Stained area in the interior: materials used, classic ways to create stained glass windows, new technologies, design techniques.

This mosaic kaleidoscope can bring us back to childhood

The stained glass in the interior will be supported by stained glass products.

The stained steel ceiling not only decorates, but also illuminates

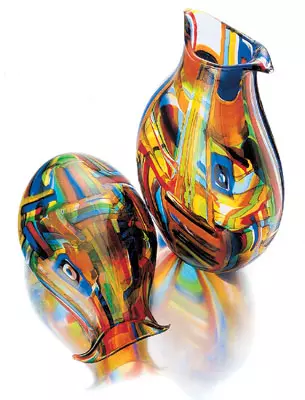

Colored glass vases can be chosen so that they are harmonized with your stained glass windows.

Photo V.Nepledov

With the help of various technologies, mosaic and stained glass windows, it was possible to achieve an interesting effect in the bathroom.

Night-night lamp from frosted white glass with color splashes serves as a continuation of the stained topic

Modular stained steel tiles made in fusing technique combined with conventional ceramic tiles and glass blocks

Conventional glasses in their cabinets can be easily replaced with stained glass, custom in a stained glass workshop. Quam not only will send the measurer, but also fit ready-made stained glass windows

The dimensions of modular stained steel tiles made in fusing techniques may vary from 1515 to 5050cm

This staircase decorated with stained-in backlight approaches, so invites you to climb it. Stained-glass windows decorated windows, doors and partitions

In any interior, this screen will look good, performed in the Tiffany technique.

In one stained glass, a glass of two textured textured "with rain drops" and "precious" convex cabochons

Stained glass window with this weighty dragonfly suitable for wall panels

Metal lantern with stained inserts fill your home with light and comfort

Stained glass is able to raise the mood even on a rainy day. It transforms any interior-makes cozy or strict, saturated colors or monochrome. However, in any case, exquisite, respectable, and most importantly non-worn. Thanks to the backlight, the stainedwalk comes to life and begins to play with all the colors of the rainbow.

The word "stitched shop" has a French origin (Vitrage- "glazing"). Now the pictures composed of pieces of colored glass, through which light passes, again in fashion. However, such works of art do not exist by themselves. The glass composition should be organically enter into the interior so that it forms a single whole with him. There is no way to go. Do not strive to turn your house to Paris Saint-Chapel. The number of stained-glass windows per unit area should be limited, otherwise they will suppress not only each other, but also the whole interior.

Stained glass serves an exquisite decoration of window openings (double-glazed windows with stained-glass inserts), door canvases, walls, sliding partitions, shirm, light lamps of ceilings, furniture, worktops, lamps for lamps, aquariums, clocks ...

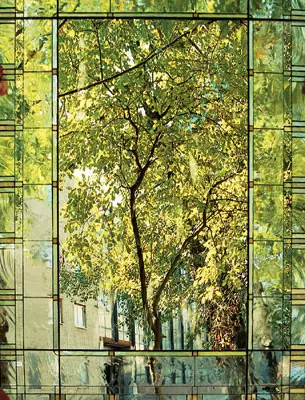

Daylight, especially solar, passing through the window stained glass, as if "worshiped" and transforms the whole house. The rooms are filled with moving non-ferrous air, which fluctuates like a meseno, pleaseing the inhabitants of the house on a permanent game of paints. If the stained glass serves as a ceiling flange, a window-bell or decorative panel on the wall and highlighted, then the space of the house as it is losing and the feeling of depth and additional volume occurs.

Stained glass technology

The art of stained glass is very old. Classic technologies for the manufacture of works from non-ferrous glass have changed little in the entire history of its existence. Each era dictated only a drawing, shades and places of use of such jewelry. We list the classic ways to create stained glass windows and briefly tell about the latest technologies.Types of stitched shops

| Soldered | Seamless | Express stained glass |

|---|---|---|

| "Classic" | Etching | Stained glass designer |

| "Tiffany" | Sandblasting engraving | Film |

| Fusing (sintering) | Lacquer | |

| Casting | Photo Photo |

Set of stained glass

"Classic". This technique preserved from ancient times is durable and beautiful, as evidenced by excellent samples of stained glass in the medieval temples of Western Europe. The artist makes a sketch, then the drawing on the cardboard is genuine value, with the drawing size and color of the elements of the future work. (By the way, for the classic stained glass it is characterized by a geometric pattern with small glass.) Then the glass is cut and insert into the lead (sometimes brass) profile. It moves close to each other, they are soldered on both sides of the stained glass. When soldering use tin solders and fluxes. Then the product around the perimeter is "dressed" into the brass side breakdown and (in most cases) are deduced. The entire lead profile of the soldering is patched, and the stained glass window begins to flicker, like the old bronze (sometimes Patina happens black). Now you can mount this glass miracle. There are similar products expensive (1m2- 800-1500 or more). Classic set of stained glass windows are suitable for decorating various parts of the room and are able to decorate the most exquisite interior.

Stained glass windows "Tiffany" technique - sophistication of lines and colors "Tiffany." For modern masters, this is the second after the "classics" deserving technology, and many practically do not make differences between them. The Creator of the Louis Technology Comfort Tiffany developed it for the production of lamps of lamps from stones of colored glass. Such products were very fashionable in America and Europe at the end of the XIX., They are popular and so far.

Each glass of future stained glass windows turns around the perimeter with a ribbon of self-adhesive copper foil, and then the elements solder. The soldering lines may have different thickness. This technique is ideal for a fine detailed pattern, when small pieces of glass need to be connected by whimsically curved lines. Thin broach makes stained glass light and hard, so it can be given volume forms. Stained glass windows made in Tiffany technique are universal, but most suitable for ceiling plaffers.

Glass is different ...

The most important thing in the stained glass. Russian, European and American firms make material that differs in color and texture. Color stained glass releases Star'Glass (Russia), rolling (patterned, with relief, reflecting light) - ISS (Russia). Textured colored glass is also produced by Spectrum, Armstrong (USA), Czech, English, French and Belgian firms. Some stained glass workshops produce glass for individual works of stained glass, others order it in Russian or foreign enterprises (for example, in Gus-Crystal). It is thin (2mm) and thick (6-10mm). It looks implicitly the faceted glass (Fatset), which resembles a gem inserted in a frame, as well as the blowing (humid), filled with air bubbles, creating a unique game of light. The storage area not only combines in its work different color and texture glass, but even uses a mountain crystal.

Seamless technology

The works of stained glass can be created without the use of metal broach and without spikes are the so-called seamless stained glass windows. Fragments of this product are combined with glue, sacht in the oven at a high temperature ... Stained glass windows made in fusing and casting techniques can crack from drafts and pressure drops if the technology of their production is not met.Etching. The master puts on the glass relief using sandblasting equipment, then paints it with silicate paints and burns in the oven at a temperature of more than 800c. Then the future stained glass windows are treated with hydrofluoric acid. The works made in this way are cheaper than others (from 300 per 1m2). The etching technique allows to achieve relief and gentle color transitions, but in modern practice, due to the harmful effects on the health of the masters no longer applies.

Decoration by sandblasting. The artist with the help of "sandblasting" causes a thickness of at least 5mm stylized (usually vegetable) ornament, sometimes in several layers. It looks like a matte relief in the thickness of the glass and resembles the frost. Such stained glass is ideal for interiors in a classic or minimalist style, when it is important not to overload the space by active color. This technique appeared at the beginning of XXV. And now almost completely suppressed his samples.

Fusing. This technology also does not use metal partitions. On the drawing, made on the transparent glass, placed several layers of pieces, colored glass granules, as well as the charge. Then these multi-layered "pancakes" bake in the furnace, hot to a temperature of 850c. Hence the name - Fusing (translated from English fusing means "sintering"). Such works will cost the buyer from 800 per 1M2.

Casting. Casting technology is similar to fusing and Muranian glass technology. Only in this case, the master fills the molten colored glass into metal embossed forms, which give fragments of the future stained glass not only the desired silhouette, but also the volume. When the forms are removed from the furnace, on the glass, until it frozen, the master inflicts the unique relief. This technology originated on the Italian island of Murano, near Venice. The secrets of glass manufacturing there are gently stored and transmitted by inheritance.

Stained-iron Mix

Many stitches to achieve original aesthetic solutions combine several techniques in their works. Intection-blue set of stained glass include fragments made in sintering techniques, or volumetric inserts made of stained glass, baked in embossed forms (casting); Sandblasting technology is easy to get along with fusing, and he, in turn, with Tiffany. Stained-friendly masters have to combine, it would seem that inequate. For example, glass with ... wrought iron or bronze.

Variations on stained glass

Stained glass window glass- Like a part of the scenery outside the window: Round one-year-old minimal view of stained glass windows expanded: now they include not only works of colored glasses, made on complex classical technology (for example, "Tiffany"), but also various imitation. However, both natural wood furniture differs from laminate and the real stained glass window is different from imitation. New technologies do not assume neither metal broach, nor spikes, nor high-temperature glass processing. Enough to take a brush and colored varnishes - and stained glass ready. For example, film and varnish stained glass windows can do or order in the glass workshop. As for the photoovatra-full-color or double-color image applied to glass or plastic, they certainly have no relation to high art.

Wincice for the cheapness (though, quite conditional is about 250-400 per 1m2) Some stop their choice precisely on such versions. However, we should not forget that the workshops producing lacquer or photovatriates prefer to receive orders for the circulation, and one-only copy will cost very expensive. Yes, it looks like this product is not too exquisite. On their features and appearance, you need to have at least the slightest idea to make the right choice when decorating your interior.

Stained glass constructor. Wimber Dmitry Bogacheva (the company "Jasmy") stained-glass windows are made by own technology based on the constructor method. Stained glass (stained glass or organic) is no more than 4 mm thick on fragments (minimum size- 55cm). To connect elements, the company has developed polystyrene forms. Insert glass and fasten with dichloroethane or toluene. Such a decor is most suitable for risers, as well as windows, doors and partitions.

Film "stained glass". Self-adhesive films imitating colored glass are placed on the glass sheet, and the joints of the films on both sides are closed with a ribbon resembling a copper or lead stretch. The service life of such a "stained glass" is small, and appearance, alas, not too exquisied. Similar products are used for doors and windows of kitchens and children. But the indisputable advantage of this imitation is that it is easy to remove when she get bored.

Varked pseudo-trap. The contour of the picture is applied to the glass of the glass of epoxy resin with dye, and the colored varnish mixtures are poured into the formed cells. Such products make glass workshops. The life of such a "stained glass" is not more than three years. Israza warned: For window openings, it is not suitable - under the action of sunlight, the picture is destroyed right in the eyes and the "skin" peeling with a flat surface.

Alexander Feriaev ("Studio Alexander Faeeva")

Stained-glass windows produce from very "active" material. It attracts attention to color, texture, "works" on clearance or has good reflective properties. Such qualities allow the artist to make an emphasis on this element of the decorative decoration of the interior. The stainedwall attracts his eyes, causes himself to admire. Even architectural or building flaws next to him are not so striking.

I want the same!

Stained glass panels may well compete with picturesque cloths saw a stained glass window, struck your imagination, and decided to order something like this for its interior. Immediately warned: the stained glass should be individual, intended for your home.

If you want to perform your interior designer, consider several nuances. Color glass partially absorbs light, and hence the room darkens. Therefore, in the south, where a lot of the sun, preference is given to stained-glass windows made of dark, saturated colors, and the glass of light shades will be suitable for the north. Often, due to the dense building, the houses window look at the construction site or in the windows of neighboring buildings. Then salvation will be a non-lass matte stained glass window, which will still pass the daylight into the room.

If on your windows windows, then in the interior it is desirable to logically continue the topic. Suppose you have conceived to make a stained glass ceiling ceiling - then make a decision before the start of repair, and not after to provide in advance to provide fasteners. Significantly easier with artistic inserts in the door of cabinets. Let's say, decorate stained glass facades of the finished kitchen quite easily: ordinary glass that you already tired or seem boring, take out, and put on their place made in the workshop by individual order. The same with the doors. An interesting solution will be the creation on one of the walls of the stained glass panel with backlight. A separate topic for reflection - stained-glass winds in the bathroom: this is a decoration of windows (appeared in new buildings), partitions and shirm.

The albums with samples of already completed products will be shown to you by the wizard. Determining with its aesthetic addictions, do not forget about the overall style of the interior (it is better to bring his photos with you). "Stained-sized desires" should be harmonized with scales, layout and color range of premises for which they are intended.

After processing the information received from you, the master-styreman makes the sketches that you as the customer will have to approve. Then the contract is signed, where the timing of the order is indicated (they usually make up three or four weeks) and payment scheme (most of the stained-glass workshops work 50% prepayment).

Delivery and installation of finished stained-glass compositions is better to entrust the workshop. There are small secrets here that only specialists know. (In addition, most often these works are already included in the cost of 1M2 stained glass, so sin does not use the services for which you have already paid.)

Calculate costs

The cost of stained glass depends on the complexity of the sketch and the size of the future work. The quality and class of glass are also important. In addition to stained glass, specifically made: Facet, cast elements, muffins with firing, rhinestone. Their use increases the cost. It's also the price that the price depends is the complexity of the assembly and installation of the work. The most difficult to mount the bulk forms, attach the stained glass window on the facade of the building or on the ceiling. Today, the cost of 1m2 stained glass turnkey is 800-3000 in various firms.Care and restoration

Classic stained glass windows are very durable and durable. Their like family silver are inherited. Considering that this is expensive artwork, pick safe places for stained glass. As practice shows, the door compositions suffer more often. If they scratched, cracked or break, contact a stratified master. Scratches are primed, fragments of damaged glass are replaced with new ones. Creation of stained-friendly masters do not require some special care, and the special "stained-glass" cosmetics also does not exist. Care for them as behind ordinary glass: Wash with contamination with special means and rub the soft cloth.

The editorial office thanks the stained glass workshops "Studio Alexander Freesheev", "Alexandria", "glass man", "Stained-glass window" ("Studio Svetlana Mikhailova"), "Russian window", "Glass", "Studio Alexander Glukhov" for help in the preparation of the material.