Heated greenhouses and winter gardens: historical certificate, design features, water and heating systems, equipment.

In such greenhouses, stationary heating, as a rule, does not apply

In the presence of a backup power supply, a modern boiler is almost invulnerable

Metal-dimensional pipes are used in heating systems for transporting heat carrier

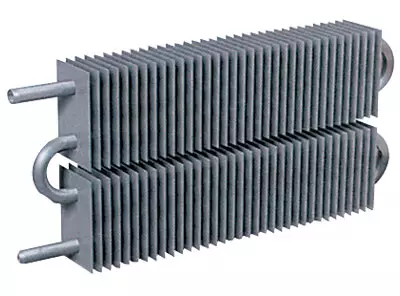

For heating air in winter gardens, water convectors are used to 700mm high. They are placed in glazing, around the perimeter of the greenhouse

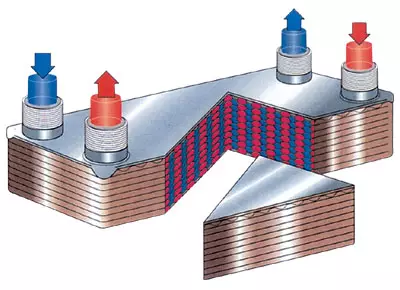

Plate heat exchanger, "selecting" Heat from the heating system for a greenhouse

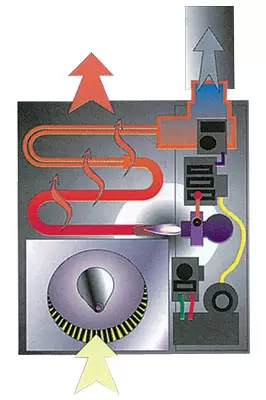

Indirect heating heater Master BV460E on diesel

Portable Electric Fan Heater ("Heat Gun")

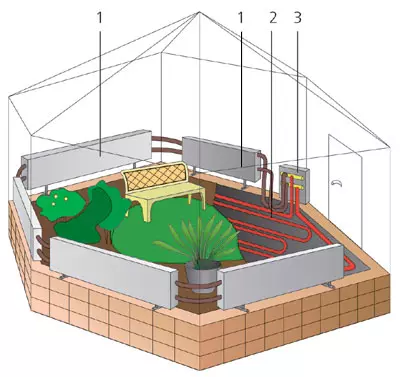

Fan coils are installed in greenhouses together with water heating systems based on pipes or convectors and soil heating devices

Photo O.Voronina

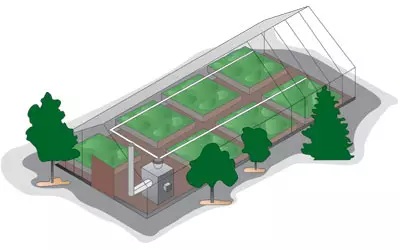

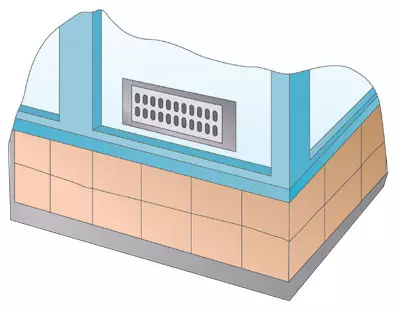

Orangery with electric soil heating

In the air-heater of indirect heating, fuel combustion products are removed to the street through the chimney

For all year round, it is not parted with in the summer, it is enough to build a heated greenhouse corner next to its own country house, where palm trees and wonder flowers grow.

From the history of the question

The Orange Orange, Orange, Orange, Orange, Orange, was not accidental. The average of the French kings, in particular during the days of the French kings, they were used to dilute various exotic plants, primarily highly revered by citrus sinks. The first glass heating glass was built in the Botanical Garden of Belteren (Holland) in 1599g.Vanglia in the XVII century, heat in them was maintained in different ways: in Oxforde, with the hard-firing carbon carts, and in Chelsea in Chelsea 1685 For the first time, underground heating of the soil was applied.

The construction of heated herenzes also has a long history. Heated by wood-grinding furnaces "Ranking Chambers" began to appear at the end of the XVII century in the embankments of the Gardens of the Moscow Kremlin. At the same time in the Arkhangelsk, near Moscow estate of Prince M.A. Cherkassky, there were two greenhouses for overseas plants (peach, oleander, laurel IDR). At first XVIIIV. Peter I laid a greenhouse in the summer garden and the pharmacaric garden of St. Petersburg.

Later, the greenhouses, intended mainly for growing exotic fruits in winter (pineapples, grapes IDR), become an indispensable element of the ussers and palace ensembles. Often they combined the functions of "nurseries under glass", galleries and dancers, decorated with paintings and sculptures, like, for example, in the manor of Kuskovo near Moscow. The richest collections of greenhouse plants in Gardens P.A. Demidov in Moscow (second half of the XVIIIV) and Count A.K. Orazumovsky in Moscow region were used to be widely fame among the contemporaries.

After October 1917. In Russia, heated greenhouses in the homes, as well as the possibility of possessing such property, gradually disappeared. Only a few decades ago, when people began to receive summer cottages, there was an interest in the technology of closed soil, but only the simplest greenhouses for growing early vegetables were in demand. The construction of large multifunctional heated greenhouses and winter gardens next to country houses is reborn only today.

Winter Garden Heating System:

2- metal-plastic pipe of the floor heating system and heating the soil;

3- collector cabinet

For the revival of traditions!

In the special literature on greenhouse economies, the discharge of cold greenhouses, in which the lowest positive temperature is maintained in winter: about 1-8c. However, the meaning of the word "greenhouse" in everyday life is somewhat wider: this is a room for growing and reproduction of plants that do not carry the climatic conditions of this area outdoors. Therefore, orangenes are often called other (including tropical) greenhouses with a temperature in winter until 25-30C. Special-type greenhouses, in which plants play a supporting role, creating, in fact, a living environment for walking, relaxing or holding holidays in winter, is referred to as winter gardens. The jackets can be pools for water and coastal plants with fresh and sea water.

Modern greenhouses usually consist of a frame (made, for example, from "warm aluminum") with glazing. Punching alternatives to single sheet glass apply double-glazed windows, cellular polycarbonate or cellular acrylic glass. Since the lighting intensity affects the photosynthesis of plants, it is better that the entire surface of the greenhouse is transparent (this will allow you to get as much daylight as possible). Sometimes there is only a light roof. In love, it is necessary to provide a system of artificial lighting. Most often, "glazed gardens" are attached to the house, so you can get into them through the door or open passage, right from the adjacent room, or placed at some distance from the building. Weekly engineering systems (the most important heating system among them) in the oranges the necessary temperatures are supported, the humidity of it.d.

Have your own heated greenhouse, even if not very much, usually dreams of any of those who breed decorative plants and flowers. After all, you can break the garden of year-round flowering, and work in it will bring true pleasure. Warm greenhouse sometimes becomes the source of environmentally friendly vegetables and fruits for its own table.

The microclimate of the Winter Garden has a beneficial effect on the well-being of a person, in the state of its skin (with relative humidity of 50-60%). You have the right to use the greenhouse (as was customary in pre-revolutionary Russia) as a hall for receiving guests located outside the main building. In winter, in the spring and autumn there is an extra festive table and chat with friends.

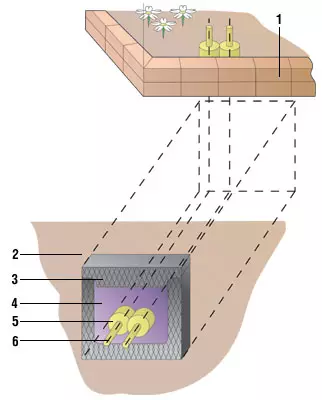

Heat "cottage-greenhouse":

2 - soil;

3-concrete channel;

4- Ceramizite;

5- thermal insulation;

6- pipes

On deductions

Construction of heated greenhouse is a complex task, the solution of which will require significant physical and material resources from the developer. The most responsible and time consuming is the stage of selecting the heating system.

To evaluate how much the content of the greenhouse (the cost of it is heated), it is necessary to carry out the simplest calculation. To do this, determine the area of glazing and the temperature necessary for the content of plants. For example, leavings from tropics and exotic vegetables need heat all year round. Many of them are comfortable at 18-21. It is also necessary to determine the climatic card the minimum temperature in the region where the Garden Garden is located (in the suburbs it is -29c). The coefficient of heat transfer of the material from which the greenhouse is made is easy to clarify in the reference book. For double glass, it can be 2.98 kcal / (m2 of emergency).

The formula of the need for heat is such: the glazing area is multiplied by the temperature difference and the thermal conductivity coefficient. It is measured in kilocalories per hour (kcal / h).

Consider an example when the glazing area is 140m2 (solid glazing a greenhouse with a size of 66m), the temperature difference 49c, and the heat transfer coefficient is 2.98. Calculate: 140m249С2.98 kcal / (m2cc) = 20443kkal / h (rounded). Since in most cases the power of the heating equipment is given in watts and kilowatts, the obtained value is translated into watts: 1W = 0.86kkal / h. So, 204430.86 = 17581W (about 17.6 kW). Insomeselylays, take into account the loss of heat with removable air, through the soil of IT.P. Of course, the heating will not work in full force of all six-seven seven months of the heating season, but the equipment must be calculated on this power so that the plants do not froze in one of the frosty days.

Actually, the heating equipment for the heating of a greenhouse usually includes a system of heating air, as well as soil and racks with flowers (if provided in the constructs of the greenhouse). Most of all, water and air heating installations are suitable for this.

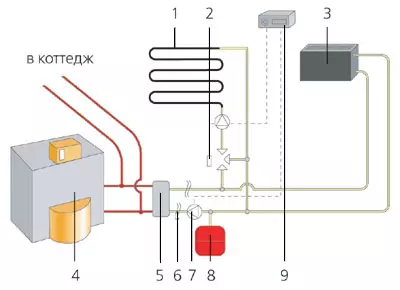

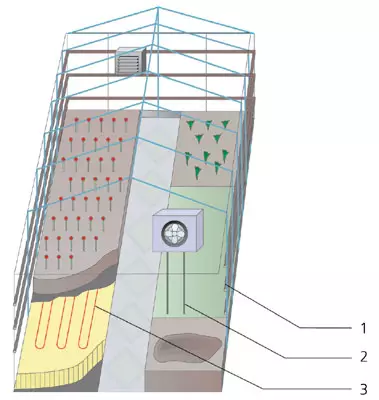

Schematic diagram of the heating system of the greenhouse:

1- contour of soil heating;

2- mixing valve;

3-heating devices;

4- heat generator cottage;

5- plate heat exchanger;

6-heat generation between the house and the greenhouse;

7 - pump;

8- expansion tank;

9- Automatic unit

Water, water

The water heating system of greenhouses is used almost everywhere. It provides the most uniform distribution of heat, which is very loved by plants.

The depositarian system is used as heating devices (depending on the temperature of the coolant), plastic or steel smooth pipes with anti-corrosion protection (for example, with a polymer coating). They are placed in the upper zone of the greenhouse - under the coating, drainage gutters and cornices; in the middle zone, the outer walls, on the internal frame racks, drains of the frames or lower belts of farms and between the rows of plants; In the lower zone, on the ground between the rows of plants, along the contour of the external walls at a depth of 0.05-0.1 m and for heating soil, at a depth of at least 0.4 m from the design mark of the soil to the top of the heating pipes. At least 40% of the total heat, including soil heating energy, is applied to the altitude of 1m from the soil surface. The shut-off and adjusting fittings provides separate inclusion (shutdown) and the ordering of heat transfer of heating devices in different zones.

For promine gardens, where plants are grown in ads, instead of pipes use other types of heating devices, such as convectors. They are placed in the lower zone of the greenhouse, on the brackets by fixing on the foundation so that they form an inseparable "heat track" along the perimeter of the room.

The soil in the oranges is most often heated using metal-plastic pipes. The step laying the pipes is determined by the calculation, but its value is at least 20-30 cm. Pipelines are layered on a layer of drainage flowing insulation (sand or slag) with a thickness of at least 30 cm, after which the layer of fertile soil with a thickness of 40-50cm is poured.

The coolant for the heating system of the greenhouses can be heated using a modern boiler operating on diesel fuel, propane, electricity or even solid fuel or firewood. In the end, the case will have to build a storage for fuel and spend time to maintain a solid fuel boiler. Increased energy carrier for the "greenhouse" boiler it is more profitable to use natural gas. If the heating of the greenhouse has not been provided at the design stage of the house, the cottage heat generator will have to be replaced with a new one, more powerful. Connect the heating system of greenhouses (pipes or convectors and equipment for soil heating) to the heating contour of the building through a plate heat exchanger. It allows you to isolate your home and greenhouse heating contours from each other and simplify heating control.

The temperature of the coolant in the branches of the heating devices can be about 60-80s, and in the branch of the heating of the soil - up to 40c (so as not to overcover the root system). Heat processor between the greenhouse and the cottage (two insulated polyurethane foam metalplastic pipes) is laid in the waterproof concrete channel filled with a clay, located at a depth of about 1.5 m. For circulation of the coolant (propylene glycol) in the heating system, pumps are used, and to compensate for thermal expansion - an expansion tank. The length of the heating main should not exceed 10-15m, otherwise the heat loss will be very large.

Create a water heating system for greenhouses can be from various components. Prices for gas boilers with a capacity of 15 to 90 kW are $ 550-6800. The most expensive and high-quality boilers produce Viessmann, Buderus, Vaillant (Germany), Dedietrich (France). Middle and moderate prices sell Roca (Spain) boilers, Protherm (Slovakia), ACV (Belgium) IDR. The burner to the boiler (if it is not supplied in the kit) will cost another $ 400-1500.

Circulation pumps worth $ 60-700, providing the movement of the coolant in the system, with a capacity of 3-75m3 / h to supply the Russian market Grundfos, Vilo (Germany), DAB (Italy). High-quality expansion tanks necessary to compensate for thermal extensions of the coolant during the operation of the heating system produces Reflex (Germany). Shut-off-regulating fittings are published by Danfoss (Denmark), Herz (Austria), Italian companies Far and Giacomini. The cost of the kit is determined, based on the calculation of $ 4 for the 1m2 heated area of the greenhouse.

It is necessary to take care of the automation that solves the temperature control problem in the greenhouse (at different height of the room), monitors the functioning of circulating pumps, will coordinate the operation of heating and ventilation systems. The production of automatics is engaged in both boilers and companies far from the production of boilers. Systems with the simplest temperature control algorithm will cost $ 75-170. The average difficulty is from $ 300 to 1000. And "Fake-up" programmable complexes with the possibility of remote control may well do and at $ 3500-4000.

Heat is delivered to the greenhouses and is distributed through the pipes. Prices for Russian steel rolled products are $ 5 for 1Pog. M. Pipes with a diameter of 75mm. Metal-polymer pipes from Henko (Belgium), Metzerplast (Israel), Unicor (Germany) will cost $ 0.5-1.5 for 1 in a diameter of 16mm. The cost of convectors of domestic production equipped with a steel heat exchanger with steel fins is about $ 30-50 for 1 km of the device. They produce them, for example, KZTO, "Santechprom", "Isotherm" (Russia). Do not forget about the coolant. Non-toxic propylene glycol based liquid costs about $ 1-2 per 1 liter; At the same time, it will take about 200 liters on the heating system with heating registers for a greenhouse with an area of 30m2.

Combined "water-air" heating system of a greenhouse:

2- fan coil;

3- contour of water heating of the soil

Warm breathing

In the greenhouse can also be used air heating. It is usually used in combination with water (consisting of pipe-heating devices connected to the heat generator and the soil heating system). Such combined heating is to equip the greenhouses in areas with the outdoor temperature of the coldest day -20c and below. The performance of air heating in the combined heating system takes equal to an average of 35-40% of the total heat consumption for the winter. However, in some areas with a mild climate, the air heating of the greenhouse can be used as the main or in tandem with the soil heating system.

The cuity of the air heating system should include high efficiency and low inertia: for 35-40 minutes the air system can raise the temperature in the greenhouse by 15-20s. This allows you to effectively heat the greenhouse even with open framugs. The injected warm air creates the necessary movement and uniform warming of the entire greenhouse. It is necessary for air heating equipment usually cheaper than other alternative systems.

Air heating of the greenhouse (when the air is heated in one place, after which it is evenly distributed on the room with the help of air ducts) can be arranged on the basis of an air heater operating on a gas or liquid fuel. It connects to the main gas pipeline or a container with bridal fuel; To remove the combustion products outside the greenhouse uses chimney. Pouring through itself filling the greenhouse air and heating it to a temperature of about 40s, the air heater then injected the flow into the network of air ducts from galvanized tin, which is located around the perimeter of the greenhouse, at some distance from the walls, at an altitude of about 2.5m. To ensure that blowing glazing, a uniform temperature, as well as the optimal mobility of air masses, ventilating grilles are put on the feed holes in the air ducts.

Air heating is installed without air ducts. For this, they will need stationary fan heaters - fankeals equipped with an indirect heating gas heat exchanger or water calorifer. Such devices provide efficient and fast heating of the greenhouse, including with frequently open framugs.

In addition to the air heating system, you can equip the electric soil heating system based on a single or two-tier resistive cable. The rapid power of the latter should not exceed 15W / m, so as not to overcover the root system of plants. The optimal temperature of the soil is 15-25 ° C for different cultures and about 30s- for peat pots and beds with seedlings.

If the cable is laid directly into the soil, it is desirable to use the heat insulation layer from the material that does not absorb moisture (for example, polystyrene foam or polyethylene). From above, the heat insulating layer is closed with a polyethylene film that plays the role of waterproofing. A layer of sand is poured with a thickness of approximately 10 cm, inside which the heating cable is lying (the height of the sand over the cable is not less than 5 cm). Stack of laying cable- Approximately 15 cm. On top of the layer of sand spread the chain grid to protect the cable from damage to a shovel or another garden tool. Then pour the fertile soil with a thickness of at least 20-25 cm.

When installing a cable in a concrete screed, the likelihood of its damage in the process of soil processing by various tools is reduced. The heat transfer coefficient increases due to the greater density and homogeneity of the screed compared to the soil.

For the air heating channel, you must purchase an air heater suitable for use in greenhouses, for example, from companies "Heat" (Russia), Steamtherm (Finland), Desa International (USA). 32kW air heater module is on average $ 1500-3200. Air duct layout (crash) - $ 20-25 at the rate of 1m2 heated area. Excellent fan coils with water facilifers manufactures Jaga (Belgium); Good equipment is supplied by VTS CLIMA (Poland), "Moven", "Weeza" (both- Russia). The cost of "fan coil" heating system is an average of $ 130-500 per 1 kW of thermal power. The heating sections on the basis of single and two-cable cables are produced by dozens of companies, including Ceilhit (Spain), Kima (Sweden), Devi (Denmark), Ensto (Finland), as well as Russian FIRS, "Terma" and "Eltech Electronics". The cost of the cable heating system of the soil turnkey is $ 10-25 per 1M2 heated orange or winter garden.