Construction of a house with a total area of 270 m2 made of light steel thin-walled structures - firmly, durable, quickly and affordable.

Metal as an alternative to wood and stone? Durable, durable, quickly erected and affordable at the price of the house allows you to build technology for assembling buildings from light steel thin-walled structures (LSTK).

With the fact that the house should be durable, durable, to build quickly and at the same time cost relatively inexpensively, everything agrees. Cases of cases disputes begins for the choice of building materials. What is technological, stronger, warmer, brick, concrete, materials based on polymers? Which of them are considered environmentally friendly, and which no? Until recently, the metal as a material for the construction of the frame of individual residential buildings, the subject of a serious discussion was not. Well, once it was considered impossible to build the walls and roofs of warm houses from glass. Complete technology of energy efficient translucent structures based on aluminum profile Warm winter gardens, greenhouses, basins with extensive glazing today is energized even behind the polar circle. Developer engineers found a way to reduce the heat-conducting ability of metal profiles to the level of the wooden handle. To do this, inside the extruded aluminum profile laid air cavities and thermal-keys from plastic, which prevent the rapid distribution of cold.

As for conventional steel, earlier we described a wooden bath, which is enclosed in a glazed pyramid, welded from a metal rolling (square tube, IT stolers). The peculiarity of the operation of this structure is not only in the rapid cooling of the metal, but also in the formation of condensate in winter. To remove it, the pyramid provides an expensive ventilation system, which allows you to remove the pairs outside the room to avoid metal corrosion.

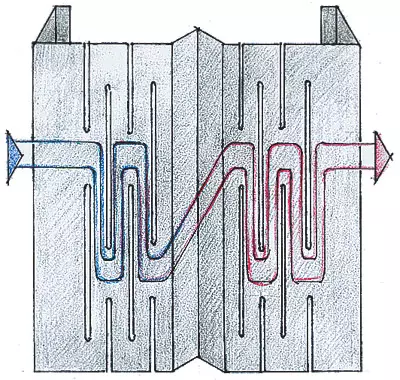

How to build a lightweight and durable frame of a residential house of metal and try to avoid corrosion, formation of cold and condensate bridges? The answer to this question was found in the fifties of the last century of the Swedes. Based on high-quality insulation, insulating and vapor-permeable protective materials, they developed the concept of erection of metal frame housing. Today, outside of our country, it is known as construction technology from light steel thin-walled structures. The frame of the frame is used galvanized thin-walled profile similar to the one that is used for mounting sheet carcarter sheets, only a larger cross section and with special perforation (it was called the thermoprophile). The gaps between the frame racks are filled with mineral insulation or fiberglass. According to studies, the openings in the profile walls significantly reduce heat loss through the walls of the building due to the elongation of the heat flux path and the features of the edge properties of the slots that have a difficult form. In addition, the thermal conductivity affects the thickness of the profile material. The thinner steel, the smaller the heat loss (but below the carrier load). They become comparable to losses in buildings with a wooden frame.

Heat transfer resistance (RPD) walls of buildings with wooden and steel frames

| Wooden frame | Perforated profiles 0.7 thickness; 1; 1.2mm | |||||||

|---|---|---|---|---|---|---|---|---|

| Circus rack section, mm | 45145. | 45149. | 145/07 | 145/1. | 145/12 | 195/0,7. | 195/1. | 195/12 |

| RPR, M2C / W | 3.38 | 4,21 | 3.35 | 3,27 | 3,17 | 4.04. | 3,92 | 3,78. |

"But what about the" dew point? "- the interested reader will ask .- After all, when the temperature drops, the moisture will still appear." Indeed, the "dew point" takes place in the wall design of any home. But it is important where it is watered. There are inside the wall of the building, the "dew point" is inside the wall wall, and the problem of the appearance of condensate can only be solved with a competently designed panel ventilation system. First, they are protected from moisture, which comes from the inside of the house with a vapor barrier film. Secondly, the frame filled with insulation the frame is covered with vapor-permeable wind hydrogen insulation (TYVEK, "Yutafol-D" and the like), which freely produces moisture in the panels, but protects the insulation from weathering and wetting. Thirdly, the ventilated gap is additionally made between the film and the external cladding, in which the conditions for the occurrence of air thrust are created. Air flow quickly removes water vapor.

Another problem that cannot but worry people who know the physics - high electrical conductivity of metal structures. But the lightning strike or random breakdown is dangerous if metal conductors are bad grounded. If preventive measures are taken to avoid the occurrence of potential difference in various parts of the metal structures, there is nothing to be afraid. Make life in the metal frame home safe helps the correct device of the equalization system of potentials. The latter becomes effective protecting - when the potential difference occurs in different parts of the electrical installation.

How does such a system work? All potential electricity conductors in the house, including the metal frame, are connected to the total chain and ground at several points. If you get into the lightning building, the electric discharge goes into the ground, without harming the equipment and people. In addition, the finishing of the house from the inside and outside the electric current with the materials excludes direct contact with the metal frame. It is recommended to use for wiring to luminaires and sockets with double insulation cables. To increase the electrical safety of the metal frame home and to protect the equipment located in it, it is customary to be installed in the switchboards of overvoltages, protective automata and selective RCDs.

Features of assembling houses made of metal

There are three main ways to assemble houses using light steel thin-walled structures.Method 1. Assembly at the construction site. Building elements are delivered to place in the form of pre-sliced and labeled profiles. On a predetermined surface of a brigade of builders with a screwdriver and self-drilling screws, it produces an integrated assembly of wall frames, farms, partitions IT.D. After such an assembly, the design is fed to the mounting place manually (without a crane), fixed on the foundation in the design position, are insulated with mineral wool slabs (or other efficient insulation) and are isolated from the inside of plasterboard sheets, and outside the board-block or other finishing material. The mass of each element does not exceed 90-100kg. The windows and doors are shipped to the construction site separately and embedded in the walls panel.

Method 2. "Mini-Plant" on the construction site. Building elements are delivered to the construction site in the form of pre-sliced and labeled profiles. It also organizes a kind of workshop equipped for the "enlarged" assembly of already insulated panels and other elements. As a rule, it is a light canopy, under which workplaces are created with equipment for connecting profiles, cutting the minicle, drywall, wood. One team of workers produces an enlarged assembly of elements, insulates the panel, hesides the plasterboard from the inside, and the second delivers the collected panels to the installation site, raises with a load-lifting mechanism and fixes in the project position. After installing the wall panels, windows and doors are embedded in them. The weight of the elements is increasing, but the installation time is reduced.

Method 3. Complete factory readiness panels. All chopped and labeled profiles are collected in the design of the walls, Farm IT.D. At the factory, in warm conditions, using the automatic tool. In the same place, windows and doors are mounted in the wall panels, electrical cables are laid, and the low-voltage equipment is made. The panels are insulated, from the inside they are attached to the sheets of plasterboard. Outside the walls can be decorated with facing panels, siding, blockchaw board or other elements of facade systems. At the construction site, with the help of a crane, all parts of the design are installed in the design position, fixed on the foundation and associated with each other. Installation of buildings with this method is very fast, and the quality of the panel assembly is guaranteed by the operation of the technical control department.

Who builds today and offers low-rise buildings from light steel thin-walled structures in Russia? The pioneer is the company Tald Profile, the technology of which allows you to build residential and office buildings based on a frame of light steel thin-walled profiles under the stall brand name. It has been developed in conjunction with the TsNII of industrial and TsNIIPSC them. Melnikova. Until then, the Swedish industrial group Lindab was engaged in Russia in Russia, the Swedish industrial group Lindab was engaged in our country. Its products and today occupies a solid position in the Russian market. High-tech equipment for the manufacture of steel thin-walled profiles supplies Finnish company Samesor in Sweden. Russian profiles manufacturers also have no attention to this area of the construction industry. Today they produce similar products in Finnish and domestic equipment. For completeness, I will call other manufacturers of LSTK components: Rannila (Finland), Hwa Kyong (Korea), "Ecurgia", "Lasar", "Baltproof", INSI, "Profile Plant" (Russia).

The main properties of light steel thin-walled structures

The initial components of the LSK are metal profiles having a cross section in the form of letters C, U, S and Z and made of 0.7 to 2 mm thick made of galvanized hot method. As we noted above, thermoprophil is considered the highlight of the beisters of the walls of the walls, in the walls of which numerous through grooves are cut into a checkerboard. Because of this, the path of the heat flux on jumpers between the grooves increases sharply, and the flow cross-section area decreases. As a result, the amount of heat lost is significantly reduced. At the same time, the strength indicators of the profile (including resistance to bending, twisting and longitudinal stability) are weakened. Therefore, to ensure the stiffness of the frame of the building, its design has to be thoroughly thinking about and calculating. At the same time, specific elements are used, such as panel farms, hard disks of floors, edge beams, fixtures in the farms of overlaps and roofs. Thermopropilles are combined with conventional thin-walled profiles with a wall thickness of 1-1.5mm. Cutting thermal profiles on design sizes is carried out at the factory. Since the electroplating metal processing is carried out by a hot way, the coating provides the creation of a protective layer with a thickness of 20 microns with durability up to one hundred years. Thermoprofili is connected on the construction site in the design with special self-drilling screws.

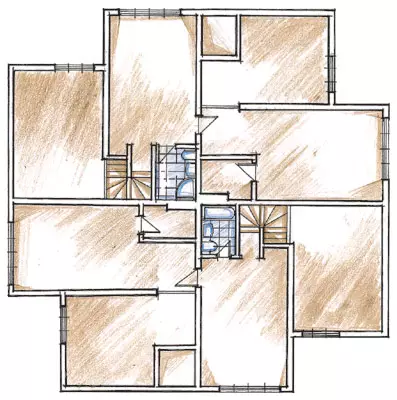

For a number of indicators of the construction of the LSTA analogs do not have. Easier buildings from these designs is that straw huts. So, the mass of 1m2 walls from the LSTK without an external finish is an average of 53kg; The farm with a student of 9m weighs 70 kg. Thanks to the ease of components, all construction is carried out without the use of lifting equipment. These buildings are not needed and the foundation of a depth of 1.5-2m is perfectly standing on finely brewed foundations (ribbons, monolithic plates or burbilling piles). The use of small-scale foundations allows 50-80% to reduce the consumption of concrete, reduce the cost of construction. Due to the ease of each element, the accuracy of the size, the correct labeling and the thoughtful drawings of the brigade of three or four people are able to assemble the frame of the house with an area of 150-200m2 in 2-3 weeks. To install all elements of the building, you must have only a set of battery screwdrivers. The buildings built from the LCTK can be single and two-storey plus attic floor, have dimensions wide up to 12m, in length to 90m at the height of each floor up to 4.2. The LSTK buildings are characterized by high seismic resistance and resistance to extreme wind loads.

The heat-displacement rates of buildings from LSTK and data on the required panel thickness

| Panel height, m | The reduced heat transfer resistance (ROPR), M2C / W, for the panels thick, mm | |||||

|---|---|---|---|---|---|---|

| 150. | 200. | 200 + 50. | ||||

| Operating conditions (SNIP II-3-79, ad. 2) | ||||||

| BUT | B. | BUT | B. | BUT | B. | |

| 3,3. | 3,46. | 3,23 | 3,88. | 3,63. | 5,1 | 4.77 |

| 3.6 | 3,56. | 3,32. | four | 3,73. | 5.22. | 4.87 |

| 4,2 | 3.72. | 3,46. | 4,17 | 3.9 | 5,39. | 5.04 |

| Note. The values of the above resistance of heat transfer panels of different height and thickness are defined on the basis of the study of Niizf "Conclusion on the thermophysical characteristics of the panels" and are shown in the table for the heat-insulation "DOBASIL M3" density of 75 kg / m3. |

LTK residential buildings of residential buildings

Preparing for the construction of the house, the builders cleared the platform, in the standard technology cast a small-dried foundation and a monolithic slab. It took two weeks. At the same time, materials were delivered to the construction site. Most of the house were collected according to the described method. For dvmeni, the metal frame of the walls, overlaps and roofs were tied, covered the house for metal roofing, engineering communications mounted.

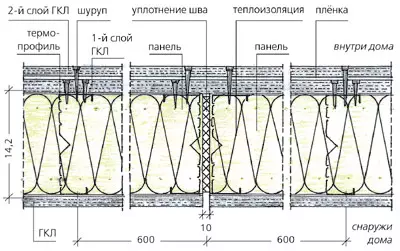

The prevailing operation was the assembly of metal frame wall panels. In this case, the wall panel assembly includes: Overallized plasterboard sheets, then a layer of vapor-permeable membrane (TYVEK membrane material), followed by plates from basalt fiber, placed in metal frame; From the inside houses, two layers of plasterboard sheets with subsequent trim (in color, with wallpaper). The upper and lower horizontal strapping of frames of panels was performed from a steel strip with a thickness of 0.9 mm; Under the bottom strapping placed the thermally insulating gasket of polyethylene foam 10mm thick. The lower strapping of the frame in the corners and the frame racks (with a pitch of 1200mm) attached to the concrete foundation by anchors. Until the hard connection of the panels at an angle to each other, they were recorded in a vertical position with belt stretch marks.

Inclusive of thermal insulation material for wall panels and floors used non-combustible mineral wool slabs from basalt fiber Paroc Uns37 density 37kg / m3. Sizes of plates: length - 1000, 1500 and 2000mm, width - 610mm, thickness - from 50 to 100mm. To simplify the laying of thermal insulation in the frame profiles and ensure the ability to dress the layers, the plates laid in two layers: with a panel thickness 150mm- 50 + 100mm, with a thickness of 200mm-100 + 100mm. Along the vertical edges of the plates, at a distance of 40 (46) mm from the edge, the cuts of 15mm depth to ensure the tight fit of the slabs to the beads of the rack profile when they are tabs in the framework.

From the inside, the wall panels were trimmed with plasterboard sheets of group A (9.5 mm thick) of Russian production ("Knauf"). For the first layer of two-layer inner, the conveyance is a regular sheet with a straight edge (GLC-A-PC), for the second layer (outgoing) - a normal sheet with a thinner front edge (GLC-A-Code). For the outer sheat, one layer of moisture-resistant leaf of HCCV with straight edge (G CLE-A-PC) was used. The main length of the sheets for reasons is the convenience of transportation and installation - 2500mm.

Between the leafs of the outer sheat and the frame as the windproof laid the Tyvek brand membrane with a thickness of 0.13mm. The connection of the adjacent panels of the membrane produced VanBestest (200mmm) by releasing the ends on all four edges of the panel. For a reliable compound with floor insulation, ceiling and in the corners of the film, the film was recorded by adhesive tape. Kmetallic frame sheets of plasterboard attached with piercing or self-drilling screws with a diameter of 4.2 or 4.8 mm with a secret head "Knauf"; Step screws - 200mm. With double trim, the sheets of the second layer have placed a rotary-with the displacement of the vertical seam to the floor-sheet, that is, 600 mm. Horizontal joints also arranged aims.

The floors from the gypsum fiber sheets were mounted in accordance with the indications of the joint venture 55-102-2001 "structures using gypsum fiber sheets". On top of the foundation and fastened with each other, the self-drilling screws of the C-shaped beam (2502mm) were placed on top of the steel flooring, which serves as the base for laying floors. The flooring attached to the onboard beams and beams overlap with self-tapping screws. According to the technology, the base base form two layers of moisture resistant gypsum fiber sheets (GVLV). They were secured by self-refined screws. On top of the base on a sonorous substrate from three-millimeter foam polyethylene laminate was laid. Directly on the foundation plate was used hydro and thermal insulation of the floor of the first floor (hydrohotloxole and mineral wool slabs).

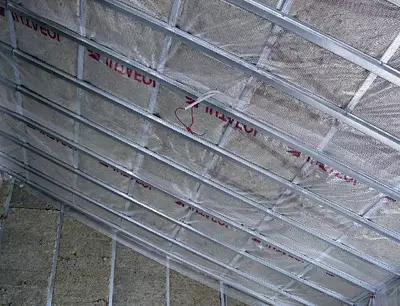

The beams of the attic ceiling made from steel thin-walled profiles, on which the floor of the attic mounted. The ceiling was laid from below, which is the following design. Klemmers klemmers attached a metal cutter from the profile having a cross-section in the shape of a hat. Knei is the ceiling of two layers of plasterboard sheets and a layer of mineral woolly insulation, laid in the cavity of the inter overlooking. The described design of overlaps, on the conclusion of the Research Institute of Construction Physics, provides the magnitude of the sound insulation index of air noise RW = 52-53DB, which complies with the standards.

The carrier structures of the roof were collected from rafting farms and beams made from thin-walled galvanized profiles. Their use allows you to create rafting systems with a span from 6 to 12m and, as a result, reduce the mass of the house as a whole.

The installation of wooden windows and door hitch was carried out according to the standard technologies of their manufacturers. Since the metal frame building is not subject to shrinkage, compensation gaps over window and door boxes did not leave. Window and door box fastened in the openings of screws, the gaps are stupid. After completing the facade of the facade of the window was decorated with wooden platbands, they set them down on them for water.

Installation of engineering systems in a metal frame house almost did not differ from similar works in the panel buildings of another design. Nevertheless, it was necessary to reckon with the abundance of metal structures. So, the engineers tried to avoid laying wiring on the outer walls, in the cavities of dual frames and in interior partitions. Electrical cables have been pulled in cavities of bearing walls and overlaps. Rims of water supply and sewage pipes placed in a special well. Pipe laying to radiators and sanitary devices were carried out in an open way along the walls. For heating bathroom used warm floors. Nevertheless, the main steel heating system by radiators connected to the Gas boiler Vaillant (Germany). For ventilation, the kitchen and bathrooms were collected a separate ventilation collector with forced air removal using kitchen exhaust and electric fans.

How and in what style is the interiors of metal frame houses? There are no restrictions on this issue. The interior walls are appropriate as classic and modern design. Sports style fans, household owners in sorcers chose dynamic modern interiors, which can be easily changed depending on mood and circumstances. The living conditions in the village meet European standards, the inhabitants of the houses are satisfied with them. Here you can not only relax fully, but also fruitfully work. Already, those who like not only winter sports, but also the opportunity to spend time outside the city throughout the year throughout the year.

Enlarged calculation of the cost of work and materials for the construction of the house with a total area of 270m2

| Name of works | Units. change | Number of | Price, $ | Cost, $ |

|---|---|---|---|---|

| Foundation work | ||||

| Handling axes, planning, soil development | m3. | 43. | eighteen | 774. |

| Device of tape foundations, monolithic reinforced concrete plate | m3. | 67. | 60. | 4020. |

| TOTAL | 4800. | |||

| Applied materials on the section | ||||

| Concrete heavy | m3. | 67. | 62. | 4154. |

| Crushed stone granite, sand | m3. | 49. | 28. | 1372. |

| TOTAL | 5530. | |||

| Walls, partitions | ||||

| Cork frame of exterior and internal bearing walls | m2. | 380. | twenty | 7600. |

| Device framework with trim | m2. | 110. | fourteen | 1540. |

| Assembling frame frame | m2. | 140. | eighteen | 2520. |

| TOTAL | 11660. | |||

| Applied materials on the section | ||||

| Guides, racks, beams, docking elements | m2. | 630. | - | 14150. |

| Professional Sheet, Obsek (KLS), Doborny Elements, Sealing Pads, Planks | m2. | 320. | sixteen | 5120. |

| Sheet of plasterboard | m2. | 1440. | 2,4. | 3456. |

| Insulation | m3. | 72. | fifty | 3600. |

| Steam, wind and waterproof films | m2. | 760. | 1.5 | 1140. |

| TOTAL | 27470. | |||

| Roofing device | ||||

| Installation of the rafter system | m2. | 320. | sixteen | 5120. |

| Metal coating device | m2. | 320. | 12 | 3840. |

| TOTAL | 8960. | |||

| Applied materials on the section | ||||

| Guides Thermoprofili, Obsek, Docking Elements, Stropile Feet, Farm | m2. | 320. | 29. | 9280. |

| Metal tile, Dobornye elements | m2. | 320. | eleven | 3520. |

| TOTAL | 12800. | |||

| Total cost of work | 25400. | |||

| Total cost of materials | 45800. | |||

| TOTAL | 71200. |

The editors thanks the company "Tald Profile" for help in the preparation of the material.