With the appearance at the beginning of the 20th century, mechanized sawmill equipment (pylorars) began to actively erect houses from a massive bar. It is easier to construct them and faster than log, since the timber has a given sizes. The facades from the massive timber look quite aesthetically look, if the bars are well strung, and the caulking is made neatly ("pigtail"). Along with the log paversted buildings are considered the best in terms of housing ecology. As a building material, a massive bar is used to this day, but builders and customers have to be reckoned with some disadvantages inherent in it. Dry the timing of a thickness of more than 100mm is almost the same throughout the entire length, because of which the house raised from it will change linear dimensions within one to two years. The timber will begin to dying and cracking, its heat transfer resistance will decrease over time. Without the appropriate processing and impregnation, it will quickly lose its natural color. In addition, an insufficiently protected tree can be an object of damage to beetles, fungus, mold. Linen insulation from interventic seams often plug in birds, and the cracks have to re-pod. Finally, throughout the service life, the house from the massive bar is vulnerable from the point of view of fire safety.

An alternative to a whole bruster and a rounded log was glued with a glued wall timber, the production of which was established in Europe in the mid-80s. last century. It was during these years that Europe began to lack natural building materials. The growing needs of the market and the ecological movement gaining strength prompted Western entrepreneurs to rationally use wood, including partially suitable for construction. New developments of environmentally friendly adhesives and protective compositions made it possible to give products from wood properties of minerals: significantly increase their strength and durability, increase the coefficient of heat transfer resistance, to be immunity to biological and chemical exposure, fire-resistant, susceptible shrinkage.

The wall of the timber is glued together from vertically installed lamella-splits along the length (up to 18m) segments of the specified cross section, having humidity 8-12%. Depending on the thickness and cross section of a bar of the lamellae (usually from 2 to 5), a package for subsequent gluing and pressing under pressure is gaining. The planing machine processes each lamella on both sides (by plastys). Special environmentally friendly glue is applied from the adhesive installation, the main suppliers of which to Russia are Aksco Nobel (Sweden) and "Kleiberit" (Germany). The package is kept in the press to the full polymerization of glue, after which the timber is passed by the final grid under the specified size.

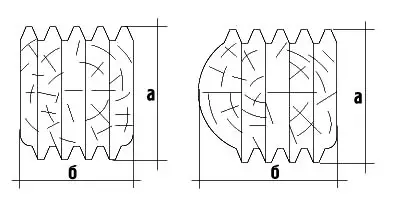

As a rule, the glued bar over the entire length has grooves and ridges of conical shape. The assembly assembly of the house with their help takes the fixation of BRUSEV. Interventious isolation is not required in most cases. Embed from bars with a number of grooves and crests of more than three beats and screws for a screed with adjacent bars are usually not used, since they are tightly pressed to each other due to their own mass.

The beams of overlaps and rafters glue from horizontally laid lamellae without grooves and ridges. If necessary, increasing the span of overlapping in the beams paste strips of metal or fiberglass. From horizontal lamellae, but with grooves and ridges, make composite parts of the slabs of overlapping thickness 100-120mm. This allows you to abandon the use of materials such as insulation and vapor barrier, and mount the floors and the ceilings are perfectly on the lags and beams.

The factory purity of the processing of the facial surfaces of the bar is so high that after assembly their additional finish is optional. The most common cross sections of the glued bar - 200 (185, 150, 100) by 140mm. The outer surface of the wall timber can have a different form: hemispherical, flat with one or two chamfer. Thus, two vehicles with a height of 140mm with one chamfer, connected into the block, have the form of a monolithic bar with a height of 280mm.

In the house built by Polyform, a certified glued bar of production of CJSC "160 DSC Stroykonstruktiya-2" (Korolev Moscow region) was used. The material is characterized by the accuracy of the size and high purity of processing, the subsequent finish is not required. Shrinking timber does not exceed 1%, it does not lose its form and does not crack throughout the life of the house. Moskovsk region glued bar produce at least a ten of companies. There are large production of this material in Sokol Vologda region, in Chelyabinsk, the Komi Republic, in the Far East. In the years, the years there was a tendency to combine the manufacturers of glued timber with construction and investment companies that build whole villages according to typical and individual projects, designed for both middle-class representatives and for those who have to save funds.