of 9595mm or more) not quite ordinary design. It has central rectangular longitudinal grooves on the upper and lower side (the bars are connected by the longitudinal chipombru, invested in the top grooves), as well as two longitudinal semicircular grooves on the underside (flashed shore seal sealants at the production stage) and two Supporting the longitudinal chamfer sites (for cords) on the upper side. When assembling between two bruschers, a longitudinal labyrinth "lock" and a double-circuit seal arise. (This was stated in more detail in the article "Cottage for 5days".)

When to pay money?

The house from glued timber, a dry profiled timber or a rounded log can be sent immediately after the end of construction. This advantage entails and a kind of problem: To start work, you need to have all the money necessary for their holding (however, something can be signed and during the construction of 2-3 months). A diploma from the materials of natural humidity (ordinary bar, log) will be able to enter no earlier than a year after the start of construction (the log house should settle down). This drawback is somewhat compensated by the fact that the payment is divided at least into two stages. That is, by the beginning of construction it is necessary to have a sum sufficient to pay for the first stage. The second part can be soaked in the time until the logberlers are defending.

And one moment. Having said that in the house built from the wood of natural humidity, it is possible to settle no earlier than a year, we have a few sick against truth. When complying with some technological rules (gaps over windows and doors IT.D.), you can enter it immediately after the construction of the box. Of course, a slightly elevated humidity and the lack of finishes will deliver inconvenience, but the house will dry significantly faster. True, and "starting capital" will need more.

Manually crashed

Used types of wood. For the manufacture of walls, pine, larch and cedar logs are used.

Pine logs come from different regions of Russia. For example, Vladimir or Arkhangelsk pine (density of 0.7-0.8 t / m3) will cost approximately 1500 rubles / m3. The price directly depends on the diameter (the thinner, the cheaper) and log lengths (the longer the more expensive). Typical diameter - 22-24cm, maximum - 32 cm (measured by a thin end). The usual length is 6m, the maximum - 12,2m (limited by the wagon dimensions). Pine, fired in the north of the Kirov region (this forest is more dense, it is considered to be northern), somewhat more expensive - 1700 rubles / m3. The most expensive Pine Angarskaya. It has even more dense wood than the northern (about 1 t / m3-sneakers in water), a dark core, a thin-eyed sequire texture (annual rings thinner). At the site of the billet "Anhard" costs 1500rub. / M3, but in the suburbs will cost already at 3400 rubles / m3. Rights People's Wisdom: "Behind the Sea Telushka - half, yes ruble transport."

The larch has beautiful wood, especially attractive white lines, well visible on the ends and protests logs. Little gives back to rotting and other diseases. Disadvantage - due to a large density (1.15t / m3), the tree dries as much as 5-7 years (that is, the period of shrinkage of the house is very stretched) and at the same time it is quite cracks. Retrieving a larch by 150 rubles. More expensive pine and after delivery will cost 3,600-3700 rubles / m3.

Cedar Wood (You can read more about it in the article.

"The bath in Russian traditions") is also beautiful, plus it highlights phytoncides and has a healing effect (justice to note that, as most of the drugs, can produce side effects of IT.D pain.). Drunk cedar is more expensive than pine at 450-600 rubles, and after delivery to the place costs 4000-4200rub. / M3 and therefore is used mainly for exclusive buildings.

For the entire listed wood, we called the minimum prices. As for the selected forest, it costs another 500-600 rubles. more expensive.

Honestly admitted: unequivocal advantages, because of which it would be necessary to order logs from cedar or larch, no. If we talk about reasonable sufficiency, then the larch makes sense to make two lower crowns at home, increasing the likelihood that when moisture sediment from the foundation, they will not rot (to carry out such an operation, can there be very large firms that have wood stocks - due to Multiple logs to drive a car from Siberia is extremely unprofitable). But it is very controversial. Our ancestors who lived in the middle strip somehow did without larch, using local wood (Osina also does not rot) and technological tricks (see the article "Bath in Russian traditions"). In addition, there is a huge selection of protective compositions, with which you can not less successfully protect the lower crowns from rotting.

Conduct: buy ready or build on site? You can buy a ready-made log cabin somewhere in the Vologda region, transport it to the site and instruct the assembly of the local builder brigade. It seems everything is quite simple. Credit manufacturers will disassemble, labeled every log and load into the truck. But when assembling there are many questions and problems: there is not a village, I did not coincide here. So that this does not happen, it is necessary to charge a grazing assembly on a plot to those who cut it (their logs and arising in place of the problem). True, you will have to pay for the arrival of the workers and organize their accommodation (assembly at home 66m lasts 1-2 days). But in this case, scandals and inconsistencies with a brigade will be possible to continue construction.

In general, it is always better to charge all the work by the firm that the log house itself will make (it is usually born not on the site, but at the production base), will bring and will bring in place, and it will also complete the house. Agenous- will give him a guarantee.

| Flow Articles | Natural Humidity Bar, 150150mm | Profiled Bar, 150145mm | Dry profiled bar, 150145mm | Rounded log, 220mm | Item pine, hand logging | Log, hand-held | Log cabin, hand-held | Glued profiled bar |

|---|---|---|---|---|---|---|---|---|

| Wood | 472.5 | 720. | 900. | 940. | 940. | 1200. | 1340. | 1550. |

| Jute | 19.8. | 10 | 10 | 27.5 * | 27.5 * | 27.5 * | 27.5 * | 70 ** |

| Begging | 35 *** | 35 *** | 35 *** | 100**** | 100**** | 100**** | 100**** | 800. |

| Work | 369. | 535. | 535. | 733. | 1050. | 1050. | 1050. | 1000. |

| TOTAL | 896,3 | 1300. | 1480. | 1800.5 | 2117.5 | 2377.5 | 2517.5 | 3420. |

| Note: * - Laying in two layers; ** - sealant; *** - Nails; **** - Wooden brazen |

Half lights and frost

Rafting prices can be somewhat different. If it is manufactured from a breeding forest, the price will be 20-30% higher than that of the log. If a sawmaker is used (a different-sighted forest), the cost is similar to the log. The half flaws produce only from the breeding forest, and the finished material is obtained 15-20% more expensive. Property programs of the boilers and half lights should be attributed to some winnings in aesthetics. Yes, even facilitating the design of the premises. It is even easier to work with the boat than with half lights, - according to the expression of specialists, it's just a large two-toned bar.

Begroes used in the construction of walls

They are needed to rally separate logs or bars among themselves. Begroes are wooden and metal. When using a wooden (round or square section) in the wall drilled (with a step 30-40cm) of the holes in a depth of three crowns. There without tight and inserted wooden brazen. The length and height of the wall of the hole alternate in a chess order.

Metal brazers produced from a pipe or reinforcement bar. Those that from the pipe behave almost the same way as wooden. Sterns from the reinforcement and work harder (difficult to drive), and the probability of hanging on them the crowns during sediment is greater (the cause is "ERS" on the surface).

Many firms in assembling walls from a bar or a small diameter log is replaced with nails with a length of 250-300mm. This service can, first, compensate for small curvature of the bar (logs) and, secondly, to pull the crowns among themselves. So that the upper crowns do not hang on the nails hats, the timber is crammed into a depth of 3-4 cm, after which the nail is still 2-3 cm with "Dobobunik".

Rounded log

The most running diameters are 22 (4550rub. / M3) and 24cm (4700rub / m3). A log in a cross section of 28cm will cost at least 1.3-1.5 times more expensive. The maximum diameter is 50cm - it will turn out what is called, in a fabulous money.

They distinguish the usual rounded log and log profiled (in the finished wall they look almost the same). If only the semi-head groove is chosen in the first bottom (it falls on the bottom log), then the second strongly resembles a profiled timber: on top of the spike, downstairs the groove under it (some specialists are called this option-round profiled timber). On the site, such a material comes already to be "in moderation" and even with twisted in advance cups, it remains only to be folded from the brought "set" of the wall.

The enclosable pluses of the otillization should be attributed to the comparative cheapness (this material is about 30% cheaper than logs of manual tester), high speed (less labor intensity) and accuracy of the wall assembly, as well as some winnings in the aesthetics are smooth. Disadvantages are also there. First, the outer protective layer is removed. Secondly, the rounded log cracks more than the Tesnic.

Features of the interior design of a wooden house

Interior design in a house built from a bar, a boiler or halflafet, no particular questions. The walls are fairly flat here, which allows you to decide their plasterboard and the like materials, and then it is convenient to arrange or cheer the parallelepiped furniture. Avota when finishing houses from a rounded timber and, moreover, a large diameter logs often arise with furnishings.

This is due to the need to create for various style solutions to the plane of walls, which could be separated by materials combined with modern furniture and household appliances. The protester assembled into a single whole log procedure is difficult and quite expensive. The construction of falseland leads to a decrease in area.

To work out the interior in advance, it makes sense to order a sketch design project even at the design stage of the house. There is such a service from 300-450 rubles. For 1m2 area. But from the very beginning you will know exactly what walls or fragments of surfaces need to be made flat, what materials you need for their finishes and how they will be combined with furniture and wooden walls left in pristine form.

Glued profiled bar

In appearance, this material is very similar to the profiled bar, but is made according to the original technology. First, the round forest of coniferous rocks is cut on the boards, which are dried in special chambers to residual humidity 8-12%. Dry boards from four sides are shifted, all unacceptable defects (knots, cracked IT.D are cut out of them, and as a result, no boards are formed, and the so-called lamellas are formed. They are sorted and glued together (use special high-strength waterproof glue) on a powerful press, resulting in a timber. The number of glued lamellae is 2-5, which makes it possible to produce a timber with a thickness of 100-200mm, which is profiled on a four-sided machine to obtain a puzzle compound. After that, the material with high accuracy is collected on the items of the required size. The rectangular wet "cups" are "killed", and the holes are drilled in which the threaded studs are skiing the bars with each other when assembling a log. There are the same materials between the crowns as when using a profiled timber.

The advantages of the glued timber can be formulated like this: practically does not give a shrinkage, does not need internal and external finishing (it is only necessary to cover the walls by biolalect-proof composition). Manufacturers argue that for the house from the glued bar 100 years old is not the limit. Disadvantage One: high material price - 13800-17300rub. / M3.

The editors thanks the company "ABS-Stroy" and "VladimirStroyz" to compose in the preparation of publication and the provided photographic materials.