Types of pipes for heating, cold and hot water. Materials, specifications, connecting elements for mounting pipelines.

A- cut off the pipe "scissors";

bonding a crimp ring;

to expand the pipe with special "ticks";

G-insert fitting. The pipe itself tightly worst it

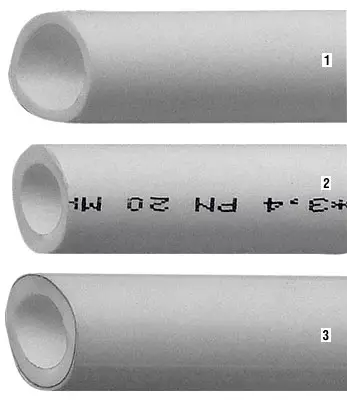

1- pn 25 with a layer of aluminum foil that prevents diffusion of oxygen;

2- pn 20 with wall thickness 3,4mm;

3- pn 10 with a wall thickness of 2.2mm

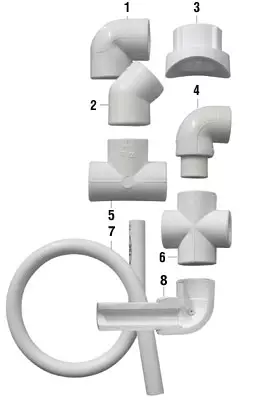

1- angle 90;

2- angle 45;

3-welded saddle;

4- angle for internal and outdoor compound;

5-tee;

6-cross;

7- compensator of temperature elongation "Omega";

8-section of the compound obtained by thermal welding method. Two parts have become one whole

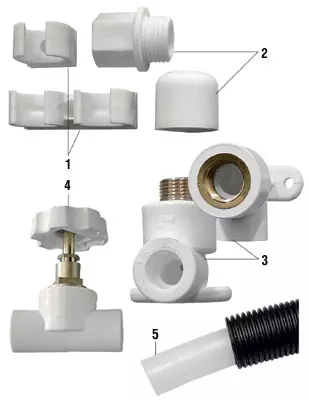

1- wall mounts;

2-plugs;

3-corners with mounting to the wall;

4- valve;

5- Curfroorcav

From Aquatherm:

A-pipe and fitting are heated by a "soldering iron" equipped with a set of adapters for each pipe size;

B- combine the details;

The compound is recorded;

G-finished system

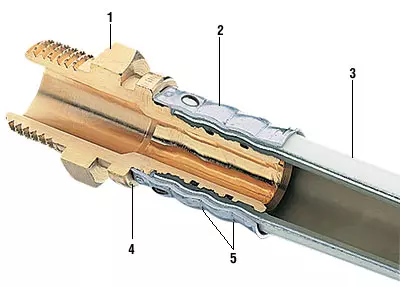

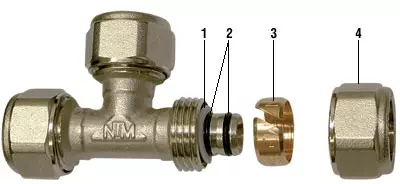

1- bronze press fitting;

2 steel sleeve;

3- pipe;

4-galvanic separator;

5- sealing rings

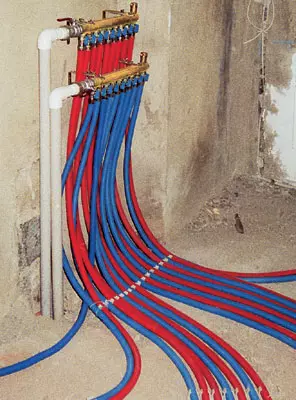

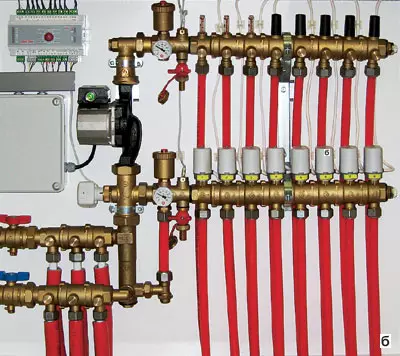

A- lower radiator liner with insulating pipes Unipie;

b-fastenings for pipes in warm floors;

assembly assembly;

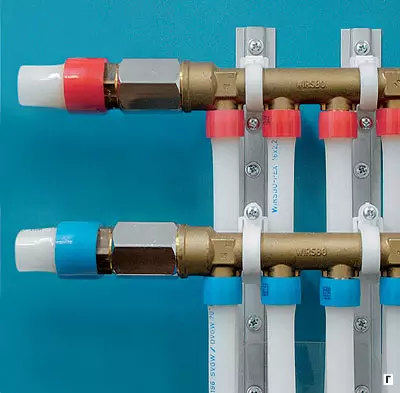

G- collector wiring using pipes of re-

1-galvanic separator;

2- rubber seal;

3- crimping ring;

4- fixing nut

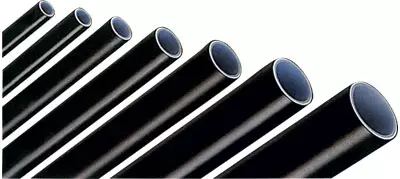

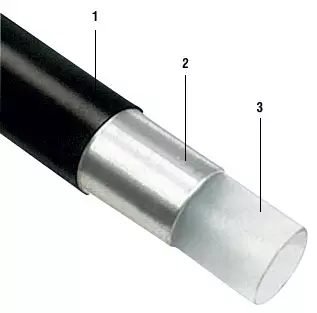

1-resistant polyethylene ultraviolet;

2- aluminum pipe, the edges of which are welded with a laser jack;

3- crosslinked polyethylene

A- press machine, working from the battery, and from the mains;

B- crimping pliers for pipes from 16 to 32mm

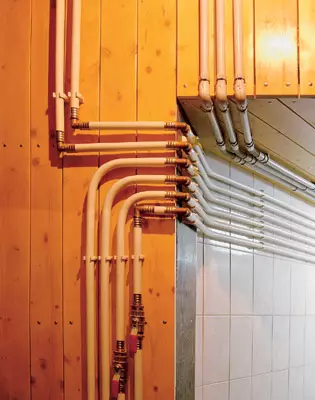

A- Introduction of Cold Water (PND);

Break-pipes in the heating system;

in the transition from copper pipes to the metal;

M- Metal-polymer pipes (heating and GVS) plus PP-pipe (HPW)

To ensure comfortable conditions in the dwelling, only by paving pipelines for cold and hot water and, of course, for heating. The market offers a huge amount of pipe options, each of which is inherent in both the advantages and disadvantages. Hurry when you choose- create serious problems not only yourself, but also the neighbors. How to avoid this?

Pipes and ... Headache

With the word "pipes" the head in those who have ever engaged in construction or repair, as they hurt thirty years ago, so hurts now. Only the scale of worries increased. After all, the pipes are used for cold and hot water supply, sewage, irrigation and, of course, heating. And now in this system, not one or two instruments, as before, and a dozen and more. The cause of headaches three decades ago was somewhat different. The question of choice then before the consumer did not stand for two reasons. First, only stylish pipes were produced. The second reason is free to buy them it was impossible. Pipes, as they talked, got it. As a deer of a yagel. Hooves. From under the snow. Therefore, the head in those commemorative years had more from the questions "How?" And "Where?", But not from the question "What?".But times have changed. It is not necessary to get anything, it is only worth going to the nearest market or to a large store, selling pipes, and purchase ... Everything that your soul. But, oddly enough, the head of the consumer and now, with the word "tube" hurts. (Those who have come across the problem of choice will confirm the truthfulness of these words, the same who did not come across ... Yes, they are just lucky!) But this long-suffering head hurts now from the question "What?". What exactly to choose from that abundance of pipes, which offers a modern market? And the point is not at cost. You need to choose so that you will not regret it later, nor neighbors living in the following floors.

To take into account the literally all: the corrosion resistance and the likelihood of leakage (including connections), the possibility of breaking due to increased pressure and behavior of pipes during emergency defrosting of the IT system. etc. Is Ikak all this not to take into account if the service life of the mounted system is directly dependent on the pipe properties complex?

To more clearly, the reason for the mentioned "migraine" was, running, without going into technical details, we list the types of pipes with which the consumer will meet. Conditionally, they can be divided into three large groups: metal, polymer and metal-polymer.

Metal pipes

Their general advantages are high strength (metal is metal) and, expressing the language of specialists, "reference oxygen-resistant" (about what it is, we will tell a little later when we turn to the polymer pipes).

Steel tubes. This, you can say products familiar with everyone since childhood, since it was they who for many years have been the main universal material for systems for various purposes. The main advantages are high strength, availability (in the market they offer more than a dozen domestic firms) and relative cheapness (price, from 40 rubles. For 1Pog. Move the electric welding pipe and from 54 rub. For 1Pog, the solid pier 202mm). The main disadvantages are high complexity of assembly and lack of protection against internal and external corrosion. Consequence - dirty (rusty) water, leaks, ingrowth of the inner diameter and other "charms". Steel pipes, according to Snipham, must be changed once in 25 years. According to the statistics of operational organizations, they begin to corrode and leak already in five or six years.

Ivot is right here and should be remembered about low cost. It is prospecting. Only at first glance the price of steel pipes may seem low. They grow up several times in the delivery process, installation and subsequent maintenance. Only the first five years the heating system from steel pipes does not require any material costs. After this period, the costs of current repairs are increasing in geometric progression, and by the end of the depreciation period (4 years), according to operational organizations, are already 20% per year. The ATEA means that for the entire service life for the current repairs is consumed 150-300% of the system cost.

For the assembly of steel pipelines, welding (gas welding or electric welding) are used, as well as standard threaded connectors with a seal (pack, sealant IT.P.).

Steel galvanized pipes Come goes somewhat more expensive "black" - from 80 rubles. For 1Pog.m Pipes 202mm. It was them that they were advised to apply later domestic slopes during the installation of cold and hot water systems in exchange for anything not protected by "black" pipes. They serve lon longer than ordinary, but, alas, slightly. The reason is simple: when using conventional electrodes in the welding zone (and without it, it is not necessary to do without it) a layer of zinc simply disappears- remains unprotected steel pipe. There is, truth, special electrodes, but it is almost impossible to find them on sale. There is also another hidden problem: during welding, poisonous substances are distinguished, and the welder refuses to work with "galvanized". In addition, the formation of a galvanic pair in the presence of non-ferrous metals is possible.

Social pipes are associated with two fairly common misconceptions regarding their use in heating systems. The misconception first concerns the ability to use galvanized pipes in the specified system. Do this impossible to do this. The reason is known and indicated in the chemistry textbook for the seventh grade: under the action of temperatures characteristic of heating systems, the Zn + H2O = ZnO + H2 reaction occurs. Simply put, a layer of zinc is destroyed, and hydrogen accumulates in the pipes, the system interferes with the system normally. Nevertheless, in 90-hgg. For some reason, they suddenly forgot about it and in a massive manner began to use pipes protected by zinc in heating systems (the idea to apply pipes, more resistant to corrosion, in general, understandable). These systems still have "gas", and can help them radically ... well, except autogen. Temporary means of installing a manual gas valve on each radiator.

According to the second delusion, galvanized pipes are better than "black", behave in heating systems filled with household antifreeze. What is happening in galvanized pipes reaction with ethylene glycol (it is the basis of most non-freezing coolants), we will not even describe, just say that its consequences are even more destructive than when the zinc with water interacts. Antifreeze manufacturers are openly recognized and even indicate a prohibition on the label.

Stainless steel pipes. What to say, the idea apply to the laying of domestic pipelines almost eternal stainless steel can only be approved. Ikrasivo (just High Tech), and reliably. But the price, which is called, bites: Imported ground (mirror) Pipe made of steel AISI304 (analogue of our steel 08x18H10) The size of 182 mm will cost 160 rubles. For 1 p. m, domestic polished pipe made of steel 12x18n10t in size 19,12mm will cost 200 rub. 1Pog.m. (By simple calculations, it is possible to conclude that the domestic pipe will cost more imported.) If this adds quite high installation prices, it becomes clear why stainless pipes do not use with a wide demand.

Copper pipes. They are the most beautiful. Iprie this is still reliable and durable (cost about 180 rubles. For 1Pog. Move pipes 221,5mm). For the domestic consumer, the use of copper pipes in water supply systems and heating is relatively new. It was brought to us from developed countries of the West - there are already dozens of copper pipes and even hundreds of years.

A variety of requirements for modern sanitary and technical systems, copper responds almost perfectly. Here and the ability to withstand any temperatures in heating and DHW systems, and resistance to the corrosion exposure of tap water (incomprehensible, to chlorine and ozone) and ultraviolet. It is especially worth noting the high plasticity of the material under which it is implied not only compliance to the change of form, but also the ability does not become fragile at negative temperatures. This, according to specialists, allows pipes to withstand one-time freezing, and with multiple it provides a minimum damage. All the combined and long-term (50-100 years) period of trouble-free operation provides copper pipes.

But there is their drawbacks from copper. It should not be used in systems with an excessive acid water (the recommended range of pH from 6.5 to 9.5), an attack with a large number of solid mechanical impurities (poorly purified water from its own well) and high water flow rates (for example, in the installation zone Temperature regulator), which cause fast surface wear. The installation of pipelines requires high qualifications of working and accuracy-not cleaned internal burr, can cause the destruction of the pipe only because the flow of the coolant flow is caused (the flow rate increases in the zone, and copper, as already mentioned, does not like it).

Classic and most reliable is considered to compound copper pipes using high-temperature capillary soldering. However, recently, compounds using threaded and press fittings began to be increasing.

What do the standards say

It would seem, to figure out which pipe and how to use, it is enough to simply, it is only necessary to read the existing slips and GOST carefully. But it was not there! Issues of application in this documentation, unfortunately, are not properly covered.

If you refer to SNIP II-30-76 "Internal water supply and sewage system", then in paragraph 4.1 and in Appendix No. 3, it is indicated: for water supply - polyethylene (PVP), for sewage and water supply and polyethylene (PNP), vinylplast and polyvinyl chloride ( PVC). IVA! There were simply no other types of pipes. 5.04.01-85 later, paragraph 4.1 is almost literally repeated, paragraph 4.1 is almost literally verified, with the difference that any mentions of pipe brands simply disappeared from it, and therefore concrete recommendations.

At the beginning of the 90s. Xxv. Our market literally flooded the pipes of foreign production from various polymeric materials. "Legislative Bodies" responded to this phenomenon by introducing change No. 2 (1996) in Sniped 02.04.01-85 *. Now item 10.1 is set out as follows: "Plastic pipes and shaped products made of polyethylene, polypropylene, polyvinyl chloride, polybuthene, metal-polymer, from fiberglass and other plastic materials should be used for internal cold and hot water pipelines, polyethylene and other plastic materials for all water supply networks. In other words, the compilers simply listed the existing types of pipes from polymeric materials, providing the consumer to the right to advise, which pipe and where to apply. In general ... Do what you want. Meanwhile, the pipe market continued to grow, and the question of the need to create a rationing document was all acute, they were waiting for both consumers and manufacturers themselves. Ion finally came out. It is GOST R 52134-2003 "Pipes pressure of thermoplastics and connecting parts to them for water supply and heating systems. General technical conditions." Menno included pipes from the following thermoplastics: polyethylene, polyvinyl chloride, polypropylene and its copolymers, stitched polyethylene, chlorinated polyvinyl chloride, polybutene.

The new GOST sets five classes of operation: hot water supply at a temperature of 60c, hot water supply at a temperature of 70s, high-temperature radiators, low-temperature radiators, low-temperature heating "Warm floor". At the same time, each class of operation is determined by the temperature complex (working, maximum and emergency) and the time of their impact during the overall service life - it should be at least 50 years (at a pressure of 0.4; 0.6 or 1MPA). Based on these conditions, specialists and calculate the necessary parameters of pipes.

We think that it is not necessary to comment on the foregoing for a long time, it is mainly intended for the manufacturer and partially for the designer (although it is impossible to ensure that even an experienced designer with such a rather difficult method of calculation is not errors in choosing both parameters and pipe material). Careful consumer - about us with you, like 30 years ago, no one thinks.

Polymer pipes

In the modern market, the demand for these pipes is constantly growing. This persistent tendency is related to the following indisputable advantages of polymeric materials:

Corrosion resistance (polymers are not capable of entering electrochemical reactions) and resistance to the effects of most chemical compounds.

No deposits on the walls.

Small pressure losses for friction due to the small roughness of the inner surface.

Low thermal conductivity.

Small mass.

The actions of the wandering currents are not afraid (in metal pipes, these currents, as a rule, cause electrochemical corrosion).

However, it is not necessary to think that polymer pipes have only one advantages. Disadvantages also have:

Pipes (expressing the language of specialists) oxygen-permeable. In other words, oxygen contained in the air, albeit in small quantities, diffuses through the pipe wall and falls into liquid flowing through it. If we are talking about hot or cold water coming to the crane, then you can not pay attention to the oxygen in it. But if it is the flow of the coolant (water, antifreeze), then the oxygen penetrating into it will certainly disable or heating devices or a boiler.

Non-Impima to direct sunlight.

Depending on the load and time, lose their strength.

Not applicable in fire fighting systems.

For each type of polymer, special installation and welding equipment is required.

Pipes need to be protected from accidental damage (including ... the invasion of rodents).

The modern market offers polymer pipes from the following materials: polyethylene, stitched polyethylene, polypropylene, polybutene, polyvinyl chloride and fiberglass.

Polyethylene (re or PE). Pipes from it are intended for external and internal pressure pipelines (water supply, sewage, drainage). The industry produces two types of polyethylene: high pressure PVD (or low-density PNP-polyethylene) and low pressure PND (or PVP-polyethylene high density). Keep in mind that these names (and, of course, marking) often disorient the consumer. After all, it does not at all follow that high pressure polyethylene pipes (PVD) should be used for pressure water supply, and low pressure polyethylene (PND) - for sewage and drainage. It is necessary to use these pipes up to the opposite, since the name reflects the production technology of raw materials for them, but not appointment. At the same time, PVD pipes have less mechanical strength than from the PND, so the walls are thicker and mass, respectively, more. By the way, the large wall thickness gives PVD pipes a certain advantage: they better absorb the noise of the transported environment.

Polyethylene pipes supply to the market in most cases domestic firms, quite well mastered their production. Import products are rare. The cost of pipes is small - for example, 1 p. m pipe 202,3mm costs 12 rubles. Larts also have polyethylene non-pressure pipes, intended for internal sewage.

The deformed pipe of the re-can be fixed using the so-called construction dryer:

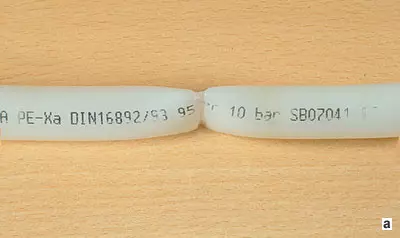

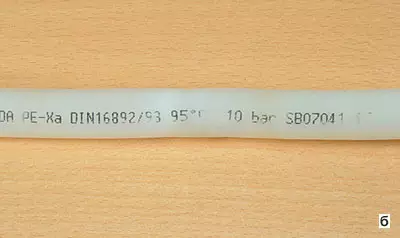

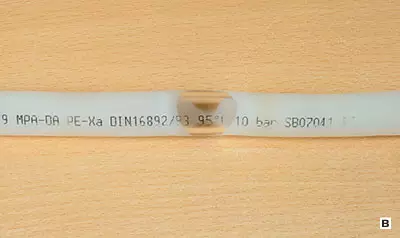

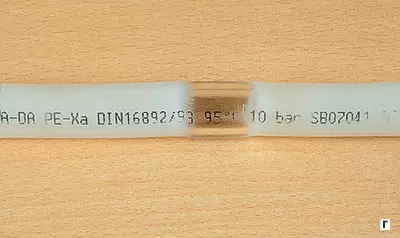

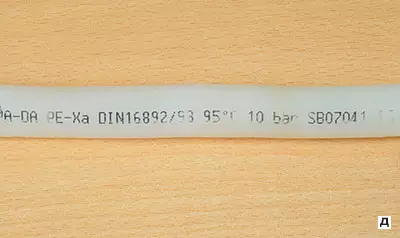

Stitched polyethylene. So that polyethylene become stronger and resistant to temperature effects, it is treated in various ways. As a result, additional transverse connections are formed between molecules, the so-called crosslinks (bridges). The processing process itself is called stitching, and the resulting material-cross-stitched polyethylene and label the abbreviation of re-X (PE-C). Depending on the used method of crosslinking, there are four types of PE-X, differing from each other, the shares of crosslinked molecules and, as a result, durability: PE-HA, PE-CHB, PE-CC and PE-HD. The percentage of stitching is most high in re-ha.

Pipes made of stitched polyethylene due to high oxygen-permeability are used mainly for cold and hot water supply. For heating systems and warm floors, pipes with an outer or inner diffusion barrier are developed, which prevents oxygen penetration. Such a barrier can be obtained using ethylene-ventilated alcohol (internal barrier) or aluminum foil layer with a thickness of 0.1-0.15mm (external barrier). Aluminum foil, in addition, it makes it possible to significantly reduce the magnitude of the thermal expansion (such pipes are called stabilized).

Repeated pipelines are constructed using mechanical connectors in the form of clamping couplings of different designs, as well as threaded and press fittings. It should be noted that the installation of threaded fittings requires more time, as well as control and maintenance during operation (tightening of crimp nuts weakens over time, and depressurization of the connection may occur).

A small range of diameters of the proposed pipes (12-32mm) has an economic and functional explanation: with a large diameter, a large wall thickness will turn out and the pipe will not be so elastic. Yes, the connectors for them will cost much more expensive.

Polypropylene (PP or PP). There are several of his species:

Rr-H (PP-g or PP-type 1) - They are made from a homopolymer, whose macromolecules consist of identical monomer units. These pipes are used mainly for cold water supply systems;

RR-B (PP-B or PP-type 2) is made from the block copolymer, they are more durable and better withstand low temperatures (up to -40c). Used in cold water supply pipelines, as well as floor heating systems;

PP-R (PP-P or PP-type 3) are made from the randomsopolymer. This is a variant of polypropylene, the advantages of which is the ability to evenly redistribute the load on the thickness of the wall and high impact strength. Used in cold and hot water systems, outdoor and water heating systems.

Polypropylene PP-R pipes are produced by three main types, characterized by working pressures:

PN 10- for cold water systems with a pressure of 1MPA;

PN 20- for pipelines of hot and cold water supply with a pressure at T = 20c 2.0 mp, at t = 75c- 0.6 mp;

The PN 25 type requires a more detailed explanation. Let's start with the fact that PP-pipes, like PE-X pipes, are presented in the market in the form of single-layer and multilayer structures (with a layer of aluminum foil or fibrous plastic). Multilayer pipes are called stabilized (in marking there is a word "stable" or derived from it). They smaller oxygen less and differ with greater stability of the form (less linear extension). The activation of PN25 pipes (reinforced) can be used for cold and hot water pipelines and heating with pressure at T = 20c 2,5MP, at t = 90c- 1,0 mp.

PP pipes are produced with a diameter of 16 to 160 mm (for example, the cost of a pipe is 202.3mm, from 17 rubles. For 1Pog. M). They are connected by the method of thermal welding, which is based on the combination of melted surfaces of the welded parts.

Polybutene (RV or PB) - Material, in many respects similar to polypropylene and polyethylene, but withstanding both higher and lower temperatures and has increased flexibility. It can be welded in a thermal way or connect with threaded or press fittings.

Polyvinyl chloride - Thermoplastic material obtained by the polymerization of vinyl chloride. There are two types of it: PVC-U (NSLH) is a non-controlled polyvinyl chloride and PVC-C (CPVH) - chlorinated polyvinyl chloride, which has a higher plasticity compared to PVC-U (12-110mm in diameter). They differ from other plastics greater rigidity, but cheaper. Also, their advantages include almost twice as long as PR, thermal elongation and natural oxygen-resistant. An essential disadvantage of such pipes, specialists believe that when installing has to use adhesive compounds (polydiffusement method), which lengthens, increases the cost and complicates the process. There are other disadvantages, such as combustible and "harmful allocations", which we will discuss in detail in our time.

Fiberglass. The basis of the wall of such pipes forms fiberglass, filler-epoxy or polyester resin. The use of these materials allows to obtain strength characteristics close to steel pipes, but about fourwise easier. Similar pipes are already produced more than 20 years, but they never received widespread. The reason lies both in the insufficient assortment of connecting parts and fittings and in the absence of a quick and reliable method of connecting pipes and fittings.

| Application area | Operating class | Used type of pipe | Thrab, S. | Time for Thrab, years | TMax, S. | Time at TMX, years | TAVAR, C TAVAR, H | Time |

|---|---|---|---|---|---|---|---|---|

| Hot water supply (60C) | one | PR-H, PP-B, PP-R, RE-X, RV, PVC-C | 60. | 49. | 80. | one | 95. | 100 |

| Hot water supply (70C) | 2. | PR-H, PP-B, PP-R, RE-X, RV, PVC-C | 70. | 49. | 80. | one | 95. | 100 |

| Low-temperature outdoor heating | 3. | PVC-C, PR-H, PP-B, PP-R, RE-X, RV | 30/40 | 20/25 | fifty | 4.5 | 65. | 100 |

| High-temperature outdoor heating, low-temperature heating heating devices | four | Rr-N, PR-B, PP-R, Re-X, RV | 20/40/60. | 2.5 / 20/25 | 70. | 2.5 | 100 | 100 |

| High temperature heating with heating devices | five | Rr-N, PR-B, PP-R, Re-X, RV | 20/60/80 | 14/25/10 | 90. | one | 100 | 100 |

| Cold water supply | Kh | Re and pvc-u | twenty | fifty | - | - | - | - |

| Recovery: Trab-operating temperature or combination of temperatures of transportable water, determined by the application area; TMax is the maximum operating temperature, the action of which is limited in time; TAVAR-Emergency temperature arising in emergency situations in violation of regulatory systems |

Scary, already horror! (It would be ridiculous if there were no serious consequences)

We give a few horror stories heard by the author during the preparation of the article.

History 1. One of the construction companies used in a multi-storey residential building for a hot water system instead of PN-20 pipes PN-10 pipes, and without establishing compensators of thermal elongation. The basement of the house was intended for passing under the offices, so thick pipes going along its walls were deposited by giving basement a civilian look. The trial launch of hot water was spent at night, and he walked like without incident. But imagine the surprise of tenants of the basement (they settled early), which the next morning discovered that the safe weight of about 700kg moved away from almost 0.5 m, and a huge bend knee of pipe was dried out of the wall behind him. It also gave the Sauna "Pink"! And could and burst.

History 2. It is believed that for a cold water system, PND pipes are well suited. Having learned this truth, the plumbing grief installed these pipes in the well with a depth of 80m. Amezhdu Topic Pipe is designed for maximum pressure 10thm. The result of such a rapid step was the tip of the pipe (I could not withstand the pressure necessary to provide water lifting up, feeding it to the house and the work of Santechnibors) and ... Long attempts to get it from the borehole of her remains ...

Metal-polymer pipes

These products not only combine the best qualities of metal and plastic pipes, but also are deprived of most of their flaws. The design consists of several layers:An outer layer of polyethylene resistant to the effects of ultraviolet rays;

The average layer is an aluminum tube with a wall thickness of 0.2-2 mm, cooked along the length of the online orcase;

internal layer.

The use of an aluminum layer allows to obtain a lower linear expansion coefficient and protect against the diffusion of oxygen. In addition, the pipe can be bend, after which it retains her shape. High strength allows pipes to withstand high pressure (up to 20MPA) and temperature (up to 95C).

There is a fairly large range of diameters of these products (14-110 mm), but it is economically unprofitable to apply large diameters pipes due to the high cost of connectors, it is necessary to use fittings similar to the PE-X pipes.

It seems that it becomes clear from our rounded review that without help in this "abundance" it is simply impossible to understand.

Who produces pipes

Copper: KME (Germany), Outo Kumpu (Finland), "Kirov Plant for Processing of non-ferrous metals" (Russia).

Polypropylene: AQUATHERM (Germany), Ekoplastik (Czech Republic), Polymelt (Germany), "Plumbing Plumbing" (Ukraine).

Polyethylene: Kan (Poland), Truvolopolymer and Kazanorgsintez (Russia).

Stitched polyethylene:

Re-ha: Uponor (T / M WirsBoin Finland), Rehau (Germany);

Re-hb: Micropol (m / m isoplast- United Kingdom); IVT (T / M Prineto- Germany), "Bir Pekc" and "Van Tube" (Russia);

Re-hs: TECE (T / M Teceflex- Germany), Kan (T / M Kan-therm).

Multi-layered (PE-X / AL / PE-X): WEFA Plastic, Rehau (Germany), Henco (Belgium), Wavin (Holland), Uponor.

Polyvinyl chloride: Kan, "Kubab" and "Agrigazpolymer" (Russia).

Metal-polymer: Geberit (T / M MEPLA-Switzerland), Hewing Pro Aqua and Oventrop (Germany).

Will specialists help?

Another way to make a choice is to contact a large company that specialists instruct "on the road". True, the pitfalls can be tied here. The fact is that firms working with all types of pipes and therefore quite well in them disassembled, no matter how regrettable, there are no services in the market. Each large company has its own experience, on the basis of which it has already given the preferences of this or that manufacturer. As a result, some work only with metal-plastic pipes of a certain brand, others, only with polyethylene pipes, third with polypropylene. By the way, such "attachments" are often financially stimulated by the manufacturer of pipes - large discounts of IT.P. At the same time, each company believes it is its own version that the only correct and unmistakable. Let us tell you many horror stories from the series "How we all reworked after competitors" and try, which is called, to "turn into our faith." But you often do not get objective information.

Here, perhaps, the whole information with which we wanted to familiarize the reader within this review. But our conversation about the pipes does not end. We have a more detailed story about various types of pipes. In general, the continuation should be ...

The editorial board thanks Aquart, Geberit, Uponor, Oventrop, "Termos", "Griff R", as well as a personally head of the Laboratory of FSU "Nisantekhniki", member of the Presidium of NP "Avok", Ph.D. Sasina V.I. See the preparation of material.