Today, almost every developer, an engaging house for year-round accommodation, faces the problem of choosing equipment for heating and hot water systems, as well as with the difficulties of its installation

Perhaps the most common type of such equipment - heating boilers. They can work on various types of fuel: solid fuel (coal, peat, firewood, pressed wood waste), gas (natural or liquefied), liquid fuel (diesel fuel or fuel oil), and also on electricity.

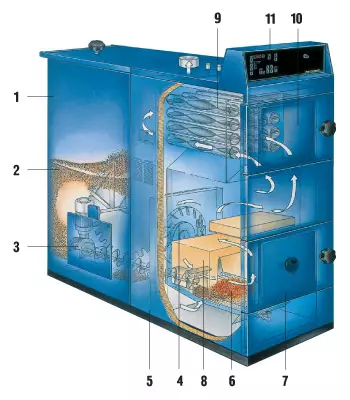

Diagram of the device of an automated wood boiler

2- granulated wood;

3-screw auger;

4-pin fan;

5- boiler housing;

6- a zone of pyrolytic combustion;

7- hatch is rally;

8- shampting arch of the furnace;

9- turbules;

10- hatch cleaning;

11- Control unit

Solid fuel boilers

Solid fuel boilers are used for a long time ago. They are easy to operate, many do not require power supply and can be used in systems with natural circulation of the coolant. You need to periodically lay fuel periodically, so their operation is impossible without the constant presence of attendants. Also, the disadvantages of solid fuel boilers include the complexity of the organization of automatic control of the fuel combustion process dictated by the need to use buffer containers to compensate for fluctuations in the coolant temperature due to the insteability of temperature in the furnace. Devices operating on briquetted wood waste-pellets are supplied to the Russian market. These boilers are automated and do not require a person in the process of functioning.

Firewood boilers can burn the fuel in the usual way or pyrolysis - in such devices, the gas is lit in the slow drainage of wood. The efficiency of pyrolysis models is much higher, but for their work we need wood with moisture content of no more than 20%. For any solid fuel boiler, a fuel supply is necessary, which will be needed to provide a special room. Solid fuel boilers on our market supply ROCA- for example, model P30-6 worth 1140, working on firewood and coal, with the possibility of installing a gas or liquid-fuel burner - Buderus, Viessmann IDR.

Gas boilers

Currently, gas boilers are most widely used. Their indisputable advantage is the low cost of fuel, the lack of necessity in organizing the premises for storing its stocks, a high degree of automation of the combustion process.

Boilers on gas fuel are divided into two types: with atmospheric burner and upgraded - with a fan burner. The atmospheric burner devices are already well known to users. The benefits include high reliability due to the lack of moving parts in the design of the burner, low noise. Kednostatokam- instability of work under reduced gas pressure, which is an urgent problem for our country. Normal gas pressure in many imported models - 20 mbar, and it is at such a pressure that a stable operation of the boiler is guaranteed and the thermal power is provided, stated in the product passport. In winter, for example, in many areas of the Moscow region, the gas pressure can be 10-12 mbar and below, in this case there is a significant drop in the power of the device (up to 30% or more). This circumstance has to be taken into account when choosing a atmospheric boiler, providing for a power supply for which you will have to lay out an additional amount. KRYMERA, VITOGAS 100-80 model from Viessmann with a capacity of 80 kW at a gas pressure of 10 mbar will provide the power of only 55-60 kW.

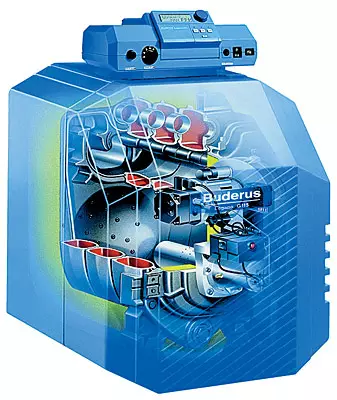

The following types of upgrade boilers. They are equipped with blowing or, as they are also called, fan burners. Such burners are designed for work not only on natural gas, but also on liquefied, as well as on diesel fuel and fuel oil. The advantage of the upgrade boilers, or rather, the blowing torches on natural gas is the possibility of functioning at low gas pressure in the highway with a development of 100% of power: for example, the STG 146 / 2R burner from Bentone (Sweden) produces 100% power at a gas pressure of 13 mbar . Also, the benefits of such devices can be attributed to their ability to use not only gas as fuel, which becomes important when organizing heating in non-gem settlements. Suppose, before gasification, you can operate the boiler on diesel fuel (diesel engineer), then, when the gas is mounted, it is possible to replace only one nodule, and the device is ready for operation on gas.

|

|

|

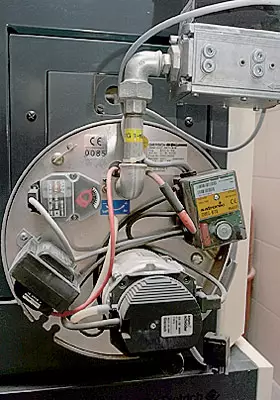

1. Device of the upgrade boiler from Buderus with a burner noise protection casing

2. Cast-iron upgrade boiler Logano G225 from Buderus can function both on gas and on liquid fuel. Equipped with built-in fan burner of increased reliability

3. Low-temperature cast iron boiler from Torus (Poland) can be connected to a water boiler with a three-way crane or circulation pump

Another feature of the upgrade boilers is the presence of a certain range of power to which the burner can be configured (atmospheric boilers have a fixed maximum power). In this case, you can purchase a device with a power reserve to increase the increasing area (if, say, the construction of an additional building is expected), and to this point, it is operated on less power. The transition to a large power is carried out with a simple resettle line. Gaza boilers are provided by many manufacturers, including Bosch, Buderus, Viessmann (all Germany), De Dietrich (France), CTC (Sweden), Roca (Spain), Protherm (Czech Republic), Titan (Russia ) and etc. The cost of the aggregates is from 900 to 4500-5000 per model with a power of about 50 kW.

According to the type of fuel, the blowing burners are gas and liquid. According to the presence of burner power steps, one is divided into single-stage, two-stage and modulating. The first work at full capacity, the second usually have an additional step of low power (50-60% of the maximum), and the modulating modulating smoothly change it from 30-40% to the maximum.

Despite the fact that many manufacturers of boilers produce fan burners, there are a number of independent producers whose products have proven well - this is Weishaupt, Giersh (Germany), Riello, Lamborgiani (Italy), Bentone Idre. The cost of gas burners is 1200-1600 per model with a capacity of 20-60 kW. Liquid fuel burners are cheaper and cost consumer in 600-950 for the device of the same power.

Liquid fuel burners are designed to burn diesel fuel and fuel oil (in the household sector, diesel fuel is used). They are mounted on the upgrade boilers. According to the rules, the supply of diesel fuel located in the boiler room should not exceed 800l. In order to store large amounts of fuel, it is necessary to equip a special storage. Often, plastic containers are used for these purposes, which can be installed in a separate room or are located in the underground caisson. In the early case, it is necessary to highlight the sealing of the structure, because the diesel fuel is lighter than water, and during the flooding of Kesson, the tanks may simply emerge, pulling off the fuel lines, and here already before the ecological catastrophe is one step. With the last flooding in Europe, fastening fuel containers began to pay special attention.

Wall boilers

Separately, you should talk about wall boilers. Most of the most of the numeral, although there are liquid-fuel models, for example, STS 950 from the company STS (Sweden). The advantage of the wall-mounted devices are compact sizes, so they are not necessarily installed in a specially equipped room, and low cost. In addition, the obvious advantage of the installation and the lack of need to acquire additional components for the strapping, as everything is required for the normal operation of the boiler is included in its design.

Wall boilers are with a natural and forced product (with a closed combustion chamber). The removal of combustion products from appliances with a forced product is carried out by a smoke throat through a coaxial chimney, which is a design of two pipes. On the inner tube there is a removal of gases, according to the outer supply of air for combustion. In this case, it is possible not to lay the traditional chimney, since combustion products are thrown through the wall along the coaxial pipe, which significantly reduces the cost of building the chimney. By the possibility of making hot water, such boilers are divided into single-circuit (intended exclusively for heating) and dual-integted, which also work for heating, and for hot water supply (DHW). To prepare hot water in them, a flow heat exchanger is installed in them or the devices are equipped with accumulative capacity up to 60l. Copper boilers are preferable, as they provide a more comfortable water supply option for the user, although it is more expensive. Cumulative water heater for the wall boiler can be purchased separately and set next to it.

Wall-mounted models make practically all manufacturers of heating equipment: German companies Viessmann (Vitopend 100), AEG, Vaillant, Buderus, Czech Protherm, Italian Hermann, Beretta, Baxi, Ferolli. Some Russian enterprises also have mastered the release of wall boilers. Their cost begins from 600-650 for single-circuit models with natural burden and can reach up to 2000-2500 for dual-circuit units with forced taiga and modern weather-dependent automation.

Electric boilers

Electrocotels are divided into bean and electrode. Forward heat carrier heating occurs due to thesters, which consist of a conductor with high resistance placed in a hermetic copper tube with conclusions for connecting electricity. Electric current, passing through the conductor, causes its heating, and, accordingly, the heat carrier, which is around the Tan, also heats up. Tanic boilers are reliable, allow you to apply non-freezing coolants in the heating system.

Electrode boilers heat the coolant directly current flowing through it between two electrodes. Plush devices The coolant is an element of an electrical circuit, so in the heating systems with electrode boilers it is impossible to use traditional antifreeze, and ordinary water often requires the addition of special reagents to reduce the explosion hazard of the installation. The advantage of the boiler is their low cost. For example, the model "Galan" (Russia) with a capacity of 5 kW will cost 40-50. The price of a chamber of the same power, say "Evan C1-5" (Russia) will already be 190. Electric boilers, as a rule, are used as a backup or temporary (until the gas is summarized). Usually choose a model, the power of which is smaller than the heat loss of the building (for example, to ensure the temperature in the room 10-12 c).

Systems with two boilers

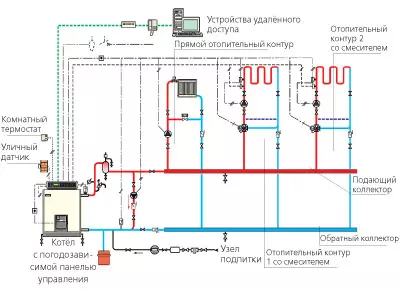

Schemes of strapping boiler room

For normal operation of the heating system, the boiler equipment must be correctly connected or, as experts say, tie. The blocking of wall boilers is quite simple, since, as already mentioned above, they have all the necessary components in their design (heating circulation pump, membrane expansion tank, safety valve, actuating mechanisms and shock fittings). Outdoor boilers are tied up in several schemes.

The collector scheme is the most common. The collector is two pipes (direct and reverse) with conclusions on the required amount of heating circuits (radiators, warm floor, boiler). To implement this scheme, the so-called fast installation kits are currently released (for example, the products of Meibes, Germany) have proven well. The composition includes pumping groups, collector beams, etc. All sets are collected in factory conditions and carefully check for tightness, so such systems are quite reliable. The use of quick installation kits allows you to perform strapping in a matter of days. The disadvantage of the Systems is their high cost: the pump-mixing group from Meibes will cost 650.

Automation in boiler room

|

|

|

2. Control Panel Logamatic 2107 M from Buderus

3. DIETRICH dialog module (de Dietrich)