Waterproofing bathroom: inlet and coating materials, preparatory work and technology of application on the surface, varieties of sealants.

Photo Mikhail Stepanova

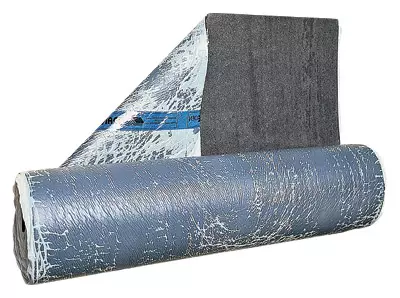

("Isoflex") has a self-adhesive inner layer, which is protected by a polymer film removed before starting work

Photo of Karen Manko

The rolled membrane laid on the basis must necessarily be filled with a screed, the surface of which is facing tiled or other material

Photo by Dmitry Minkina

Photo Mikhail Stepanova

Photo Vitaly Nefedova

Photo Vitaly Nefedova

Photo of Evgenia Lichina

The fact that water, or rather, its constant (and so familiar) presence in our everyday is an integral part of a comfortable existence, especially sharply realize at the time of its sudden disconnection. However, sometimes this "source of life" is able to cause many trouble. For example, leaks that originate in such a "water-free" apartment zone, like a bathroom, are fraught with rapid explanations with neighbors from below and pay them considerable compensation for damage caused. It can be, without hoping for the eternal "Avos," it makes sense to decide once and make waterproofing the bathroom.

The nomenclature of modern waterproofing materials is extraordinarily wide-products produced by domestic and foreign manufacturers, has hundreds of items. Waterproofing is the sphere where specialization is given great importance. It is possible to add a simple, but important rule: before you begin to carry out waterproofing work, it is necessary to weigh everything thoroughly and consider a predetermination on the "initial positions" to be considered significant costs of time and money. So a single, very faithful (everyday professionals) Note: Waterproofing is not bad or good, it is or there, or it is not. By the way, participation in this case specialists can sometimes be at all unnecessary.

Today, two types of waterproofing materials are used for waterproofing floors and walls in the bathroom. The type of material selected is directly related to the surface features and the timing of work.

Waterproof waterproofing materials

Traditional waterproofing coatings used, in particular, in the bathroom, are rolled materials. Created on the basis of bitumen modified by polymer polymers (styrene-butadiene-styrene) and APP (Atactic polypropylene) and reinforced with polyester or glass fiberglass, they are produced two species-installed (a burner is applied) and self-adhesive (more modern and convenient in installation). It should be said that the choice of rolled materials for waterproofing the standard bathroom box is, as a rule, is not considered appropriate. Practitioners are noted that such waterproofing is reliable and durable, but labor-intensive. It requires a carefully prepared surface: unacceptable irregularities more than 2mm, dry base treated with bitumen primer, and extremely neat cloth sticking. Well, the main trouble is a resistant sharp smell of bitumen. But if it is still a decision to use this particular waterproofing (by the way, the most economical), then the self-adhesive materials are definitely preferable.

Equal waterproofing has a number of advantages over other materials. It quickly and simply stacked (cut-down), fixed throughout the area, due to which its random offset is excluded, and finally, on the coating can be walking immediately after installation without fear of damaging it. Before laying rolls, experts recommend priming the surface, for this purpose it is convenient to use "fast" bitumen primers, for example Indever from Index, "primer bituminous (concentrate)" from Technonol and ASOL-V from Schmburg drying for 3-8 hours, and also waterproofing paint, which is suitable for applying to various, including concrete, bases.

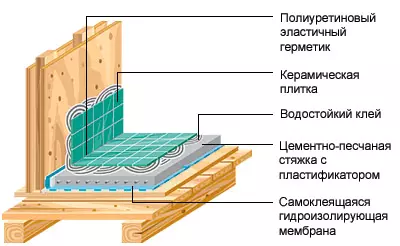

There is one important disadvantage of this type of waterproofing: a rolled membrane, laid on the basis, must necessarily be filled with a screed, the surface of which is further facing tiles or is frozen by other finish materials. The problem arising from this may be related to the removal of the floor level, since in the process of installation of waterproofing, screed and tiles, the floor in the bathroom will rise at least 5 cm. It is necessary to take into account the thresholds with a height of about 2 cm, which does not give water to quickly penetrate other rooms if the pipe suddenly breaks over or the bath will overflow. Thus, we will get an "obstacle" on the way in a bathroom with a height of 7cm. If you do not want to stumble about it every time, you will have to raise the floor in all other rooms. Additional benefits are sound insulation for neighbors below. Plus the ability to hide various wires into the screed. But in such situations, the decision is made separately for each specific case.

Required time on the Russian market of inlet waterproofing materials, the products of domestic companies "Tekhnonikol", "Plasteks", "Filichangel Plant", as well as foreign Schmburg (Germany), Index (Italy), Firestone (USA), ICOPAL (Sweden) are presented. Imported analogues are distinguished by high and stable quality, but it is much more expensive. For example, the InDex rolled self-adhesive material from Index has a bituminous layer (1.5mm), modified by the SBS polymer, which has increased elasticity. In addition, polyethylene with a special longitudinal sticky layer ensures reliability of the joints of the seams between the canvas. The InDextene roll (20m2) will cost 126. One of the latest developments of the company "Tekhnonikol" is a self-adhesive bitumen-polymeric material "Barrier OS". The basis of the foundation in it is used glass cholester, which is covered on both sides by bitumen, modified by the SSP (styrene block copolymer) composition. The use of special types of polymers significantly improves the elasticity of the material and increases its adhesive properties. Comes "Barrier" in the rolls of 15m2 and costs 3 times cheaper than a foreign sample - $ 32 per roll.

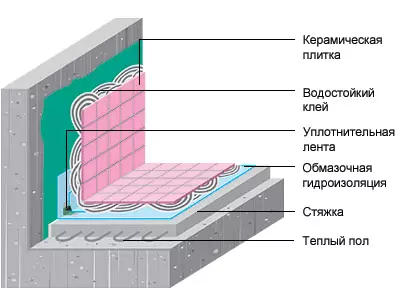

| Waterproofing bathroom in concrete overlap with heat floors (index) |

| Waterproofing bathrooms on wooden overlap (index) |

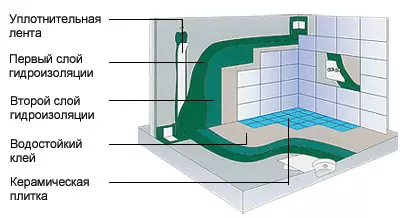

| Diagram of the waterproofing device in the bathroom (kiilto) |

Foolish waterproofing

In modern construction practice, replacing with inlet materials come with coating, and today they are widely used for waterproofing rooms with high humidity. The coating materials constitute the largest group that includes various kinds of bituminous, cement, cement-polymer and polymer mastic, sealants. Given the diversity of this product, the use of one or another its type should be strictly substantiated- the choice of technology and material is determined by the requirements of the situation. The universality of coating (liquid) compounds, their "unpretentiousness" (applied to any surface) give significant savings of the time - the intermediate stages of the work preceding the finishes are excluded.The most famous variety of coating materials - bituminous (bitumen-rubber and bitumen-polymeric) masts. They are made on the basis of oxidized bitumen with the addition of organic solvent and various filling-rubber crumbs, plasticizer, latex, increasing coating elasticity. Distinctive features of bitumen mastics are good adhesion with the base and increased resistance to external influences. From the materials of this series, Indesol and Elastobits of the Italian company Index can be called (they have high elasticity and can be applied to a wet surface), BIL20 / 85 and DYSPERBIT produced by ICOPAL, KALLASFACT from Beckers (Sweden), "Hydromeb" Russian enterprises "Riccardi-Build" and "Grid", Bitumast Gidrolitex MBG from Bitumast (Russia). However, it should be borne in mind that to obtain a high-quality waterproofing coating after applying such materials, a screed is required. This communication will not be superfluous: the ties of the so-called fresh fill is often given shrinking cracks, and therefore it makes sense (justified substrate) to add polypropylene reinforcing fiber. It increases the strength and resistance to abrasion of concrete, cement bases, reduces the possibility of cracking.

Cobmatic waterproofing also includes cement-polymer mastic. They are prepared from a dry mixture of cement and mineral filler and are inducing with water, a special binder emulsion or aqueous dispersion of polymers (acrylic, silicone or vinyl). Thanks to the cement component, these coatings have good adhesion to the base, and plasticizing additives help them successfully work not only on rigid surfaces. The polymer binding components penetrate the pores of the base and tightly clog them. The thickness of the coating layer is small - 1-3mm. Kmaterials of this kind include the isolation of "Akvasyl" from OZSS (Russia), Aquafin-2K from Schmburg (Germany), Covercol AB Rapid from Index (Italy), Thoroseal from Thoro, Barralastik produced by Heidelberger Zement. In a good account, elastic two-component masses OSMOLASTIC and OSMOFLEX from index. They are obtained by mixing in certain proportions of cement powder and latex. Vitoga turns out a material resembling liquid plasticine consistency. The recommended mixture consumption (applied into two layers with a spatula) for waterproofing the standard bathroom is about 3kg per 1m2. They can be used as a waterproofing coating in the shower, as well as when mounting a warm floor, withstand crack opening at a base to 2mm.

High reliability indicators demonstrates a single-component waterproofing cement mixture of "Glims-Water-Support" of the company "Glims-production". The material has good adhesion to any types of surfaces and is distinguished by increased water resistance. Weightly looks like one of the characteristics of "Glims-Waterstop" - waterproofing withstands the waterproof pressure with a height of 70m. Preparation for work with the mixture (however, working with it itself) is pretty simple: cement powder is diluted in water-established proportions, it is thoroughly mixed several times, after which it is applied to several layers to the surface.

Materials on a cement base supplies the Italian firm Litokol to Russia. The most widespread was the single-component waterproofing mixture of Elastocem Mono, consisting of portland cement, synthetic powdered resin, organic additives and silicon inert fillers. When diluted with water, the mixture turns into a plastic mass, which can be applied both on the horizontal and vertical surfaces of the layer to 2 mm without climbing. Elastocem Mono is distinguished by high elasticity and good adhesion to cement and concrete bases.

Well established highly elastic polymer waterproofing materials of domestic and foreign production. So, Saniflex from SchMburg does not contain solvents and is intended for use in wet rooms and bathrooms. The insulating mass is applied to one or two layers (the coating thickness must be at least 3-4mm) on the prepared surface and after rapid drying (5-6 hours) turns into an elastic, waterproof, but transmitting a synthetic film. Floor joints and walls are recommended to smoke with sealing ribbons. It should be borne in mind that if in the following bathroom it is planned a warm floor device, then Saniflex should not apply.

Polymer mastic on the Russian market are also the Finnish companies Kiilto and Optiroc, the Italian plant Litokol (Hidroflex masty). From the entire range of Kiilto, one-component Keragum polymer mastic, created on the basis of a CBR-polymer (rubber from copolymer, butadiene and styrene), is specifically for rooms with high humidity. It should be mentioned that the insulation system includes fibrous tapes. The composition of the composition of the composition they are fixed between its layers (in the corners and seams) and enhance the waterproofing. Avot Specialists from Optiroc offer a complex of several materials with various functions. "Waterproofing" is a mastic based on the aqueous dispersion of synthetic resins. It is applied to a brush or roller in two stages on a dry surface (temperature 15-30C), then aligned with a toothed spatula. Punching base for mastic are suitable cement plasters, ties, masonry blocks. When the first layer of composition dries, the canvas of the reinforcing fabric "Old" are laid on it (with a margin in 50cm). Especially carefully processed outputs of drainage, mounting holes, angles and joints. Points of waterproofing are reinforced by the second layer of tissue.

Refractory waterproofing materials

| Manufacturer | Material | Material type | Specific, kg / dm3 | Consumption, kg / m2 | Packaging | Price 1kg, $ |

|---|---|---|---|---|---|---|

| INDEX (Italy) | Indesol | Bituminous polymer mastic | - | one | Metal bank 10 and 20kg | 2,2 |

| Osmolastic | Cement-polymer two-component mastic | 1.65 | 1,6 | Kraft Bag 15kg, Canister 5kg | 2.7 | |

| Schmburg (Germany) | Aquafin-2k. | Cement-polymer two-component mastic | 1,3. | 3.5-4.5 | Bag 6 and 25 kg, bucket 2 and 8,33l | 1.5 |

| Litokol (Italy) | Elastocem Mono. | Cement mix | - | 3.2 (with a layer thickness 2mm) | Bag 20kg | 2,3. |

| Hidroflex. | Polymer mastic | 1,3. | 1.3 (with a layer thickness of 1mm) | Bucket 2, 8, 18 and 24kg | 5.3 | |

| Kiilto (Finland) | Keragum | Polymer mastic | 1,4. | 0.7-1 | Bank 1, 5, 10 and 15l | 7,7 |

| Optiroc (Finland) | "Old waterproofing" | Polymer mastic | 1,1 | 0.7-0.9 (for walls); 1-1.2 (for the floor) | Bank 5 and 10l | 7,2 |

| Rickardi-Building, Grid (Russia) | "Hydromeb" | Bituminous polymer mastic | 1,2 | 0.25-0.3 | Bucket 5kg | 1,6 |

| "Glims-Prodakshn" (Russia) | "Glims-waterstop" | Cement mix | - | 3-4 | Bag 20kg | 0.8. |

Technology device waterproofing

Preparation of the basis . An equally important factor in the quality of waterproofing than the composition of the insulating solution is the observance of its technology. Forward turns from the base, traces of oil, paint and other substances worsening adhesion are carefully removed. The desired degree of surface cleaning from dust can be achieved with the help of a domestic vacuum cleaner. Before applying the waterproofing, the prepared base is processed (brushed or from a sprayer) by primer (primer). The most important thing is not to be mistaken in its choice, since the primers used for high-art and poorly absorbing moisture surfaces are different in their physicochemical nature, and therefore, poorly work with "someone else's" basis. The irregularities of the base up to 2mm are allowed. The presence of any sharp protrusions on it (even small). Aligning screeds (from cement-sand, gypsum, drying solutions) should be laid with 2-3m width strips on guide lighthouses. Porous surfaces (cement ties, plaster, concrete IT.D.), not treated with primer, before applying cement-polymeric materials, it is necessary to moisten with clean water with a sponge or sponge. This will avoid too fast drying of the waterproofing solution.

The main places of leakage of horizontal and vertical surfaces - in front of the waterproofing device, can be sampled by a strengthening sealing ribbon (for example, Coverband from Index, "Gerland" firkarovl firms), or nailed to the semi cartlers, covering the gap between the wall and floor, and use the caustic Waterproofing. It should also be borne in mind that if in the future you intend to equip the warm floor in the bathroom, it is better to use elastic coating materials that work at elevated temperatures (for example, such as BinerDesmo from Alchimica (Greece) or Elastobit from Index). Many experts recommend in this case to apply coating waterproofing on top of the screed, under the glue layer to immediately protect both the cable, and the screed.

Preparation of mixes . Bituminous and polymeric mastic are produced ready for use. Avot Materials on a cement basis are delivered in the form of dry mixtures. The bubility with the necessary amount of pure water (each composition has its own proportions) is covered with a dry mixture and is thoroughly mixed with a mechanical stirrer (an electric door with a special nozzle) until a homogeneous mass without lumps and clots is obtained. The solution is made to mature for 3-5 minutes and stirred again, after which it is considered to be ready for use. The optimal water temperature is 15-20s. The viability of the solution is limited (0.7-1.5 hours), so it is necessary to drain the mixture in a small amount and apply immediately.

Application of waterproofing . Works on the device for waterproofing "must be performed at the positive ambient temperature and the surfaces of the surfaces are not lower than + 15c and air humidity not more than 60%. Such a temperature in the room must be maintained around the clock for at least 2 days before the start and 12 days after the end of the work" ( SNIP3.04.01-87). Waterproofing is evenly applied to the base with a brush, roller or smooth spatula. The drying time and solidification of the composition depends on the thickness of the layer, as well as on the temperature and humidity in the room. Before creating a screed or styling of the finishing flooring, the humidity of waterproofing should be monitored and compared to it with an indicator allowable for this type of material.

Waterproofing Technology:

| A- surface treatment with primer composition; |

| Basic waterproofing; |

| Cladding with tiles and sealing of joints |

Sealants

Problems of sealing of seams, seals and sealing of various joints (for example, when installing plumbing) are designed to solve silicone and polyurethane sealants. There are still acrylic masses, but due to the rapid aging in the bathrooms, they are not recommended. To compact and compensate for the movement of seams, silicone compositions are perhaps optimal. As a rule, sanitary sealants used in bathrooms and toilets, in addition to the silicone itself, contain a small (5-10%) the number of organic extenders and fungicides that prevent the formation of the black mold formation. These materials are distinguished by good elasticity (lengthening when breaking up to 1000%), excellent adhesion to the most diverse surfaces, moisture resistance, strength and durability.

Sealants (silicone including) are distinguished by the curing mechanism and the content of fillers (usually the fewer fillers, the better). Acid sealants are universal and cheapest (about $ 2 per 1 cartridge with a capacity of 310 ml) and, of course, the most widely represented in the domestic market. Their marking in many companies includes the Latin letter A (eng. Acid acid). When cured, this type of sealants selects some amount of acetic acid into the air (2-4% of the total mass), which to some extent limits their scope. They should not come into contact with lead, copper, brass and zinc, because acetic acid causes corrosion of these metals. Also, acidic sealants are not used when working with marble and cement containing materials that have alkaline compounds and capable of reacting with acetic acid. Applying such drugs, it is necessary to ventilate residential premises.

Neutral curing sealants are isolated by ketoxime or alcohol. They are suitable for all the basics without exception, including marble and cement materials, but are somewhat more expensive - from $ 5-6 per 1 cartridge. The marking of such compositions is the Latin letter N (English Neutral-neutral).

The Russian market provides products of both domestic and foreign companies. Among them "Plovetonit", "STROYSERVISGERMETY", NGO "Polymer sealants" (Russia), Index (Italy), Schmburg (Germany), Kiilto and Makroflex (Finland), Dow Corning (USA), Flm-Firmen Gruppe (Switzerland), Soudal (France) and others.

The editors thanks the firm "Convent-Center", Tehnonikol, "Glims-Prodakshn", as well as representative offices of Optiroc, Schmburg and Kiilto for help in preparing the material.