Electrical work in the house: practical recommendations. Safe electrical installation.

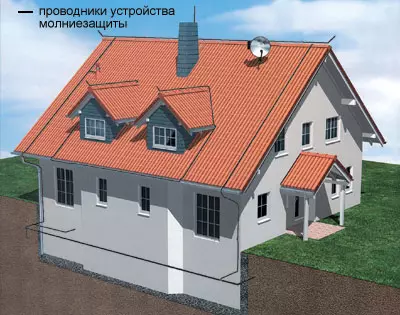

In buildings with metal roof, the external lightning protection system is necessary. One of the options

For hollow partitions and frame walls, special mounting boxes are produced. They are distinguished by the presence of elements that allow them to secure them to the plates with a thickness of 1 to 35mm.

We have repeatedly wrote about different aspects of the problem of the power supply of a private house. They talked a lot not only about hardware, wiring, all sorts of automatic devices, electricity accounting, but also on the allocation of electrical power organizations. Today we will touch the topic of modern practices in the house of electrical work.

Everything flows, everything changes

Over the past decade, the power of the electrical installation has increased almost 10 times, mainly due to the increase in the requirements for the comfort and advent of new equipment. This is the sauna stoves, and the pumps of artesian wells, washing and dishwasher machine IT.D. The consequence was the complication of the concept. The completion of the installation products, along with the socket, switch, protective machine and the meter, includes various control, distribution, switching, protective and control devices. The quality of products has improved, the rules, technologies and methods of their installation have changed. B2004 Instead of the standards of VSN 59-88, regulated by the procedure for the implementation of electrical installation work, a set of rules of the joint venture 31-110-2003 "Design and installation of electrical installations of residential and public buildings". It remains in force on 3.05.06-85 "Electrical devices", which regulates the production of such works as a gasket of wires and cables, installation of grounding devices, arresters, transformers IT.D. Watch documents account for the experience of installing and operating new technology.Electrical installation at home

What components are the modern electrical installation of the house? Without the causthery, say, say: it includes everything that somehow is associated with electrical equipment and purposefully carries out electricity. The boundary between the electrical installation of the house and the transmission line is the injection of electricity in the building - air (from hooks with insulators on the wall) or cable (from the passage of the sealing coupling in the foundation). The electrorestation includes all the instruments included in the chain - from the light bulbs to the razor. Energy consumed by them is taken into account by a single meter. When we say "10 kW electrical installation power, meaning the total power of devices used in the house. The electrical installation is designed depending on the tasks that its user puts before experts, taking into account the characteristics of the engineering structure of the building and materials from which it is built.

What different electrical installations differ from each other? First of all, the capacity, a variety of components and degree of protection against the impact of natural, technogenic and human factors. At the place of installation, they are divided into Open (external) and closed (internal). Outside the house is also a mass of devices and devices related to its electrical installation. This is a wall or garden shield of power supply, pumps (wells, fountains, basin and irrigation system), gate drives and protective blinds, video cameras, electric locks, roof and stairs cable heating systems, landscape lamps. Also part of the external electrical installation at the time of use are electrical lawn mowers, trimmers, garden vacuum cleaners, grills, different types of power tools and other equipment with power supply of the building.

Elements of open electrical installations are Grounding system at home and Lightning protection equipment . If the metal roof is grounded (it is necessary to do it with the rules!), It is also part of the external electrical installation. Correctly calculated and mounted grounding systems and lightning protection protects people from the consequences of direct hit in the building of lightning and the discharges of atmospheric electricity, from the leakage and wandering currents, they save from damage to the internal electrical installation with all the instruments included in it.

By the way, many insurance companies significantly reduce the amounts of risks, if we are talking about a house in which the lightning protection is not established, connected to the grounding of the building and interacting with the level of potential leveling. It is etched by a metal construction from conductive elements that protects the entire construction in the case of direct lightning. The presence of a lightning part, lightning reel, grounding device, a slope for the protection of internal electrical circuits from pulsed (wave) overvoltages. In addition to the system, an active antenna lightning conductor is included in the system, which has the property to accept in advance and carry out thunderstorms to the land until they achieve critical values.

Safety electrical installation

We are indispensable to our readers that any electrical installation should be safe for humans and instruments included in it. The main rule of protection against lesion is reading: "Dangerous current-carrying parts should not be accessible, and the available conductive parts should not be dangerous." Among the measures to protect various devices, an important place occupies the so-called Double isolation . In this technical solution, safety is ensured by enhanced insulation of current-carrying parts, which is also duplicated for greater reliability. Double insulation has modern wires and cables, as well as equipment, which, according to the method of protection against electric shock, is divided into classes from zero to the third. The choice of class depends on the type of room (wet, dry, roast, dusty) and the appointment of the device. The simplest protection (zero class) is used in electrical equipment, designed to operate in the persistent potential, lesion to the current (for example, in residential rooms, where the default is dry). The most complex defense, third-class, is used where the danger of electricity lesion is most likely (napanese, in raw basements).Whatever serious protection measures have been serious, no electrical installation can function normally No automatic power supply devices . Because really effective protection of a person from lesion to the current can only be implemented by the method of turning off the power supply! This operation is performed using Protective automata and Protective Disconnection Devices (UZO) . The first react to a short circuit in the electrocups, the second, non-normal leakage currents, which are a consequence of direct or indirect touch of a man of current-carrying parts, disorders of integrity or fire wiring. Single protective machines ensure the safety and performance of wiring and electrical appliances. The Uzo primarily saves a person life, and also protects equipment from fire.

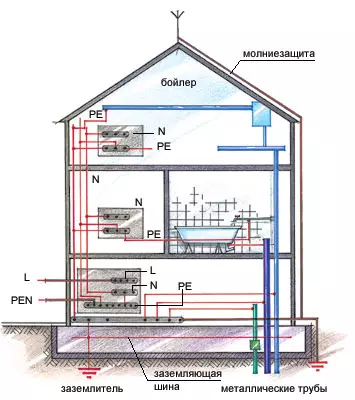

Another safety rule prescribes "grounding and zeroing everything that can, equalize and align any potentials." This is done in order to exclude in the house the possibility of stresses life-threatening people and violating the normal operation of the instruments. Of great importance for security conditions in the electrical installation has the right execution. Systems of equalization Potentials, as prescribed PUE last edition. In order not to overload the reader with special information on this issue, we only explain that the essence of the system in combining with the headed tire of all parts of engineering communications capable of conducting a current. A single chain is associated with all protective conductors, metal pipes of communications of buildings and pipes between buildings, metal parts of building structures and lightning protection, heating systems, ventilation and air conditioning, gas supply, metal electrical supplies and elements of the grounding device.

Ground

Obviously, any electrical work on the plot should begin with the grounding device. Its classical scheme for soils with a low resistivity of 150-200 ohms (not stony), which are characteristic of the middle strip of Russia, is a broken structure in the ground, which includes three electrodes with a length of 2.5-3m in the form of reinforcement sections with a diameter of not Less than 20mm or angle with a width of the shelf 50mm. They are clogged into the ground for the entire length in the angles of the equilateral triangle with a side of 3m. The electrodes are connected by a steel strip by a cross section of about 120mm2 (for example, 304mm) by means of electrical welding. Strip from the grounding circuit rolls into the house. The cost of material for the classic scheme is approximately 900-1000 rubles., And the cost of installation is $ 80-160.

For effective grounding, even in soils with high resistivity, it is recommended to use natural grounding machines: metal casing pipes of artesian wells, water pipes, lead cable shells and reinforced concrete structures of the building are blown in the ground (for example, foundation). Recall that the use of central heating and gas pipeline systems as natural earthing machines is strictly prohibited!

Entry of electricity

The electrical installation begins with the input of electricity to the house. Earlier in the article"How the heart beats the heart" We wrote in detail about the ways of air input into the building. Today we will last in more detail on the cable version. It is performed in the pipes. Segments of asbestos-cement or polymer (PVC, PE) pipes, which are called sleeves are used. In the presence of the basement floor or basement, the sleeve is laid, as a rule, when the foundation is at a depth of 0.8m from the surface of the Earth. If you enter the input at a smaller depth, the likelihood of damage to the cable will increase. In the absence of premises below the ground level, you can choose any other convenient place. At the same time, the cable is paved along the outer wall of the building (regardless of its material) and be sure to protect the suitable cross section from damage to the steel corner or chamber. Subsequently, this unaesthetic element of the facade can be reappeted. Entering into a wooden wall is made through a pipe from a non-corrosive material (steel, cast iron, asbestos).

Underground entries in the building (however, as an air), and especially if there is a basement or ground floor, it is necessary to sealed in order to avoid moisture from the ground and especially gas, such as methane, radon (the strongest carcinogen!) IDR. The selection of sealing material is based on two conditions:

When repairing and replacing the cable, the sealing material should not interfere with the work.

Since due to the movement of the soil and periodic heating and cooling cycles (under load conductive cores are heated, and when it is turned off, there is a change in length, the cable moves in the sleeve, sealing materials must be plastic.

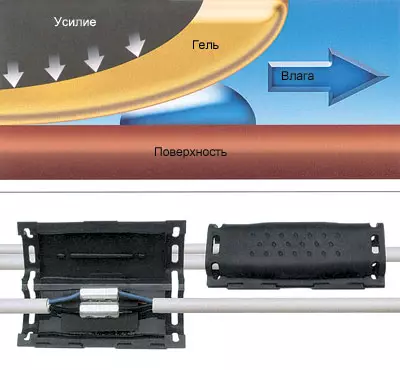

Along with the traditional method of sealing the cable entry channel at easy-to-wave tube from a mixture of perlite and building gypsum (option: clay, cement and sand), which does not provide one hundred percent tightness of the wall, since it is easily cracking in cable moving, there are more advanced patented technologies. They are developed by Raychem and 3m. According to Raychem technology, the cable pass is compacted by one of two ways: either with the help of self-tight hermetic seals made of polymeric material (they are fixed on the pipe of the penetrations, and others are tightly seated on the cable itself), or by sealing the channel from the inside expanding seals. If you need to repair or replace the cable, these elements are easily removed, and then restored.

Raychem technology is especially convenient in the case when the passage is performed using a pipe stamped into the wall. But if the hole in the wall has an irregular shape (and this often happens when it is punched by a perforator after the construction of the foundation for cable input in a new place), the tighting technology is more suitable from 3m self-sewing compound. It is possible to seal the passages performed by one or more cables (pipes) in both underground and terrestrial parts of the building. The cable previously treated with a special composition is shaken by a bulk reinforcing grid, which is placed in a sealed channel cleared for greater adhesion. For the supply of a compound to the channel cavity, two plastic tubes are introduced. Outside and from the inside the hole is muffled in a foam ribbon. The compound through the tubes is extruded from the package to the cavity of the channel, where it is expanding, penetrating into the smallest pores and cracks. The polymerization of the material lasts at least an hour, after which the passage is ready for operation. If necessary, the seal can be easily deployed, removing the compound from the channel with a screwdriver. The cost of expanding seals Raychem- $ 50. Price set 3m- $ 83.

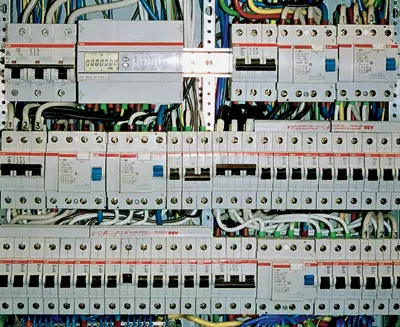

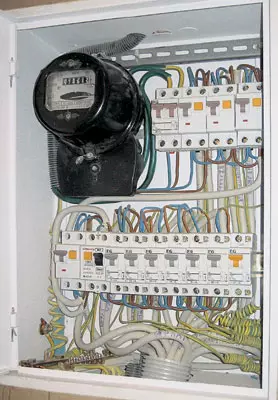

Enter distribution devices and switchboards

In the order of electrical installation elements are input and distribution devices (SERM) and switchboards. Which there is a difference, you ask. I am lying, this is the main shield, which includes a counter, protection machines, RCD, sometimes voltmeters and other newest devices (for example, insulation control), as well as switching devices, for example, disconnecting a group of consumers in the event of a team receipt. Distributing devices are additional shields that solve the same tasks, but only local nature. They are put on separate groups of electricity consumers, for example on a separate floor or in the sauna pre-banker, in the boiler room, bathroom, pool. This is done in order not to overload the LED various devices, as well as not to pull a large number of wires from one end of the building to another to each consumer. It is enough to bring one cable of a larger cross section to the distribution shield.

The disadvantage of the electrical devices of the new generation became possible that earlier in the electrical engineering was not allowed. Recompute with new rules, LED and shields are now allowed to be placed not only in specially created dry rooms, but also in any convenient and accessible places, provided that the degree of protection is lying will not be lower than IP 31. But still prohibinant I lie and switchboards in rooms located directly under the toilets, bathrooms, shower, kitchens and washing, except in cases where special measures have been taken to create reliable waterproofing of these premises.

Almost all the largest international companies, including ABV, General Electric, Gewiss, Legrand, Schneider Electric (European Union), Spelsberg (Germany) IDR, produce hand and distribution panels of second-class protection against electric shock. They are well protected from dust and moisture ingress (before IP 65) and can be installed almost everywhere. The region of their application is, raw and especially raw rooms, from the point of view of electrical engineering related to the category of hazardous and especially dangerous. These are garages, basements, wine cellar, swimming pools, baths, bathrooms, greenhouses and winter gardens. So, shields of impact-resistant and fire-resistant plastics for various purposes of the Fix-O-Rail Junior series from General Electric, EK, AK, AK-Plus, LK, ZK, LTK from Spelsberg are suitable for mounting any devices with dust and moisture degree from IP 54 to IP 65. Additional sealing of these products is ensured by using special sealing couplings on the enclosure of the wire (cable) in the shield. This class of plastic models can also be highlighted relatively cheap, durable, reliable and easy-to-install Kaedra shields from Merlin Gerin. Depending on the size of their value ranges from 280 to 1000 rubles.

Sealed wall metal shields with degree of protection against dust and water on IP 55/65 is in the assortment of the Italian Gewiss company (47CVX, 46QX and QM series), Siemens (Stab Series) and Legrand (Plexo). They cost from $ 50 to $ 200.

Connections and contacts

Special attention in any power grid are contacts and connections. In80% of cases, their faulty work is the cause of various refusals of the technique, up to the exit of the electrical installation and the occurrence of fire. Cleverly performed twist, "unconctricated" screw contact will be spoken and warm, which can lead to a violation of the integrity of the wiring insulation, cause damage to the junction box, socket or switch and even melting plastics and the ignition of the base. That is why, despite the appearance of all sorts of automatic devices, almost instantly disconnecting emergency chains (read more in the article "Online"), the quality of electrical wiring connections should always be paid to high attention.Recommended Time is increasingly used by spring connections of wires both in the input and distribution devices, distribution and branching boxes and in the terminals of lamps, sockets and switches. They produce Wago, Woertz, Fenix Contact, Legrand, Kopp, ABB and some others.

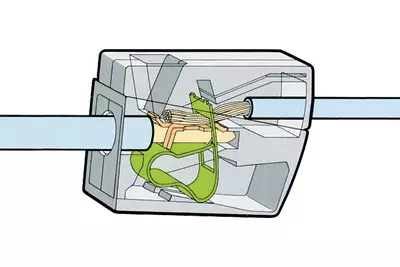

Connecting terminals . Construction and assembly terminals for mounting sockets and lamps, ordinary and passing terminals for mounting on a DIN rail, detachable compounds, which is not a complete list of electrical installation products of the last generation, which are supplied to the Russian market. The main difference of new terminals from traditional lies in the fact that the electrical conductors are connected not by the screw, but Through spring clamp . The benefits of the use of spring-clamping system double. In addition to reducing the assembly time, the quality of the contact is also increased, provided by the clamping force corresponding to the cross section of the conductor. A results arise resistant to vibration and do not require technical care (as opposed to screw) clamping devices. For now, they are used both to connect only rigid single-core (single-wire) conductors with a cross section of 0.5-4mm2 and for any, including multi-flow, cross section of 0.08-35m2. For the case, the conductor is simply inserted into Plancreen clamp . In the second, first mechanically, by pressing or opening a special lever (series 222 from WAGO), a spring is squeezed and only then pasted and fix the conductor.

Construction and assembly terminals With a flat-spring clip are designed to maintain a reliable and compact electromotion in junction boxes. There are "dry" terminals (Legrand, ABB IT.D.) and filled with the conductive paste (WAGO), which, when connecting the conductor, automatically removes the protective oxide film from it, lubricates and reliably protects against re-oxidation. Construction and installation terminals are available for compounding 2-8 conductors of different sections, each single clamp is allocated. Do not require additional insulation, since they have a plastic case, providing safety during electrical installation. The reliability of contact eliminates the occurrence of short circuit. Separately produced terminals For connecting the lamps . The sides, they have a plane clamp (for rigid and single-core conductors), and on the other, the opening clamp for multi-boosters, including tinned, copper wires. Also there are "dry" and filled with the conducting current paste. Terminal value from 10 rubles.

Traditional Screw connections Also are constantly modified. For example, Tyco Electronics Group of Companies uses universal clamps in its products with separate attachment and an insulating cap. They allow connecting wires with a cross section of 2.5-25mm2 and perform branches from them with a cross section of 1.5-25mm2. To protect such compounds in the splicing of cables and performing branches, connective, branch and repair clutches with gel filling are used, which protect compounds from oxidation and do not penetrate them with gases and moisture. The cost of TYCO Electronics clamps is from 20 rubles.

Sockets, switches

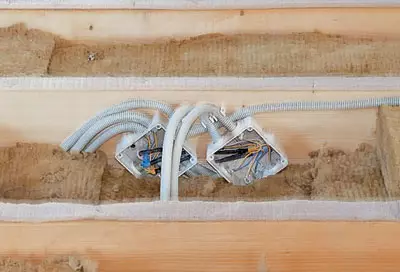

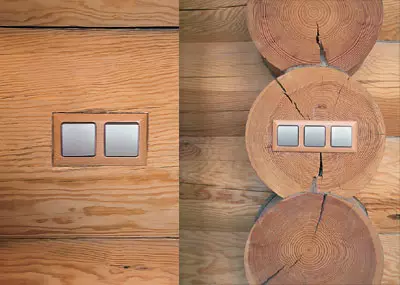

It would seem that in such a region as electrical outlet and switches, nothing new can already be. Nevertheless, it is not. The technology of their installation is also improved, and the design itself. With hidden installation, they are installed in universal mounting boxes, manufactured mainly from plastics. The black side of the box are easy-to-wave plugs, designed to enter wires of various diameters and tubes that protect them. Boxes intended for mounting in hollow walls are equipped with special fastening screws with legs capable of fixing the product on the front surface of the wall made from any material thickness from 1 to 35mm. Holes under the boxes on the hollow walls are drilled by a drill with a special nozzle, the diameter of the cutting part of which is equal to the diameter of the box. Standard diameter - 68mm.

If the mounting boxes are installed in the stone and concrete walls, the eyeliner is carried out through the channels in the wall panels or through the flexible plastic corrugated broth. The box itself is usually fixed in the holes of the wall with plaster, cement-sandy solution or special glue. According to experts, sealing alabaster is unacceptable, because when drying it increases in the amount, which further makes it difficult to finish. Holded houses the box is fixed in the prepared hole with the help of self-tapping screws. Plugs or elastic membranes located around the circumference of the box, allow you to seal the locations of the wires. Boxes can be connected to blocks.

In the Russian market in a variety of options, the ABB and its Busch-Jaeger Electro division, as well as Btichino, Legrand, Simon, Spelsberg and Russian manufacturers, such as GUCY, are presented in the Russian market.

Sockets and switches are also improved, and not only in terms of design. They are increasingly released with the eventless (spring) connecting contacts. Often, pair terminals are installed in sockets - to ensure switching two conductors, for example, with a parallel installation of several sockets in one block. Increased reliability of contacts between plug pins and socket sockets guarantees a triple pin. Modern switches provide the ability to quickly switch without intermediate positions due to the special form of contacts. This is carried out by the so-called forced poverty. Patented on / off mechanisms appear, as, for example, in the Impuls series from ABB. The Impuls return switch allows you to perform an action by pressing any point of the key. Recognized leaders in the field of production of high-quality sockets and switches are ABV, Btichino, Jung, Legrand, Simon, Kopp. A variety of wiring products of the new generation are supplied to Russia from Korea, China, Turkey, the Czech Republic and Romania. Release innovations and Russian firms. The cost of sockets and switches, depending on the producer and brand country, varies within $ 5-50.

Wires and cables that do not support burning

Whatever perfect compounds, due to a short circuit, due to the untimely triggering of automata protection, the absence of the UZO and in the event of a fire construct, the insulation of the cable may catch fire. The result is a large amount of smoke containing poisonous combustion products. This chlorine, dioxins IT.P. From this not it follows that you need to abandon the use of traditional wires and cables, widely represented on the Russian market. When complying with the rules of installation and operation, each brand of wire or cable justifies itself. Nevertheless, new, increasingly perfect types of wires and cables appear constantly.

Even in the seventies, AEG began to produce cables that do not support burning, non-poisonous gases, little smoking and non-active corrosion. Evroinskaya regulatory documents such wires and cables received the designation "NG" and "NG-LS". According to the new rules, in buildings with construction structures made of combustible materials of G2 and / or G3 groups (the latter includes log walls and wooden panels), an open laying of single cables and wires in the protective shell "NG" and "NG-LS" is allowed With copper cores with a cross section of no more than 6mm2 without an insulating substrate, as well as their hidden wiring in the layer of plaster. That is, they do not need cable channels and protective sleeves for their gasket. Wires and cables of this type are more expensive than usual, however, in some cases, their use allows you to solve specific engineering problems, somehow: to provide additional safety of the electrical installation, not to stick the walls of the IT.P.

Deliveries of non-burning wires and cables in Russia are engaged in Pirelli (Nokia) and Nexans. The Russian manufacturer of similar products is "Sevkabel". For gas laying underground, the Austrian-LS cable is produced, for the internal space-hub-Ls.

Of course, little smoking cables are good, but the electrician practice shows that open wiring without cable channels is not so often. We have already spoken above that in brick and monolithic buildings, the gasket of a protected corrugated tube (with a diameter of 16mm under the wires with a cross section of 31.5 and 3 2.5mm) NYM type cable is performed in the strokes. They are cut in the wall with the help of a special tool of stroke-cutting (gorozdowel), which significantly increases productivity. When the walls of the drywall, the cable is laid between metal rims of the frame.

The main feature of the electromotion in frame and wooden buildings, in contrast to stone buildings, is that here, according to PUE, the hidden laying of wires is permissible only using non-combustible metalworks or metal pipes. When building a house from a log or bar, they are laid in pre-performed holes and channels. Insertion installation is similar. The arsenal of modern electrical equipment and electrical installation materials are so wide that it is simply impossible to embrace in one article.

The editorial board thanks the company ABB, Legrand, Master Electric and Head of the Department of Engineering Ecology of the Moscow Institute of Radio Engineering, Electronics and Automation Associate Professor V. K. Monakov for help in preparing the material.