Artistic element

Legrand equipment safe for people

The resources of wooden house-building in Russia are inexhaustible. Nevertheless, the tree should be rationally. Glued bar - a modern achievement that allows you to build beautiful warm houses quickly and with minimal labor costs

Foundation

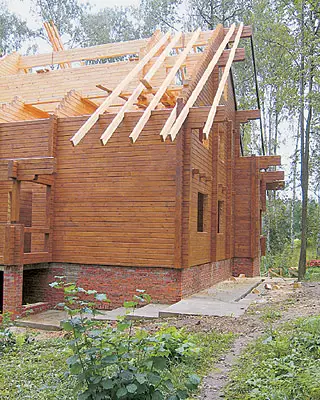

The house of glued bar, with the construction of which we introduce the reader, stands on the hillside. Soil structure is ordinary loam. The only threat to the foundation is possible soil movements under the influence of soil waters. The situation of the designers and the builders were admitted as follows. From the sole of the hill, where the base is higher, laid the foundation tape on 20cm deeper than from the side of the elevated part of the hill. Increased pillars used asbestos-cement pipes with a diameter of 300 mm, installed in pre-drilled shurten at a depth of 160-190 cm. Pipes pillars raised around the perimeter of the foundation every half meters. The charity of the pipes laid a three-moisture frame of the reinforcement and poured it with a concrete mixture. Frames with a width of 40cm from the same metal reinforcement a frame of the foundation tape was associated. The first fill with the concrete mixture was brown with the surface of the Earth. Then, the foundation was installed on the tape, inside which the additional framework from the reinforcement was tied, and cast the upper part of the foundation 50 cm above the ground level. The base of the house was posted from the rank red brick.

|

|

|

Build houses from a bar resembles work with a children's designer: there are standard elements in it to solve any non-standard tasks. Barbed houses are built from the material of the single cross section along the exhaust technology. Nevertheless, architects that design such buildings have complete freedom of self-expression.

The pronunciation formed between the walls of the foundation was mounted engineering communications. Forward the queue, asbestos-cement pipes with a diameter of 200mm, through which we suspended the water supply and sewage pipe, an electric cable. The pillow from the soil was pillow, thoroughly tumbled and covered with a smooth layer of sand. Armature framework across the plane of the future foundation of the house. Inscribe by setting an additional formwork on the sides of the foundation, cast a monolithic concrete slab.

|

|

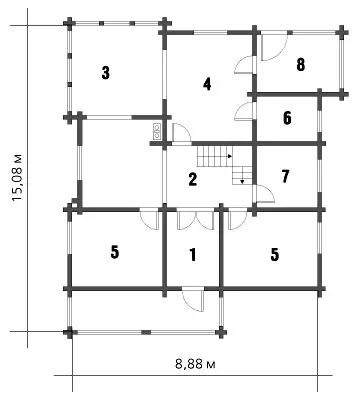

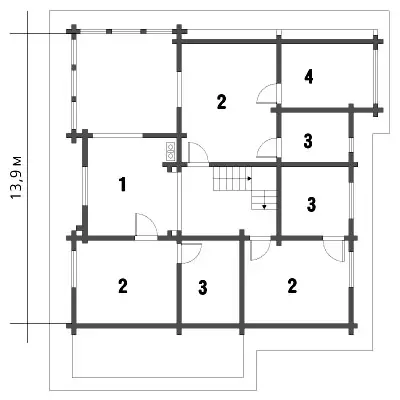

Explication

Ground floor

1. Hallway 2. Hall 3. Living room 4. Kitchen 5. Residential Rooms 6. Boiler room 7. Bathroom 8. Veranda

Second floor

1. Hall 2. Bedrooms 3. Balcony Balcony

Technical data

Total area of the house .................. 259,0m2

Ground floor area ............. 115,53m2

Square of the second floor ............. 97,79m2

Square of the attic floor ..... 45,55m2

Walls

The walls of the house should rely on an absolutely level basis. For this, builders have brought "zero": the markup of the plate and on the perimeter of the bearing walls and interior partitions made a concrete screed with a height of 5 cm, having hydrated it with hydrokhotklozol.

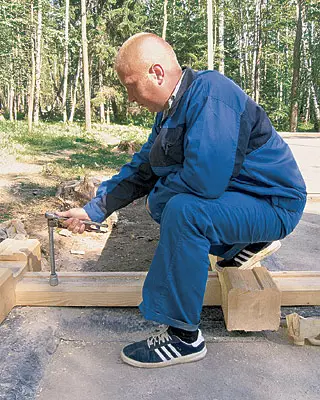

Before starting work, the timber was treated from the sprayer with a primer antiseptic "Waalty-Lushyust" (Tikkurila, Finland). After this operation, they started marking the bars and the manufacture of cups of compounds. Cups on the bars were spoiled by a disc electronized with a movable plywood pattern. Excess wood was removed by a chainsaw and a chisel. The angular compounds of the first crown were performed using a semic chain, which "in trusted" (with the release of the ends) laid the full-size bars with a height of 160mm and 180 mm width. To fix the walls on the foundation, the first crown fastened on the basis of anchors. Subsequent crowns were collected from a full-sized bar with the same compound "in drapery". This element looks beautifully both on the facade and inside the house.

|

|

|

BROUSEV interconnecting nodes are placed and washed with disc electric saw in templates, excess wood is removed by a chainsaw and a chisel

After the house was started under the roof, the workers produced the machine grinding of the walls and the ends of the BRUSEV. The fact is that during the construction, the surface of the bar is subjected to different atmospheric influences. Of the result, the purity of its processing is broken, and it has to be restored. In addition, wood is able to absorb the atmospheric moisture (mainly through the end sections). The prevention of the prevention of this process and warning the cracking of the bar workers covered the walls with the preservative composition "AiDol" (Remmers, Germany). For the finishing finish of the facades, a linseed oil lesing antiseptic "Valtikolor-Satin" (Tikkurila), which tinting bars and simultaneously protects them from the negative effect of atmospheric precipitation and sunlight. It should be noted that the options of the outer decoration of the walls provide not only tinting and lescing, but also a color hiding the texture of the bar. Many customers like this solution. Moreover, the preparation for opaque painting is less laborious and is cheaper.

Overlapping and rafal

Roof farms - the upper part of the house design, they account for the load of "roofing pie" and snow. Actual Strip of Russia The burden of snow on the roof is 1300kg / m2. We add a lot of natural tile on the roof of 420m2, and it becomes clear why the roof farms are made from high-strength materials. Of course, glued elements are certainly the most reliable in the design of the wooden house. The case of the beam overlap in the attic is made of a conventional glued bar. The rafters are made of wood glued down by several other technology providing them with increased strength. Stropile legs are a glued bar of 210mm height, 78mm wide and 12m long. They rely on the upper wints of the walls and intermediate racks with which they are connected through "delay".

Roof and roofing

Roofing works on a broomage house, as well as the technology of roofing the roof, do not differ much from those under the buildings of other structures. "Roofing Pie", as it should be supplied, contains sequentially located bottom-up layers of vapor barrier, insulation and waterproofing. Nevertheless, there are nuances for which you want to pay attention. Thus, the Palex-Stroy specialists over the rafters are squeezed by the entire surface of the roof of a well-antiseptic tank board (25mm). It would seem, without this item you can do. However, to increase the strength and durability of the design, such a solution is desirable. The downtown protects the roof from the seating under the severity of the tiles and snow and is an additional leakage protection. The Palax-Stroy's attachment is preferred to use Rockwool's rigid mineral wool slab, which, according to company specialists, is most convenient in wooden house-building. Punching clamps under the laying of natural roofing "Braas" applied a bar 55cm. The laying technology of such a tile is described in the manufacturer's instructions attached to the goods, so let yourself omit these details. We only note that the terracotta color of the tile and slightly tinted under the oak bars of the walls make up a delightful ensemble.

|

|

|

The bars of this profile are installed in the wall with the gasket of the insulation of the foamed polyethylene. They are also insulated by the pairing places BRUSEV

Outdoor stairs

The area surrounding the area has a gentle relief. To protect the foundation from the slope of the water hill and remove it into the stream running below, a perfect surface drainage system is organized around the building. At the site of concrete flats, the builders pre-put drainage polyethylene pipes into the soil, connecting among themselves somewhat installed at the perimeter of the house of waterfronts. The water flowing from the hill or from the roof falls through the funnels in the drainage collector and then in the stream, the arrangement of the channel of which is not completed yet. On the two sides of the house are cast concrete stairs on both sides of the house. They can be climbed onto the porch or continue the movement above - on the hill, in the direction of the forest.The technology of casting outdoor stairs deserves attention. After the drainage pipes were laid in the ground, the workers were made on top of a sandy-gravel subfolder, tied out of the armature frame of the steps and collected the formwork of future staircase marches. Nearby time ladders are bold with stone.

Interior decoration

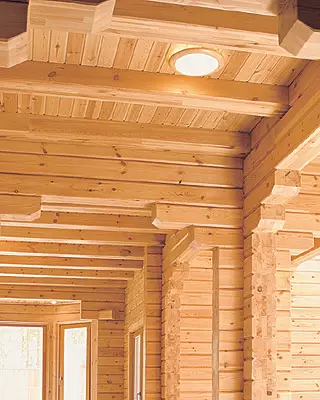

The method of interior wall decoration, ceiling and floor of the house is particularly thorough grinding, coating with high-quality varnish and finish polishing of surfaces. First, the walls are intensively treated with ribbon and vibratory grinding machines until they get a homogeneous rough texture. Then - the primer is a strongly diluted colorless matte varnish Paneli Assa (Tikkurila) on a water basis and re-grinding, at the end of which the same composition is applied to the base, but double concentration. After complete hardhand, the surface is polished with a felt disc. The lacquer process with subsequent polishing is repeated three times. The result is formed a thick coating layer (according to the quality of comparable to the furniture), perfectly detecting the texture and color of wood. Wooden designs trimmed in this way do not lose their natural decorative properties, "breathe", passing air and moisture, and create a favorable atmosphere in rooms. To process the surfaces of the ceiling and ceiling beams, a water-based lacquer is applied by Dulux (United Kingdom): it is shelled, durable, quickly dries and does not attract dust. Applied in two layers.

All the boarded parts of the ceiling are laid in the groove of floor beams and are simply pressed to each other. Immediately to nail the boam board was impossible. Drops of temperature and humidity in the heating period lead to what the movements of these elements occur. They either expand, gaining moisture, or, on the contrary, narrowed due to drying. The result is formed gaps. For 1-2 years, specialists from the firm are observed for the behavior of the tree and consistently eliminate the disorders. Balks of the attic ceiling overlaps milling a special groove, where the boards were placed one after another. Later, while in the house of service, the cracks eliminate by attracting boards to each other.

Wood flooring technology also has its own characteristics. Boards will not fail if the humidity and temperature indoors and under the floor will be approximately the same. The base of the final floor is the case, nailed in 10 cm, to the beams of inter-storey floors at an angle of 45 or 90 (depending on the future direction of laying the board). Due to the mismatch of air temperatures at the floor and the ceiling occurs convection (air movement from below and back). At the same time, the air through the ventilation holes in the floor receives free access to the bars of the crate. As a result, the indicators of humidity and temperature above and under the floor are at the same level.

The finishing floor was used before the beginning of the interior decoration of the building. This is explained by the fact that the floorboards stored in different conditions have an unequal humidity, and should go through the time so that it is leveled. Castled boards did not knocked, but while they were bored with an organomet. During the period of construction work, the coating moisture was made uniform. After completion of the premises, the floor was dismantled. Single jack, screws that boards on both sides are screwed to the beams of overlaps, and the glue "liquid nails" of the boards pulled together to each other. Then the surface of the floor is cycled and grinding TRIO machines (Germany).

The inlet of the squabble on individual boards due to the features of the saws is formed minor chips and cracks. These defects were eliminated by applying the special composition of MixFill, which is preparing on the technology of the Swedish company BONA by mixing with woody dust. After the floor, machine grinding was subjected. When the desired cleanliness of the boards was achieved, the surface was treated with an impregnation for wood based on White Spirit Protective Wood Stain (Dulux), aligned black. The impregnation is impregnated by the impregnation more active than in more dense. That is why in the process of subsequent grinding with a skin (this operation is produced by hand) dense fibers restored their natural color, and black splashes remained in soft. Thanks to this, the floor acquired a kind of "aged" view with an underlined black and white wood texture. To protect the surface, it was coated with a colorless half-made varnish on an alkyd-based interior varnish (DULUX). The result is the result of the floor finish significantly different from the design of walls and ceilings on texture and color, and the design of the interiors looks richer and original.

Engineering Communication

After installing the windows and the completion of roofing work, engineering communications started. Since the house is built on a previously cast concrete slab, through which an electrical cable, sewage and water supply pipes are made in the room, the entire wiring of the first floor engineering networks was performed under the floor. Together input communications in the building in the floor equipped the technological hatch. Where the floor wooden, pipes and wires were laid in a layer of rigid mineral wool insulation Rockwool between lags, and where it was lined with tiled or stone, - in the ceramzito-cement tie.

Firefighters are placed by the Kelectro installments of wooden buildings. The laying of electrical wires and cables - to rosettes, switches and luminaires - were carried out in the process of the construction of walls through metal pipes or metalrukaw (vertical holes dried in the bars and horizontal grooves were chosen). Watching wiring ignition they should prevent the spread of fire. For greater reliability, a cable with a zero protective conductor (NYM brand produced by Sevkabel plant) was used. It has triple insulation, does not release harmful substances when burning, racks to high temperatures arising from a short circuit.

When installing sockets and switches, LEGRAND mounting boxes (France) were used, made of non-supporting plastic combustion. In addition, the contact location of the boxes with the wall was pre-covered with special paint, preventing the fire fire. Holded houses increased attention should be paid to the quality of electrical connections. Parallel shunt connections between sockets are not allowed. From each outlet (or from two to three, to which non-energy household appliances are connected) a separate wire (cable) must lead to the mounting box, and from it to the protective machine. This is done for uniform distribution of the load on the sockets and protective automata. Along with the protective machine, each rosette group, and in special cases - a specific outlet must protect the protective shutdown device (UZO). If the isolation is damaged and the occurrence of leakage currents, it will save people life, prevents the fire, will retain the performance of electrical appliances. This montage and protection rule also extends to lamps.

The laying of heating and hot water systems is made by the reinforced layer of aluminum by the polypropylene tube of the German company Aquatherm. Such a pipe has a smaller linear elongation coefficient than other plastic pipes, which simplifies the solution to the problem of compensation for its bending in length when heated. For cold water, a conventional polypropylene tube of the same manufacturer was used. The warm floors in the bathrooms and in the kitchen are equipped with a flexible tube of cross-linked PEX polyethylene using Wirsbo technology (Sweden). The wise acts a climate installation. It includes practically without noise Osberg ventilation system (Sweden), central air conditioner Daikin (Japan), Axair air humidification devices (Switzerland), Calorex dryers (United Kingdom). The operation of the instruments is carried out under the control of Siemens automation. Ventilation channels are laid in inter-storey floors, climate installation equipment is concentrated in the technical room on the second floor. Wuttomatic mode is carried out control of air quality and organization of ventilation, maintaining comfortable temperature and humidity, its purification from dust and harmful microorganisms.

You can erect buildings from a bar in different ways. There are differences and in the material, and in construction technologies, and in the cost of work. Many Russians buy household houses that are collected on a construction site from relatively inexpensive conveyor production details. In this case, interventic insulation does not apply, bars pressed their own mass. You can specify a number of other significant features of this technology. Nevertheless, the houses built in this way are optimal at the ratio of "price - quality" and are popular with people with limited material capabilities. How and from how to build, to solve you. The main thing is that it is not in a burden, but in joy!

Enlarged calculation of the cost of work and materials on the construction of a two-storey house with a total area of 259m2

| Name of works | Units. change | Volume / Number | Price, $ | Cost, $ |

|---|---|---|---|---|

| Foundation work | ||||

| Removal of the axes, layout and development of the site under the foundation, ground recess | m3. | 92. | eighteen | 1656. |

| Device of a chicken base | m2. | 170. | eight | 1360. |

| Foundation Device, R / B Plates | m3. | 98. | 60. | 5880. |

| TOTAL: | 8896. | |||

| Applied materials on the section | ||||

| Concrete heavy, crushed stone granite, sand | - | - | - | 6500. |

| TOTAL: | 6500. | |||

| Walls (box) | ||||

| Cutting walls from a bar, setting columns | m3. | 90. | 150. | 13 500. |

| Heated walls for chopped walls | m2. | 320. | nine | 2880. |

| TOTAL: | 16 380. | |||

| Applied materials on the section | ||||

| Lumber (glued timber, edged board) | m3. | 90. | 500. | 40 500. |

| TOTAL: | 40 500. | |||

| Roofing device | ||||

| Installation of the rafter design | m2. | 180. | 12 | 2160. |

| Roofing coatings | m2. | 180. | eight | 1440. |

| TOTAL: | 3600. | |||

| Applied materials on the section | ||||

| Tile cement-sand braas | m2. | 180. | 29. | 5220. |

| Sawn timber | m3. | nine | 120. | 1080. |

| TOTAL: | 6300. | |||

| Engineering systems | ||||

| Drilling well | ||||

| Installation of the sewer system (septic) | - | - | - | 2900. |

| Plumbing and electrical work | - | - | - | 4600. |

| TOTAL: | 7500. | |||

| Applied materials on the section | ||||

| Sudtik Uponor (Finland) | set | one | 6200. | 6200. |

| Equipment boiler house Diematic | set | one | 6700. | 6700. |

| TOTAL: | 12 900. | |||

| FINISHING WORK | ||||

| Installation of stairs, joinery work | - | - | - | 9200. |

| Painting and facing work | - | - | - | 6700. |

| TOTAL: | 15 900. | |||

| Applied materials on the section | ||||

| Gulf board boards, lining, etc. | m2. | 320. | 40. | 12 800. |

| Ceramic tile (Italy) | m2. | 69. | 29. | 2000. |

| TOTAL: | 14 800. | |||

| TOTAL: | 133 276. |

The editors thanks the Palex-Stroy and RSM-Stroy company for organizing filming at the facility and for help in the preparation of the article.