Photo of Karen Manko

The floor and part of the walls in the bathroom bath are lined with ceramic tiles. Decoration of shower in a log building- complex operation. Since the tree is unstable, it is impossible to lay ceramic tiles directly on it. There are several ways to facing wooden surfaces.

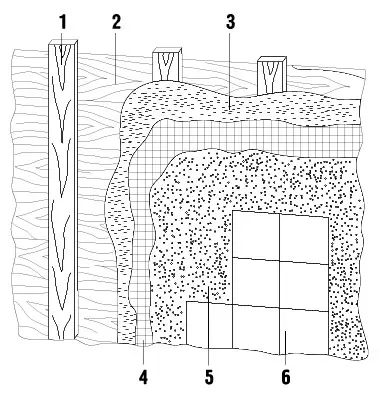

Method first. Wooden rails with a thickness of 20-25mm and a width of 30-40mm in a distance of 40 cm one of the other are nourished on the wall. The tree is coated with an antiseptic that protects it from rotting. Between the rails and the wall lay a layer of roofing or rubberoid. (When changing moisture, wood is undergoing strokes and cracking. The presence of an air layer will protect the facing from damage.) Brokes are nourished with a metal mesh with a cell size of 10-15mm. It is deceived by cement mortar with the addition of fibrous substances and plastered the surface. The thickness of the plastering layer over the steel grid should not exceed 20mm. When cladding with a tile of wooden floors, you must first cut them with a steel mesh, then perform the cutting layer of a concrete mix with 2-3cm with a thickness of 2-3cm, after which it is again to put a metal mesh and on top of the concrete mixture of the same thickness as the first. The resulting surface is cut by a scratch or a nail brush in two directions. The kitel is proceeded after the final grasp of concrete (after 3-5 days).

The method of the second. To finish various surfaces today, moisture-resistant plasterboard (G CLEB) are increasingly used. On wooden walls, the material is placed using frame mounting - on a frame of metal profiles, wooden bars or plasterboard rails. When installing a metal frame, the profiles with a width of the shelf are not less than 50mm and with a pitch of 600 mm, and the G Clac is laid into two layers on each side. At the stage of the frame assembly to it, mortgage elements are fixed (metal strips). All seams between the sheets, the locations of the walls with the floor are sealed with a sealing ribbon and a waterproofing composition.

Facing on wooden rails are made as follows. First, 5030mm rails are fixed to the base. They are equalized by vertical, if necessary, resting wooden bars of the necessary thickness in certain places. To improve thermal insulation between the rails, lay a layer of insulation. Then the wooden frame with insulation is coated with GLB. Walls made of drywall should be carefully covered. Before putting the edge of the sheets at the joints, curved edges are mounted. Since the thin layer of putty does not have a bearing capacity, the surface is additionally ground to enhance the clutch, as well as to improve the waterproofing properties, which is especially important in rooms with high humidity. The primer in liquid form is applied to the wall before facing.

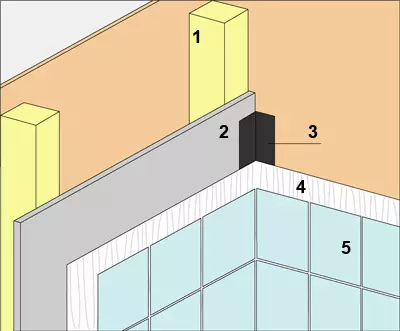

a) Plasterboard laying in the corner:

1-card; 2-plasterboard; 3- seal; 4- tiled glue; 5-tile tile

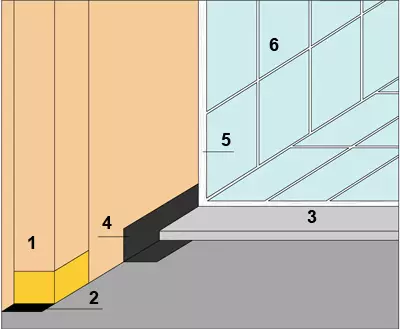

b) Laying drywall at the site of the wall and gender connectivity:

1-frame; 2 tape from rubberoid; 3-plasterboard; 4 - seal; 5-tiled glue; 6-tile

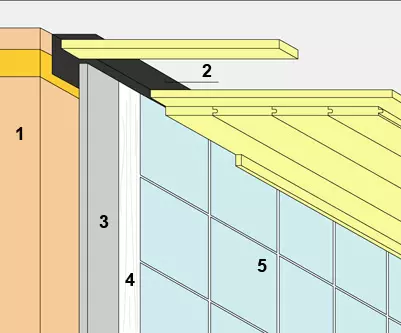

c) laying drywall at the wall connection wall and ceiling:

1-frame; 2-seal; 3-plasterboard; 4-tiled glue; 5-tile