The use of wide PVC profiles. Evolution of window systems, principles of installation, manufacturers. Features of the installation of the balcony unit.

The windows of PVC profiles today are successfully used both with the modernization of the old residential foundation and under new construction. With thoughtful design, they become an integral part of the facade

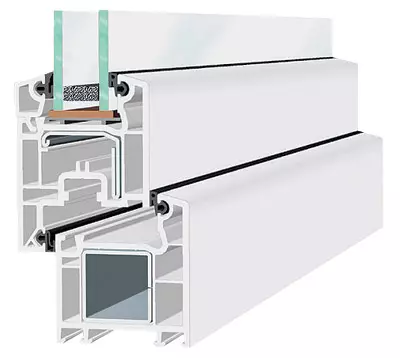

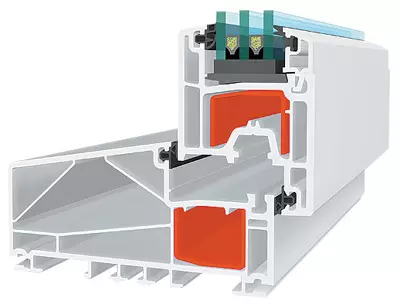

70mm width profiles and with two medium seals and internal contours

0.77m2c / W.

Laminated plastic window is almost indistinguishable from wooden

The windows of three-chamber PVC profiles have long and firmly settled in our apartments and homes. But over the past two years, the market was filled with windows from PVC profiles, in which the cameras are no longer three, and four and even five. Why do you need to consumer?

The most important material for the manufacture of windows is polyvinyl chloride-PVC. Chermannia The share of the windows market from this material is approximately 50%, in Russia, about the same. In Europe, in general, this figure is slightly smaller.

PVC profiles come to us from Austria (Laoumann), United Kingdom (LB Plastics, Heywood Williams), Denmark (Plastmo), France (Tryba), Belgium (DECEUNIBK), Turkey (Asas, Pirnas), Slovakia (Novacke Chemical Zavody) and other countries. The last year, this list has replenished LG Chem, which is the division of the famous Korean LG Concern. But leadership undoubtedly belongs to Germany (Aluplast, Artek, Dimex, Brgmann, Gealan, Kbe, Kmmerling, Nortec, Roplasto, Plustek, Rehau, Schco, Thyssen Polymer, Salamander, Trocal, Veka IT.D.). Accessories and other components also come mainly from Germany (Roto Frank, Siegenia Aubi Idr.). A number of firms (Dimex, Salamander, Kmmerling IT.) will be brought to us products produced only at factories located in their homeland. Other manufacturers (mostly German) built plants and produce a profile in Russia (Aluplast, Kbe, Trocal, Veka, Rehau). This, let's say, the German profiles of Russian production. But there is also purely domestic products ("Russian Shield", "Plafen", "Profile", "Proplex", "Samara window designs" IDR.), Which is no less popular with consumers.

The wation of the last two years, the overwhelming majority of foreign manufacturers presented the new productive systems wide 70 and 115-127mm wide or improved manufactured products in order to increase its heat-saving properties. Why did this happen?

"The law of everything head"

A serious impetus for the emergence of mentioned new products was the adoption of European standards ENEV 2002, they lists the requirements for construction technologies that should reduce energy consumption by about 30%. Large European manufacturers of PVC profiles for this quite quickly responded and began to move from sixty-millimeter three-chamber models to the systems of greater width. They led them, apparently, the following considerations: since the window as a whole should be warmer, even if the profile will be warmer, then the whole design will be easier to customize under norms.In its own way, reacted to the pan-European movement of energy savings and Russian legislation. From October 1, 2003. The support of the Russian State Building Adopted SNiP23-02-03 "Thermal Protection of Buildings", which was to change the SNiPII-3-79 * operating before. New standards slightly increased the requirements for heat transfer resistance for southern areas, but for some reason left almost unchanged requirements for this parameter for the districts of the North. But ... Even such a "soft" SNU is still denied state registration, and its entry into force is suspended until 2007. (and therefore, until this time, SNIP II-3-79 *). We will not understand this in the framework of this publication. Let's just look at the problem. Just if Europe with her relatively warm climate accepted more stringent norms, then where to go to us living in the climate more severe! Until 2007 Not so far, and the new SNiP will enter into force. Azodino, it is necessary to think, he will be revised by this time towards tightening the requirements. In general, without warmer windows, we will not ourselum either.

Window profiles and aesthetics of architectural solutions

It is the windows that form the architectural appearance of the building and give it an individuality. Manufacturers of specialized systems, each in their own way, try to facilitate consumers to solve this problem.

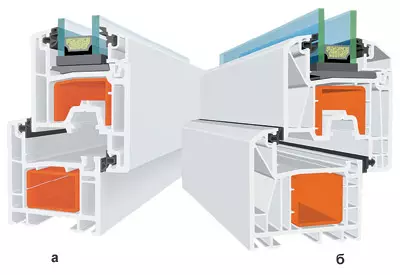

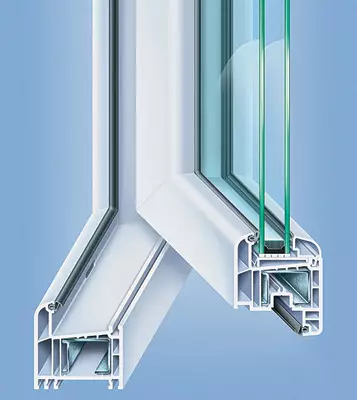

Profiles and window plane . Many firms offer specialized systems in two versions: flat-mounted and flat-plane. Wokon from flat-cheated profiles (implemented in the profile SoftLinead systems from VEKA and in most KVE systems, Kmmerling, Trocal) surface of the sash and frame lie in the same plane. Such a system has certain constructive advantages:

The probability of penetration flowing on the glass and the sash of the rainwater is reduced inside the frame;

Thrust glass windows can be used for glazing.

When restoration of old buildings, flat-furnished profiles are often used (the sash is shifted towards the frame towards the room), creating the impression of the old wooden window. Such products and produces most manufacturers. But this does not mean that profiles of different firms are similar to each other. Each manufacturer tries to give its products individuality, offering systems with expressively rounded, well-rectangular (classic option) and even concave outdoor surface contours.

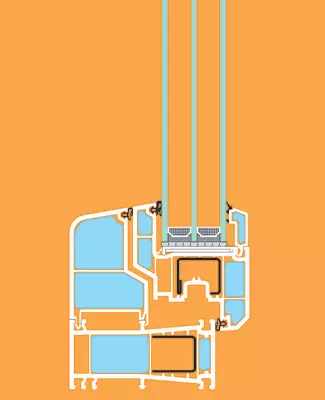

How many cameras should have a profile

Specialists argue that the thermal insulation properties of the plastic profile affect, first of all, the number and shape of the hollow cameras located inside its hollow cameras. Than they are more on the heat flux path from the inside to the outside, the better. Is it really? To understand this issue, let's follow the history of the development of PVC profiles from the moment of their creation to this day.

Recall that the first PVC profiles had only one chamber, and the value K (heat transfer coefficient) of the structures were made from 2 to 2.4W / (M2C), which corresponds to the resulting heat transfer resistance RO at the level of 0, 42-05m2c / W. They were changed by two-chamber profiles. They included a predocation located on the outside, which is necessary for the removal of moisture that falls inside, and the large chamber, in which elements of steel reinforcement were. The coefficient of heat transfer K such profiles has already had a value from 1.6 to 1.9W / (M2C), and therefore RO = 0.52-0.62М2С / W. It is clear that the increasing level of the requirements for thermal insulation neither single-chamber nor two-chamber models corresponded, which is why their production has been discontinued.

They replaced three-chamber profiles, having a pre-commerce both from the side of the street and on the side of the room. The heat transfer coefficient K is already in the range from 1.3 to 1.7W / (M2C) (RO = 0.59-0.73М2C / W). The width of these structures is about 60mm. Until the heat transfer standard, the windows manufactured from them, were reached only under the installation of the glass package with thermal conductivity, as close as possible to the standard (the window cover is about 30% of the window area, and if the frame has a somewhat higher than the standard, and the glass is slightly lower, then on average The window will fully fit in the norm). Three-chamber models were used and used so far.

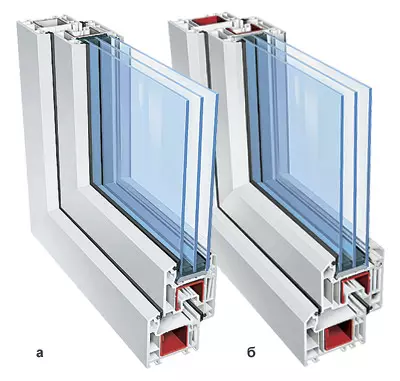

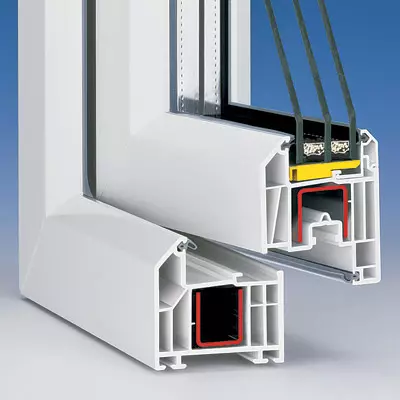

European consumers, and for them and legislators on the creation of a three-chamber design did not stop themselves and with the adoption of ENEV standards further increased the requirements for the thermal insulation of the premises, in particular the thermal insulation properties of windows. Tightened requirements forced profile manufacturers to make refinement of products. The simplest step in this direction is to increase the number of chambers without changing the profile width. So there were sixty-millionth profiles with four and even five cameras. But this step did not led the manufacturers to the desired result - heat transfer through the profile decreased, but did not reach the expected indicators (the specialists believe that with the width of the chamber less than 5mm it does not create the necessary effect of thermal insulation). The solution to the problem was the creation of profiles with a structural width of 70mm and more. Such a way using a standard steel reinforcement made it possible to achieve the magnitude of the reduced heat transfer resistance of about 0.8-0.9m2c / W, which, in combination with the use of special thermal insulation glasses, it combines the window structures with RO of about 0.8m2c / W.

What the market offers . Many manufacturers simply released new series of five-chamber 70mm wide profiles. This was done, for example, Gealan (S7000IQ system), Aluplast (ideal4000), Rehau (Brillant-Design and Lignotherm-Design), Schalamander (Design3D and Strimline), Schco (Coronact70 Cava / Rondo / Plus), Thyssen Polymer (" Favorite "and" Prestige "), Veka (TopLinead), KBE (" Expert "), Trocal (Innonova), Kmmerling (Eurofutur) and some other companies.

There are also supporters of four-chamber 70mm width systems, for example kmmerling (EUROFUTUR ELEGANCE AND EUROFUTUR CLASSIC SYSTEMS), GEALAN (S8000IQ) IT.D. True, the possibilities of their KMmerling systems have expanded with a variant of five cameras, and Gealan is six. You can find the combined structures in which the frame has kept the width of 60mm, and the sash rose to 70mm. Such is, for example, the Ultra series from LaoMann. Another example is the combination of the TopLine system (VEKA). The battle of these profiles have four chambers, and in color-five.

A peculiar record holder is the Termolocker-System profiles from Novacke Chemicke Zavody. They have 6 aircases with a frame width of 80mm, and the sash is 90mm (glass 47mm thick). The profiles with six cameras also offers Thyssen Polymer (Luxury series), however, the width of these products is somewhat less than 80mm.

There are also such manufacturers who "modernized" the old proven system. This was done, for example, VEKA with the Softline window profile system, developed back in 1970. As a result, the profile will noticeably "stolen": its width is now 70mm, and the number of chambers is five.

At the beginning of this year that appeared in our market at the beginning of this year, Lgchem immediately suggested consumers two series "warm" profiles: L600 with a depth of 60mm and four cameras and L700 with a depth of 70mm and five cameras. And the L700 is sold at the price of the three-chamber system.

The transition to the release of 70mm width profiles does not mean at all that large manufacturers completely abandoned three-chamber profiles. By completing the production of products, some of the products with fairly high heat transfer resistance. Well, and there are also such firms that have not been modified and both offered old three-chamber profiles and offer. To date, in Russia, the share of broad profiles in the total sales volume does not exceed 10%.

Collecting profiles

Kve, Trocal, Rehau and Schco offer another original solution to the question of staining and protecting window profiles from the PVC system with an aluminum overlay, which allows combining them with aluminum profile systems for winter gardens and facades.

Wair began to offer products from a profile laminated film. When applied, the "hot" lamination method is used, in which the film is practically welded to the PVC surface. It comes to the window, it enters the seal and edges of the mounting plane and therefore does not peel. For example, the use of Renolit film (Renolit-Werke, Germany) allows you to "paint" a window in 17 homogeneous colors plus almost as many options for the tree. Film can be applied with both one and two sides of the profile. One-sided lamination increases its value by about 30%, double-sided 40%, which increases the cost of the window by 10-15%. It should be borne in mind that the profiles laminated under the tree are usually offered not white, but a beige-brown.

Volley on four "hares"

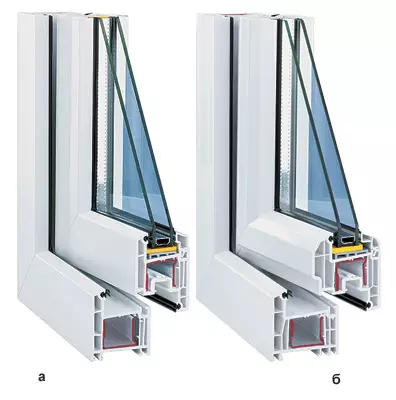

The creation of broad profiles made it possible to "kill", except for the already mentioned (higher heat-saving properties of the profile itself), three more "hares": to use a thicker double-glazed glass, increase the depth of its landing in the sash and solve the problem of the freezing of slopes.Fat glass . As already mentioned, the lion's share of the window surface is occupied by double glazed, and it means that the basic loss of heat occurs through it, and not through the frame. Since the frame has become wider, it is possible to install a thickest glass in it, and then the design of the window as a whole with more than will block the regulatory requirements. The result is double-glazed windows 42-44 thick and even 47mm. But it seems that this limit and further growth of thickness is not expected. First, according to experts, the distance between the glasses cannot exceed 16mm, otherwise the air will begin to circulate inside the chambers of the glass package, leading to significant convection loss of heat. Secondly, using conventional glass of 4mm thick, it is still possible to force the thickness of the glass package to force it to comply with the current standards. Thus, an increase in thickness from 32 to 44mm causes an increase in the value of the resistance of the heat transfer from 0.49 to 0.55m2c / W, but to normal, for example, for Moscow (0.56m2c / W) it will still do not meet. So why increase the thickness of the glass block, if the problem is easier to solve with special energy-saving glasses?

Depth of installation . The main problem of most double-glazed windows is the so-called "edge zone" effect. This refers to a sharp drop in temperature near the windows ends as a result of the formation of the "cold bridge" through the metal remote framework, holding the glasses in the package at a certain distance from each other. With a glass thickness of 30-32mm, the "edge zone" effect often leads to the fogging of its edges from the side of the room. This moisture flows into the window sill, scaring the owners of the window. To get rid of the unpleasant effect of the glass, it is necessary to burst into the sash so that the remote frame is in the "warm" zone protected by the profile chambers. It can be sufficient to consider the blowout for 15mm (though, it is not provided in all profile systems). New 70mm width profiles in most manufacturers allow not only to fulfill the norm, but also to block it substantially. For example, in a Nortec profile, which has a width of 75mm, a double-glazed windows are 18 mm, and in the SoftLinead system (70mm) from VEKA- by 21mm.

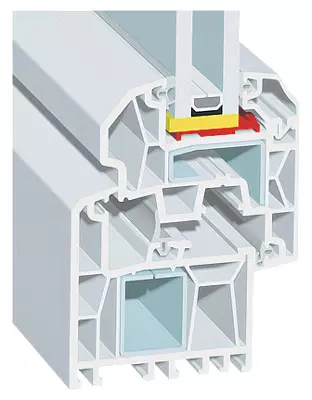

Problem freezing of slopes

The experience of operating PVC windows in a depth of about 60mm convincingly proved that they cause elevated heat loss through the slopes during the cold season. Satim is associated with condensate condensation from water vapors contained in indoor air, both on the surface of the slopes themselves and on the surfaces of the frame, sash and double-glazed windows. Why is this happening? When mounting windows with a narrow box in a single-layer outer wall, the heat drain dramatically increases through the slopes bypassing the box. The oblast is that the window block turns out to be in the zone of negative temperatures, heat flows are not only in docking along the box, but also in the thickness of the wall. By the way, the frosting of slopes and the formation on their condensate surface is manifested not only on the windows of PVC, this is a general lack of window blocks with narrow boxes from any material.

Of course, the problem of condensate appearance can be solved by displacement of the frame to the center of the opening and the insulation of the space between the window box and the outer wall with the simultaneous insulation of slopes. But it is possible to perform this. It is not always a deeply installed window begins to stand out on the facade of the house. When installing windows from a seventy-millimeter profile, the probability of freezing is significantly reduced. True, it does not mean at all that by installing such windows, you will not have to warm the slopes. Should! And the installation rules must be observed at least strictly. But honestly admit: windows from a wide profile forgive some errors of installers, and such, due to which the window from the sixtieth millionth profile would have to be reinstalled.

| Firm | Country | Place of production | Model rows | Profile width, mm | Number of cameras | Double glass thickness, Max, mm | Number of contours of seals | Heat transfer resistance, m2c / w |

|---|---|---|---|---|---|---|---|---|

| Salamander. | Germany | Germany | Design 2D. | 60. | four | 32. | 2. | 0.63 (up to 0.7 *) |

| Design 3D | 76. | five | 48. | 3. | 0.77 | |||

| Strimline | 76. | five | 48. | 2. | 0.72 (up to 0.8 *) | |||

| DeceunInck. | Belgium | Belgium | Mondial 2000. | 60. | 3. | 32. | 2. | 0.60 |

| Zendow. | 70. | five | 41. | 2-3. | 0.78 **** | |||

| Thyssen Polymer. | Germany | Germany | "Standard" | 60. | 3. | 32 (55 **) | 2 ***** | 0.64. |

| "Favorite" | 71. | five | 47. | 2 ***** | 0.78 | |||

| "Prestige" | 76. | five | 39. | 2 ***** | 0.79 | |||

| "Suite" | 71. | 6. | 39. | 3 ***** | 0.76 | |||

| "Favorite" | 128 (STV. 70) | five | 47. | 2 ***** | 0.79 **** | |||

| Kmmerling. | Germany | Germany | Eurodur Km. | 58. | 3. | 31. | 2. | 0.69 |

| Eurofutur Elegance | 70. | four | 39. | 2. | 0.81. | |||

| EuroFutur Classic. | 70. | four | 39. | 2. | 0.81. | |||

| Thermowin. | 100 | four*** | 49. | 2. | 1.25 | |||

| Rehau. | Germany | Germany, Russia | Basic-Design. | 60. | 3. | 33 (53 **) | 2. | 0.62-0.71 |

| Basic-Design. | 115 (STV.60) | 3. | 33 (53 **) | 2. | 0.62-0.71 | |||

| Thermo-Design. | 60 (SV.76) | four | 33 (53 **) | 2. | 0.67-0.75 | |||

| SIB-Design. | 70. | 3. | 41 (61 **) | 2. | 0.71-0.76 | |||

| BRILLANT-DESIGN. | 70. | five | 41 (61 **) | 2. | 0.79-0.84 | |||

| TROCAL | Germany | Germany, Russia | 900. | 62. | four | 54. | 3. | 0.71 |

| Comfort. | 62. | 3. | 36. | 2. | 0.64. | |||

| Innonova 70 A5 Elegance | 70. | five | 38. | 2. | 0.81. | |||

| Innonova 70 m5 Classic | 70. | five | 58. | 3. | 0.81. | |||

| Veka. | Germany | Germany, Russia | Softline AD. | 70. | five | 42. | 2. | 0.78 |

| TopLine AD. | 70. | 4-5 | 42. | 2. | 0.77 | |||

| Euroline. | 58. | 3. | 42 ** | 2. | 0,68. | |||

| Kve. | Germany | Germany, Russia | "Reference" | 58. | 3. | 32. | 2. | 0.65 |

| "Expert" | 70. | five | 38. | 2. | 0.79 | |||

| "Extra" | 127 (ST. 70) | 4 (ST. 3) | 32. | 2. | 0.71 | |||

| * - when using the glass package of a special design; ** - in a flat-composite design; *** - Internal cavities of the box, sash and stroke are filled with foam insulation; **** - certification is carried out; ***** - Seals Strengthened by Kapron thread |

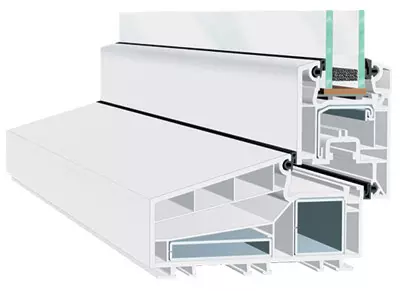

Width frames more than 100mm

With the creation of 50mm wide profiles, manufacturers have not calmed down. Some went even further and offered Russian consumers frame boxes 115 widths and even 127mm. Such frames are sometimes called "Danish" or "Dutch", although, for example, the Kve has developed its profiles with a width of 127mm specifically for us. Prosusia these boxes turned out to be more by the way, since the problem of frost freezes decide even better. Such frames can be installed, for example, when using modern energy-saving three-layer panels, inside of which there is a layer of insulation (foam, mining of IDR) with a thickness of 100mm, the frame securely covers this layer. Today, the installation scheme is most common, in which the front edge of the frame profile is flush with the outer surface of the wall. Such a scheme makes it easier to organize an adjuncing unit of the window box to the wall and even refuse to finish outdoor slope. Nevertheless, the search for the optimal installation scheme continues.

There are devices in wide frames: the cost and complexity of the window installation increases. The input systems contains a kind of paradox: a pair with a wide box used clarifying profiles of 60mm in size that do not give advantage from the point of view of resistance to heat loss. Only in 2005 The position finally changed - there were options with a sash 70mm. Profiles with frames with widths up to 115mm offer companies such as REHAU (Basic-Design), Kve (Extra system) IDR. The record holders are Kve ("Extra +"), Trocal (Relief) and Veka (Euroline), Thyssen Polymer ("Favorite"), the frame profiles of which are 127-128mm width.

Chronicle installation of the balcony block from the profile S 8000 IQ from Gealan:

| 1- drilled mounting holes; |

| 2- installed two connecting profiles and self-seeping tape; |

| 3- compounded frames; |

| 4- installed and leveled the design in the opening; |

| 5- fastened with anchor bolts; |

| 6- anticipated sash; |

| 7- marked gaps; |

| 8- installed sings; |

| 9- installed windowsill and threshold; |

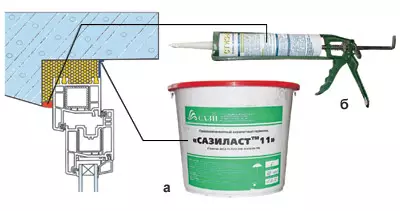

| 10- treated with a sealant; |

| 11- insulated internal slopes; |

| 12- sealed gaps; |

| 13- ready! |

Where come next?

Prices for energy over world market continue to grow, which causes further development of energy-saving technologies. The result in Europe has developed a program that called the "passive house", in which the windows are reserved far from the last place. Several simplifying terminology, let's say that the "passive house" is a house without active heating, but before energy saving, that the consumption of primary energy is approximately 20W / m2 (in more specifically, it is enough for heating heat released by light bulbs, iron and other household devices). This process makes think about the future and profile manufacturers. Yipod This program, many of them have already suggested special highly energy-saving profile systems: Kmmerling- Thermowin, Veka- Topline Plus, Rehau- Clima-Design, Kve- "90mm". Profiles are of the width of about 104mm with four cameras filled with a special foamy insulation. Special steel reinforcement provides the window high stability and unchanged static indicators, and also allows the use of a wide range of anti-burglar fittings. The use of a two-chamber glass glass thickness 44mm allows you to achieve heat transfer coefficient within 1W / (M2C). Similar profile systems are offered by Kmmerling (Thermowin), Kve ("Pole") IDR. It seems that in Russia the windows from such profiles will also be useful. This is an excellent solution to the problem for the regions of the Far North, although quite expensive.

The editorial board thanks DECEUNINCK, Gealan, Kve, Kmmerling, Rehau, Salamander, Thyssen Polymer, Trocal, Veka for help in preparing the material.