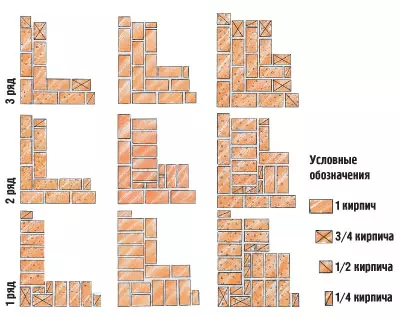

with the formation of corners and quarters

Laying walls of brick-traditional and to this day the widely used method of erection of enclosure and supporting structures. The variety of masonry options allows you to build from brick buildings of any architecture and storey, plastering the facades, ferry their face brick, tiled, decorative stone. Our article introduces a reader with the most common in cottage construction and masonry methods

Brick and mortar

Builders include brick to the category of artificial stone. Indeed, the brick is not inferior to the stone, and in many respects it exceeds it. Brick-clay and silicate is hollow and full of white. Since silicate brick is more hygroscopic, then below the level of waterproofing or in places with high humidity it is not used. Full brick today apply only for laying partitions, furnaces, chimneys. The fact is that in its heat shielding properties, it is inferior to most of other building materials. For example, the resistance of the heat transfer of the walls of full-scale bricks is three and a half times lower than the wooden walls of similar thickness. Therefore, the outer walls are erected mainly from the hollow (effective) brick. Additional insulation of a brick wall with mineral wool slabs, an aggregate of cellular concrete, foam makes it possible to increase the energy efficiency of the structure from 30 to 200% and reduce the consumption of bricks.

Walls made of bricks are laid out on binding solutions consisting of cement, sand and water, with added, if necessary, lime and chemical components to work in winter. When using cement of grades 500, 400 and 300, the ratio of cement and sand in the solution should be 1: 3, gras 200 and below - 1: 1. Usually, the cement is taken to the construction site in bags, sand is sifted in place manually. The masonry solution is prepared in a small concrete mixer, but it can be done without the use of technology. In the case of the boards, the shallow chest with a bottom of the metal sheet is pinned, where sand and cement are poured in the desired amount and mix the shovel until the mixture becomes homogeneous in color. Then the water gradually poured into the sandy cement mixture and thoroughly mix the mass to obtain the solution of the desired consistency. A row for the next brick is laid on the solution, filling also vertical laying seams. The thickness of the solution in horizontal seams of walls is from 10 to 15 mm, in the vertical (between the chips) - 8-15mm. The solution is prepared in an amount that can be consumed until the mixture loses viscosity and starts to fit.

Characteristics of bricks for masonry walls

| View of brick | Dimensions, mm. | Mass of one brick, kg |

|---|---|---|

| Clay ordinary plastic pressing | 25012065. | 3.2-3.5 |

| Clay hollow plastic and semi-dry pressing: | ||

| single | 25012065. | 2.2-2.8 |

| Overhead | 25012088. | 2.9-3.7 |

| double | 250120138. | 4.6-5.8 |

| Silicate: | ||

| single | 25012065. | 3.3-3.7 |

| Overhead | 25012088. | 4.5-5.0 |

Types and Masonry Methods

As long as the masonry reaches a height of 1.2 m, the mason works without auxiliary devices. Then for the convenience of movement and in order to ensure the safety of people around the perimeter of the building under construction, the layers are installed, a little later, the collapsible metal forests. The main tools for laying brick are trowel, hammer, plumb, batch, rail, level. Slitty brick is cut in a diamond disk saw.

The brickwork consists of the versts laid down along the wall outside and from the inside, and there is a fill between the versts. A row of masonry, in which the bricks are located long side (spoon) along the wall, are called a spoonful, end part (tych) - twin. The strength of the masonry and the creation of a certain pattern on the front surface of the wall is achieved by dressing brick-alternate of spoonful and twitch rows with the displacement of the vertical seams of each row to a quarter or half-clip. When the walls are erected with the outer extender of the seams, the lining of the facing row is made at no less than five rows. With a solid laying of the outer walls, the rebirth of seams can be both in each row and through three or five rows. The strength of the masonry increases significantly if it is reinforced by a steel grid with 6-12 cm with a steel grid with a steel grid.

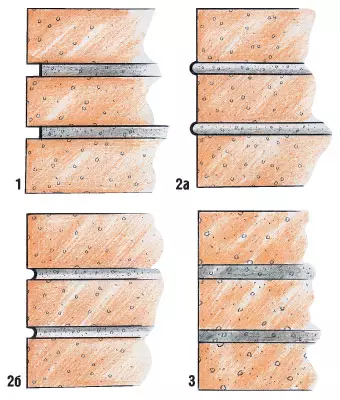

The masonry of the vest rows is performed in two ways: if you use and let's use. The first is incomplete filling sew-applied when the walls of the walls are inlet, the second, with full filling of the seams, when laying in two bricks along the outer circuit of the wall. In this case, the solution, squeezed on the front surface of the wall, is trimmed with cells. The vertical of the masonry is checked with a plumb, horizontally-plated on top of a row of bricks direct rail with strictly parallel sides with a length of 2-2.5 m and level. The irregularity of the wall surface is revealed by applying similar rail to it vertically and diagonally. The seams are carried out with a metal tool (extender) after masonry every 3-4 tights. The first to expand dry vertical rows faster, follow the horizontal.

Processing seams of masonry:

1.Vpustovoy

2. With the screening of the seams:

a) roller;

b) Flip

3. Codefactor

Effective masonry

In modern cottage construction, a three-layer laying was distributed, allowing to make walls thinner without changing their heat engineering properties. The smallest consumption of bricks and the greatest heat transfer resistance are obtained in a three-layer enclosing structure, where the inner (carrier) part is made of effective brick, and the outer (self-supporting) is a vesting brick. The required meaning of the resistance of the wall heat transfer is provided by the use of heat-insulating plates with the necessary thickness installed between the bearing wall and facing. If the architectural solution of the facade involves plastering the outer wall, then the front rows are tied up with the main wall with tile rows or metal reinforcement every 5-6 rows of masonry. Quite often for the heat insulation device, plates from basalt fibers or polystyrene foam are used. The insulated wall with a thickness of 51cm in its heat-shielding qualities is equivalent to solid brickwork from full-length brick twice as much thickness. The heat insulating plates are installed vertically between the inner and outer walls. Parts of the three-layer brick enclosing design bind to each other to the mortgage parts made from the reinforcement with a diameter of 4.5-6mm or fiberglass, at the rate of 4 bonds per 1 m2 of the wall area. Their step in height and width depends on the thickness of the insulation slabs. The ends of the links are laid in the outer and inner part of the wall to a depth of 6-8cm.

Ideally, a device of a ventilated air layer is needed between the outer part of the wall and thermal insulation plates. Its thickness should be 20-30 mm. For good ventilation, the upper products should be performed in the eaves, the lower, the basements. The creation of air clearances is technologically complex and expensive. The cost of 1m2 of the wall of such a design approaches the cost of the wall from the more expensive material-pierced brick, with which the similar result is achieved. Therefore, at construction sites of the Moscow region often make a compromise solution, lay insulation into the body of a brickwork without an air gap. For three-layer masonry use hollow or porous hollow bricks. Facing a facade with brick is carried out with a decree of the seams. We are departed by I practitioned by some companies, the masonry is performed from two walls with a thickness of 380 and 120 mm and laid between them with a thickness of 5 cm. The strength of the design provides metal connections or reinforcement of the rows of masonry grid. We are depicting the II wall laying down under the plaster, taking the face rows with the main wall with tile rows. The constructive feature of this type of masonry requires a high level of production of work, as well as an additional reinforcement of the seasplets and the bottomroom parts of the building walls.

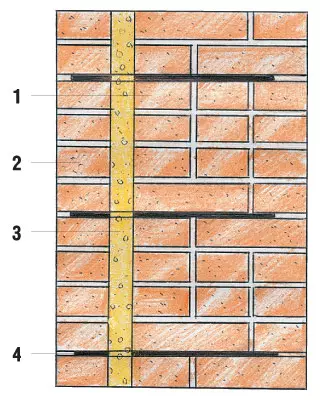

Three-layer wall for lining

with metal connections

1. The inside of the brick wall.

2. Outdoor part of the brick wall.

3. Insulation.

4. Metal bonds from the reinforcement w 4.5-6mm or fiberglass at the rate of 4 interface to the 1m2 wall surface.

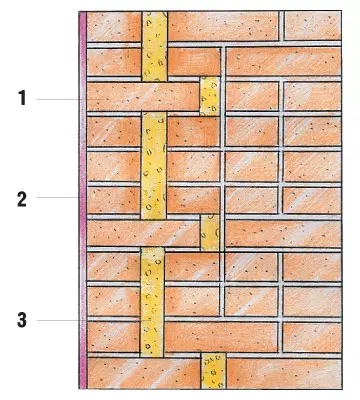

Brick three-layer wall under stucco with brick connections

1. Brick communications

(Outdoor layout of tychos bricks)

2. Facade plaster.

3. Insulation.

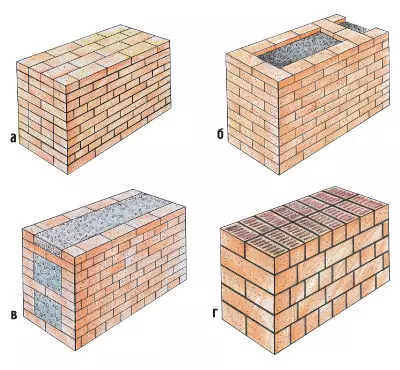

Varieties of masonry wall

from artificial stonesa) solid laying of ordinary brick;

b) lightweight walls of ordinary brick with vertical transverse walls

(Welding masonry);

c) lightweight walls of chipped bricks with horizontal bonds in the form of tychkaries

(brick-concrete laying);

d) a wall of ceramic target brick.

Masonry

The masonry solution for cursing requires a positive temperature and wet environment. When the temperature decreases, the process slows down significantly, and with negative values, it stops at all. The freezing solution loses plasticity, horizontal laying seams are not compacted. When thawing under the influence of gravity, uneven precipitation and the loss of stability and strength of the structure occur. The period of rejection of the solution is 28 days, therefore, with early freezing and thawing, its strength is reduced by half from the calculated one. Chemical components that increase its resistance to low temperature are added to the solution in the winter.

The masonry solution with chemical components freezes at a lower temperature, the cement in it harvester faster. Punching supplements use sodium chloride, calcium chloride, sodium nitrite, Potash (carbon dioxide). The type of additive is determined by the project. The chemical inclusion solution is not used if the project has increased humidity in the project facilities (in basins, bathrooms). Chemical additives are hygroscopic, as a result of which the distributions may appear on the walls. The driver with additives should be used before the setting. Hummer laying it has a temperature of 5 ° C. Frozen and re-heated with hot water solution is prohibited. Be sure to comply with the requirements and instructions that determine not only the species, but also the number of additives, the conditions for subsequent operation of the premises.

Even when dealing with a solution of increased frost resistance, masonry seams must be highly filled to freezing. For this, the solution covers small areas: for two bricks of spoonful and for four-six in the slaughter. Stop the brick and make the extection very quickly. Also quickly should lead the masonry at the same time along the length of the wall and in height, in order to have time to compact the underlying solution with a load of the upper rows of bricks. This is accounted for by plots. Performing work in the winter, the mason must especially strictly observe the established thickness of vertical and horizontal seams. The masonry freezes for two hours, the compression of the unewned solution occurs only after its complete thawing: in thaw or spring. Therefore, the seam thickness exceeding the norm can lead to severe sediment and even the destruction of the wall.

All vertical seams of winter masonry before a break in the work must be carefully filled with mortar. During breaks, it is necessary to cover the unfinished layer of a roofing layer or brick without a solution (dry). Before starting work, the surface is purified from snow, frozen solution, nondes. Be sure to check the verticality of the wall, since the deviation from the norm during the expansion period is fraught with disastrous consequences. Hospital, within the framework of the popular article it is impossible to consider all the numerous features of brickwork technology. I think this is not necessary to the reader. The main thing is that the owners of the brick houses have developed an idea of how and from which they are erected. You can read the problem in more detail by contacting specialized literature.

Average brick consumption for wall laying

| Masonry volume / masonry thickness, cm | Brick size | Excluding mortar seams, pcs. | Taking into account the dissolved seams, pcs. |

|---|---|---|---|

| 1m3 masonry | one | 512. | 394. |

| 1.5 | 378. | 302. | |

| 2. | 242. | 200. | |

| 1m2 masonry in 0.5 bricks / 12 | one | 61. | 51. |

| 1.5 | 45. | 39. | |

| 2. | thirty | 26. | |

| 1m2 masonry in 1 brick / 25 | one | 128. | 102. |

| 1.5 | 95. | 78. | |

| 2. | 60. | 52. | |

| 1m2 masonry in 1.5 bricks / 38 | one | 189. | 153. |

| 1.5 | 140. | 117. | |

| 2. | 90. | 78. | |

| 1m2 masonry in 2 bricks / 51 | one | 256. | 204. |

| 1.5 | 190. | 156. | |

| 2. | 120. | 104. | |

| 1m2 masonry 2.5 bricks / 64 | one | 317. | 255. |

| 1.5 | 235. | 195. | |

| 2. | 150. | 130. |