Installation of equipment for rotary drilling well

Fragment of the hydrogeological map of the Lotoshinsky district of the Moscow region

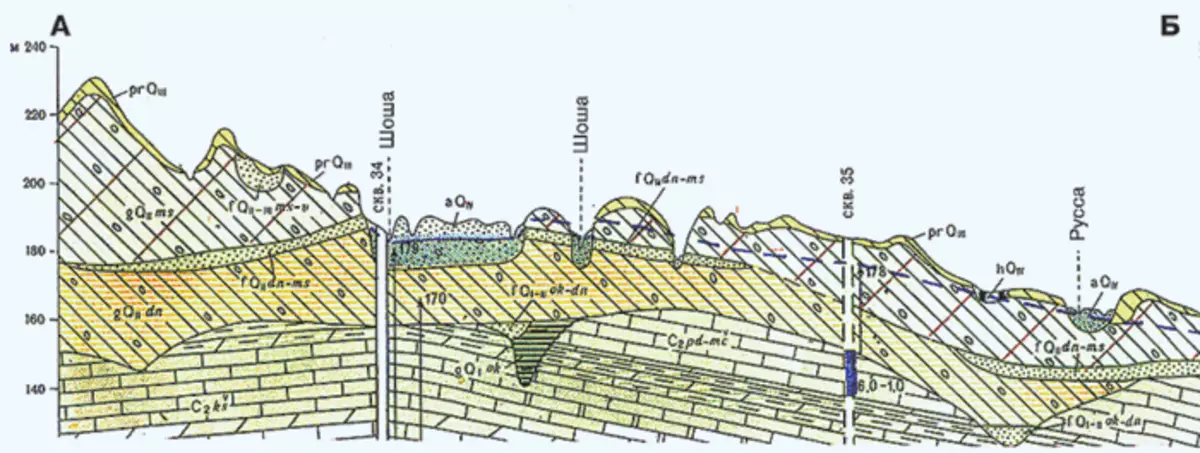

Hydrogeological section of the same section

Borehole pumps are designed to pump pure, non-solid particles or liquids fibers. Usually, these devices are used to supply groundwater to the water supply system for private houses, for irrigation systems and pumping water to tanks.

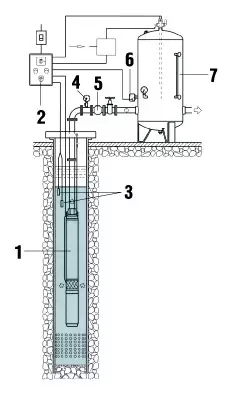

Well scheme in sandy breed

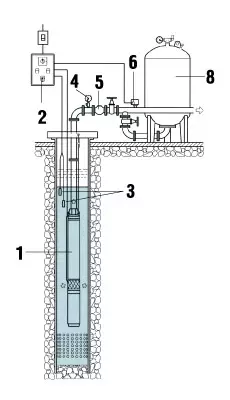

Scheme of artesian well

Over the city, where there is no centralized water supply (or it works inefficiently), wells used to be used as a water source, bores drilled to water-saturated rocks (aquifers). Acceleration water supply There are many advantages compared to well (and, of course, with water fence from the so-called open water sources, lakes, rivers)

Underground water typically distinguishes a much lower level of contamination, abundant "represented" in surface waters - sewage drain, mineral fertilizers from fields, petroleum products, dangerous microorganisms and other "uninvited guests". As a rule, the well provides a steady consumption of water, that is, its constant calculation quantity, regardless of the time of year. In addition, water quality and well productivity (of course, correctly arranged) change little over time. It is not surprising that abroad, such a type of water supply in many cases is considered the only alternative to centralized.

The whole cycle of work on the organization of well water supply can be divided into three stages: the first-preparatory (obtaining permission to arrange the well and preparation of the necessary documentation), the second-drilling, third-selection and installation of pumping equipment. At the first stage, the approximate location of the future well is chosen. It is best if the customer invites the hydrogeologist in advance, which will recommend it really suitable for this plot, taking into account the requirements of the SES on the placement of well water intakes. The cost of such consulting services with the departure of a specialist in the construction site is approximately $ 100. But this amount is incommensurable with expenditures on the design of the package of documents on the licensing of the well. "The price of the question" depends on which aquifer is expected to carry out drilling and how much water is calculated to obtain a consumer. Some building organizations involved in rapid work offer their license issues. It will cost the customer a little more expensive, but the hassle will be much less.

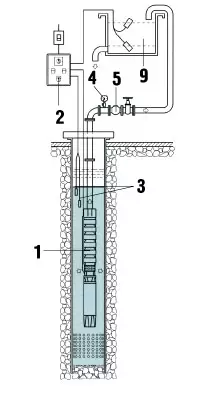

Examples of installation of submersible pumps Calpeda

1-pump, 2-electrical, 3- Minimum level probe, 4-pressure gauge, 5-check valve, 6-pressure switch, 7- pump station tank, 8 - membrane tank, 9- cumulative tank

Sand or limestone?

At the stage of design of the well, it is necessary to determine its type. The wells of two well-drilled wells were widespread to the aquifers and fractured limestone (they are sometimes called artesian). These types of wells differ greatly among themselves. The aquifers are shallow sand, as a rule, at depths of up to 40 meters. The construction of wells "in the sand" is carried out quickly, in 1-2 days, and costs relatively inexpensively: the temporal meter of such a well, about 2-3 times cheaper than bored "on limestone". In addition, sand wells are not subject to licensing. Hospital, they have many drawbacks: relatively small performance (about 0.5-1.0 m3 / h); service life is only 5-8 years due to high rapidization rate; Low water quality, as the contamination from the surface of the Earth albeit in small quantities, but fall in shallow sands (water at a depth of 6-8m for chemical composition can almost not differ from the water from the nearby pond). Due to the low quality water, sand wells are not recommended to be equipped in those places where the risk of surface pollution is especially large. This refers to industrialized and densely populated areas, for example, to the Moscow region. Finally, the aquifers are far from everywhere. The same Moscow region is "rich" in the north-west, and in the south they are much smaller.Metal or plastic?

There are still disputes about what material is more suitable for the manufacture of casing borehole columns. For a long time, steel pipes were considered stronger, more reliable and cheaper. In the early years, however, the cost of metal is steadily growing, and the plastic, on the contrary, is reduced. In addition, metal pipes, no matter how good they are, involuntarily serve as a source of additional amount of iron dissolved in water. For saving on steel pipes, the owners have to "pay" the installation of more expensive filtering systems. That is why the optimal solution from the point of view of sanitation and hygiene will be the use of steel pipes, from within lined plastic.

Wells, drilled to water-saturated fractured limestones, are distinguished by a stable chemical composition of water, high performance, durability (30 or more years). Their depth and quality of water directly depend on the characteristics of one or another region. For example, in the Podolsky district of the suburbs of limestones, close to the surface of the Earth (and even in some way goes on the surface). The wells "On Limestone" in such places can be completely shallow, but the probability of water pollution increases. On the contrary, in the north of the Moscow region, limestones lie at a depth of 100-200 or more than meters. The water in them is reliably protected from superficial contamination, but it happens quite strongly mineralized, contains dissolved calcium, magnesium, iron salts, and other chemical compounds deteriorating its quality.

Subtleties of drilling skill

The cost of drilling affects the final depth of the well, the method of its construction and the diameter of the trunk. Sand wells are often drilled by a screw method using a special auger bore, resembling the outlines of the knife and auger of the meat grinder. The screw method is cheating cheaper (cost 1 m- from $ 30), but applicable only for small depths of wells (up to 20-25m) and, subject to the absence of large-grade rock rocks in the soil, the presence of which significantly complicates its work. The well bury until the layer of the sandy aquifer with a sufficient amount of water is opened. When this horizon is reached, the casing with a diameter of 127-152mm is placed in the wellbore. To install the pump, the well, the well is bueled into the aquifer 2-3m (the interval between the pump and the bottom is about 1m, the length of the pump is about 0.6-0.8m plus the stock on water level fluctuations).The drilling of deep wells is carried out with washing the trunk with clay mortar. After passing the upper sandy-clay sediments and achieve limestone, the casing is lowered by a casing and further drill with clean water. The casing can be made of segments of the steel pipe, cooked with each other or bonded on a threaded connection. The last option is more reliable, since poorly performed welded seam begins to flow over time. The cost of drilling wells "on limestone" is $ 40-100 or more for 1 p. M and depending on the diameter, the number of casing columns, the method of sealing the pipe (the main task of sealing is not allowing mixing surface waters and pollution of the underlying aquifers). In the intelligent case, the casing pipes are laid to the upper limestone layers, and further drilling continues to open the barrel to the full opening of the water-saturated layer. Such a technology is cheapest, but unsafe, since the opening of waterproof reservoirs often leads to a bribe of limestone and the flow of water along the outside of the pipe from the upper sand horizons. Thus, there is a gradual contamination of aquifer and deterioration of water quality. To prevent these undesirable consequences, tamponage is used: the well is drilled to limestone, they put a metal pipe, and then pumped into it a cement solution that fills the cracks and cavities in limestone. The tamponage increases the life of the well, although it increases its construction by 15-20%, but some probability of limestone crown and water pollution remains. Therefore, the optimal (and, alas, the most expensive- $ 70-100 for 1 pm) is considered to be the technology providing for the use of an additional operational column from food plastic. In addition to the level of limestone, the well of a larger diameter was dried, into which one or two columns of steel casing pipes are placed. Below, in limestone, the well is already a well diameter. Inside lowered a plastic operating column with perforated walls. The gap between the columns in the lower part is filled with gravel, and in the uppermost (compact). The gravel cushion serves as protection against casing, and compactite under the influence of moisture swells and hermetically clogs the gap, blocking the path of polluted water from above.

Grundfos experts recommend

Do not hurry with the purchase of a downhole pump. It should be chosen after the well has been drilled. Also, it is also necessary to receive a well passport from the drill organization, where the following characteristics should be indicated:

Debit (well performance, m3 / h);

static level (water level with a non-working pump);

dynamic level (water level at the pump running);

Geometric well parameters.

In addition, for the selection of the pump, the water supply system layout is needed (the number of waterproof points and their location relative to the level of land, the geometric dimensions of the pipeline system). The required supply of the pump is determined on the basis of the number of water treatment points (but it should not exceed the flow rate). Next calculate the necessary pressure head. Since the choice of the device is a relatively complex procedure with the holding of engineering calculations, we recommend entrusting these professionals. It is best to contact the official dealers, providing them with source information. Aoni, in turn, will offer you a suitable model of the pump, as well as accessories for it (pressure switch, tanks, pressure gauges, valves, pipes IT.D.).

Present documents!

Regardless of the type of well, its headpoint must be properly "decorated". This purpose is to build a bubble-beyond 2-well (the simplest options are the simplest options from the finished concrete rings or cooked from steel sheets). Its depth and width should be sufficient to provide the ability to conduct a prophylactic inspection of the wellhead of the well placed in it of the reinforcement (shut-off valve, tee) and parts of the removal pipeline, with which water is supplied to the house. For promotional operation, the water supply should be paved below the depth of the soil freezing. Top of the well closed with a hatch with a lid. After the entire complex of drilling work, the construction company's specialists constitute the so-called well passport. This, in particular, indicates the technical characteristics of the wells necessary for the subsequent selection of pumping equipment.Wilo specialists recommend

One of the important characteristics of submersible pumps is the material from which the impeller is manufactured. If a large amount of suspended particles is present in the water, then the appliances with a stainless steel wheel will last longer. When the filter is chosen correctly and the amount of suspended particles is small, the pump with an impeller from the polymer is suitable (for example, from Norila). For reliable and durable operation, the pump must be equipped with protective automation. Foreign complete set of many models includes a starting box (switch and thermal protection of the motor), an option is also included in the starting condenser there. There are also simpler automation kits:

ER1 is a control device with electronic protection of the motor, test start, the main switch and switch of the operation modes of the pump, indicating the lack of water and the disappearance of the voltage, the potential-free contacts of the indication of the overall malfunction and operation, with a disconnected relay in terms of level;

SK-701- Device for protection against dry motor current and immersion electrode, protection of the current motor and from voltage drops, to control the pump; When the pump malfunction is triggered by separate light alarm;

FluidControl- electronic pressure control and duct control and pump control.

We advise you to establish a membrane pressure tank, which will avoid too frequent inclusion of the pump due to the water supply in the tank. Also, the membrane pressure tank will serve as protection against sharp pressure jumps (so-called hydraulic shocks) capable of damaging hydraulic equipment. Listening to the emergence of force majeure situations (let's say, when the electricity is disconnected), the tank can work for some time as an additional reservoir for water supply.

From the well- to the pump

So, the well is ready, her passport - the owner in his hands, and you can start the choice of the "your" pump. What is important to pay attention to? First of all, of course, it is necessary that the pump complies with its technical characteristics to comply with the task set before it, that is, it was capable of lifting a given amount of water (feed) to the desired height (pressure). The confusion does not normally arise: the device's performance ideally must correspond to water consumption at all points of water intake in the house (bath, garden) included simultaneously in the "unfavorable" combination itself. As practice shows, even for a solid suburban cottage is enough a pump with a capacity of 3-5m3 / h (for comparison: Open at full capacity, the water tap spends per hour 0,6m3 water).

More "tricky" magnitude of the pump pressure. Many mistakenly understand the heights of water levels at the highest point of water treatment in the house and in the wellbore. Meanwhile, in the hydraulic engineering pressure is the increment of the specific (related to unit of weight) of the mechanical energy of the liquid flowing through the pump, or the total amount of energy reported by the pump of the mass of the fluid mass. Ita Energy is spent not only to rise water from the lowest point of the water supply to the highest, but also to create the necessary working pressure in the pipe, and to overcome the internal resistance arising from friction of water about the inner walls of the pipeline. The larger the surface of the walls and a longer and winding pipeline, the greater these conditional meters of pressure is spent on compensating for the loss of friction energy. Thus, the calculation of the required pump pressure should be made on the basis of three factors. The first-geodesic height of water lifting, the difference in the levels between the water-based point (for example, the spout of the tap) and the water mirror in the well. The second necessary working pressure. For comfortable use, water pressure in the domestic water supply should be at least 2 bar, which corresponds to the 20m pressure. If the pressure is too low, some household devices (flowing water heaters, washing and dishwashers) simply will not be able to work, and unnecessarily high pressure is able to withdraw the technique. The third factor of the pressure of water for friction along the entire length of the water pipeline. They depend on the speed of water movement along pipes, roughness of the inner surface of the pipes (using polymer pipes instead of cast-iron pressure losses are reduced several times), the length of the pipeline and the number of its turns. Knowing the required submission and pressure, pick up the pump of the desired brand is already the "work of the technology". But here, to avoid mistakes, it is better to consult with a specialist. Thus, manufacturers usually indicate their models maximum computational pressure and submission. These values are not related to each other, on the contrary, most often with the maximum possible pressure of the pump, its performance will be close to zero, and at maximum flow, the pressure will be extremely low. Therefore, the device is chosen using special charts, on which the pump performance is reflected on one axis, and on the other applied to it. The area on the diagram limited by the curves of performance and pressure is a "working", but it is desirable that the efficiency of the device will be the greatest. Extreme cases manufacturers additionally lead a chart of a change in the PDD of the pump depending on its performance.In the absence of such a schedule, experts are recommended to be guided by the following rule. The point corresponding to the feed and recording of the selected device model must be as close as possible to the center of the chart. If it lies in the area located on the right of the operating characteristics curve, this means that the feed exceeds the optimal (project) value. Operating the device in this mode may result in damage to the nodes and parts of both the electric motor and the pump. If the point lies on the left of the pump working characteristic curve, it is operated at high pressure and low or zero feed. The high pressure in the pump is the cause of significant mechanical overloads, which is capable of damageing the nodes and parts of the device. With a small volume of water supply, the liquid in the pump overheats, and it can also fail.

It is also important to take into account the possibilities for the subsequent "increasing" capacity: if you plan to build a greenhouse in the future, swimming pool, break the garden with an automated irrigation system, then buy a pump more powerful, as they say, with a margin.

| GRUNDFOS BOUNTY PUMP STYLE 1. Built-in return valve that prevents reverse flow formation. 2. Optimal design of impellers, high efficiency, low production costs. 3. Modern bearings that prevent the reverse axial offset and allow you to install the pump also in a horizontal position. 4. "Floating" installation of working wheels prevents wear under the influence of sand. 5. The input filter protects the pump from entering large particles. 6. The electric motor with a rotor equipped with a permanent magnet provides large starting and torque and high efficiency. 7. Corrosion-resistant materials provide a device for a long service life, not worsening the quality of drinking water. 8. The built-in function of protection against work dryly protects the electric motor from damage due to overheating. The built-in functions of the smooth start prevents damage from the hydrowards. Built-in electric motor protection from voltage, overheating and overload oscillations. 9. The hermetic plugger power allows you to easily mount the pump without the use of any tools. |

Under quality sign

The borehole pump is not an electric kettle, which is easy to replace in case of breakdown. Alas, but the work on the extraction of the enveloping pump will cost the owners in the amount comparable to the cost of the pump itself. Therefore, many prefer not to risk and choose models from companies that have long proven themselves in the market with the best side. Among these many years of sales leader is Grundfos (Germany - Denmark), whose products (SP, SQ series pumps) are characterized by good quality. The market also contains products of companies Wilo (Germany), Calpeda, Nocchi Pompe, Water Technics (Italy), Ebara (Italy - Japan).Choosing a borehole pump, pay attention to the following points. First, the diameter of the device case must match the diameter of the well. Most household models have a diameter 4 ", and only SQ Series (Grundfos) - 3. The use of SQ pumps allows you to do a well diameter, which reduces the cost of its arrangement by about 10-15%. Big diameter devices (from 6) are required Only with very high water flows. As a rule, they serve several cottages at the same time.

The casseled pumps are used and stainless steel impeller and engine water cooling, normal for submersible models. This cooling system, however, can fail if the device for some reason begins to work "dry" (say, with a significant decrease in the water level in the well). The work "dry" is fraught with overheating and the output of the device. Manufacturers such as Grundfos provide for borehole pumps built-in drying protection (SQ model).

Specialists of IC "Water Technique" recommend

There is an opinion that it is simplified to take pressure losses equal to 1M per 10m pipeline length. This is a widespread misconception! With the correct selection of pipes (especially plastic, in which the losses are much lower than in the metal) pressure loss can be an order of magnitude lower. In love case, accurate calculations will be required.

The editorial office thanks the company "Watering technology", "Geoprofsservice", representation of Grundfos, Wilo for help in the preparation of material.