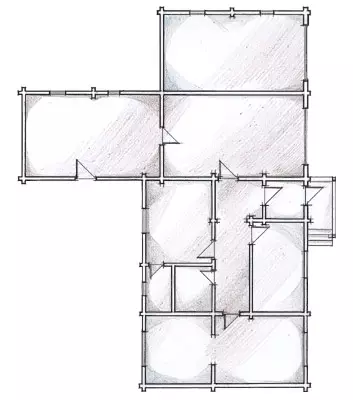

House (158 m2) from a warmed bar. The construction of the construction is based on the principle of combination in the wall structures of the tree and polyurethane foam.

Wood house-building technology is constantly being improved. One of the modern solutions is combining in the wall structures of the tree and insulation. Our report is devoted to the construction process and the external features of the building from a bar, insulated polyurethane foam. Energy efficient walls make it possible to significantly reduce wood consumption, facilitate the structure.

Bicycle invention benefits

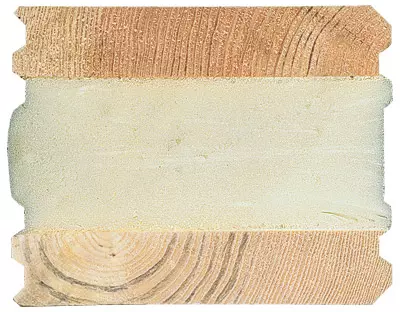

Experts paid attention to the properties of polyurethane foam to form durable and durable structures when combined with other materials. A visual illustration of this is insulated polyurethane foam steel pipes with outdoor insulation from polyethylene - their service life is at least 50 years. The same principle is based on the design of the insulated polyurethane foam timber (Bruus PPU), the patent for which was obtained by the company "777Diko". This building material has the strength characteristics of the glued profiled timber, but surpasses it in such properties as heat transfer resistance and heat capacity. Improved indicators Bruus PPU is ensured by the joint action of wood and polyurethane foam, as well as a reliable fixed compound of bars in patented technology.

5cm thick polyurethane foam, having a thermal conductivity of 0.03-0.045W / (m2c) [for comparison: this figure is 1.33, the brick is 0.7W / (M2C), it holds the heat just like a brick wall 1m thickness or mineral wool plate thick 15cm. The PPU bar has good environmental and hygienic properties, does not interfere with the air exchange, not cracking, is subject to the minimum shrink (limit of its strength in compression - 4,6 mp). By the amount of work, the house raised from it is cheaper than buildings from a rounded log or glued bar. For example, a house of 158m2 from a PPU bar of 150180mm without engineering communications under the Tiles BRAAS in 2005. Customer costs about $ 78,000.

In fact, the PPU bar is a hard frame of profiled wood filled with foam insulation with a transverse wooden inserts, which are uniform along its entire length. The ratio of the total thickness of the facial layers of wood to the thickness of the heat insulating layer on average is 1: 5. The wall thickness of the timber and insulation is calculated in relation to the region in which the house is built, as well as taking into account the functional purpose of the walls. This building material is usually made to order. For carrier walls, the timber is made thicker, for interior partitions - relatively thin and less insulated. Wasil that the walls of the upper floors are experiencing smaller loads, the thickness of the facial layers of the bar for subsequent floors is reduced.

Calculation of the thickness of the layers of the PPU timber during the construction of the same residential building in various climatic zones is made from considerations that the temperature in the premises should be 21c.

The wall element is also known for nomotable housekeeping, the outer layers of which are made of plywood or chipboard, and the inner layer is polyurethane foam. Different manufacturers are also attempts to manufacture the PPU timber with thinner outer walls, but this material has obvious disadvantages: a small area of contact of the surfaces of neighboring elements and fragile fixation. As a result, there is a significant shrinkage of wall structures in the vertical direction and a leakage connection in the seams.

Creation characteristics of the main thermophysical parameters for various building materials (according to "777 D and K")

| Characteristic | Glued profiled bar | Bar PPU | Effective brick | Insulated foam concrete |

|---|---|---|---|---|

| Coefficient of heat transfer U *,W / (m2c) | 0.86 | 0.26. | 0.48. | 0.43 |

| Heat capacity **, kWh / m2 | 0.046 with TSR = 1C | 2.07 | 1,8. | 0.88. |

| * - The smaller the heat transfer coefficient U, the more heat savings. According to European standards, the value of U must be no more than 0.5. If this condition is not performed, additional insulation of the wall is necessary; ** - The heat capability is the greater, the higher the surface density (kg / m2) of the structure and the temperature difference between the wall and air. The age of the day the wall accumulates heat and gives it in the evening and at night through the air coolant. In winter, during the period of heating, the walls are accumulated heat, and when it is turned off, it is warm in the air. The data in the table is shown for winter conditions in the Moscow region. |

Wall parameters from the PPU timber for different latitudes (PPU-70mm thickness)

| Parameter | City | ||

|---|---|---|---|

| Moscow | Krasnodar | Oymyakon | |

| The number of days per year at a temperature not higher than 8c | 214. | 149. | 286. |

| The average annual temperature, with | -3,1 | +2. | -24.3 |

| Calculated heat transfer resistance R, M2S / W | 3,21 | 2.39 | 5,92 |

| The actual value of R for the PPU bar, m2c / W | 3,86. | Similarly | Similarly |

| Calculated layer thickness of PPU, mm | 56.6 | 38.6 | 116. |

| Total thickness of facial layers from wood, mm | 1st floor: 100 + 100, 2nd and above: 38 + 38 | Similarly | Similarly |

Justified savings are also desirable and everywhere

The author of these lines was observed for the construction of a house from a bar of PU 158m2 from the moment of booking the foundation and before the jilts. The possibility for comparison was, because at the same site, a building from a glued timber was built. The wealthy customer allowed himself an experiment: a guest house, he chose to build from a bar of PPU, and for his own dwelling chose glued bar of Finnish production. The foundation of the building from the glued bar with the ground floor was built much longer than a low-profiled belt foundation and the base plate of the house of the PU meat, due to which the assembly work at the facility began later, when the autumn rains were gaining. When you start the bookmark of the walls of the master's house intended for guests, the construction was already headed under the roof. The building from the glued bar was completed only by the spring, and the decoration was transferred to the summer, while the Customer's family had already lived in the house from Brous in the winter. According to the owner's reviews, the house is dry and warm, it is comfortable, children and old people do not hurt.However, about everything in order. As usual, the process began with earthworks. Construction machinery for this did not need, except for the drilling machine, with which experts easily entered the water at a depth of 25m. The ledge of the well and the pump with automation was placed in the caisson blunted into the ground. At a distance of 30m from it, on the opposite side of the future building, the septic tank "Osina" was trembled and made an eyelid to the house of PVC pipes. The exercise of the septica can be judged by two sewering hatches, the covers of which are installed flush with the ground. Then they started the ruin of trenches, the mating of the reinforcement, the casting of the walls of the foundation and the base plate of the house. There is nothing new to add to the construction of buildings from the logs and the bar of the preceding publications about the construction of buildings here. The process was repeated almost in detail, after the only exception: concrete was prepared in place, in a small concrete mixer with an electric drive. The source of electricity served as a diesel generator SDMO (France), lighting lamps were also fed. So in the design of the foundation there was no breaks, work for the week was carried out in three shifts.

While concrete froze, building materials were delivered to the construction site. The mass of the PPU timber is an average of 30 (!) Kg, so the crane for unloading the workers did not need. The first wagon was unloaded within an hour. All assembly works were made by technology card. The numbered bars were collected in the manner specified in the document, practically the same way as which was done at the construction site of the house from Brous. The discrepancy was to build technology.

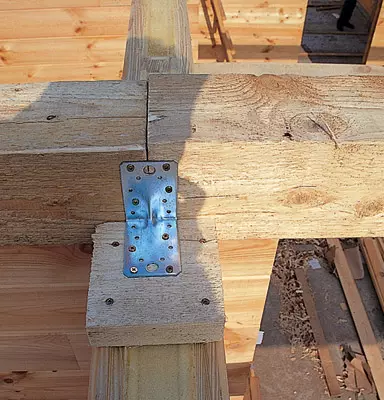

Votchchychi from the full-scale glued bars, which are connected by the brazers, are tightened with screws or are not tightened at all, the bars of the PPU sat on the long threaded studs, which are drilled through holes in their place. The studs were put at the ends of the mating bars and at all their length in a step of 2.5m. If the lanes was lacked, they were increasing with connecting threaded couplings. As soon as the walls reached the required height of 2.7 m, metal lining worked on the studs, the edges of which are based on the walls of the bars, and the nuts screwed over the wrappers. The lining evenly presses the bars around the perimeter of the walls, providing a uniform shrinkage. The tightening of the nuts produced several times as the installation of rafting farms and overlaps was installed. Then the ends of the spills were spilled with hacksaw.

Installation of walls was carried out by three workers simultaneously in different parts of the building. The small mass of the bars PPU 150180mm allowed them to install them alone. A splitting compound along the entire bar was laid a strip of interventional insulation-foamed polyethylene with a thickness of 5mm. This material makes the connection absolutely sealed. There is an option of installing bars without interventory insulation. To do this, on the lamellas of polyurethane foam on the machine, an increased (5mm) protrusion is performed, which when laying the bars is crimped.

Relying on the foundation of floor overlapping beams (40120mm) were recorded using steel corners and dowels. Black floor boards laid the cranial bars attached to beams. Between two layers of pergamine on the surface, a rolled mineral wool insulation URSA (Finland) is 100mm thick. Clean floors are made of 35mm thick from the t-shuttered board. Their case, they were simply covered with a layer of high-quality linoleum. In the same place where the floor finish is required, the boards are attracted to each other, their ends are screwed to the beams of the floor with screws, after which they are polished and lacquered.

Low on the bars of the walls of the ending beams of the ceiling overlap (100150mm) secured with steel corners and screws. In advance, ground ceiling boards put perpendicular to beams, the cranial bars nailed to them. The number of insulation in the ceiling overlap depends on whether the attic will be warm or cold. The customer did not want to organize the attic, therefore, in this case, the overlapping was insulated with two layers of mineral wool insulation with a thickness of 150mm with vapor barriating from pergamine from below. On the attic made only draft floors, on top of which there were ladders for the movement of people.

Wooden roof farms gathered on Earth from elements of factory manufacture (made from 40150mm board), on durable ropes, tightened up and put on the last crown manually. Among the farms joined the shellboards and attached to the base with steel corners and screws. The customer wished to cover the roof of the natural tiled BRAAS (Germany). The counterclaim under it was knocked on the technology recommended by the manufacturer. Punching paosity was used in parchment. This material, although morally and outdated, is quite popular in construction due to its cheapness. On the same cold attic, where people do not live, there is no need to use more expensive materials. The chimneys of the boilers brought through the wall, and the ventilation and sewer risers are roof through the corporate roofing penetrations.

After the roofing is completed, the frontones of the clapboard (12mm) were laid and installed waterproof systems. Around the house made a concrete breakdown width in 1m. The base of the building was tiled with a facade tile imitating a natural stone. At the site of the temporary porch, the permanent, with a wooden staircase and a canopy. Located under the horse's house installed window and door blocks. The technology of their installation takes into account the slight shrinkage of the walls, so the window and door boxs strengthened on the sliding elements that are part of the grooves on the ends of the BRUSEV. Windows and doors in this case are wooden, domestic production. Double window blocks are well preserved heat, modern fittings allows you to open the frames in the horizontal and vertical direction. The fillety canvas of interior doors 40mm thick were painted in the elected color. The walls of the house from the inside and outside were treated with fire-protected composition "Sezheng Optimal" ("Sezhengskaya NLL", Russia), after which the Special Staining Technology (Zowosan Coating System) was applied to a brush with a two-component paintwork coating of Zobel (Germany) with an intermediate machine grinding.

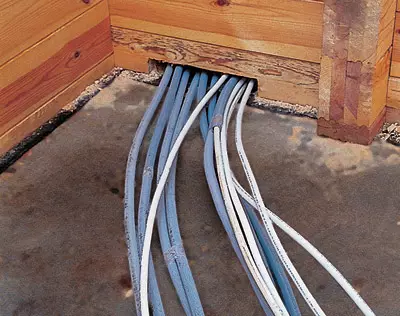

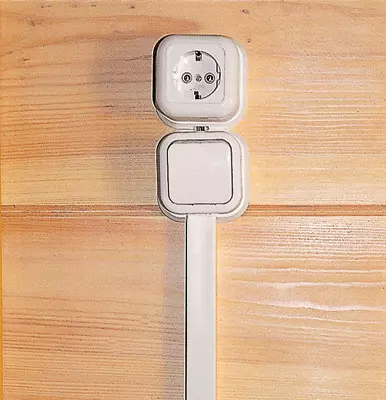

At the floor of the flooring of overlaps in the house began a laying of engineering communications. Entering pipes and cables carried out through a single opening in a concrete plate for the convenience of subsequent maintenance. The wiring to radiators and to the plumbing devices was made by the Oventrop (Germany) metal plate in the floor overlap. The electrical wiring to the lamps was performed in metal sleeves in the ceiling overlap. The eyeliner to sockets and switches were carried out in an open way in cable channels.

At the request of the customer in the technical premises of the house for guests equipped the boiler room, from which the other, master house heels. For reasons of fire safety, wooden walls of the boiler room were tested by Knauf (Russia) plasterboard attached to a movable frame of metal profiles. It was installed fairly powerful (two to 18 kW) steel gas boilers Vitola 100 (Viessmann, Germany) with a capacitive water heater (boiler) VitocellH300 with a capacity of 350l. Gas was held on a plot in advance. Also in the boiler room collected equipment for water treatment and water purification.

You can live modestly, but beautiful and tasteful

Although the guest house was conceived as an auxiliary structure, it has everything for the life of a separate family: entrance tambour, hall, kitchen-living room, two bedrooms, bathroom, veranda, garage, boiler room. Hospital, at the initial stage of arrangement of a lot of interest in terms of design, he did not imagine. Therefore, the construction company proposed to put a visit to another house from Bruus PPU, for two years used by a young family as a summer cottage.

Located in the village of Village, on the shore of a big pond, it looks good in the environment of the fruit garden. The building itself is smaller, but with the attic. No boiler room. The house is heated by four electrical convectors Siemens (Germany) with a total power of 4kW. Nevertheless, at a temperature of -25c, it is warm, as in an urban apartment. The fireplace is arranged, which in winter is used as another heating device.

The owners themselves were engaged in the design, who have a clear idea of what a country house should be: not very large, but cozy and comfortable. Therefore, in the center of the living-dining room, the fireplace was constructed in the style of "Rustics", opposite which the soft sofa stands in the lady and contemplation. Under hand, the controls of the music center and TV. The queen is enough space for both children's games and a civilized bedding family and for a feast of adults. For holidays in the dining area there is a large table, followed by a dozen invited. Sink, stove, kitchen furniture are compact and with such a calculation so that the owners can cook, continuing to communicate with guests. About the hunting preferences of the head of the family resemble the deer horns on the wall of the dining room and at the entrance.

The borders borders the bedroom of the owners. Wooden marching staircase leads to the second floor. Here are a children's and a small library, in which, if necessary, you can retire with a laptop and work. The waging of the day in the house is always light. Bright "rustic" curtains protect the dwelling from direct sunlight and revitalize a nomudinal, but fulfilled with the soul interior, to be in which it is very convenient and pleasant.

The owners are grateful to the builders and are proud of their small and cute suburban estate.

Enlarged calculation of the cost of work and materials on the construction of a single-storey house area of 158m2

| Name of works | Units. change | Number of | Price, $ | Cost, $ |

|---|---|---|---|---|

| Foundation work | ||||

| Takes up axes, layout, development and recess | m3. | 64. | eighteen | 1152. |

| Foundation base device, waterproofing | m2. | 175. | eight | 1400. |

| Preparation of concrete mortar in the construction conditions | m3. | 49. | fifteen | 735. |

| Device of the foundations of ribbon reinforced concrete, monolithic w / b plates | m3. | 49. | 60. | 2940. |

| Caution lateral isolation | m2. | 86. | 3. | 258. |

| TOTAL | 6490. | |||

| Applied materials on the section | ||||

| Cement, sand | set | - | - | 1290. |

| Crushed stone granitis | m3. | 22. | 28. | 616. |

| Bituminous polymer mastic, hydrohotelloisol | m2. | 86. | 2.8. | 240.8. |

| Armature, knitting wire, sawn timber, etc. | set | one | 360. | 360. |

| TOTAL | 2510. | |||

| Walls, partitions, coatings | ||||

| Installation and dismantling of scaffolding | m2. | 120. | 3,4. | 408. |

| Cabinet of walls from a bar PPU | m3. | 48. | 95. | 4560. |

| Heated walls for chopped walls | m2. | 158. | 12 | 1896. |

| Device board coatings | m2. | 158. | 10 | 1580. |

| Surface coverage with varnishes, impregnation | m2. | 690. | four | 2760. |

| TOTAL | 11200. | |||

| Applied materials on the section | ||||

| Bar PPU, "Teplon", screed, trimming | set | - | - | 23460. |

| Poland boards | m2. | 158. | 7. | 1106. |

| Sawn timber | m3. | nine | 120. | 1080. |

| Protective Forms (Russia), Lucky, Impregnation (Germany) | set | - | - | 350. |

| Fasteners and other materials | set | - | - | 240. |

| TOTAL | 26240. | |||

| Roofing device | ||||

| Installation of the rafter design | m2. | 248. | nine | 2232. |

| The device of the calane vaporizolation | m2. | 248. | 3. | 744. |

| Tile Coating Device | m2. | 248. | eight | 1440. |

| Enderbutting of eaves, soles, device of frontones | m2. | 39. | 12 | 468. |

| TOTAL | 4880. | |||

| Applied materials on the section | ||||

| Cement-sand tile Braas | m2. | 248. | 29. | 7192. |

| Sawn timber | m3. | nine | 120. | 1080. |

| Pergamine | m2. | 248. | 0.4. | 99. |

| TOTAL | 8370. | |||

| Warm outline | ||||

| Insulation of coatings and overlaps insulation | m2. | 406. | 2. | 812. |

| Filling opening windows and door blocks | m2. | 28. | 35. | 980. |

| TOTAL | 1790. | |||

| Applied materials on the section | ||||

| Mineral Wat Ursa. | m2. | 406. | 3. | 1218. |

| Wooden window blocks | m2. | 12 | 72. | 864. |

| Door blocks | PC. | eight | - | 940. |

| TOTAL | 3020. | |||

| Engineering systems | ||||

| Autonomous Water Supply Device (Well) | set | - | - | 2200. |

| Installation of the sewer system (septic) | set | - | - | 3400. |

| Electric installation work | set | - | - | 4200. |

| Plumbing work | set | - | - | 3140. |

| TOTAL | 12940. | |||

| Applied materials on the section | ||||

| SPEETTING "OSIN" | set | one | - | 6300. |

| Gas boiler Viessmann. | set | 2. | - | 3800. |

| Water treatment system | set | one | - | 690. |

| Plumbing and electrical equipment | set | one | - | 3900. |

| TOTAL | 14690. | |||

| Total cost of work | 37300 | |||

| Total cost of materials | 54800. | |||

| TOTAL | 92100. |

The editors thanks the company "777 D and Co." for organizing photography and for help in preparing the material.