Problems arising in apartments with a single-tube heating system. Methods for maintaining comfortable temperature indoors and equipment.

The thermostat with the built-in sensor installed horizontally

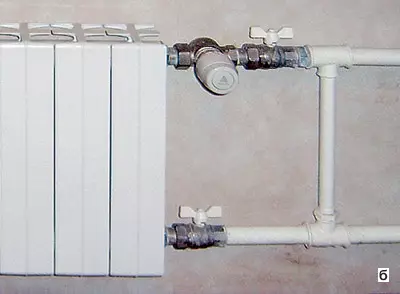

1 manual valve;

2-ball (shut-off) crane;

3- thermostat;

4- thermostat with remote sensor;

5- bypass;

6-three-way valve

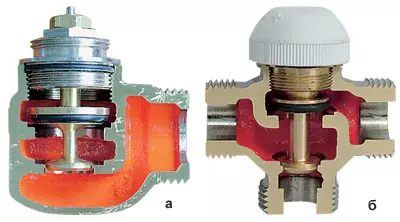

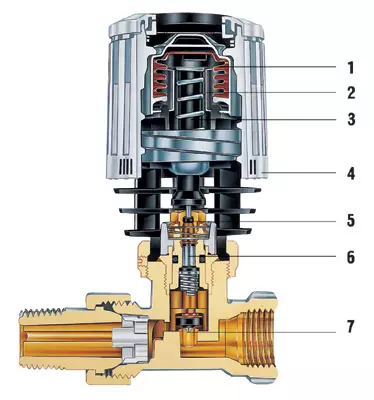

1- temperature sensor;

2- bellows;

3- springs tuning;

4- settings;

5 - rod;

6-spindle;

7- cone locking

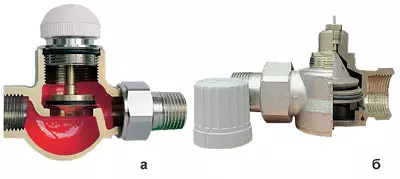

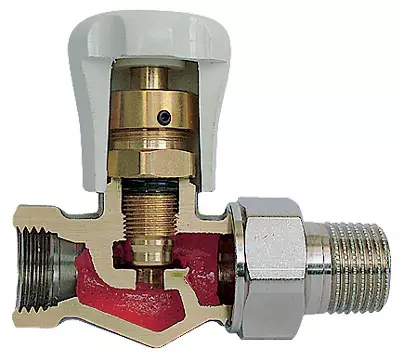

Angular H-shaped valve (ICMA);

b-direct n-shaped valve (FAR);

single-point sealing unit with thermostat (FAR);

G-node for connecting radiators with lateral liner (ICMA)

Comfortable temperature in the dwelling is ensured by the possibility of adjusting the flow of the coolant into radiators. But if it does not occur with the adjustment of the two-pipe system of heating of special problems, then everything is not so simple with a single-tube system. How to solve emerging problems?

Two-pipe and single-tube systems

In the fifties, XXV. When designing heating systems of almost all Russian cities and towns, a course of minimizing costs was adopted. How and on what could be saved? That's right, first of all, on pipes and works on their laying. A results of this course and one-tube heating systems appeared.Such systems are arranged in two schemes. A more simple version, all radiators are consistently associated with each other pipes (the riser, as such, is missing), and the current water passes through the top through each of them, starting from the top. Vitoga in the radiators below, it arrives, already cooled in the upper. So on the last floors in winter, the heat, and first-cold. To compensate for the difference, the radiators with a flax number of sections were mounted on the lower floors than on the upper, although it helped it a little. Regulation This system is not amenable to: if you install a regulator on one radiator, it will immediately affect the entire chain. On the existing problem for a long time simply did not pay attention to as an insignificant. The main thing is the cheapening of construction.

The most advanced version of the single-pipe system of the riser exists, and the water from it is simply allotted into each of the radiators, after which it returns to the riser (expressing the language of professionals, this is a flowing system with closing areas). Water in such a system cools slightly less, and therefore, less and the difference between temperatures on the upper and lower floors. The amount of water coming into each of the heating devices is already possible to somehow adjust with the help of the valve installed on the upper supply tube.

All these disadvantages are devoid of a two-pipe heating system, in which each radiator is connected to a straight line, and to the inverse pipes (straight pipe supplied to radiators, and returns returning water from radiators). This scheme allows you to adjust the amount of coolant coming into each heating device, not only manually, but also by automatic radiator thermostators. This is the principle of the supply of the coolant that is implemented in modern high-rise buildings and cottages. Moreover, each heating device is equipped with an individual regulator (all regulatory documents and Moscow MGSN are required, and all-Russian slopes), which, depending on the air temperature in the room, automatically adjusts the amount of water incoming to the radiator.

Akak is the same one who lived in a house or an apartment with a flow-tube system or purchased such a housing in the secondary market? Are there modern comfort for them and will remain a non-abundant dream? Nothing like this.

"Close" plot

For those who function normally a classic single-tube heating system and the apartment is too hot, there is a simple solution: arrange closing areas on heating radiators. Simply put, install the waterproof tube (bypass), according to which the coolant could flow from the upper supply tube into the lower rush-remarks (it should somehow get to your neighbors from the bottom if you blocked it in the radiator). When performing this operation, it should be remembered that if you use the bypass of the same diameter as the supply pipe, the coolant into your radiator will flow in a very limited volume (the hydraulic resistance of such a bypass is much lower than the resistance of the radiator, and most of the water will go exactly Him). Therefore, the diameter of the closing area should be one size less than the diameter of the eyeliner (for example, with the diameter of the supply pipe 3/4, the bypass diameter should be 1/2). Bypass should be positioned as far as possible from the vertical section of the pipe, that is, as close as possible to the radiator. Owning pipe or manufactured in place (from pipes and tees or with welding), or buy in finished form (for example, bypass with a 900mm intercentrome distance from Danfoss (Russia), installed on threaded connections will cost 15).

After that, between bypass and the inlet of the radiator, depending on the desired degree of automation of the radiator control, can be placed either Manual adjusting valve either Radiator thermostat The same connecting diameter as the eyeliner.

It is worth paying attention to another important point. After the device of the closure area (bypass), the volume of the coolant of the coolant of the coolant will be reduced compared to the flow system (before reworking) to 30-35%. This will lead to a decrease in the heat transfer of the heating device by about 10%. In practice, such a phenomenon should not cause any problems for two reasons: first, your radiator and so gives it too much warm (otherwise the question of modernizing the system), secondly, during the selection of radiators, their sizes are rounded to the nearest more which gives a stock of 10-15%.

If the last for some reason during the selection is not done, then in order not to acquire a new radiator, it is recommended to install the heat-insulating reflecting gasket on the wall behind the radiator. As a rule, it represents two thin metal layers with heat insulator shed between them. Such a reflector will increase the efficiency of the heating device just for the required 10-15% - the radiator will warm the air in the apartment, and not a concrete wall.

Soder-tube systems that already have closing areas that meet the requirements described above are all easier. It is necessary to simply install the hand adjustment valve (and if it stood before, but for some reason it did not work, then change it) or, instead of the valve, the radiator thermostat (automatic regulator). If the previously installed bypass does not comply with the requirements, it should be replaced.

If indoors are hot

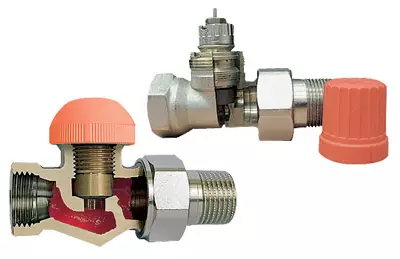

Manual adjustment valves

Manual adjustment valves are used to achieve the economical operation of heating and cooling systems, as well as for hydraulic device linking. Different with accuracy and ease of use. They are released both domestic and foreign manufacturers: bases (Bolkom), "ADP-groups" (Moscow), RBM, FIV, ICMA, Carlo Poletti, Far (Italy), Herz (Austria) IDR. Prices fluctuate from 4 to 10. The models of direct and angular structural form are offered. A distinctive feature of modern valves is that they do not require maintenance and highly reliable. Especially convenient manual adjustment valves, having an "American" connector fitting from the heating device, which allows, to refuse to apply the use of the usual paneling and sealant, and secondly, it is easy to remove the radiator.Nefirma Herz has valves that can be converted to work under the control of the thermostat, this is an option for those who immediately did not solve the installation of an automatic regulator, but allows such an opportunity hereinafter.

It should notice that some of the devices offered by the modern market are designed not only to perform their main function - adjust heat power, but also serve as design objects. When using them, the radiator looks stylish and functionally completed. You can use them almost any interior. An example is the product of CARLO POLETTI, FAR products. Of course, the price for the valves of improved design above is 20-50.

Radiator thermostators

Radiator thermostators, or, as shortly called them, thermostats are simple and reliable devices that allow automatically (and without the use of electrical or other external energy) to maintain the specified temperature in the room from 6 to 26C with 1-2C accuracy. Placed in front of the heating device, on the pipe that feeds the coolant.

Note that the required temperature in the room is set by turning the setting scale, showing the temperature not in degrees (such a scale cannot have any device, because several parameters affect the real temperature: the temperature of the coolant, its flow, the sensor conditions), and in indexes, Designed only for indicative management. To understand exactly which temperature will fit every division, you will have to initially navigate the room thermometer.

Design . A radiator thermostat of two parts is consisting of a thermostatic head and actuator-valve.

In the inmostotic head there is a cylinder (belliff), filled with a working substance, which actively reacts to changes in the air temperature in the room: with increasing temperature, it increases in volume, with a decrease. These changes are converted to the progressive movement of the pressure rod connected to the cylinder. If you put the head on the actuator (valve), then its rod will be pressed (release) on the spring-loaded locking cone of this device, which, in turn, will cover (open) the passage hole, thereby adjusting the flow of the coolant.

The working substance in the thermostat can serve both special liquid and gas. Recompute with this modern market offers two types of thermostators: fluid - they are released by such firms such as OVENTROP (Germany), Caleffi and Far (Italy), Danfoss and HeatonTrotrol (Russia), Herz, IDR., And gas-filled- are produced only by the company Danfoss. Which of them are better? There is no unambiguous answer to this question, it is still the subject of discussion among specialists, the end of which is not yet visible. It is believed that gas-filled bellows are distinguished by a greater speed of the response of the sensitive element to change the temperature in the room, and the fluid is better and more accurately transmit changes in the pressure inside the bellows to the actuator. We do not intervene in this argument - in our opinion, it is better that sensor that is more reliable. Anadequia is determined by the quality of manufacture, and not just the medium that is inside the bellows. In other words, choosing a valve, you should give preference to the products of the well-known and "tested in battles". The price of thermostatic heads ranges from 9.5 to 18. Execution valves are straight and the corner - the selection is determined by how the pipe is performed to the radiator. The valve size must correspond to the diameter of the hole in the tube of the heating device or the diameter of the pipe supplying water.

When buying a valve, pay attention to and another moment. These devices are available for one-tube and for two-pipe systems and differ in design. Without going into details, let's say that they have different hydraulic resistance: valves for two-pipe systems it is higher, for one-tube- is significantly lower. So in no case cannot be used valve for a two-pipe system during the modernization of a single-tube system, it threatens a significant decrease in the receipt of the coolant into the radiator, and therefore the loss of its thermal power. To make it easier to figure out the consumer, some manufacturers provide their products with colored caps: the valves for two-pipe systems are white, for single-tube-colored. These caps not only serve to recognize valves, but also perform certain functions. For example, during construction, when the thermostat is not yet established (the likelihood of its damage), the flow of the coolant into the radiator can be adjusted manually by means of a protective cap. The cost of valves for single-tube systems ranges from 11.7-18. The valve must be mounted so that the convex arrow on its housing (it is cast together with it) coincided with the direction of the coolant movement in the supply pipe (if you put the vice versa to "buzz"). It is desirable that from the radiator the valve, as well as the manual adjustment valve, had a detachable fitting - "American".

Do you need filters in the heating system?

If we talk about the system of heating your own home, then, no matter how well the heat carrier, circulating in the system, is still the likelihood that there remains skills and other contaminants in the pipes after installation. Filters here are definitely needed. The price of the mesh filter is small - from 1.5 to 15.

If we talk about a single-pipe system of central heating, serving several huge houses at once, then before carrying out recommendations, it is worth thinking. After all, the filter will clean the coolant for the entire system and, therefore, not a tangible benefit will not bring. ARDOW DEZE Even Thank you will not say. Large manufacturers install filters are not advised, and in order for the valves produced by them for single-tube systems, they have not clogged, increased their passage section.

Built and remote sensors

Thermostat sensors are the elements directly perceiving the air temperature. There are built-in and outstanding.Built-in sensor As it is clear from the definition, it is directly in the thermostatic head (it was about such structures that we were told above). When the valve is set to the device with a built-in sensor, it is recommended to place it so that the control head is in horizontal position, the effect on the thermal flow sensor from the valve itself and from the pipe supplying the coolant is reduced. In addition, the sensor needs to provide free air circulation.

Remote (remote) sensor . The built-in sensor cannot be properly reacting to the temperature in the room in cases:

If the radiator is installed in the niche;

With the width of the windowsill more than 220 mm and the distance from it to the radiator less than 100mm;

If the transverse size of the thermal device exceeds 160 mm;

When the axis of the thermostatic element cannot be installed in a horizontal position;

If the radiator thermostat is closed with curtains or decorative screen (thermostat is isolated from the main volume of the room).

In all listed situations, the thermostatic element with a remote sensor should be applied, it is transferred beyond the device and is connected to it by the "capillary", that is, a thin metal tube. It is clear that the sensor reacted further from the radiator more accurately to changes in the room temperature in the room. It is necessary to establish it so that it is not exposed to direct sunlight and electrical appliances that allocate heat (TV IT.P.). It is necessary to think about how to hide the "capillary" in order not to damage it during operation.

The prices for thermostats with a remote sensor are slightly higher than on devices with built-in, from 16.

"Priesges"

If metal-plastic, plastic or copper pipes are used in the strapping of the radiator, it is most cost-effective to use the tee proposed by the FAR to join the bypass. It has a pipe thread on one side and is directly screwed into the regulating valve, and from two other sides is equipped with adapters for the required type of pipe.

A very good alternative to the method of upgrading a single-tube heating system described above (homemade or purchased bypass plus a two-way valve with a thermostat) can be the use of a three-way valve of the Calis-TS-E-3D series of Herz. This device is designed to regulate and distribute the flow of the coolant between the instrument and bypass, and controls its operation The thermostatic head. The devices of two sizes - under pipe 1/2 and 3/4 are produced. According to the manufacturer, the main advantage of these devices is that they do not expand the heating system, and this is very important for apartment buildings. The quoted valve to collect bypass will have to add the necessary fittings independently, as well as purchased the thermostatic head. Device price - from 17 to 20.

To facilitate the creation and installation of a bypass node based on a three-way valve, the same manufacturer offers a special "thermostat" Herz-Utke radiator " , bypass, ball valve (on the inverse tube) and the necessary nozzles. That is, on a modern jargon, "everything in one bottle". Nodes of all running sizes are produced, both in diameter and by the intercentrose. Prices of 35 to 50 .

On the speed of operation of thermostat

Another statement is that high-speed thermostats when used in the cottage will make a tangible contribution to fuel economy- is also very controversial. If this is a cottage relative to a small area, the difference to feel almost impossible, the owner is unlikely to notice that the valve closed for 1-2 world faster. Isconomy for these 2min will understand what. Avota with a massive application of thermostatic regulators in a sixteen-storey residential building The difference in response time will have a tangible effect on fuel economy. Imagine that 200-300 radiators stopped the consumption of the coolant 2-3min before! And such cycles in the year about a thousand! The total annual effect of this can be easily calculated on the calculator. True, you can't save money, but a local CHP.

Technical Director of the company "Time" Nikolai Mikhailovich Ivlev

What else will need?

In some cases, it is necessary to completely overlap the flow of the coolant into the radiator (for example, when an accident or its prophylactic flushing). It should be borne in mind that in itself an automatic thermostat does not give such an opportunity. This is only possible to cover the flow to a minimum (which corresponds to the value of the 6C-measurement measurement against freezing). If you remove the head of the thermostat, then the valve itself is manually closed at all. To do this, set the valve already mentioned the protective cap and use it as a "lamb". True, the cap is plastic and therefore weak. More powerful and durable is the brass cap sold, as a rule, separately. In this case, locking using the valve is more secure. In order to overlap the flow of the coolant in the tap tube, the ball valve with the above-mentioned "American" should be installed on it. Broken both devices, you can remove the radiator.

Naturally, the method of locking only with the help of the valve is quite uncomfortable, and not quite reliable. Uncomfortable, because, firstly, it is necessary to remove the head of the thermostat, and secondly, it is firmly remembered where the brass cap is hidden. It is unreliable because the pressure in the heating system is still able to open the valve (from the "input" side on it there is a pressure in the supply pipe, with the "output", after removing the radiator, the pressure is generally absent). That is why experts recommend installing a ball valve (price-3.5-4) in front of the valve. Already his pressure will not definitely open.

Extractive assembly organizations to the client, instead of installing at the output of the ball valve radiator, they can set to install a shut-off valve (for example, the company Danfoss is called RLV, from Herz-RL-5). Such valves are really designed to disable the individual radiator in order to dismantle or maintenance without emptying the entire heating system. They are also convenient because the valve can be installed a special descent crane and with it to drain water from the removed radiator (the tap has a nozzle to attach the hose that can be rotated in any direction). So, from installation of this, even if a very convenient device should be refused. The fact is that the valve is intended only for two-pipe systems, which means it has quite high hydraulic resistance. It is categorically not recommended to use it in the system of one-tube manufacturers.

The last thing readers want to pay attention to. If you have removed the pipes in the walls and the floor when repairing the apartment (so as not to spoil the design), then for this case, almost all major manufacturers offer a wide range of sets for connecting radiators. The wtach headset is already built by bypass, thermostators- in general, all that is needed. But this is probably the topic for a separate conversation.

The editorial board thanks the company Danfoss, Herz, "Time", "Heat-Art", "Termoros", "Egooplast" for help in preparing publication.