Protection of metal from corrosion: classic agents, rust converters, paints for different types of surfaces, modern "two in one".

Ground-enamel "on rust" conquer increasing popularity worldwide. After all, working with them is so easy

Photo K. Manko

Coloring metal surfaces with special compositions is needed not only to protect against corrosion. At the same time, metal details can be given exactly the color or shade that fits the best in this interior.

Design Studio "Two Houses"

Photo K. Manko

Openwork forged railing will be converted even such a small bridge. Paint will save their beauty for many years

The protective coating will allow not only to extend the service life of the roof, but also give it an attractive appearance.

Architect and decorator T. Kontrant

Photo K. Manko

Metal elements of stairs and fences may not be the main part of the interior, but their painting is not the last detail.

Photo K. Manko

Photo K. Dubovets

You can paint the metal surface in two ways: classic (primer plus paint) or more modern, applying the compositions of "two in one" or "three in one"

Ground-enamel "on rust" are very convenient for domestic use. All work can be held in one day

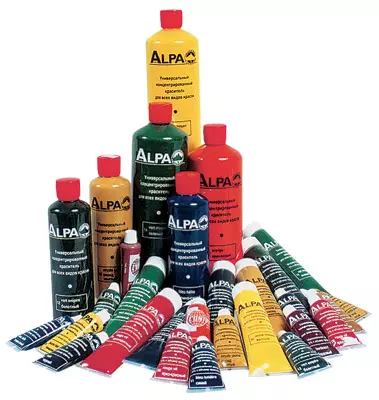

Universal caloring pastes will allow to give paint for metal any desired color and shade

How to paint a metal fence, a window grille, a visor over the entrance to the house or roof? It seems that everything is clear: in the store you like paint and, without thinking, we appline for metal structures. Only now I sometimes have to repeat this operation every year. Why?

What to defend

Metal surrounds us everywhere. These are all sorts of fences (for example, balconies and stairs), fences, gates and wickets, these are window lattices, without which neither the urban apartment, located on the first floor, is neither the more suburban house. And, of course, it is the roofs. But it is only, so to speak, the visible part of Iceberg. Astra More Invisible: Fastening and Power Elements, Introduction / Offering Communications IT. All of them are subject to corrosion, which was, is and will be as long as we use metals. It makes the designs of irreparable harm, impairs appearance, reduces strength and can even be completely destroyed. Special paints are used to protect metal from corrosion, a wide choice of which offers a modern market. Otah compositions and will be discussed in this review.From what to protect

The cause of corrosion is most often the electrochemical processes occurring on the metal surface. Water that falls here during the rain or condensing from air when the temperature is reduced, it turns out to be an indispensable participant in such processes. Methods to stop the above electrochemical reaction a lot, but the easiest and cheapest of them- isolate the metal surface from the contact with water. How? Very easy to paint the special composition.

The existing methods for protecting the metal surface of the metal method can be divided into two types: classic and modern. We will tell you a little later than later. Let's start with the classic method.

Classic metal protection

How to defendThe surface of the metal is best protected by the so-called primers, which are introduced special additives. According to the method of primer action, they are divided into passivating, phosphating, prohibiting and insulating.

Passivating soils oxidize the surface of the metal, which translates it in the passive state. The most famous composition is a lead Surik, practically not applicable at the moment because of harmfulness.

Phosphating primers . The composition contains orthophosphoric acid, forming a film of low-soluble iron phosphates on the surface of the metal.

Processing primer They are distinguished by the presence of a metal powder (for example, zinc dust), in which the pre-becoming capacity is higher than that of the painted metal. Zinc, located on the surface of the metal, will become anode, which, destroying himself, will, thereby defend it.

And finally Insulating primers Form on the surface of the metal dense film that prevents moisture penetration.

All primer compounds have high adhesive properties and are firmly held on the surface in the surface. The disadvantage is that they are all distinguished by low atmospheric, shock and wear resistance, and also have low decorative properties, and therefore the corresponding coating must be applied on top of them. It should be remembered that the anti-corrosion properties usually it is primer, and the coating is designed to extend its life as much as possible. It is clear that the eternal compositions have not yet invented and sooner or later any of them collapses, and then the process of corrosion will begin again. Therefore, when choosing, you should give preference to coatings with a longer service life, which is longer, the lower the operating costs.

The deposit of operations on the corrosion protection device by staining the metal surface looks like this:

one. It is possible to consider rust (manually or mechanically), and at the same time remove the old peeling paint (if the metal was previously stained).

2. Transform a unlucky rust (and it is completely almost impossible to remove it) into the product protecting the metal surface.

3. Apply a layer of soil (as we will see in the future, steps 2 and 3 are sometimes performed in one operation).

four. Apply a decorative (decorative-protective) coating.

five. Protect the painted surface with a special composition (not all manufacturers are recommended).

It seems that the process of removing rust, carried out with the help of metal brushes and grinding, does not need detailed comments. It is also possible to remove the exfoliated layer of the old paint in some places, and if there is a need to remove it completely, we use special compositions, we will not describe in detail in detail. Avot every one of the following operations will look more carefully.

How corrosion proceeds

Perhaps the most common in construction surface electrochemical corrosion occurs in aqueous solutions of salts, acids and alkali-electrolytes. On the metal surface, there are always sections with different electrochemical activity - the so-called anode and cathode. For example, in the steel anode is the hardware itself, and various impurities (carbon, iron carbides, sulfur, IT.P.) can act as a cathode. Anode and cathode form a galvanic pair. The electrolyte can be condensate moisture from the air, in which CO2 was dissolved from the same air. On the anode sections of the iron cations Fe2 + go to the electrolyte solution. At cathode areas, the oxygen dissolved in electrolyte oxygen is carried out to form hydroxyl groups of ON-. Fe2 + cations with anions on- form iron hydrock FE (OH) 2, which is oxidized to a hard-soluble FE compound (it) 3 red-brown. I call him rust.

Rust converters

There is a large number of rust converters used in the repair color of the car. Orthophosphoric acid can be included in the composition of the main component (converts rust into stable iron phosphates), tannin (tannic acid - converts rust to the tanat of iron having a solid grip with steel), substances converting rust into stable iron oxide (Fe3O4), which will become Part of the protective coating.

When choosing, preference is worth paying the compositions intended for domestic use. This, for example, Novalis Ferro Convertitor (Oikos, Italy), as well as domestic products "HOTEX chemical converter" (DIAL), "Rust-1" neutralizer ("I. Y. Sverdlova", price- from 0 , 65 / l). If the converter from OikOS is manufactured on a water basis and, when working with it, special safety measures are not needed, the compositions on a different basis may require special protection for the eyes, respiratory organs, and when working in the ventilation.

After removing the irradiated paint and rust on the surface of the metal with a brush, a roller or spray, a converter is applied (for example, the expense of NOVALIS FERRO ConvertItte- 20m2 / l, cost-35.1 / l). Under its action, the rust turns into a chemically neutral connection - a fairly durable dark brown layer is formed on the surface, which additionally protect metal. It should be borne in mind that under the influence of the drug, the rust can completely and not eliminate, but supporters of the application of the converter believe that this liquid makeup penetrates in the most hard-to-reach places where the primer sometimes does not count. After the treated surface is driving (it will be required for at least two hours), it should be primed, and then paint.

Note that all manufacturers of LKM insist on the use of rust converter. Moreover, many of them, on the contrary, are categorically not recommended to do that. The reason is exactly the fact that the converter may not completely eliminate rust. This point of view is even fixed in existing standards. For example, DIN 55 928 "Corrosive protection of paint-coat design" of their use does not allow them.

A results of firms such as Meffert, Caparol (Germany), Beckers (Sweden), Tikkurila (Finland), rust transducers do not even produce.

Primer

As supporters of the use of rust converters and opponents offer a wide selection of special primers. To properly stop the process of corrosion, isolate the surface of the metal from contact with moisture and ensure good adhesion of the soil with metal, as well as with the subsequent decorative coating.

In order to achieve this, manufacturers include so-called inhibitors (moderators) of corrosion. Some companies, in addition, add substances that are chemically converting rust. What exactly is added to a particular soil and what a protective action mechanism, manufacturers do not report. However, on the bank, for example, in the latter case, an inscription appears: "contains inhibitors of corrosion and target additives, allowing it to be applied to a dense rust thick up to 100 μm." Including an example of such a soil can be given to the domestic composition of "stainless ground" ("Krako"), as well as MetallGrundTck (Beckers), "Natura Antipas" (Polisan, Turkey) IDR. According to the manufacturers, these compositions allow a minimum to extend the life of decorative anti-corrosion paints to the surface of decorative anti-corrosion colors. Moreover, "stainless ground" perfectly feels even in conditions of chemical and petrochemical industries.

But this is not all that you should know to choose the right thing. It is important to remember that there are Sockers intended for internal works only (for example, Grepp Grundfarg from Beckers) or only for outdoor (MetallPrimer from the same Beckers), as there is an appropriate inscription on the bank. Most manufacturers produce so-called universal soils, which can be used both outside and inside buildings. The versatility has, first of all, who are not smelling water based products, manufactured by such firms as Caparol (Capacryl HAFTPRIMER), Tikkurila (Rostex Aqua composition), Oikos (NOVALIS AGGRAPPANTE) IT.P. There were also soils based on solvent (GP-021 and GF-02C for conventional surfaces and VL-02 for galvanized from "StroyKomplekt"; Capalac Allgrand, Capalac RostschutzGrund from Caparol Idr.), In which it is necessary to strictly observe the recommended measures security.

But that's not all. Many firms offer soils of two types: for conventional surfaces and for problematic. It is customary called the surface of cast, forged and rolled products, it has sufficient roughness for a good grip with her soil. The bribed is galvanized iron, stainless steel, aluminum, copper, the surface of the metal frame of mounted facades and fasteners, coated with oxide protective films. With more materials, the usual soil joins, let's say, not particularly good. It does not close for two reasons: first, due to the chemical reactions on their surfaces (for example, zinc gives an alkaline reaction with water, with the products of which not all soil is connected), secondly, due to their small roughness. Two types of soils offer, for example, companies such as Oikos (Novalis Antioggine for conventional surfaces and NOVALIS AGGRAPPANTE for problematic), Tikkurila ("Rostex Aqua" for ordinary and "Rostex Super" for problem), Caparol (Capacryl Haftprimer and Capalac Allgrad) etc. Naturally, the soil for problem surfaces costs 10-15% more expensive. You can use the usual soil, but for this you will have to treat the surface with sandcar.

The soil layer is applied with a brush, roller or spray gun (in the latter case, the composition should be diluted with the appropriate solvent). The color of the soil is better to choose as close as possible to the color of the finish coating - paint into one layer.

| Firm | Mark. | Purpose | Solvent | Consumption, m2 / l | Drying time before applying the finishing coating, h | Colors | Packing, kg. | Price, / kg |

|---|---|---|---|---|---|---|---|---|

| MEFFERT. | Dfa rostschutzgrund * | 2 ** | Type White Spirit | About 10. | eight | 3 colors | 0.37; 0.75; 2.5; fifteen | From 6.8. |

| DFA Allgrand * | one ** | Type White Spirit | About 11. | eight | 3 colors | 0.37; 0.75; 2.5 | From 10. | |

| Caparol | Capacryl HFTPRIMER ** | one | Water | About 10. | From 12 to 48 *** | On Caparol Color cards; 3D; RAL, NCS, Monicolor | 0.37; 0.75; 2.5; 10 | From 11. |

| CPALAC ALLGRUND ** | one | White Spirit | About 10. | 3. | On the COLOREXPRESS card (Capalac Mix) | 0.12; 0.37; 0.5; one; 2.5; 10 | From 8. | |

| Oikos. | Novalis aggrappante. | one | Water | 10-12 | 12-14 | 10 colors | 0.75; 2.25 | From 25.5 |

| Novalis AntrugGine. | 2. | Water | 6-8 | 12-14 | 6 colors | 0.75; 2.25 | From 26.7 | |

| Beckers | Grepp Grundfarg. | 2. | White Spirit | eight | 6. | On the map NCS, Monicolor, RAL | 0.5; 0.9; 2.7; nine | 10.1 |

| MetallPrimeR. | one | Glycol | 10 | one | Grey | one; 2.5; 10 | eighteen | |

| Sadolin. | Pansarol Base. | one | White Spirit | nine | 24. | Red | one; 2.5; 10 | From 7.3. |

| Master Base. | 2. | White Spirit | 5-8 | 10 | On Tintorama map | one; 2.5 | From 7.0 | |

| Tikkurila | Rostex Aqua | 2. | Water | 7-9 | 24. | According to the catalog "Symphony" | 0.9; 2.7; nine | From 9.7 |

| "Rostex super" | one | 1120. | 10 | From 5 to 24 *** | 4 colors | one; 3; 10. | From 7.3. | |

| "Krasko" | "Staplemet-Soil" | one | White Spirit | 5-8 | 24. | Red-brown | 25. | 0T 1,8. |

| "StroyKomplekt" | GP-021 / 021c | 1; 2 ** | Xylene, solvent | 8-10 | 24. | Light gray / red-brown | one; 2.5; 22. | From 1.1 |

| "VGT" | VD-AK-0301 | one | Water | 6-10. | 24. | The black | one; 2.5; five; 10 | From 2. |

| Designations used: 1- for galvanized iron, aluminum, copper and many other critical surfaces; 2- for conventional metal surfaces; * - heat resistance up to 120s; **- For interior and exterior use; *** - depending on the composition of the finish coating |

Paints for the roof

Usually, oil paints are used for these purposes. For his time, they were really the best, now the situation has changed. The fact is that the elasticity of the film coating formed by oil paints, over time, under atmospheric influence decreases. Vitoga film paint simply does not sleep behind the temperature expansion-narrowing of the roof metal (and it is quite significant) and at a certain point begins to crack and peel. Instead of the former oils currently, alkyd, acrylic and other compositions are proposed, and those intended exactly "for roofs", that is, designed for harsh operating conditions. Separations, for example, in paints on galvanizing and ordinary in the roof products may not be even, it is believed that the surface must be primed.

Alkyd compositions on sale are presented quite wide. This "enamel alkyd for roofs" from the company "StroyKomplekt", "Pansarimali" from Tikkurila Idr.

According to experts, the most modern acrylic paints on the solvent. They will cost a little more expensive than alkyd, but they will serve much longer, because they have a higher and stable elasticity in time. Including example, the composition of Takfrg from Beckers can be brought. Not particularly for a long time for the processing of the roofs began to use another type of acrylic painting-water-dispersion. These are specialized materials that form a dense coating with good adhesion. In the domestic market, such products are widely offered both foreign and domestic manufacturers: Oikos- compositions Novalis Ferromicaceo (with the addition of mica pigments), Tikkurila- "Repko", anti-corrosion paint VD-AK-1179 from "VGT" IT.D.

I would like to warn one more. Almost all manufacturers produce appropriate primer to each of their paints. Even more accurately, paint and primers are produced in pairs so that they combine well with each other. For example, in the line of materials Sadolin, intended for the roofs, the Akzo Nobel concern offers the following pair: Alkyad Pansarol Base Plus Alkyd Pansarol paint. Of course, it is always more reliable to choose and acquire a new product recommended by the firm.

Paints for lattice products

In this case, under the grids, the grid is implied not just installed on the window, but any design of metal, collected in one way or another from individual parts: fences, gates, wickets, visors, stair and balcony fences IT.D. Their surface is pre-ground and then painted. For this, the paints described in the "Prayer Roof" section, as well as enamel on a different basis. Alkyd enamels on a solvent are offered by such firms as "StroyKomplekt" (PF-115, PF-115 "Lux" with improved properties, quick-drying enamel "Sprint", PF-1217VE), Beckers (Hammerlack Hammer Hammer), Caparol (Capalac Seidenmatt-Buntlack and Capalac Hochglanz-Buntlack), MEFFERT (HOCHGLANZLACK) IDR. Water-soluble acrylic enamels are considered to be a "pisch" of fashion, for example, Novalis Smalto from Oikos, VD-AK118 from Aqua Decor IT.D.

Here, too, as in the case of roofs, it should be purchased and paint in a pair. For example, in the range of sadolin materials for lattices, an alkyd soil on the Master Base solvent is proposed in a pair of paint Master on the same basis.

Protective formulations over paint

Immediately mention: on their use, most firms are not insist. Meanwhile, the NOVALIS line from Oikos has the composition of Ferro Protettivo (the price of 25.7 / kg), which can be used for additional protection of problem surfaces. The product is a water-soluble acrylic varnish, which increases the moisture resistance and wear resistance of the painted surface. The whole effect of domestic LCMs can be achieved by applying a transparent "zapon-varnish".

| Firm | Mark. | Binder | Diluent | Consumption: m2 / l in one layer | Drying time before re-applying, h | Color | Degree of gloss | Packing, kg. | Price, / kg |

|---|---|---|---|---|---|---|---|---|---|

| Dissoller paints | |||||||||

| MEFFERT. | Hochglanzlack | Alkid. | Type White Spirit | eleven | 12 | 25 colors | Glossy | 0.37; 0.75; 2.5; 10 | From 6. |

| Aqua Hochglanzlack | Acrylic | Water | eleven | four | 21 color | Glossy | 0.75; 2.5 | From 7. | |

| "StroyKomplekt" | "Enamel Alkid for Roofs" | Alkid. | White Spirit | eight | 24. | 5 colors | Glossy | one; 2.4; twenty | From 1,4. |

| Tikkurila | "Pansarimali" | Alkid. | White spirit 1050 | 8-12. | 24. | On the map "Panstamimali" and "Symphony" | Semi-bang | 0.9; 2.7; 9, 2. | From 4.9 |

| Beckers. | TackFrg. | Alkid. | White Spirit | nine | 24. | By catalogs NCS, Vinicolor, RAL | Glossy | 0.94; 3.8; 9,4. | From 17. |

| Water-dispersion paints | |||||||||

| Oikos. | NOVALIS FERROMICACEO. | Acrylic | Water | 7. | 12 | 29 colors | Glitter mica | 0.75; 2.25. | From 29. |

| Novalis smalto. | Acrylic | Water | 10-12. | 2-4 | More than 2000 colors | Glossy / half-handed, matte | 0.75; 2.25 | From 20.4 | |

| Tikkurila | "Repko" | Acrylic | Water | eight | 24. | On the map "Symphony" | Halfmite | 0.9; 2.7; 9,2 | From 6.8. |

| "OCTAVE" | VD-AK-116 | Acrylic | Water | 4-7 | - | Red-brown, green | Halfmite | five; 10; fifteen; 55. | From 3. |

| "VGT" | VD-AK-1179 universal / for ferrous metals | Acrylic | Water | 10-15 | one | According to the catalog of colors "VGT" | Semi-bang | one; 2.5; five; 10; thirty; fifty | From 1.9 / from 2 |

Modern methods of protection

The primer-paint-protection converter is good, but ... first, long, secondly, as we have already said, it is necessary to remember the possible incompatibility of these products. Remove both problems are designed by products from the series "All in one bottle" offered by a number of manufacturers.

Paints "Two in One"

Soil and paint in one bank. Ktakim products include, for example, water-dispersion latex paint "Polyfan-A" from "NIZB-trading" (can also be used along concrete, CSP, chipboard, brick, sewer IT.D.). It is used as a primer under various LKMs (it is possible to apply on rust) and for final color. According to the manufacturer, in conditions of temperate climate, the coating is at least 10 years.

Offers the compositions of "two in one" and overseas companies. For example, Beckers releases a semi-premium primer and cutting paint METALLGRUND TCK on an alkyd basis. For processing the gate, railing and drainage pipes, the product can be applied without primer. Tom in the color of the surfaces exposed to the strong effects of aggressive media (roofing, chimneys), it is recommended to pre-primed them with MetallPrimer. Caparol manufactures epoxy communal thick-layer soil-enamel Capalac Dickschichtlack.

It is especially worth highlighting the so-called blacksmith paints WS-Plast, the wide range of which offers Weigel + Schmidt Lackchemie (Germany). They are produced on acrylic binding - the service life of the coating reaches 6-8 years. Paint is allowed on any surface, including previously painted (it is recommended to make a trial paint). Consumption on average is 125 g per 1m2.

The same company developed the composition of WS-Patina with a patina effect, imitating the effect of gold, silver and copper coating.

Another unusual coverage, Zinga, manufactured by the Belgian company Zingametall. This is a single-component, fully finished product product on a solvent, which includes an electrolytic zinc powder. Zinga forms a thin-film coating that simultaneously ensures the mechanical and electrochemical (with sacrificial anode) protection against corrosion of ferrous metals. The timing of the coating, according to the manufacturer, is 10-50 years, depending on the thickness. Price, from 15 / kg.

Paints "Three in One"

Rust transducer, soil and decorative coating in one bank. Such formulations can be applied directly on rust (when preparing the surface it is recommended to consider only its loose layer). For a long time, thanks to advertising, domestic consumers believed that he produces such paints exclusively English firm Hammerite. But actually it is not. Just for Hammerite, this product is basic, and for others, one of the paints produced by them, and therefore they did not particularly advertise it. In addition, quite a lot of manufacturers have recently appeared, and above all domestic, which have begun, like Hammerite, specialize in rust compositions. In general, competition in this market exists, and even what.

Photoxark coloring staircase for "classic scheme" with compositions from Oikos:

Imported compounds . Perhaps the most famous paints of Hammerite. Thanks to fast solvents, the surface painted with them dries in just 60-90min. Thus, work that includes three operations is usually performed in two or three days, it can be done in one day. The thickness of the final coating should be at least 100 μm. Problem surfaces (stainless steel, galvanized) are primed by Special Matals Primer. According to the manufacturer, the service life of the coating, subject to the observance of the application of the application is at least 5 years. Paint is offered with three textures: hammer, smooth, half-one.

Hammerite products have one feature that must be taken into account when staining in several layers. After 8 h, the polymerization of the coating begins, and you can apply a new layer only after this process is over, in two weeks!

MEFFERT- Product Correx also offer their compositions; Sentapol- Hammer Paint Idr.

Domestic products . Domestic water-based soil-enamel produces the Firm "Palette Russia". These are the compositions "on rust" (latex), "shell" (acrylic), "Panciro Zn" (by galvanized) and un-soil "shell" (for problem surfaces). Coatings have a high moisture resistance for at least 5 years.

Gradually conquer popularity from domestic consumers and paints of Nova. This is an anti-corrosion enamel of NOVAX on an alkyd basis and the two-component composition "NOVAK", intended for products operating in a wet aggressive environment.

And finally, the three compositions from the company "Krasko". "Stazmet-luxury" is intended for both ferrous and non-ferrous metals and is distinguished by high chicasticness, resistant to abrasion and impact influences (designed for use in a heavy industrial atmosphere). "Stazmet-Chem" - for coloring and protection of surfaces exposed to oils, gasoline, acids, alkali, salts, fats. "Stazmet-cycron" - for painting roofs, drainage and other parts from galvanized metal.

It is also possible to find paints "Rust", manufactured by such firms as "Yaroslavl paints", "Novbythim" IDR.

| Firm | Mark. | Binder | Diluent | Consumption, m2 / l, in one layer | Drying time before re-applying, h | Texture / number of colors | Packing, kg. | Price, / kg |

|---|---|---|---|---|---|---|---|---|

| Hammerite | Hammerite | Alkid. | Hammerite | 4.5 | From 1 to 8 | Hammer / 12; smooth / 12; half grams / 8. | 0.25; 0.75; 2.5; five; 20, aerosol-0.4 | From 12. |

| MEFFERT. | Dfa-Correx | Alkid. | Type White Spirit | eight | - | Smooth / 7; Hammer / 4. | 0.75 | From 8.1. From 12,4. |

| "Palette Rus" | "According to Rzavchin" | Latex | Water | 11-14. | one | Semi-man * | one; 3; five; 10; twenty | From 1.2. |

| "Shecir" | Acrylic | Water | 8-11 | one | Half-one * | one; 3; five; 10; twenty | From 2. | |

| "Pole-Zn" | Acrylic | Water | 8-11 | one | Matte ** | one; 3; five; 10; twenty | From 2,3. | |

| Nova | Novax | Alkid. | Novax | 6-8 | one | Semi-shaped / 11 sets *** | 0.4; 0.8; 3; five; 10; 20+. Aerosol- 0.52. | 5.5 |

| "Krasko" | "Stazmet-cycron" / "Suite" | Acrylic | Type White Spirit | 3-5 | 12 | Matte / on Mos cards. Palette, RAL | 20/25 | 2.4 / 2.9 |

| "Stazhemet-Chem" | Polyurethane | Solvent | 5-6 | 24. | Semi-catch / via catalogs "Mos. Palette, RAL | 25. | 6,2 | |

| * - Colors - black, gray, yellow, red-brown, chocolate, green, blue; ** - Colors - "Tile", "Chocolate", "Asphalt", light gray, black, blue, green, red, yellow, lemon, orange; *** - chromatic and achromatic colors (tint is not normalized |

The editors thanks Akzo Nobel, Caparol, Tikkurila, MEFFERT, "VGT", "Design Intercrass", "Krasko", "Nova", network of salons "Decor Center" Okos "," Palette Rus "," Old Man Hottabych ", "StroyKomplekt", "Factory of German Forging", "Finnish" for help in the preparation of material.