Western House for Russian rubles. Construction of a country house on Danish panel-frame technology. Estimation.

Want to build a high-quality western house for Russian rubles? Do you dream that it is beautiful, warm and long did not require major repairs? And at the same time do not want to turn the construction into an infinite process? Then make interest in how the Danish-skeleton-skeleton-skewers are available to the middle class of Russians are erected in the suburbs.

Golden mean

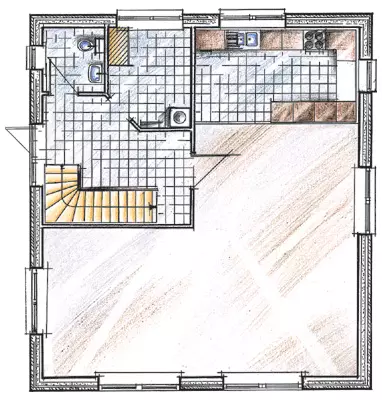

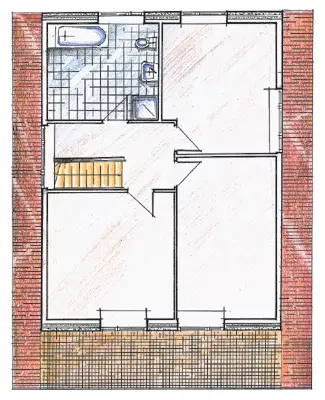

Regarding inexpensive typical houses are built using tested technologies. Individual design increases the cost of the building at least twice. Danish firms offer the customer to choose several options for houses of different sizes. In this case, each project can be finalized. For example, the same building is offered both with a terrace and without it. However, Danes are ready to build buildings and according to individual projects. Twencing two months from the moment of coordination of the project at the factory are collected and prepared for sending all components of the future at home, including consumables. During this time, the foundation is cast on the construction site, water, electricity, gas are mounted to the object.

Brick cladding is needed to increase the energy efficiency of the frame and give the house complete architectural form. The combined structure of the walls allows to facilitate and at the same time strengthen the structure of the house, increase the resistance of walls and windows heat transfer, reduce the cost of construction, speed up its process. Such houses are equally well withstanding the northern cold, and the southern heat, possess wind and seismic stability. Suffice it to say that heat loss construction is reduced to the highest possible level to date. Well: Soundproofing of the walls and floor overlap reaches the value of 45db. This means that in the premises will be quiet, even if construction equipment works on the street.

Of course, it is impossible to attribute Danish houses to the category cheap. The cost of a typical area of 150m2 is 110 thousand (abnormal finishes). But according to Moscow standards, to call such a house, the expensive will also be wrong.

Principle of conveyor assembly

The assembly of the house and its exterior decoration is carried out by domestic personnel who have passed special training or in Denmark or in master classes that the Danes are carried out in Russia. The brigade is armed with all the necessary consumables and tools, including workwear. The use of tools and materials not provided for by the manufacturer's technology is not allowed. All construction operations are carried out by branded manual intended for official use. Each operation is normalized in time, as in the solid dealership. Integration of time saving lunch for workers is brought to a construction site in thermos.

The beginning of time

The theater begins with hangers, and the house is foundation. The foundation laying is preceded by geodesic works, which are drilling the Shurfs in various parts of the territory to identify the soil structure, as well as the presence or absence of surface groundwater. For these purposes, a mobile drilling rig based on the UAZ car is used. Next is the binding of the future home to the terrain. This is done with the help of the theodolitis by the geodesist and his assistant. The data obtained are entered into the cadastral plan of the site compiled by the local land committee.The geodesist makes markup, on the lines of which the pings of the foundation are digging by a manual or excavator. From how exactly exactly and properly cast the foundation depends, whether the combination of wall panels will fall in place and whether the building will be strong. No special documentation for the construction of the foundation of the Danes. The solution of this issue is entrusted by the subcontracting Russian company, which specializes in the conduct of zero cycles.

The requirements of the house collectors are strictly compliance with the strength characteristics of the foundation of the calculated loads (the construction of the building weighing 80 tons will be based on it), the exact coincidence of the foundation tape with the design dimensions of the walls along the axes and the quality of the screed for the installation of wall panels. In the case, the width of the foundation, on which the panels and brickwork are based on 50cm; The screed is made of foam concrete blocks and removed "at zero" with a solution. Savorified buildings The load on the foundations is about the same, so the principles of their construction are a little different from each other. For more information on the device of the foundations of wooden houses, you can read in the articles "When Izba Red Corners" and "House in which the walls help."

Dictionary of special terms

Mauerlat. - Substropical timber.

Gable - Architectural completion of the facade of the building, limited to the roofs.

Dormer - Vertical window in the attic part of the building.

Lucarna - The design forming the opening to install the vertical window on the roof.

The first steps

Work begins with the installation of the frontal wall panel. It is a facade of the whole, with an already inserted window block that does not require additional finishes. For the convenience of mounting at the top of the panel there are hinges from a durable synthetic cable, for which the hooks of the crane chalk hooks (subsequently the loops are trimmed with a knife). The other three walls of the house look also look. There are already windows, entrance and balcony doors produced by the German company VEKA. The windows and doors are made of PVC profile and are equipped with hermetic two-chamber glass windows filled with argon.

The wall of the wall is served as a crane directly from the wagon. The base of the base along the entire length is applied by a pneumatic sealant layer FermaCell (Germany), which in minutes fixes the product set on it. The wall panel is placed on the base and is fixed in a strictly vertical position of temporary disconse from the board. Also, the panel additionally binds to the base of metal linings. Nails in the wall are clogged with a pneumatic hammer. In addition, it already has holes for the bolts (M20, length 250mm), which it will be sealed with an adjacent wall. For the entire operation takes 15-20 minutes. Nails, anchors, bolts, self-tapping screws supplies the German company Wurth. The next wall is placed in relation to the first at an angle of 90. along the line of its adjuncing to the first wall, the layer of glue-sealant is also applied. The connection is made by bolts using a pneumatic wrench (under their walls are made to mortgage threaded sleeves).

Next comes a turn of the installation of interroom partitions. They are similar panels, only with fewer insulation inside. It is also connected to each other with the help of glue and bolts. Partitions are set by a crane in order allowing to provide stiffness of the structure. At this stage, the work is conducted by two collectors and two riggers using only the aircraft with a glue and spanner tube. Simultaneously with the installation of walls inside the box at home, the crane loads small structural elements (packing with mansard windows, consumables IT.P.). Outside in strict order, the facade panels are installed, packed in the blocks of the rafted detail, beams of overlaps. Sensity of unloading has an explanation: payment of carriers of hourly. Workers are confident that the next wagon will come to the construction site strictly on schedule, so they seek to comply with the assembly schedule and not violate the rhythm of work. For the day, they manage to build walls and partitions of the first floor. The construction site remains a security guard; Nevertheless, the entire tool will take care of them.

Full forward!

As in Denmark, work on the Russian construction site begins at 7 am. The first thing to the house is entered the compressor to which the pneumatic tool is connected. WTO Time for unloading The second waga rises from which the frontone panels and the parts of the roof design are retrieved. Two workers begin to build rafters on Earth.

After installing farms, the frontones panel are put. Like the walls, they are one-piece structures with existing windows. Under each fronton at the wall of the wall panel, a layer of glue-sealant is applied. The frontplate panel is put in place and twisted with bolts with extreme farms. According to the project, in the attic part of the house there are two symmetric windows-Dormer produced by VEKA, located in large lugarns on the roof rods. The front wall panels are lug-free with the windows already mounted in them are put on the places prepared among rafters and firmly fasten with them with metal corners. Later, the part of the rafter from the inside the lugar will be carefully drank to form a free space by the window. Insisuses to ensure the stiffness of the connection, the cut parts of the farms are fastened with the riglee from the glued bar.

Simultaneously with the installation of farms, frontones and lug-free two workers are building a balcony. Its design provides variable loads on the support pillars, as a result of which they are made with adjustment nodes at the base. When a balcony shrink, which will occur already during the operation of the building, the pillars can be lifted by tightening the adjusting nut. The technological opening under the door and the window block of the balcony is insulated with plates from extrusion foamed polyethylene.

Meanwhile, the unloaded wagon replaces the third (last), which brought the insulation and engineering equipment. The insulation in the polyethylene packaging is stored outside, the equipment is also (the boiler of the German company Vaillant, a fireplace, boiler, plumbing and water pipes, wires, wiring products IT.P.) It is placed inside the house. The working day ends with the guidance of order on the construction site, loading tools in the car and the transmission of an object under protection.

From above can be seen

After two or three hours of operation, the main actions of the builders focus in the attic part of the house. For prompt access to rafters and subsequent facade works on both sides of the building, light inventory forests are installed. On them moved workers, fixing the beams of overlaps. The design of farms and the rafter system is quite complex, it is replete with articulation made at different angles,

Forward time, not all the beams of ceiling floors are set and fixed, it is necessary to walk with caution. Immediately after they are installed, the temporary boardwalk is laid on top, which can already be moved completely calmly. After assembling farms, workers cover their pair-hydro-insulating membrane Delta-Vent (Germany), fixed on the stapler braces rafters. At first it serves as protection at home from precipitation, and then becomes part of the "roofing pie." The membrane makes a doom and a counterclaim, after which the natural tile of the Russian production "Braas-DSC 1" is stacked. Also, the cake includes thermal insulation from rigid mineral wool plates Rockwool and vaporizolation.

In parallel, there is a preparation for the insulation of the interlated overlap. Al across the beams of overlappings from below, bars are nailed to which the mineral wool mats of the insulation will be relying. A little later, they will be close at the dry ceiling of FermaCell with drying plates. In the meantime, the openings remain open between the beams. Along with the dormer windows, the attic windows of the model GL308 produced Velux (Denmark) are provided in the attic. Workers conduct preparation of openings to their installation. The second day of construction ends with garbage from workplaces, loading tools in special and transmission of the object under protection.

Facade of the house

Over the next three days on the roof and facade of the house there are installers and electrics. The roof is the responsible part of the building structure. The developer attracts a highly professional team of Russian masters from the company "RSM-STROY" for this work, which has passed an internship in Germany. The roof is performed on the patented technology of the German company BRAAS (you can read in the article "Roof of your house"). These same specialists are inhibited by vinyl siding karnis and mount the water-felled production system of the Danish company Plastmo.

Enlarged calculation of the cost of work and materials on the construction of a two-story house with an area of 148m2

| Name of works | Units. change | Number of | Price, $ | Cost, $ |

|---|---|---|---|---|

| Foundation work | ||||

| Layout, development and garment | m3. | 67. | eighteen | 1206. |

| Preliminary work, waterproofing | m2. | 100 | eight | 800. |

| Stone tape base | m3. | 28. | 40. | 1120. |

| Caution lateral isolation | m2. | 140. | 2.8. | 392. |

| TOTAL | 3518. | |||

| Applied materials on the section | ||||

| Stone block | m3. | 28. | fifty | 1400. |

| Masonry solution, crushed stone, crushes, sand | m3. | thirty | 28. | 840. |

| Bituminous polymer mastic (Canada) | m2. | 240. | 3,2 | 768. |

| TOTAL | 3008. | |||

| Walls (box) | ||||

| Installation and dismantling of scaffolding | m2. | 270. | 3.5 | 945. |

| Installation of walls and partitions | m2. | 255. | thirty | 7650. |

| Installation of overlaps, stairs | m2. | 148. | sixteen | 2368. |

| Facing wall bricks | m2. | 76. | twenty | 1520. |

| TOTAL | 12483. | |||

| Applied materials on the section | ||||

| Frame, panels, stairs, etc. | set | - | - | 70,000 |

| Brick facial | PC. | 4300. | 0,3. | 1290. |

| Masonry solution, etc. | set | one | 420. | 420. |

| TOTAL | 71710. | |||

| Roofing device | ||||

| Installation of the rafter design | m2. | 130. | 12 | 1560. |

| Tile Coating Device | m2. | 130. | eight | 1440. |

| Installation of the drain system | rm. M. | 40. | 6. | 240. |

| TOTAL | 3240. | |||

| Applied materials on the section | ||||

| Cement-sand tile Braas (Germany) | m2. | 130. | 29. | 3770. |

| Steam, wind and waterproof films | m2. | 130. | 2. | 260. |

| PLASTMO drainage system (Denmark) | set | one | 450. | 450. |

| TOTAL | 4480. | |||

| Warm outline | ||||

| Insulation of coatings and overlaps insulation | m2. | 580. | 2. | 1160. |

| Filling opening windows and door blocks | m2. | 51. | 35. | 1785. |

| TOTAL | 2945. | |||

| Applied materials on the section | ||||

| Insulation Rockwool. | m2. | 340. | 2.6 | 884. |

| Window blocks veka. | m2. | 35. | 170. | 5950. |

| Mansard windows Velux | PC. | 3. | 530. | 1590. |

| TOTAL | 8424. | |||

| Total cost of work | 22200. | |||

| Total cost of materials | 87700. | |||

| TOTAL | 109808. |

To be continued.

The editors thanks Danhaus for help in preparing the material.