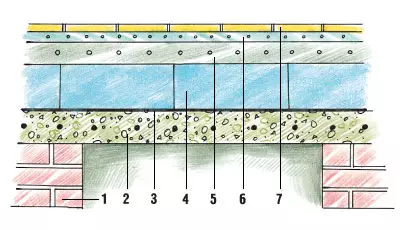

1- Foundation;

2-concrete slab overlap;

3 - waterproofing;

4- insulation (extruded polystyolster);

5- screed with reinforcing grid;

6-glue with a warm floor system;

7- tile

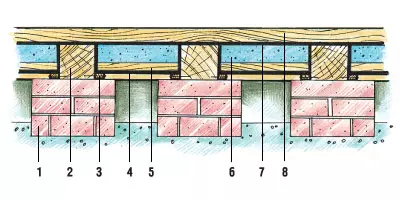

1- Foundation;

2-beam overlap;

3-cranial timber;

4 warehouse;

5-black floor;

6- insulation (extruded polyneolster);

7 - waterproofing;

8- Sex board

The time of centuries were not attached to the residential house, and they were erected aside so that in the event of a fire did not burn all the buildings at once. The most common option is a separate bath on a column foundation, the blackboard boards of which they rest on the beams of overlapping. Floor insulation in this case starts with dismantling wooden finishes. Then on the lower parts of the opened beams nourish the cranial bars, the vapor polyplator (more often orally) and fasten the black floor boards (sliced in the distance between the beams). Next fill the space between the beams with thermal insulation material and finish the "Cake" device with a layer of waterproofing (not forgetting about the slope for the drain). It should be noted that if all types of mineral insulation (with a mandatory videos and waterproofing gasket) are fitted in the house (with a mandatory vault room, as a winter bath, only materials with a closed cellular structure are suitable, that is, foam.

Since the floors are often tiled, which implies the presence of a thick concrete screed, then the foam applications must have high compressive strength and a small degree of deformation.

Ktakim insulators include extruded styrofoam styrodur, Roofmate, Ursafoam / Glascofoam, URSA XPS Natur-III, Natur-III-PZ, Penoplex IDR. Styrodur - Green Plates from Solid Polystyrene Production of the German Concern BASF. The firm plate of type NATUR-III happens with a compacted smooth (N-III) and a corrugated heat-treated (N-III-PZ) surface. Roofmate - a solid insulating plate of blue. Due to the closed cellular structure, the polystyrene is practically zero water absorption, high compressive strength and long retains its insulating quality.

If the insulating properties of materials with a fibrous or open cellular structure almost disappear during wetting, the water does not penetrate inside the polystyrene foam; Low thermal conductivity of the insulation is preserved for almost unlimited time and when exposed to moisture, and during mechanical loads.

All listed materials are difficult to ignite. Aob of their resistance to mechanical loading loads says the fact that they are intended for use as a carrier element for composite parts of structures and "sandwich panels", as a frost-resistant protective layer when building railway tracks and highways, as well as for insulation of foundations.

The use of extruded expanded polystyrene foaming for the insulation of the bath is justified and from an ecological point of view - the material is replete with carbon dioxide or air and therefore free from hazardous gas reagents containing freons. It is easily cut by an ordinary tool, and therefore it is convenient to install. Despite the hardness of the heat insulator, when the plates are horizontal, they must be placed on a flat substrate. They are lungs and do not waste the foundation or overlap.

When working with foam, the amount of waste is minimal, which significantly reduces the total cost of thermal insulation work. The apack plate of such insulation is not subject to biodegradation, then no danger in contact with water and soil does not occur.

The thickness of the insulation on the floor of the bath is usually 100-150mm, but it can reach 200-250mm. This is due to the desire to provide minimal heat loss in such a hot and raw place. ASOPLAGE Parotranslation, for example, Penopelex plates with a thickness of 20mm equivalent to one layer of rubberoid.

A rare case - when the floor overlap in the bath is not wooden, but is a massive reinforced concrete plate. Then the "pie" of its insulation and finishing should contain compulsory waterproofing. So that the dampness penetrates through concrete did not lead to the formation of the fungus, the optimal option will be the use of two or three layers of coating waterproofing (for example, a rush-bobitume mastic from Feidal). To enhance the effect, there are still rolled waterproofing on top of the mastic (admit, hydrokhotloxole).

The insulation layer is placed on the waterproofing layer (either the grainzite of the shallow fraction (0.5-0.3 cm) and poured a layer of cement-sand tie with a thickness of at least 30mm. For this, the reinforcing mesh is pre-installed on plastic or concrete stands. The reinforcing tile is glued on top Which in most cases there are mats or a cable of an electric heating floor system. Agree that in the winter bath with ceramic facing floors it will not be completely superfluous.