Bath erection with a total area of 64.4 m2 from the selected Krasnoyarsk cedar. The advantages of the material, a description of building and finishing works.

Beautiful, a little archaic

And endlessly loved.

Many of our fellow citizens and today respect and as they continue to continue wonderful Russian to be batted in the bath. Remove the sauna per hour is not in their character, they prefer their own pair. However, she is worth it to dedicate a separate article. Next, we will talk about the construction of a bath from the selected Krasnoyarsk cedar.

Why exactly cedar?

Choose a tree breed for the construction of the house, and even more so the bathroom, it is not easy. Mounting wood your advantages. For example, the pine is the material inexpensive and easily processed, and besides well-carrying fluctuations in temperature and humidity and having a pleasant smell, but unfortunately, soft. It is easy to scratch, and the resins are allocated too much. A spruce of a homogeneous, a low-alolist, has a steady white color, is poorly prone to warp, but due to the greater suchcottyness is treated somewhat worse than pine. The fashionable larch is one of the most resistant to mechanical damage to the rocks, it is not amenable to rot (this can be operated by hundreds of years without antiseptation). But it is hard to work with her (the density and strength of this wood is almost 30% higher than that of pine, as a result of a nail to score, and pull out very difficult). Therefore, the exercise costs from larch can exceed similar costs for pine and spruce log cabins in 1.5-2ruse.According to the physico-mechanical properties of wood cedar, according to experts, it occupies an intermediate position between the Siberian fir and the fir, but according to resistance to rotting, they are significantly surpassed and very close to larch. It is processed at no worse pine. Isao mainly, its wood has a high antibacterial force (the so-called phytoncidity). The phytoncides isolated only to kill pathogenic microorganisms, but also have a beneficial effect on a person, primarily on his nervous system. So, in contact with this wood, the activity of the cardiovascular system and respiratory organs is restored, asthmatic and allergic symptoms are facilitated, stress is removed, the fatigue decreases (and hence the performance increases), the clarity of consciousness is improved, irritability decreases. Judge, due to the rapid restoration of the forces, the necessary sleep time is shortened. Residents of the Urals, Siberia, the European North of the time of time, knew about the healing properties of the cedar and used it for the treatment of many ailments. By the way, the smell of cedar (remember an unforgettable aroma of freshly sufficient school pencils) do not endure a mosquito-built house they simply fly out by the party. The listed properties and forced the owners of the future bath to stop their choice on this breed.

For example, for example, we need to note that real agencies grow mainly in the territories with a soft subtropical climate. There is not a cedar himself, and one of his varieties is a cedar pine, according to properties somewhat different from their southern fellow. Since Kedrachi is used in Russia mainly for the workpiece of nuts, for domestic construction, trees are meant older than 280 years (cedar pine lives up to 1500 years and reaches 35m in height and 2.5m in diameter at the base) that fell under the so-called age-called seray. The entrance is mainly the tops of the cedar pines, but they also have quite a strong taper, which, of course, makes some features of construction technology.

Aishche is one important nuance. Nature itself became a guarantee that the harvesting of the Siberian cedar was carried out exclusively in the winter, - in the summer in Taiga simply not to enter.

Brewery billet.

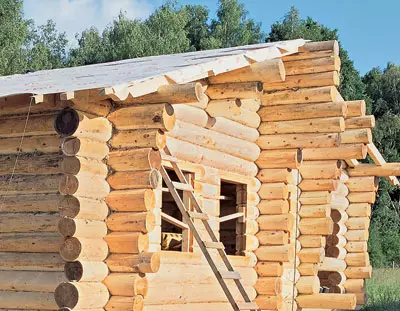

By tradition, the log house is handed manually. Why manually? There are several reasons for this. First, with a hand logging, a ham ham method is used, which allows you to maintain the upper protective layer of wood. The ATU, in turn, is a guarantee of log durability (rounded log as a result of fitting under the overall diameter, as a rule, loses the natural protective layer). Secondly, only with a hand logging, you can use logs of the above diameters. The embellishment alternate them, laying the subtle ends towards each other, which makes it possible to simultaneously save the external aesthetics and high thermal insulation characteristics of the material (the last circumstance for the bath is especially important). The pre-construction of the Future Bathhouse was made in the covered hangar and lasted 2 months. Then the logs were dismantled and transported to the customer's plot.

The construction of a church was away from the customer's plot, this is also a Russian tradition. This is how our ancestors did: the log house made somewhere in the field, and then transported to the place. What an interesting principle is taken by weapons and Western manufacturers: they are called Prefabricated Houses (in more detail this was stated in the article "Cottage for 5 days"). For the client, such a way of work is very attractive: you do not see a long process of manufacturing the harm itself, and therefore the construction time (after all, only the assembly occurs on the site) it seems much shorter. Yes, and the construction of garbage and sawdust, which are formed when cutting, is not necessary to export.

Ateper will talk about the processes that took place directly on the customer's site.

Foundation

As for every wooden house, for the bath, in principle, any option of a lightweight foundation (more on this topic we wrote in articles"In your format" and

"In the spirit of constructivism"). The concrete design selects the architect based on the soil composition on the site. In the case in the clay, and therefore, the bunched ground was decided to build a column foundation with painter. The pillars of such a foundation are necessarily placed under each angle of future construction and in places in the connection of the inner walls with outdoor. Between these pillars, intermediates are installed with such a calculation so that the distance between them does not exceed 1.5-2m. A pens with a diameter of 250mm with a diameter of 250mm and a depth of 1.7 m (below the ground freezing level). Then the sand pillow was arranged in them at least 200mm high. Reinforced into four "threads" (diameter 12mm) pillars are cast from concrete M300 brand and are bred 200mm above the ground level. At the same time, the releases of the reinforcement were left on top, which subsequently tied the rustling fittings. Then around the perimeter of the foundation was removed about 400 mm of soil and in its place also staged a pillow from coarse-grained sand (the soil in all circumstances should not put pressure on the foundation).

After that, around the perimeter of the future tape, the woodwok was putting a formwork from waterproof plywood, inside which the reinforcement frame was laid, and then bought a concrete solution. In advance, across the formwork was installed segments of asbated pipes with a diameter of 200mm to organize the blood-based required for ventilation of the underground space. It should be recognized that for the bath under consideration, it was not required to be the foundation of such power, it was made with a large margin of strength at the request of the customer. When the concrete froze, the waterproofing of two layers of hydrohotlocola was put on top of the tape.

All communications (electrical cable, sewage, heating, water supply) to the bath is carried out from home (about 15m) before the manufacture of the foundation. When laying water supply and sewage, Upolar insulated tubes (Uponor, Finland) were used. Where these pipes are directly included in the construction of the pipe out of the soil is the most likely place for their freezing in winter), the heating electrical cable was mounted on them.

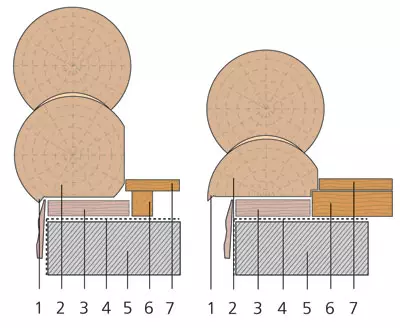

The salary began

The durability of the log cabin, and even more so the log cabin, largely depends on the correct technology of its cutting and assembly. Let's start with the first strapping or, as it was called in an old crown, a bustling crown. In order for its logs as close as possible to the top plane of the foundation, they are fed. And not just twisted. All the trick is that not flat, as a figure surface, should be turned to the foundation. That is, on the front edge of the log, the protrusable dropper is necessary. When installing a log on a tape, the dripper is put forward for the edge of the foundation (note: the log center is shifted to the outside relative to the center of the ribbon ribbon - it is laid at the design stage!). So the horizontal surface of the "Fundam-log" section is protected from the rain moisture flowing along the wall. There is another trick. Despite the waterproofing and drip, the logs of a bustling crown in the course of operation are destroyed in the first place. It is explained by the fact that on the surface of the waterproofing layer, the condensate of moisture from the air - concrete is still cold. Replacing the same salary is very complex and troublesome. In order to protect it from destruction, the so-called lining from larch is installed under the logs (this wood, as already mentioned, is not amenable to rotting) with a cross section of 50200mm. Additionally, the lining boards are processed by the antiseptic composition. Of course, the lining may eventually be contracted (after 50-70 years), but it is much easier to replace it than the salary logs.

It is clear that the salary set according to the described technology is more expensive than simply laid on the foundation tape with the surface of the section between it and concrete with a conventional metal tide (it is inserted into the longitudinal breakage in the log, where rainwater will fall). But the increased service life fully justifies these costs.

Installation scheme of salary logs in perpendicular to each other walls:

2-log salary;

3- gasket;

4 - waterproofing;

5- Foundation;

6 lags of the floor;

7- waterproof plywood

Wall cutting

During the construction of the walls, the traditional Russian view of the cut into the Oblos with the residue was applied. This method provides the strength of the cut, and good protection of the corners from the wind and the rain. In order to prevent the longitudinal displacement of the logs, the so-called indigenous spike is made in the burst in the log cabin.For dense fit, the logs on the top of the vertical in the upper logs are chosen by the longitudinal semicircular grooves (gutters). In addition to dry moss, sphagnum. Why is it? Build a church on the moss, another old Russian tradition. This natural material is known for its ability to withstand extreme temperatures and drying. Being a natural antiseptic, he practically does not rot and even be able to survive the wooden structure itself.

The log verticals are bonded between themselves from larch (size - 3535mm, length, 250-300mm). They are located at a distance of 1.5-2m apart. Holes under bent in the underlying log drilled strictly perpendicular to the foundation plane, and they themselves brazenly scored in them with a slight force. The holes in the upper log are made in the diameter of 2-3mm more, so that the log in the shrinkage does not depend on the brazier.

Alert portion of each logs perform longitudinal loop chainsaw. It is done along the entire length, from the cup to a cup, but in no case should not go to the end of the log. Such a propyl does not give to develop large cracks in the log, which spoil the appearance, increase the heat loss and reduce the service life of the tree. If the log and cracks, then it is on the cutyl, but the crack on the middle of the log will not go (it will not split into two fees).

Inconale, about protests performed on the logs on the side of the room. They allow you to get to the pink cedar core and show her beautiful drawing. Do not protest, the walls made of cedar logs in appearance would not be distinguished from pine. Made protests (still in the hangar) so: they made transverse cuts with a saw, the tree between the cuts were cut into the ax, and then burned in the rigine and the plane.

Overlap and roofing

The bartal design of the roof (one for the entire structure) is carried out beyond the walls of at least 1.2 m, which allows to protect the log house from the rain. The rafters are made of a bar with a cross section of 15050mm. They rest on the walls of the construction and a powerful skate log. But this is not just rafters, their deposits are decorated with the so-called hazellets (hand over manually), which are a decorative element of the facade. Inside the bath to the rafters, additional railings are nailed from below, which made it possible to increase their height, and then laid a Jutafol Silver vapor insulation material (Juta, Czech Republic) and is fixed with the crate. Light Buts (Rockwool, Russia) layer 200mm is laid between the rafters. From above, the insulation (according to rafters) is closed by the superdiffusion membrane TYVEK (DuPont, Switzerland). Klowropylas are nailed a controlled (its thickness determines the magnitude of the ventilated gap), and on top of the cutting board. Waterproof plywood is laid on the crate, then the so-called lining carpet is on, and the soft tile of Tegola (Italy) is laid on it) of a rather bright blue color.

I foresee that the solar layer of the insulation said to someone from readers will seem unnecessary. But his hosts do not consider it at all, with heating and houses and baths currently copes the boiler capacity ... 6kW. So unnecessarily similar insulation?

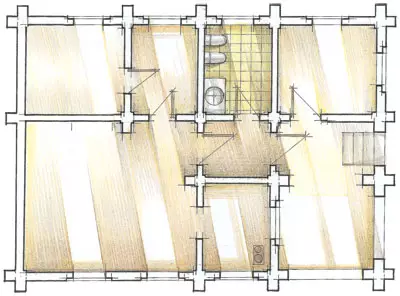

Floors

In steam, washing and bathroom, heated water floors with tiled coating are made. Under them staged a concrete base: cast a monolithic reinforced concrete plate with a thickness of 100mm, which rests on the ribbon frame (the width of the reference site is not less than 150 mm). The mixture of concrete floor was made with a bias 2-3cm per 1Pog. Mo for water drain. On top of the concrete laid a foam and pipes of a warm floor, scissors in a concrete screed with a thickness of 80mm.The stall part of the bath floor was performed so. The first crown was embedded larch lags (from three sides, they were processed by antiseptic), relying on the ribbon painting. Unsteraged boards used by antiseptic to them, which serve as a draft floor. The focusing "pockets" were put on a moisture insulation film and 150mm insulation, which covered the JutaFolh vapor barrier film on top (Juta). Waterproof plywood was naked on the surface of the lag. At the choice of the Customer, this foundation can be laid different types of modern coatings (parquet, board, tile, cork tree).

Steam

The agencies have two small windows, located at different heights. The top is small, used for natural ventilation, a second-hand window placed under the regiments, is designed to increase illumination. By the way, about the regches. They are made of solid aspen logs, on which protesters are made on cedar logs of walls. Only in this case they are collected together horizontally, not vertically. The Kastor furnace (Finland) is installed on the concrete floor, connected to the Schiedel (Germany) ceramic chimney. It has a high self-supporting ability, is not afraid of exposure to high temperatures and condensate, easy to install. Isaoy main thing - has excellent fictional safety indicators (the temperature of its surface does not exceed 40C), which allows you to organize the swirrel's passage through the wooden structures of overlaps and roofs. True, heavy chimney (from 80kg per 1Pog) requires a powerful foundation.

Restroom

From the Russian rules decided not to retreat here, allocating a fairly spacious room for rest. There is everything you need, even ... Fireplace: A large boot door of a bath furnace installed in the steam room remains in the relaxation room (the heat from it remains where it is supposed to be, and the flame game can be admired from the room).Avtot bedroom (as it is now fashionable) the owners decided not to arrange. However, it is possible to take a break on the so-called departure - in a small room under the roof (on overlaps). Changing device is also Russian tradition. There were broken brooms, eared and other necessary bath equipment. In this case, the floor of the floor is shown with a thick layer of the hay, on which it is proposed to relax everyone. The owners claim to sleep on such a "mattress" just wonderful. In addition, children are very loved here, often accompanying an adult company. They are even more interesting to them in small space than with adults.

A rather unusual staircase leads to the flaps, which is cut from a thick cedar log. The design took significantly less space than the usual, and moreover, it became hardly the main decorative element of the interior.

Window and doorways

The ends of the logs, leaving the openings, aligned vertically. In addition, on both sides of the opening, the grooves width and a depth of 60mm are cut. The campaign inserted vertical bars (placked), the width of which is equal to the wall thickness. They are made from the larch massif and are equipped with a "spike" corresponding to the size of the groove. The placade reliably holds the logs, emerging in the opening, from the displacement and protects the frames from the deformation during the shrinkage of the house. Over the lump left the technological gap (5% of the height of the opening). Then in the openings installed wooden windows with double-glazed windows and deaf wooden panel doors.

Interior decoration

Interior decoration is simple and laconic. The vertical surfaces of the protests on the logs were ground, after which they were covered with transparent wax. Prix seds pasted the rope, and a thick rope was knocked out at the junction of the walls and the ceiling instead of cornice.Exterior finish

Outside the walls are covered with composition 3V3 (France), only ends of the logs are left untreated. For what? When the room is warm, and on the street it is cold, the diffusion pressure causes water vapor to move on the log. But this diffusion will occur mainly not across the fibers, but along (by the way, it is such a way along the fiber moisture on wood and then when the tree is growing). Waxing walls from the inside is nothing more than vapor insulation.

But no matter how high-quality, we tried to steamize the logs, they will still be absorbed by moisture. She will be with the ends. Aesley does not give her to go out, the log will rot, and just from the end. That is why the ends of the logs outside to handle are impossible, except that the film does not form the film. This is confirmed by the old masters: in Russia, the ends of the logs are nothing but lime, never covered. Avot on the side of the room to paint them, then they will not absorb moisture.

After coloring logs, they are re-cocoon. In the case, it was done after a year and a half after the felling (by this time, the bath for a year as he was heated and fastened quite well). Outside, the interwidden seams are cocked by a jute blade (a moss between the logs is compressed). Seam must be even and solid. The quality of cauldium is determined by the density of the material of the material, it should be joined so that it is impossible to stick a nail into it.

Enlarged calculation of the cost * Bath construction with a total area of 64,4M2, similar to the presented

| Name of works | Number of | Price, $ | Cost, $ |

|---|---|---|---|

| Foundation work | |||

| Takes up axes, layout, development and recess | 23 m3. | 12 | 276. |

| Device base from sand under the foundation | 17m2. | 2. | 34. |

| Foundation of the foundation of the column, concrete woodwork | 9m3 | 65. | 585. |

| Waterproofing horizontal and lateral | 40m2. | four | 160. |

| TOTAL | 1055. | ||

| Applied materials on the section | |||

| Concrete heavy | 9m3 | 62. | 558. |

| Sand career | 6m3 | fourteen | 84. |

| Hydrosteclozol, Bituminous Mastic | 40m2. | 3. | 120. |

| Armature, Formwork Shields and Other Materials | set | - | 200. |

| TOTAL | 962. | ||

| Walls, partitions, overlap, roofing | |||

| Wall cutting from logs | 90m3 | 95. | 8550. |

| Build overlap with laying beams, flooring | 70m2. | 10 | 700. |

| Build elements of the roof with the device of the crate and coating plywood sheets | 140m2. | 12 | 1680. |

| Isolation of overlaps and coatings insulation | 150m2. | 3. | 450. |

| Device of vaporizolation | 95m2. | one | 95. |

| Bitumen Tiles Coating Device | 140m2. | 7. | 980. |

| Filling opening windows and door blocks | 25m2. | thirty | 750. |

| TOTAL | 13205. | ||

| Applied materials on the section | |||

| Building logs (larch, cedar) | 90m3 | 150. | 13 500. |

| Sawn timber | 17m3 | 100 | 1700. |

| Steam, wind and waterproof films | 170m2. | 1.5 | 255. |

| Moss (insulation) | 450kg | four | 1800. |

| Insulation Rockwool. | 35m3 | 40. | 1400. |

| Penophol for additional insulation ceilings | 60m2. | 2. | 120. |

| Bitumen Tile Tegola. | 140m2. | sixteen | 2240. |

| Wooden window blocks with double-glazed windows (Russia) | 15m2. | 140. | 2100. |

| Door blocks (to order) | 6 pcs. | 200. | 1200. |

| Wooden copper | 400 pcs. | 0.5 | 200. |

| TOTAL | 24515. | ||

| FINISHING WORK | |||

| Grinding of wooden surfaces | 220m2. | 6. | 1320. |

| Wood surface coating wax | 220m2. | 3. | 660. |

| Corps of wooden chopped walls | 950 pound M. | 2. | 1900. |

| Decorative processing of seams between logs | 950 pound M. | one | 950. |

| Other works | - | - | 4000. |

| TOTAL | 8830. | ||

| Applied materials on the section | |||

| Poland Boards (larch) | 40m2. | thirty | 1200. |

| Ceramic tiles | 30m2 | 25. | 750. |

| Joinery | set | - | 5200. |

| Dry mixes, putty, varnishes, protective compounds, paints | set | - | 2700. |

| TOTAL | 9850. | ||

| * - the calculation is made on the averaged rates of construction firms Moskva without taking into account the coefficients |