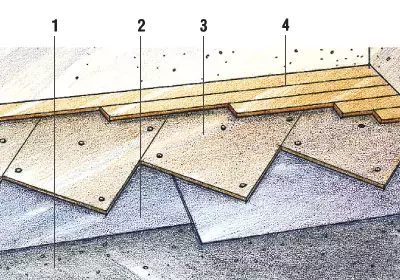

1. Betting tie

2.Plenka

3. Lovers waterproof plywood

4. Massive board

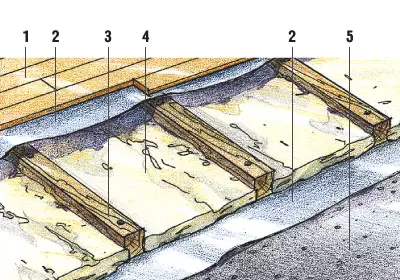

1. Massive board

2.Plenka

3. Lights

4. Depth

5. Bettonian screed

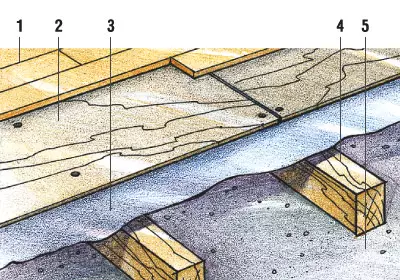

1. Massive board

2.Quable plywood

3.Plenka

4. Lights

5.Derevatovanny roll

The floor of the residential premises of this house rises the so-called massive board. From other wooden flooring, it is characterized primarily in its size. Her width ranges from 80 to 150mm, length is from 1200 to 3000 mm, and thickness - from 22 to 60 mm. Aota of a two-praidera-smooth heating board is different in that it has a "groove" fastening elements on two or even four sides, which allow the flooring tightly.

It serves such a board for a very long time, not afraid of multiple grinding. But, unfortunately, there are no cases when it is a non-dry flooring begins to swell and be covered by cracks. Why does this happen?

The reasons for premature destruction of the coating can be several. Forward, this is not enough careful selection of lumber. Here is a list of the basic vices of wood, which are extremely undesirable for a massive board:

Cracks. Through frosty cracks, directed radially, appear as a result of the freezing of internal moisture at low temperatures; Running cracks are separated from each other annual layers. Methic cracks go along the barrel from Komly to the top. All of them arise due to the internal stresses in the trunk. In addition, cracks can be formed due to the drying of the sawing tree.

Bitch Significantly reduce the value of wood. Insides, the strength of the material decreases in the germination of the branches, since after drying, the bitch often loses with the basis and falls.

Kososala - various deviations about the longitudinal axis of the tree. Wood with such a vice poorly perceives the transverse load.

Proportion - Defect that appears due to local mechanical damage to the fiber of a tree. Often in this place are formed mushroom spots and "squeezing". Similar vice spoils the appearance of wood and makes it difficult to finish.

Mushroom lesions Arise as a result of the impact on the wood of concrete processes, it changes its mechanical properties and color.

It should also be mentioned that the wood array board should have a humidity of 7-10% (verified using a special device-electrolylagomer). Deviations from geometric dimensions cannot exceed 0.5 mm.

It should be considered the fact that the wood is extremely hygroscopic. If the air humidity is redundant, the massive board can swear and even bent, and if not sufficient, on the contrary, is brewed and cracking. Therefore, in premises with wooden floors, it is necessary to maintain a certain microclimate-humidity of 45-60% and the order of order +20 C.

Laying

Having been pretty while spending a high-quality massive board, many are trying to save on its laying, inviting low-qualified masters. This should not be done, the risk is too large as the floor covering itself, and the necessary oil, varnishes and adhesives for its installation.

When laying, you must comply with a number of rules:

Ateper Let us dwell on the process of laying an outdoor coating. The massive board can be found on the so-called parquet technology (on the prepared even base, for example, waterproof, chipboard) or on lags.

Before laying the board, the slate or dump truck is roughly grinding the ribbon grinding machine. Then the treated surface is purified from dust. The floorboards are attached to it using self-samples with a size of 335-45mm in a step of 30-50cm (the boards are departed from the side of the spike at an angle of 50). The first row is mounted as a groove to the wall. If the coating is placed on a flat base (plywood, osp, wooden flooring), it is recommended to additionally apply parquet glue.

The laid flooring tightly poke them (if necessary, they are tightened with wedges). Between the waters and walls around the perimeter of the room, it is necessary to provide a gap of 7-10mm width. The first and the last rows of boards are fixed with self-proof over the facial surface, but so that in the future the place of fixation turned out to be hidden plinth. When laying a boards, more than 150mm width is also recommended additional mounting through the facial surface. Facial self-tapping screws are combined to a depth of 9-10mm and closed with impudent.

After grinding and removal from the surface of the dust, the boards of the board with varnish or oil-wax composition are processed.

The massive board can also be painted by verses or tinting compositions in various colors - white, bluish and even black. As a rule, companies providing this service offer several dozen color options. By the way, such processing is often choosing from economic considerations. You can purchase a board, say, from a conventional oak and tinted it under a wenge or other exotic tree of wood. It will cost it much cheaper, and it will look rather believable.