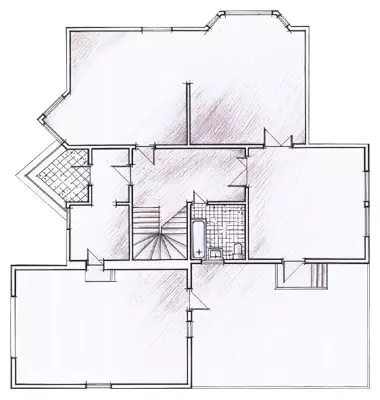

The construction of the house with a total area of 208 m2 according to the technology of the constructive construction system "Module": inexpensive housing in the shortest possible time.

("Rogunda"). Farms are put in place with a crane and are attached to Mauerlatam with steel corners. Klowropilas are nailed to the boards of the crate of 25150mm in 800mm increments. Farms are designed for a permanent load of a metal tile roof, a mineral wool insulation and a seasonal snow load. Punching of roofing material can be used. Natural tile

The technologies of the rapid construction of buildings allow you to build inexpensive housing in the shortest possible time. By numerous requests of our readers, we will return to this topic again. Today we will talk about the design and construction system "Module". Developed almost 30 years ago for the needs of the military, today she fell into civil service.

Conversion technologies in the service of the people

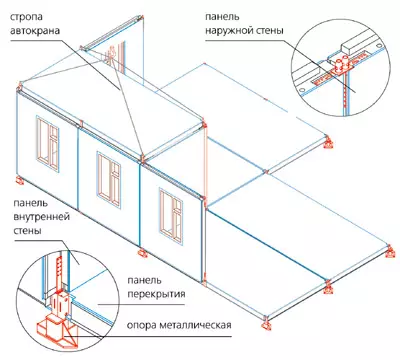

Back in 1978 On the task of the USSR Ministry of Defense Design Bureau "DSC 160" A constructive construction system was developed (CCC) "Module". Complete delivery of these lightweight structures allowed in a matter of days to build a barracks for the personnel of units, headquarters, hospitals, hostels for officers at any point of the Soviet Union as in the regions of the Far North (Salekhard, Evenkia) and in the seismic hazard regions of the Caucasus. Today, the creation of building structures "Module" is engaged in the enterprise "Moscow region 160 DSC." At special German equipment, buildings up to three floors seismic resistance are produced here.CCC has certain advantages over other technologies of the rapid construction of houses. Build buildings of any type and destination can be carried out from a set of standard structural elements (wall panels, racks, panel floors), the production of which is supplied to the conveyor. Options for buildings can be as you like. The only condition: their linear dimensions must be multiple with the size of the structural components. Such construction reminds work with a children's designer, which in this case "play" adults. Assembling the skeleton of a single-storey house with an attic and the establishment of the construction of "under the horse" by the forces of four workers and the crane drivers lasts from two to ten days, depending on the area of the house. If necessary, the building can be disassembled, transported to another place and collect anew. Conveyor production of standard components makes it possible to significantly reduce the price. The square meter of the residential area without decoration and engineering communications costs the buyer about $ 250. At the same time, the construction corresponds to all the requirements for residential buildings on the bottom.

KCC "Module" - what is it?

The CCC buildings "Module" are panel-rack structures both in the usual and in the seismic resistant execution (withstand the earthquake to 9balls). The spatial rigidity of the buildings is provided by transverse and longitudinal carrier walls associated with the rigid base of the floor and overlap. Vertical loads inside the building are perceived by metal racks, which are included in the hinge collapsible connection with floor panels and overlap.

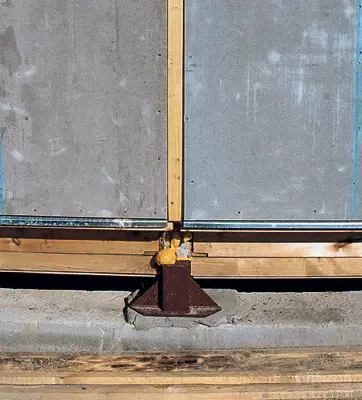

Constructive elements are connected to each other with a unified stingy hinge node "spit-jack". This help you can quickly and reliably collect horizontal and vertical elements of the construction, rigidly fixing them in the desired position. The connection strength in the seismic resistant execution is ensured by fixing the spike in a glass using a pin. The connection of the connections of the structural elements coincides with the main planning module 24m (where M = 100mm).

All structural elements are made in the Korolovev at the plant of low-rise house-building, on the technological line of the German company Streif, and are supplied to the construction site, in packages and boxes. The greatest size has a horizontal overlap plate (180-40024004800mm). But such dimensions correspond to the standard of container shipping, allowing to use railway, automotive, sea and air transport.

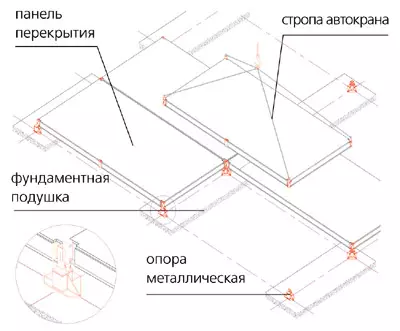

Installation of the structural elements of the zero cycle.

CSC buildings are assembled on finely brewed or superficial (road plates, concrete "pillows" IT.) foundations. When binding a residential building to the area, the foundations must correspond to the hydrogeological conditions of the construction site. Side of external engineering communications is performed below the layout of the foundations before they are erected. Input to the house of electrical cable, pipes, water supply and sewage is carried out through a special hatch.

Punching base overlap is used horizontal floor panels (180-40024004800mm). The design of the panels is as follows: from above Plywood of the FSF brand (18mm), the bottom of the CSP (16mm) is fastened with screws to a metal-contained frame that bears the element of which is Schweller No. 6. Kshveller welded square in the cross section of the coupling ("cups") for docking with vertical elements that are equipped with barrel-shaped spikes. Mass panels - from 500 to 1200kg.

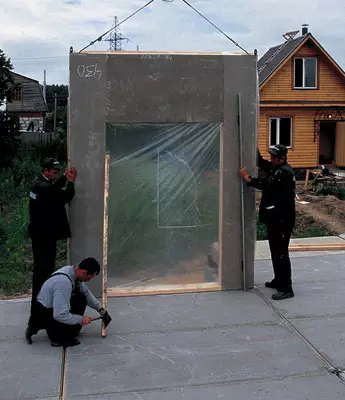

The outer walls consist of carrying crustacean panels (180-30024002700-3000mm). They are equipped at the corners of metal spikes, which, when installed, enter the nests of the floor and overlap panels corresponding to them. CSP SSP 16mm thick or plywood - 10-12mm. When installing the panel are connected by plate retainers. Mass panels - 350kg.

The inner walls are not bearing, are frame structures of arbitrary sizes. Wheel body laid bearish racks. These walls themselves indirectly perform the function "hardness diaphragms" and also work to strengthen the building structure.

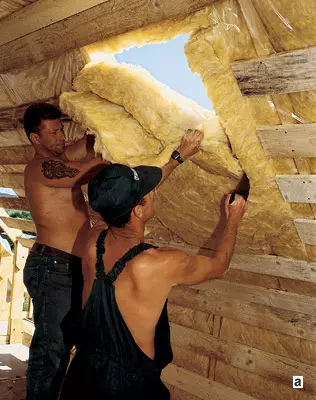

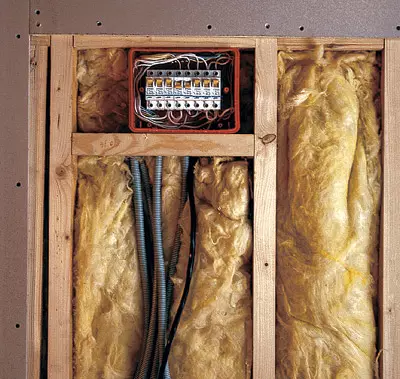

The cavities of the panels are filled with an environmentally friendly insulation of the ISOVER (Finland) of the KL brand for the outer walls and the KT brand for horizontal elements. Its thickness is calculated in accordance with the climatic conditions of particular locality. All mating nodes are reliably insulated with polyurethane foam. Materials for internal and external finishing, roofing and plumbing are chosen in agreement with the customer.

According to the CCC technology, buildings up to two floors are most often built. It does not follow from this that such houses cannot be multi-storey. Simply, with increasing floors, it is necessary to solve additional design and technological tasks, such as ensuring fire resistance of the construction in accordance with the standards. The proposed technology makes it possible to build buildings with a height of up to three floors, having the III degree of fire resistance. When complying with a number of conditions, you can also extend the existing stone houses. To do this, the first floor should fit into the Module's CCC grid, and overlapping - withstand the calculated point loads.

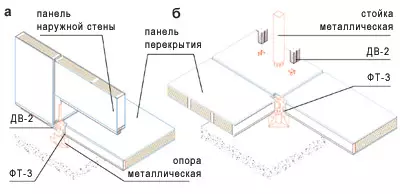

but. Node connection of external walls with horizontal panels.

The main element of the conjunction of the designs is the "spin-nest" node. The ply-resistant building in nodes is strictly required to install FT-3 clamps. After installing the clamps in the socket of the overlap panels, wooden DV-2 liners are inserted (cross-section 5060mm).

b. Metal rack connections node with horizontal panels.

Loads for overlapping

| Load name | Regulatory loads, kg / m2 | Reliability coefficient | Calculated loads, kg / m2 |

|---|---|---|---|

| Permanent loads from the weight of structures | |||

| From metal structures | 10.8. | 1,1 | 11.9 |

| From wood insulation | 41,4. | 1,2 | 49,7 |

| From walls, partitions, wooden structures | 50.0 | 1,2 | 60. |

| Short-term loads | |||

| From people and equipment | 150.0 | 1,3. | 195. |

| From snow | 100.0 | 1,4. | 140. |

Speed construction is not a hindrance

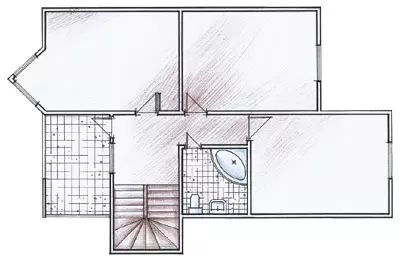

The attic floor of the house built on the basis of farms collected on the spot from the elements of the factory manufacture. According to the project, the attic is a wooden frame structure, insulated with mineral wool and covered from the inside of the CSP. Work performed in a couple of days. Then covered the house with metal tiles, installed windows, after which they started the installation of communications, internal and exterior decoration.

At this stage, the construction pace slowed down. The owner of the house decided to separate him from the inside inexpensively, but thoroughly. I had to seek from working quality, which does not happen with forced construction. Outdoor finish, the owner wished to perform a block-block board. In addition, allowed himself to gather on a bath of a bath along the same technology as the house.

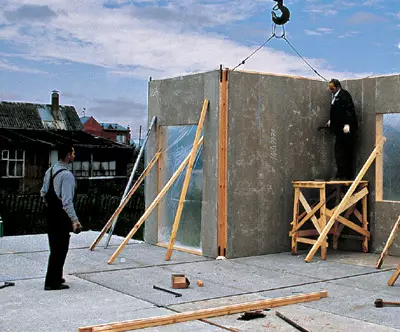

Installation of structural elements of the first floor.

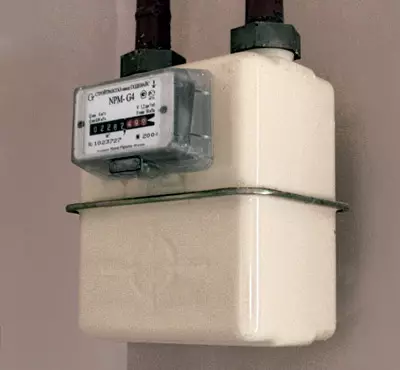

Engineering equipment was selected and mounted taking into account the average material possibilities of the family. Drop the house was solved by a two-circuit gas boiler with a capacity of 30kW. The boiler and boiler houses were installed indoors, part of which is an entrance hall. The wiring to bimetallic Sira radiators (Italy) was performed by polypropylene pipes in the open method. Electric wiring, on the contrary, laid hidden. The wires in PVC-sleeves stretched through emptiness in interior partitions and under the board facing the ceiling. Plumbing devices (sinks, baths, toilets, shower cabin) two bathrooms connected to a polypropylene riser. To collect wastewater in the courtyard mounted a local sewage system.

When the heating has earned, the finishers began to put off and paint the walls, it takes them with wallpaper, to fit the floors. At the final stage of finishing work at the site of the ladder-showcase, a wooden marching staircase from the pine mass was installed, the doors were hung. The housekeeper took up the décor. Consulting with the designer, she acquired furniture and lamps, ordered curtains. The queen of many colors that occupy in the interior are not the last place. There are still not all the premises. But guests and hosts have already come to the guests and the owners: warm, durable, spacious, beautiful and relatively inexpensive.

Those who are interested in practical details of construction, the specialists of the enterprise "Moscow region160DSK" give a number of recommendations.

The installation of the building is carried out by an autocrante with an arrow departure of at least 18m. The work of the crane is made from any convenient point, from where there is access to the designs stored on the site and to the angular part of the mounted building. The most rational way of parking a car crane is the main facade of the building. It is possible to place the structures on the right, on the left, as well as for the auto crane. The method of installation of structures from the wheels of the car is not excluded.

Before installation, it is checked by the correctness of the geometric sizes of the foundation, the leveling of the base at the points of intersection of digital and alphabetic axes. According to the results of the leveling, an act is drawn up with the design of measurements. After calculating the lining thickness, each point can be proceeded with the distribution of metal supports. Punching linings under support can serve as metal plates 5180180 and 10180180mm, located with a deviation of no more than 5mm from the horizon.

After marking the axes on the foundation and setting of the supports (they are fixed in place with a solution), they are starting to install the floor. Start for convenience from the corner (actually allowed from any panel).

All wall panels during installation require mandatory temporary fastening with wooden bars (cross section of at least 4050mm). They are nailed with 4120mm nails and are removed when the design of spatial rigidity is achieved. Between the panels in the upper part set clamps. After fixing the first five outdoor wall panels and racks, it is necessary to install the interlated overlap panel, which is above them to create a rigid kernel at home. Next, the installation is carried out in the same way: they increase, according to the scheme, around the created hard kernel, elements of external and internal wall structures and overlap them with horizontal panels. The field of fixation of window wall panels is not allowed to damage the polyethylene vapor insulation film, which closes the opening of the window. Glk and sheets of plywood should be connected to overlap to avoid deformation cracks.

For every taste and wallet

How much is the cottage built according to the CCC technology? The cost of any building depends on many factors and for each order is calculated separately. The main pricing factor is the thickness of the panels, which depends on the mass of the insulation. The parameters of the latter, in turn, are determined by the climatic conditions of construction. The cost of the building is determined by other factors such as the floors, the area, saturation of interroom partitions. In order to more accurate the price of the future at home, the customer needs to be coordinated to the construction details with designers and economists of the developer.

The easiest to assess the basic package. The following products and details include:

Panels of flooring and overlap (for two-storey houses);

panel of exterior walls;

frame partitions;

a rafter system (wooden farm) with a crate;

Other products: racks, timber, nicknames, layouts, plinths, sealing, fasteners.

So, the cost of the base kit of the cottage "debut" with the garage is 1725140 rubles. It is possible to make a house without inner partitions, as a result of which its price will decrease. In this case, the building is completed only by floor panels, inter overlap (with a multi-storey version) and outer walls. Only bearing metal racks installed on the module grid (24004800mm) remain inside. In addition to the inner partitions, you can abandon various migrants, as well as the rafter system (if the customer is able to buy them cheaper from other manufacturers). All of this, of course, affects the final price of the supply kit (it can decrease up to 40%). Subsequently, partition can be performed from drywall on a wooden frame (or in any other version). If the Customer is not inclined to save, the base set is offered to be supplemented with carpentry, materials for the manufacture of roofing, outer decoration, floor IT.D.

You can save on installation. There are two options. The first is a chief montamontation, in which a specialist of the manufacturer's company leaves the platform and builds the forces of the contracting contractors (the estimated cost of the service - 2% of the cost of the supplied kit). The second option is the installation of "under the roof" when the manufacturer's brigade fully collects the house without finishing on the finished foundation (the estimated cost of work - 10-25% of the value of the delivery set, depending on the complexity of the project).

The idea of modular construction in our country was implemented in a large-scale city building project with tens of thousands of Khrushchev five-story buildings. Such a scope of construction became possible, thanks to the unification of the structural elements produced by house-building combines for a single catalog. At a certain stage of the development of domestic house-building, the modular technology has made it possible to solve the problem of urban housing deficit. As for small towns and villages, their development of individual houses of the modular type for a long time has not been engaged. Today, with the help of modules, landscaped villages for rural turnkey residents can be erected. The rapid construction of private houses allows you to solve the state task of providing the population affordable and high-quality housing.

Enlarged calculation of the cost of work and materials on the construction of the house with a total area of 208m2

| Name of works | Unit. | Number of | Price, $ | Cost, $ |

|---|---|---|---|---|

| Foundation work | ||||

| Foundation base device, waterproofing | m2. | 24. | eight | 192. |

| Ribbon Foundation Ribbons | m3. | 12 | 60. | 720. |

| Caution lateral isolation | m2. | 73. | 3. | 219. |

| TOTAL | 1130. | |||

| Applied materials on the section | ||||

| Concrete heavy | m3. | 12 | 62. | 744. |

| Crushed stone granite, sand | m3. | nine | 28. | 252. |

| Bituminous polymer mastic, hydrohotelloisol | m2. | 265. | 3. | 795. |

| Armature, wire, sawn timber, etc. | set | one | 340. | 340. |

| TOTAL | 2130. | |||

| Walls, partitions, overlap | ||||

| Installation of building structures | set | - | - | 15500. |

| Filling opening windows and door blocks | set | - | - | 970. |

| TOTAL | 16470. | |||

| Applied materials on the section | ||||

| Building structures (wall panels, racks, overlap panels, etc.) | set | - | - | 61600. |

| Window and Door Blocks | set | - | - | 9800. |

| TOTAL | 71400. | |||

| Roofing device | ||||

| Installation of the rafter design | m2. | 370. | 10 | 3700. |

| Device of inlet vaporizolation, insulation insulation | m2. | 370. | four | 1480. |

| Metal coating device | m2. | 370. | 12 | 4440. |

| TOTAL | 9620. | |||

| Applied materials on the section | ||||

| Profiled metallic sheet | m2. | 370. | 12 | 4440. |

| Sawn timber | m3. | 6. | 120. | 720. |

| Mineral Wat, steam, wind and hydraulic films | m2. | 370. | five | 1850. |

| TOTAL | 7010. | |||

| Total cost of work | 27200. | |||

| Total cost of materials | 80600. | |||

| TOTAL | 107800. |

The editors thanks the company "Moscow region 160 DSC" for help in the preparation of material.