Countertops - laminated, steel, wooden, stone. Characteristics of materials, principles of installation, manufacturers, prices.

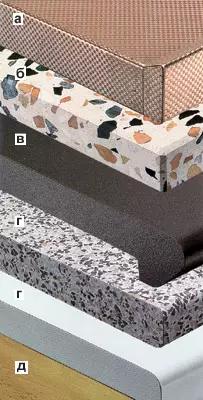

There are tabletops from a wide variety of materials. In its properties, the most suitable stainless steel (s), stone agglomerate (b), artificial acrylic stone (B), laminated stove (g), seed wood (E)

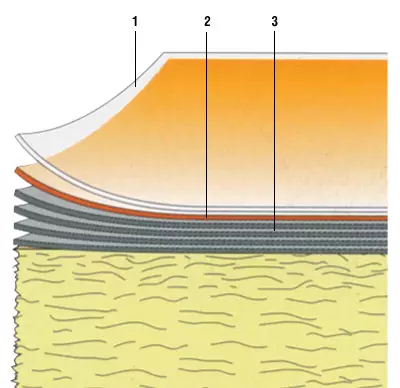

1- protective melamine coating;

2-decorative sheet;

3- kraft paper

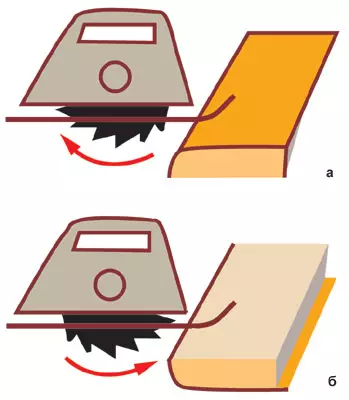

a laminate from above;

Blue laminate

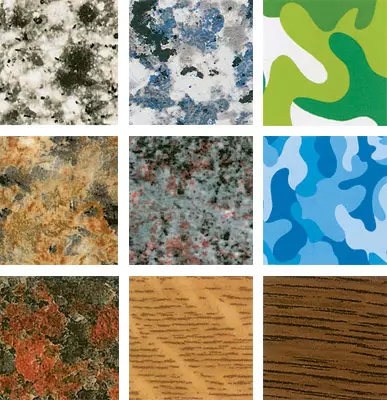

Decorative paper included in layered plastic (laminate) can have any design. Fantasy is not limited thanks to digital printing

Postforming top in Country style well will fit into the interior of the cottage

Countertop from the breed of Zebrano

DuPont has developed a new DuPont Montelli composite material. It does not have flexibility, unlike the Corian material. The novelty consists of a filler binder (a mixture of acrylic and polyester resin) and food pigments. The material is characterized by a high hardness, so it opposes shocks and other mechanical impacts

The main advantage of acrylic countertops is seamless gluing - solves the problem not only the finishes of the front edge, but also the production of corner countertops. They have the form of an absolutely monolithic product without junctions.

The agglomerated stone consists of pieces of natural stone and resin

When buying a kitchen, we are somehow faced with the problem of choosing a countertop. According to general ideas, it should be durable, hygienic, well resist mechanical exposure and, most importantly, please the eye.

As a rule, a modern kitchen countertop is a three-four-step meter, which rests on the couches. Its length and form are determined by the length and location of the entire headset (from 1.5 to 3m, straight or angular), and the width is (or a little more) standard depth of cabinets- 60 cm. Previously of view of the convenience is better preferred by the tabletop sewn- 62-65 cm. It will not affect the general view of the kitchen, but you will cling less to the acting fittings and rest on the knees in the door. The striking of the beauty of beauty may be better to look at the top flush with the facade. You decide.

Countertops are made (in order of price increases) from laminated chipboard (post-forming), sometimes plywood, stainless steel, massive wood and, finally, stone (acrylic, agglomerated, natural). The chipboard of 28mm thick (Russia) or 38mm (Europe), strong enough and rigid, is able to serve as the basis not only for the laminate coating, but also for thin sheets of metal (0.8 mm) or acrylic stone (3.6mm). Apacks precisely the material determines the appearance and properties of the countertops, we will dwell on each form in more detail.

Post-Forming countertops (from 24 / pog. M)

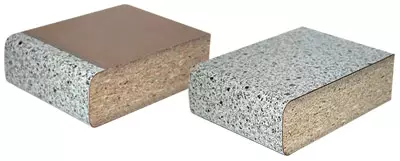

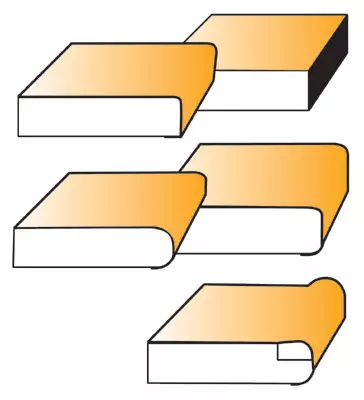

Postforming is a chipboard cladding technology (MDF) from all sides with layered plastic. It is used in the manufacture of the cheapest from the laminated countertops known to us. To do this, use high-quality flexible and thin (0.7-0.8 mm) paper-layered high pressure plastic (HPL). They wake the surface of the chipboard, rich front (sometimes rear) edge so that it is completely or partially wrapped with a coating. Postforming is also products obtained using post-forming technology.

The laminate consists of several layers of a solid base (3-4 sheet of craft-paper impregnated with synthetic resins), decorative paper on which Nakatan drawing, and a protective coating of transparent melamine and acrylate resins. It is the protective layer that gives the surface of wear, light and heat resistance, makes it insensitive to blowing dishes, scratches from knives and forks, the effects of cleaning agents, solvents (even acetone) and other substances: vinegar, blood, coffee. But weak acid solutions (up to 10%) and alkalis, hair paint, varnish and glue, scale solvents, hydrogen peroxide and mangartage should be removed by no less than 10-15 minutes after entering the worktop. And a damp cloth, after which the surface to dry. Otherwise, the likelihood of spots is high. The stronger solutions of inorganic and organic acids (more than 10%) must be erased immediately, even short-term effects on the laminate causes clouding of the surface. Remember this, buying a child a set of young chemist! In addition to the functional, the protective coating bears a decorative load. It gives the depth of the drawing, and the matte "granite" surface extinguits glare and pleasant to the touch.

The decorative layer of paper allows you to get a tabletop with any pattern - from the notorious "salt-pepper", imitating granite, to the zebra skins or pictures of the famous artist (Westag Getalit). You can even order your own design (with photos of mother-in-law), but manufacturers are not yet so interested in the private customer to perform an exclusive model in one instance for it. Avtus dozen- Please!

The lower side of the table tops are usually covered with kraft paper. Achetoba Rolling drops did not fall into unprotected places, on the border of the laminated layer and paper fasten the so-called kapellable bar of plastic.

Laminated countertops are sold in building supermarkets and in the markets in the form of plates (with untreated side and rear edges). Sometimes you can ask to cut them right in place. Standard dimensions of products of domestic production - 6203050 and 6002440mm (Scythy, Petropropal. Usually such a length is enough, but if you have a highly long kitchen, we recommend Westag Getalit, Wodego products (both Germany), Kronospan (Austria) 4m long. Russian countertops based on a thinner chipboard (28mm) cost about 25 for 1 mm, imported thickness 38mm- depending on the surface design.

Photo M.Stepanov

Laminated Phaneur uses as a working surface

The tabletop can spend a few standby headset. So you are less likely to hit the knees about the door

As already mentioned, only the facade edge of the table top is laminated. Akak to be with end surfaces? After all, they are also visible! The question is solved with the help of a special melamine edge ribbon, which should be purchased further (1 m. M- 0.5-3). It is glued with an iron, heated to a temperature of more than 150s. Ribbon and allows you to make a tabletop required length with preservation of an elegant appearance. Surplus the edge tape should be removed with a knife so that the chipboard does not have the slightest open areas.

The disadvantage of laminated tops is that water that fell even on imported moisture-resistant material of the base can lead to its slow swelling. So the negligent installation of expensive stands. We emphasize that all non-aluminized areas are recommended to protect the sealant, especially in places of sinking and embedded equipment. In addition, according to manufacturers, it is important to always immediately wipe the water on the tabletop so that it does not penetrate the base through the seams.

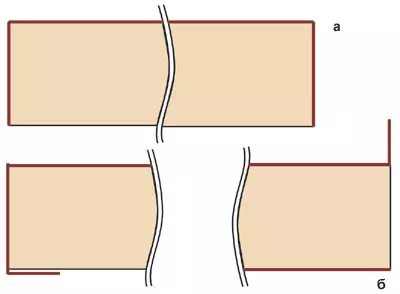

Low moisture resistance of the foundation of laminated tabletops with more than compensates for their cheapness, availability and simple installation. Is there one but. It is known that the share of kitchen headcases oriented in a straight line is only 30% of the total. Most people order corner compositions. How to be with them, if the table top is straight? Very simple. The plates are flooded at an angle and fit into the formation of a barely noticeable seam or by decorative metal molding, which can be bought on any market (70-250 rubles / p. M). Of course, the "continuous" design will be broken, but the price of the question will be low (the dock costs 30-40), and the chipboard will protect against moisture.

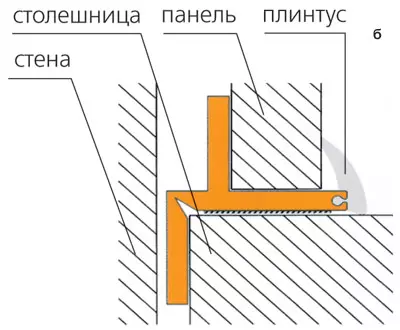

The entrance of the laminated countertop mounting is hosted unknown edges, cut and plant the sink and the cooking panel on the sealant. The top is then fasten directly to the carcass of the Tumb with metal corners and screws and only after that the plinth is installed. It is he who protects the cabinets from moisture ingress and, due to its flexibility, it closes those gaps that are formed between the wall and the worktop.

"Facade work"

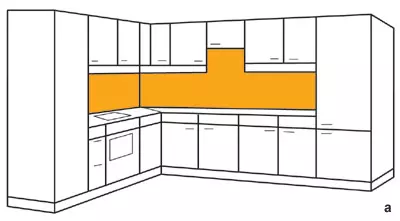

The kitchen "apron", that is, the rustle between the tabletop and the headset hanging cabinets, usually protect against splashes and food dirt. Often, these surfaces are facing tiles or mosaic, which are difficult to surpass in moisture resistance, durability and, probably, decorativeness. The only difficulty is associated with the choice of material. One want to play on the contrast and create a bright causing "apron", others suits the uniformity of finishes. It is the last one and the proposal of most producers to perform a "apron" from the same material and in the same design as the worktop. Limit is the laminated panels with a length of approximately 3m (3050mm from Petropropal and 2960mm from Westag Getalit, the GETALAN trademark) and a width of about 60 cm ("apron", as a rule, make a 60cm tall). They have a smaller thickness than the work surface - from 4 to 16mm- and differ from the tile with ease, simplicity and, therefore, cheap installation. The cost of such panels is approximately 20.

"Apron" from metal, artificial and natural stone will cost approximately as much as a tabletop. Reduce costs can be reduced only by applying thinner blanks. But the Master of the Stone Master does not go to avoid scattering of natural material in color and texture.

Steel Top (from 60 / Pog. M)

Oddly enough, the most durable, durable, moisture-proof and hygienic stainless steel countertops are extremely more expensive than the products from post-forming. One square meter of the working surface of the metal costs only 100 that translated into the route meters is 60. It is 5-10 times cheaper than natural stone. Agree, impressive!

Stainless steel (Italy, Finland) 0.8 mm thick (38mm) thick (38mm) with "liquid nails", after which the edges bend on the press around the edge of the plate, or completely covers the entire stove (at the request of the customer). Seam, formed at the corner, you can brew and polish. These operations are summarized in 1.2 per month. See, respectively, two angle of 4 cm will add to the cost of 9.6 products. The maximum possible length of stainless steel countertops is about 3.7m.

While such countertops are exclusively rectangular. AESLI You will need an angular option, you will have to docile it from two parts. They are attached to each other in small screeds. To cook two components so far, unfortunately, do not suggest, although, in our opinion, it is no more difficult than to separate the angular seams. The stuck joint on the matte surface will be almost indistinguishable, and the product will take the type of monolithic.

In addition to matte steel, a mirror stainless steel and sheets with a repeated decorative pattern of the type of braided or circle are offered to choose from. In fact, the processing options have become much larger, but there is no demand for them. The manufacturers themselves recommend a matte metal, since it is easier to wash off the dirt than from a decorative sheet, and the scratches can almost be sanded. This sense is the most despicable mirror stainless steel, which, according to experts, restore almost impossible. Countertops from such steel stand at 20-30% more expensive than from the usual.

To protect against moisture, the plastic is glued to the chipboard, and the side-adjacent to the wall bends up. Thus, water does not fall behind the cabinets.

Stainless steel table tops are good for everyone: hygienic, durable, stylish, functional. They can be filled with hot dishes without fear. Scratches are easily removed by shallow skin

Photo K. Manko

From a wooden disheveled boards, it is easy to make curvilinear top, second kitchen outline

Specialists of the "firms of the ATP" proposed to realize the interesting idea of the finishing of the "Apron" kitchen by the Hi-Macs stone from LG. They flashed the sheet of material with seams, as if the wall was finished with tiles

Wooden "deck" (from 70 / pog. M)

For the production of wooden countertops, set-up shields glued from solid trees solid planks are used. Such a technology allows you to avoid warping under the influence of moisture and get a spectacular appearance, resembling a yacht deck in miniature. We will not describe the decorative advantages of the tree of different breeds, this is a topic for a separate article, but still note that the best neighborhood for furniture trimmed with a veneer than the interior of a log or brusade house, find it difficult.

The edges of wooden tabletops are milling, all surfaces and edges are covered with transparent oil (Neoooil from Neopur, Habiol from ArmBruster, Germany) deep penetration. Oil processing technology is not easy and largely depends on the initial roughness and wood porce. According to Odyssey specialists, after the first passage, the pile rises, so it takes a subtle grinding. This time-consuming occupation takes a lot of time. With double processing, you will have to supplement 60 for 1m2 table tops, including the opposite direction, with triple-70 / m2. In addition cases, the procedure starts at the factory, and then, after installation, the buyer continues at home.

Cook-tops from imported and Russian raw materials are seded. For example, the MM-Engineering company offers products from Italian blanks. Material - beech, alder, nut, cherry; thickness - 32-42mm (depending on the wood breed); The maximum width is 630 mm and the maximum length is 4100mm. The time of manufacture of tabletops is only a few days, cost - from 150 to 240 / p. m. Russian analogue from the company "Siberian Master", glued from the domestic larch, which is practically not amenable to rotting, cheaper, from $ 135 (with a thickness of 40 mm) to $ 195 (with a thickness of 60mm) for 1m2 (this is approximately 66-96 / mm ). Noble oak is more expensive than larchs one and a half times. The deadline for execution of the order is 2-4 weeks.

The most diverse, including exotic, wood (disheveled in Denmark) uses Odyssey. If larch and oak tops (domestic) firm assesses 78 and 138 for 1 p. M (without oil treatment), then the price of Araputango and Wenge (Denmark) reaches 381 and 540, respectively. Against the background of such numbers, oil treatment (1 m- 60-70) looks like a trickle. To decorate the line of adjustment to the wall, the company offers a variety of plinths - from 10 (larch) to 27 for 1 p. M (wenge). Cut the hole for the cooking panel or the sink costs as much as in the laminated tabletop, - 20.

Under the wooden countertop you can install a special sink with smooth sideboards. It is fixed from bottom to the sealant

The surface of the agglomerates based on quartz is very solid, durable, like porcelain stoneware. She is almost not threatened with scratches and chips from sharp items. This dignity allows you to cut the products right on the tabletop.

The wooden countertop is fixed with a "floating" way, using brackets with oval slits. So it is possible to compensate for the change in the geometric dimensions of the wood under conditions of changing relative humidity. If this does not take into account and scout a wooden product tightly, it simply cracks.

Wood, like no other material requires care. Try not to put hot and wet dishes on this tabletop and heating appliances (electric kettle, coffee maker). They are better to provide special supports. Wooden top weak soap solution wash (literally with the Fairy drop) and in no case do not allow the surface of caustic agents.

It is possible to restore the former gloss using a grinding skin (P600 or P800), oil (1l- 30) and a polishing cloth, which is acquired separately or in a reducing kit (250 ml, paper and napkins - 30). While the services for the passage of wooden countertops are not in the price list of manufacturers, but we hope that it will appear in the near future.

Tiletop from tile

Acrylic Stone Countertops (from 144 / Pog. M)

First, let's say a few words about the material. Over the past five years, since almost half a century patent for DuPont (USA) has been completed on the production of products from acrylic stone, known to many under the Corian brand, there have been a great many firms producing similar products under their own brand. Among them are Hi-Macs (LG, South. Korea), Getacore (Westag Getalit), Staron (Samsung), Gibraltar (Wilsonart), Hanex, Silestone. Included in the race and Russian manufacturers who make such composites from imported raw materials ("Astra-forms"). One way or another, all these products consist of mineral filler (70% of aluminum oxides), pigments and a binder component-acrylic resin.

Acrylic Stone belongs to the Acrylic Solid Surface group. It has a non-porous structure and, therefore, does not absorb moisture and solvents, impenetrable for fungus and bacteria. The surface of the material is easily washed with conventional soapy water and even in case of strong contamination does not require the use of special means, abrasives or dissolving fluids. Footprints on the surface remain only from hot saucepan, pan or not covered in time cigarettes (tobacco resins can be removed), since the acrylic stone is thermoplastic at a temperature of 180c. In order to avoid damage to this kind to the working surface, metal strips are specifically cut, which protect it from dangerous contact. At the same time, this material is exceptionally racks in relation to domestic reactivities (alcohol, vinegar, juices and fermented milk products). Assethe he is resistant to shock, but it can be quite easy to scratch, so it is necessary to show accuracy when handling forks and knives. It consesses that if the chip appears, the countertop is easily renovated (exit specialist - 100, plus work). AESLI surface is scratched, it can be cleaned with sandpaper and polished (polishing 1m2-80).

Acrylic stone has a silky, pleasant to the touch surface, more warm, than its natural polished fellow. And, unlike it, the composite instantly absorbs the sound from the impact. In general, acrylic stone is a fabulous material for designers. Separate elements of one or different colors or designs glued together with each other without the formation of visible seams, which gives the product of any complexity "litter" form. Among the wealth of textures are found both resembling natural stone (granite, quartz, sandstone) and monophonic, right up to completely amazing, unusual. All this allows you to use these stones in the widest range of design solutions - from classics to the style of High Tech. Seamless gluing makes it possible to connect different colors in a common drawing and eliminate severe stone damage, not leaving traces of repair. Often, this method is used in the production of tabletops to which the side is attached, and sometimes the wall covering the "apron".

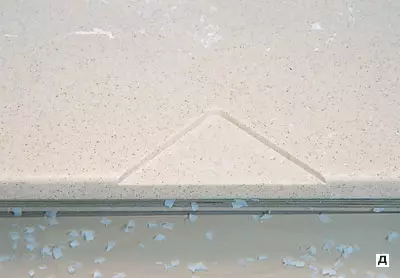

Domestic firms produce countertops from the sheets of acrylic stone with a thickness of 3-12mm (DuPont and Lgchem do not recommend using the sheets of sheets thinner than 12mm. The thinner sheet, the cheaper the product. The thin blank is glued to a solid wood chipboard, thicker - on the frame, and then on a seamless technology, a decorative curb border is attached, an adventure side. The advantage of acrylic stone countertops is that the same technology allows you to produce "monolithic" table tops of any form, including curvilinear, without seams.

The approximate cost of the square meter of the table tops from the imported three-millimeter canvas - 350, from the sixmillimeter domestic raw materials from the company "Astra-forms" - 240, and from the plate with a thickness of 12mm, it is already 450-500 or more.

Stands should be made for hot dishes

Stone Top (from 300 / Pog. M)

By its magnificence, significance and price, no material compares with a natural stone. The tabletop is from the undisputed queen of the kitchen. She sets the mood to the whole interior. At one glance, it feels cold luxury, decent palaces. There is not enough space for epithets to describe all the emotions that cause the beauty of crystals, streaks, color gradations ...The basis for the manufacture of kitchen tops is the so-called slabs with a thickness of 2-3cm of solid rocks (granite, basalt). Marble is trying not to use because it is too soft and not racks to the effects of chemicals, lemon juice and coffee. Similarly, the billets from the agglomerated stone on a quartz and granite-based basis, which we rank with natural prototypes due to the similar price and processing technology.

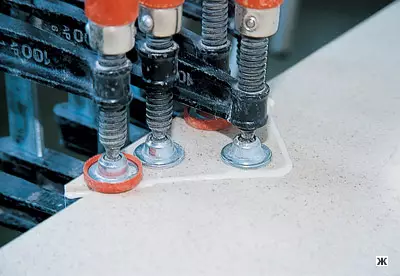

On the complex stone-processing equipment, the plates give complete features: the surface is cleaned, grind and polished, process edges (they are made straight, with champions or fake, figurines), cut the openings to install the sink or embedded equipment. All operations are very laborious and make a significant contribution to the final cost of the product, which is calculated individually. Given the price for the starting material (it may vary with each delivery), the area of the treated surface, the length of the edge, the perimeter of the propyl, the presence of holes. We give several price examples. One client of the company "Olver" Table Topper 3cm thick and the size of 22565cm from the agglomerated stone Santa Margherita cost 770, and another 880 had to pay for the granite product with dimensions of 210603cm. The restoration of natural stone is practically not subject. Do not believe in a miracle to eliminate chips with a waxy pencil.

From order to mount

Table tops made of wood, steel, acrylic, natural and agglomerated stone are released only to order. How products are not cheap, they require an accurate sketch. If you make it on your own, the claim will present a certain one. More reliable options - cause markers. This service is paid and, according to our information, costs 50-100. If the order exceeds 900-1000, its cost is read as a prepayment.

It is necessary to find out the accurate installation dimensions and the location of the washing, cranes and the embedded hob, since it will not be possible to remake the worktop. Especially carefully consider the functional elements of the stone top. We are aware of the case when the workers spent a lot of time to drill a hole with a diameter of 14mm in a granite plate with a thickness of 50mm for a small crane for drinking water.

Emboss and pay the order is still not enough. Separate installation. If the countertop is sold together with the kitchen in the cabin, the installation of the headset with the top is estimated at 5-15% of the amount.

The cheapest is the installation of laminated and steel countertops (approximately 50-60), as they do not require a special approach. They are installed workers who make repairs in an apartment, or specialists recommended by sellers of kitchens or tops themselves. At the same time, the wizards can cut the sink and the cooking panel. Docking on the screeds at an angular arrangement sometimes adds 30-40.

The installation of wooden tabletops "floating" way can be made on both the services, the services of the company are estimated at 10-15% of the order value, but not less than 120. A similar amount will be required to install a kitchen top of an acrylic stone, although some firms with a significant order value ( From 900) carry out this work, as well as measurements, for free.

The most expensive is the transportation and installation of table tops from natural or agglomerated stone - 30% of the order value. These are not simple procedures, especially if you consider the impressive weight and relative fragility of a material that is almost impossible to restore.

The editors thanks "Firm ATP" for assistance in holding filming, as well as the company "Odyssey", "Meg-Trade", "Astra-Form", "Olver", "Psp-Farman", representative offices of DuPont and Westag Getalit for help in preparing material.