The technology of building a summer cottage designed to operate from May to September, from a profiled structure of a lap.

Each room of our magazine will certainly be told about the construction of a country house. At the same time, we usually go about homes for permanent or so-called seasonal accommodation, in which you can not only be comfortable from early spring to late autumn, but also periodically appear in winter. Today we will talk about the summer dacha, designed to operate from May to September.

The word "cottage" people perceive in different ways. Some imagine a spacious building (once in the city apartment is closed, so at least in the country it is not different from the dacha) is not different from the brick or similar "stone" materials, with a street pool and other suburban comfort attributes. But we are unlikely to make a mistake, if we say that the overwhelming majority understands the giving as a small and at the same time capacious wooden house. Each each has a separate room, and therefore, finally family members do not interfere with each other to engage in love or enjoy peace. The house is wooden. After all, the tree naturally, eco and for a long time mastered by man. Yves the same time is not very expensive, although not cheap construction material.

As the house chose

It is no secret that the most common during the construction of DACs in recent decades has received a non-corrupt rectangular pine timber, which is stacked on various types of seals - from moss and pacles to a special jute canvase. The bar is sufficient sufficient, technologically, and the houses are created relatively quickly and simply. But he leads himself in the already built building, it is quite peculiar, just enough that it cracks, it is still strung out and twisted, causing the need to re-housing the seams, after which it is necessary to wait for the shrink shrink. Yes, and the appearance of non-corrupt walls with a compactor protruding from the seams does not differ in the present. They are required to find them anyway, which naturally means additional costs. But you can start the finish only after the end of the re-shrinkage.Some discontent consumers, as well as the expansion of the scale of country, including country, construction demanded that the technological process simplifying specializing in this firms and at the same time reducing the timing of the construction of wooden houses. As the result began to be widely used to use the so-called profiled puzzle bar equipped with a compound "groove-comb". It is easier to dock in height and is less twisted (the design is more rigid). In addition, the appearance of the walls becomes much more aesthetic. However, this has appeared little to many firms. The idle reduction in the number of operations performed directly at the construction site, they decided to transfer the main process into a warm and dry workshop, which allows to gain almost complete independence from weather conditions. The "assembly" site of the customer comes the finished set of construction parts, of which experienced installers in the shortest possible time and collect a country house. Abroad it is called Prefabricated Houses, that is, houses made in factory conditions and ready for installation. We reacted to the idea with full seriousness and decided to find and describe such construction.

By the way, one of the familiar at the end of November decided to put a new country house on the site, he chose the company himself ("Technology") and the project (Dubrava "), having tied it with his own financial capabilities. The house is absolutely standard: the size of 66m and a height of two floors. Lower floor made of profiled timber, top-frame-shield. The structure promised ... in just five days!

I liked the option. All we saw on the "Assembly" site in one of the country's country villages near the District Center Fryazevo (Moscow region), and is offered to the attention of our readers.

Pros and cons of wooden construction

Wood-traditional material for the walls of low-rise buildings. Of particular importance is its high thermal insulation properties. For example, a wall of a wooden bar with a thickness of 10cm has almost the same thermistribution, like a brick wall with a thickness of 30cm (for winter, of course, it is not enough, but in the summer you can live). The tree is well processed, without difficulty, it is connected by nails, shuruses of IT.P. The walls of the house are quite durable, but at the same time they have a small weight, which, in turn, makes it possible to apply facilitated, and therefore, and cheaper type of foundation. Isaoy main and wood has good air and vapor permeability, which provides comfortable living conditions.

However, wood has disadvantages. First, it burns. Consequently, it will have to observe in the house increased fire safety measures, as well as use special impregnations to increase fire resistance. Secondly, it is subject to fungus, bacteria, mold IT.D. Therefore, wood should be treated with special compositions and, most importantly, ventilated, both during storage and in the already assembled design. Another disadvantage of the sedimentary deformation of the log and brusched walls in the first year after the construction. This means that with the final finish of the walls will have to be closed.

Delivery of materials

A week after the conclusion of the contract on the territory of the country village, two heavyweight trailers were entered, in which there were everything necessary for construction, from materials for the foundation to roofing sheets from galvanized steel. Unloading was performed manually and lasted almost 8h. After that, four neat stacks have grown on the site and adjacent territory. In addition to building materials, in one of the trailers lay in the disassembled state, the insulated firewall in size is 2.54m, which was intended for the accommodation of builders (the design is quick-discharged- is set for 1.5 to 3 second, heated by an electrical convector). At the end of the work, it should have either disassembled and transported to the next object, or to leave the owners, subject to payment of the residual value, about 4 thousand rubles. (Cost of new households - 12 thousand rubles.). But since the plot was a small old house with a metal stove, which builders were recognized as suitable for temporary accommodation, sent to the trailer back.

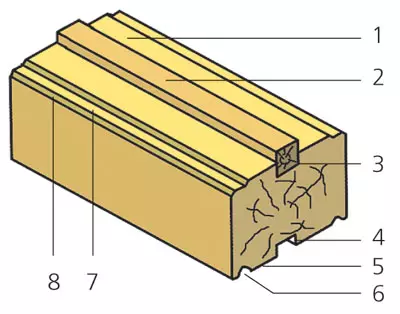

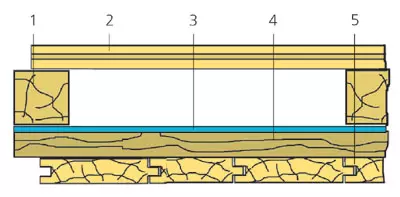

Construction of profiled bar

1- upper support surface;

2- longitudinal spike;

3,4-central groove under the longitudinal spike

(3- on the upper side of the bar; 4- on the bottom);

5- lower support surface;

6-longitudinal groove under the cord sealing agent;

7- Supporting surface under the cord seal;

8- "Tear"

Foundation

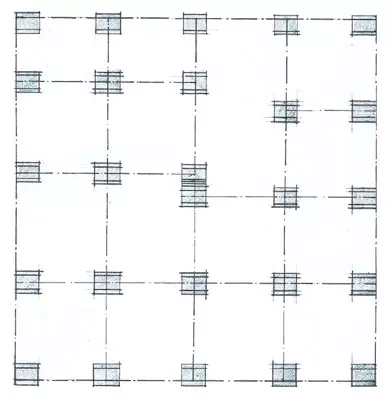

In this case, a column foundation was chosen (this option is most often offered for houses with light wall-breveled, bars, frame and shield). This type of foundation is 1.5-2 times cheaper than the ribbon (taking into account labor costs and consumption of materials). The cost of 1m2 area of building house is approximately 200 rub.Under each base of the foundation, a rectangular deepening was dug in, in which the sand pillow was a thick for 10 cm and thoroughly tamped. After reconciling the level of all pillows (it was produced using a hydraulic level) concrete slabs (40405cm) were placed on them. Next, from concrete blocks (202040cm) laid the columns with a cross section of 4020cm with a minimum height above the level of Earth 40cm (approximate thickness of the snow cover in the middle strip). Such columns are erected in the corners, in places of the intersection of walls, under rustles, supports and other points of focusing loads. The distance between the columns is 1.5 m (if this value exceeds 2-2.5 m, the bar will be fed). So that in the walls of the house did not penetrate the dirty moisture, the rubberoids were installed on the columns in two layers.

Wood moisture and shrinkage

In most cases, a log or brusade house is invited to build natural moisture from wood. The undoubted plus of such a material is low: it costs 2-2.5 times cheaper than dried in factory conditions to a moisture content of 12%.

The moisture content of the tree is determined by the two terms: humidity free and associated. The peculiarity of free moisture is that only the severity of the tree is changing with its increase, the strength properties do not change. Free moisture evaporates quite easily, it is enough to remember how the tree wet in the rain dries in just a few hours. With the associated moisture, everything is absolutely the opposite. Increase the strength of wood falls. The bound moisture evaporates extremely slowly, and in order to dry the tree with a natural way, it may be necessary for several years. The asymal main thing is to evaporate its evaporation, the volume of wood is reduced, that is, the last period occurs. Moreover, the magnitude of the dermist depends on the direction of wood fiber-across the fibers it is almost ten times larger than along. A results of a frame with a height of 2.5-3m per year and a half can settle almost 10 cm. It should be noted that the decrease in the size of the precipitate contributes to the forced screed of the bar, performed when building the construction.

Alsome one important point. Related moisture evaporates unevenly. First, it leaves the outer layers and only then the internal and the drying process slows down repeatedly. Uneven evaporation of moisture leads to the occurrence of internal stress-stretching in surface layers and compressing in the inner, as a result of which it cracks.

Walls

The walls were collected from a grip profiled bar not quite ordinary design. With a section of 9595mm, it is equipped with a longitudinal labyrinth "lock" and a two-kinning seal. According to the authors of the development, the main advantages of the design are more reliable fixation of bars among themselves and high tightness of the connection. This is ensured by two main elements. The first-central longitudinal groove with a longitudinal spike installed in it on the upper side of the bar and a response groove under such a spike on the underside. The second element is formed by two linen-hemp cord sealing agents, fixed in longitudinal grooves on the underside of the bar. On the upper side of it, these cords are made of two supporting and pressing longitudinal sites (with chamfering) underlying the reference surface.

The assembly of the walls began with a barous row. The horizontally selected wintis in the corners were combined with nails. All subsequent crowns were tightened with a vertical of 6200mm with steel heater. They are driven into a bar every 1,5m walls. And not just driven, but plunge (using a special "Dobochnik") by 20-25mm, due to which they are "crosslined" not even two, but at once three crowns. The double task is copied: first, they interfere with the twisting of the bars during drying, secondly, pressed them to each other as close as possible, which allows you to slightly reduce the overall shrinkage of the walls of the first floor in height. The arms of the wedges were made of staggered. At the corners of the bars, after one, had a vertical sample in a quarter, it covered the ends of the bar, joined with the data. For greater strength, this compound was pulled by nails with cutting (the presence of "threads" they resemble self-tapping screws).

Simultaneously with the external walls gathered internal. Their interface with the outer was carried out. The wrenched crowns were made in one row (in his place in the bars, a shot was made at the factory), which blew up the inner wall timber. The bar of the next row of the inner wall was simply applied to the wall bruus of the outside. In such cases, the bars are stitched with nails (painshock from top to bottom). It is worth noting that the result was quite neat walls, in essence that do not require additional finishes.

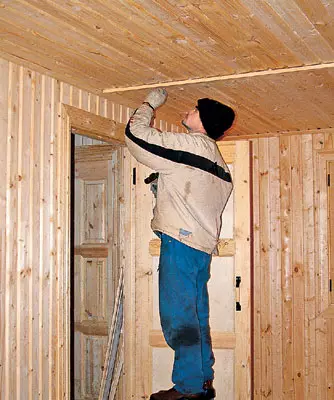

The assembly was continued until the builders had enough growth to work, standing on Earth. When the height of the walls reached this level, started installing the floor of the first floor.

Build turnkey

The construction of the house turnkey on the corporate technology is perhaps the most common wording of all which you can find in advertisements. Sounds very tempting. That's just perceive all this should be extremely careful.

First, because the design of the profiled timber, and, consequently, the design of the walls and the technology of their assembly in different firms differ greatly. However, the designs of the floors, overlaps, roofs, not to mention windows, doors and insulation are distinguished. Ivo All these details you have to delve yourself. Otherwise, conflicts with the company when surrendering at home not to avoid.

Secondly, the concept of "turnkey" has its own. Harmful cases really mean the house, trimmed both outside and inside, with a finished electrician, heating, water supply and other blessings of civilization. Such cases are rare because the construction price turns out to be very high and not particularly attractive to customers. The overwhelming majority of firms will give you only a ready-made box of houses, with the promised walls, floors, ceilings, roofs, windows and doors. The long-awaited key from the entrance door will also be presented, naturally, if the cost of the lock and its insertion in the door is included in the estimate. But the total amount will be quite moderate. Questions for finishes, as well as equipping the house by the "benefits of civilization", you will have to solve either independently or with the help of the same company, but already on the basis of an additional contract.

Floor floors

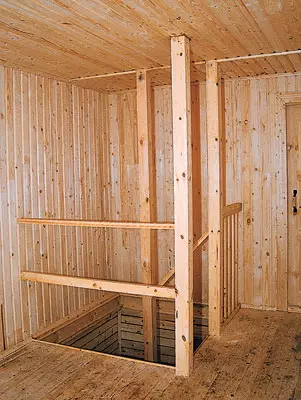

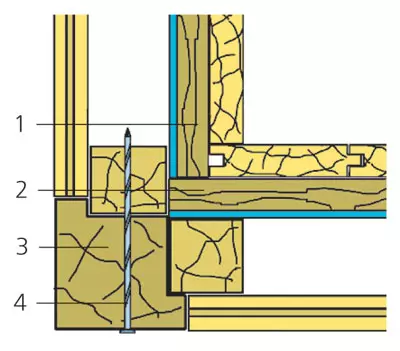

Floor lags based on foundation columns made from a bar with a cross section of 155cm. On top of the lag in 40cm, the controls were laid on the edge, in shape resembling an inverted letter "T". They are made of a cutting board of 102.5 cm, to which bars 34cm are nailed from below from both sides. Mospus between controls around the perimeter of future rooms to the strapping brusade crown was knocked off a cranial timber segment 44cm. The result was a pretty durable overlap farm. The segments of the 16 mm lining were invested between the controls of the "pockets", having obtained a rough floor. All its items facing the ground under the house were previously treated with moisture-proof composition. In order not to be staining the finishing floor (on the street, the frost, then the thaw), with its laying, decided to wait until the end of the construction of the house. Subsequently, the "pockets" of the draft floor was laid insulation (polystyrene foam 20mm thick), climbing the kraft paper under it as waterproofing, and then a 22mm thick chopped board (with a small step, the lag of such a thickness is quite enough).By mounting the draft floor, continued to lay the brusched walls. When their height reached a critical mark, several stairs were made of undergraduate materials and then the installation was carried out with them, refusing to the facilities of forests.

Overlapping

The overlaps of the first and second floor are modular shield. Their power elements are on the end of the lags (timing sections 155cm), located in increments of about 40 cm. From the bottom to the lags of the second floor of the lining of 16mm thick, it forms a ceiling. Votchchychi from the overlaps of the second floor of overlapping the first is insulated with a roll "plenipal" (foamed polyethylene with closed pores) 4mm thick, placed in the grooves between the lags. The shields of the floors simply laid on the walls and was attached to them with nails. The in the distance on the lower lags was used a t-shunting board with a thickness of 21mm, thus creating a clean floor.

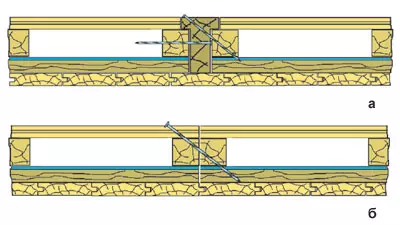

Second floor

The walls of the second floor are assembled from panel modules. The basis forms a frame from a bar with a cross section of 44cm in a step between vertical ribs 40cm. It will be covered with horizontally located clapboard, the width of which corresponds to the width of the profiled timber (as a result of the wall of the second floor, externally very similar to the brusched walls of the first). The sides of the sides are adjacent to the frame (the same "voicer" thick 4mm thick), held by the crate (bars 24cm with a step 40cm), on top of which the lining is vertically nailed, similar to the outer one. Modules are connected with each other in three ways: on the corners, with the help of special wooden angular elements, butt through T-shaped wooden connectors or directly. In all cases, the design is bonded by nails with cutting. To remove rainwater flowing through the walls of the second floor, from the brusal walls of the first, in the bases of the panel modules, water-grades made of galvanized steel were installed.

Second floor shield design:

1-frame from a bar 44cm installed in 40 cm;

2- outer covering, horizontal lining;

3- insulation- "PVIEKS", 4mm;

4- doom (bars 24cm with a pitch 40cm);

5 - internal sheathing - vertical lining

Methods for connecting shield shields:

B - directly

(In both cases, shields are fastened with nails with cutting)

Roofing design

After mounting the attic ceiling, the two-screw roofing structure has begun. The mucose and the back side of the house was set to be lapty frame-shielded frontones, covered outside with clapboard (in their bases, also spaced water-graded steel). For the creation of a rafter design, pine boards were used by a cross section of 102cm, which knocked off to the longitudinal lags of overlapping and the skate bruse of the same section. On top of the rafter, the cutting of the cutting board was placed on top of the cutting board, and then the roofing plates of galvanized steel, having trapezoidal ribs along the edges (during installation, the sheets are overwhelmed with these ribs each other). The eaves of the frontones and the raids skes were laid by clapboard.Outdoor and interior decoration

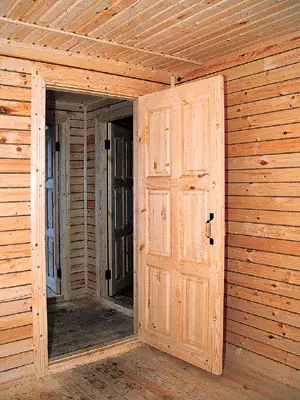

First of all, fired window and doorways. On the first floor installed window blocks with a size of 102118cm with a single binder under double glazing (glass are located on both sides of the frame), on second-similar blocks, but for single glazing. It and others provided with wooden platbands. After that, the frame was glazed (the window glass was sliced in advance in the size of the factory). Door canvases preferred the pilient-on-the first floor in size 90210cm, with filling with a glued furniture shield, on the second-size 80199cm, with plywood filling. The windows and door frames and the first floor doors are installed on the so-called sliding landing-design, as it were, "hugs" ends of the bar, but not attached to it with nails, which avoids its warping at the inevitable shrinkage at home. The compensation gaps were left for the same purpose over the frames, the value of which was approximately 5 cm.

All vertical and horizontal angles both on the first and on the second floor have been decorated with wooden plinth. Similarly, all the external corners of the building were treated.

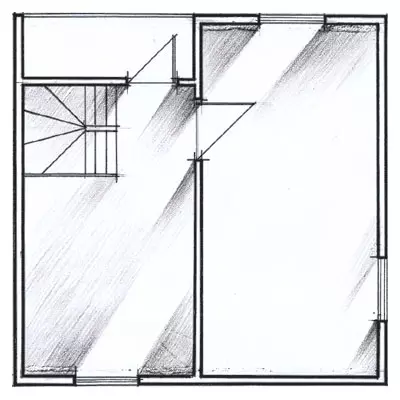

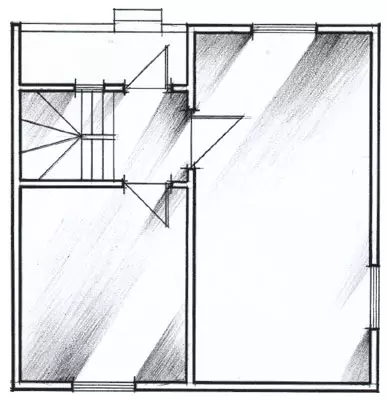

For lifting to the second floor, parts brought from the plant collected a wooden staircase with a central support post. It consists of two small straight spans and swivels with running steps. Another staircase was built before entering the house, two-stage. At the top it relies on the wall, downstairs concrete tiles, similar to the foundation laid under the columns.

Here, perhaps, all about the design of the house described. "Modest" and not very expensive- 220 thousand rubles. He was put on time. On the fifth day, the brigadier solemnly handed the host keys, and he signed an act of acceptance of work.

We told you how the country house is built turnkey, on the example of only one company. However, it was already said that the idea of how such a house was look like from a turnkey bar, each "manufacturer" has its own, individual. Extended construction capabilities We will discuss in the next room. That is, the continuation should be ...

The enlarged calculation of the cost of building a house with a total area of 65.9M2, similar to the submitted

| Name of works | Number of | Price, $ | Cost, $ |

|---|---|---|---|

| Foundation work | |||

| Takes up axes, layout, development and recess | 3m3 | eighteen | 54. |

| Device foundations of pillars from concrete blocks | 1,3m3 | 40. | 52. |

| Horizontal insulation device | 3m2. | four | 12 |

| TOTAL | 120. | ||

| Applied materials on the section | |||

| Concrete block, concrete slab | 1,3m3 | 80. | 104. |

| Masonry heavy solution | 0.4m3 | 55. | 22. |

| Sand career | 1m3. | fourteen | fourteen |

| Hydrosteclozol, Bituminous Mastic | 3m2. | 3. | nine |

| TOTAL | 150. | ||

| Walls, partitions, overlap, roofing | |||

| Cabinet of walls from bar (first floor) | 6,6m3 | 95. | 627. |

| Cabinet of the frame of external bearing walls, a device of frame partitions with a trimming, installation of a rafter design, overlap device | set | - | 1800. |

| Device of vaporizolation | 45m2. | one | 45. |

| Insulation of coatings and overlaps insulation | 117m2. | 2. | 234. |

| Metal coating device | 45m2. | 7. | 315. |

| Filling the openings by window blocks | 6m2. | 35. | 210. |

| TOTAL | 3230. | ||

| Applied materials on the section | |||

| Home Mounting Kit | set | - | 4100. |

| TOTAL | 4100. | ||

| Total cost of work | 3350. | ||

| Total cost of materials | 4250. | ||

| TOTAL | 7600. | ||

| * - the calculation is made on the averaged rates of construction firms Moskva without taking into account the coefficients |

The editors thanks the technology "Technology" for help in the preparation of material.