Modern automatic control systems: their advantages, characteristics and operation.

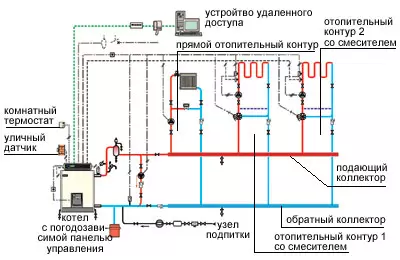

Collective strapping boiler

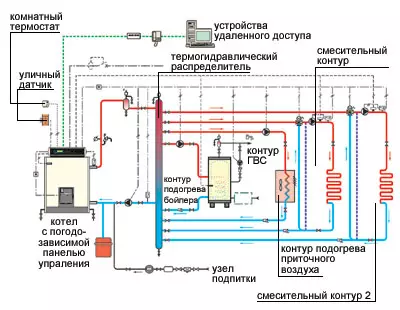

Scheme for performing a boiler room using a thermohydra-lyric distributor developed by de Dietrich

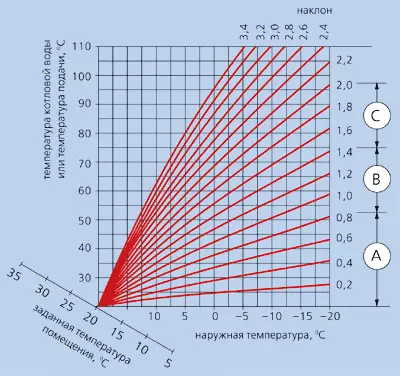

Family of heating curves. Lines with a large inclination are used for buildings with a low thermal insulation and vice versa

Planning home heating device, only a few consider the possibility of working boiler equipment with modern automation systems. Aveted Such systems are currently widely distributed and are designed to increase the comfort of dwellings and significantly reduce the costs of its heating.

Advantages of automatic control

Modern boiler room is impossible to imagine without automation systems that united all the latest achievements in the field of heat flux control. It is noteworthy that for most people so far, unfortunately, the main criterion for the quality of the heating system remains the principle "warming is not heating." He is absolutely not applicable to automated heating systems, few people assess the significance of the installation in their boiler house special automation, which would provide the maximum level of thermal comfort in the house.To date, it is significantly reduced by heating costs and at the same time to form a favorable temperature background in the house for only the modern thermostat system. This is due to the optimization of the work of all components of the heating equipment. Note that almost all boilers in their basic configuration have a standard automation that controls the burner, takes signals from the boiler security devices, and also supports the desired coolant temperature. Please note: it is the "boiler" temperature, and not room. What does not save the user from the need to constantly adjust this temperature depending on the need for heat.

By installing such an imperfect equipment, you involuntarily encourage yourself to the eternal "Watch" to the Handle of the thermostat: when the street temperature drops, water in the system will need to heat stronger, and when it is warm-up on the street. It is possible to effect these manipulations with a thermostat to infinity. But if at the onset of cold weather "Discontinuity", the boiler falls by the Will-Neils (otherwise accommodation in the house becomes problematic), then when warming, as it often happens, to reduce the temperature of the boiler water, it seems not necessarily. After all, as you know, pairs of bones will not lie. Yes, and did not transfer more among us lovers to open the window when the room becomes too hot.

Naturally, this approach to heat and energy saving will notice the homeowner affiliate after a short time. Just just because of the overpowering of fuel. AVEDE Trend of rising prices for basic energy carriers, clearly manifested in recent years, according to experts, will continue in the future. Of course, there can be no speech about any thermal comfort with such methods of thermostat. According to experts, the user of the boiler, which is not equipped with the automation system, spends more than 210 hours of personal time per year only on setting the coolant temperature in the boiler!

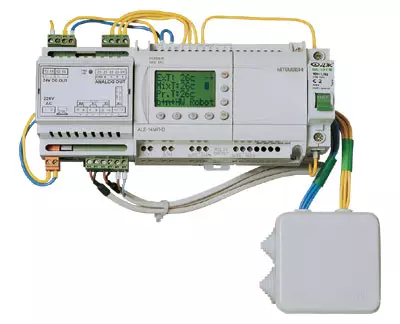

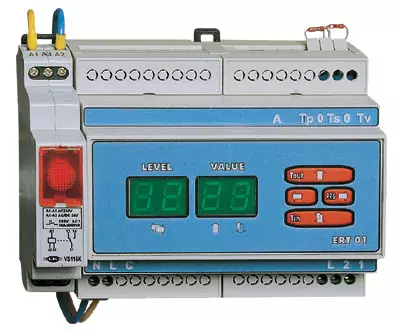

Another business is modern microprocessor control panels. They allow you to maintain different temperatures immediately in several heating circuits. Under such a contour is a part of the system working with its temperature and hydraulic characteristics and having the possibility of their adjustment. This, let's say the contour of radiator heating or one contour of water warm floors. For example, the system R 33/4 Digi Comfort from Wolf controls four independent circuits, and the Color Matic from Vaillant has the ability to control the work of fifteen immediately, and the temperature of the coolant inside them directly depends on the state of the weather on the street. Systems with such a principle of regulation are called meteo-controlled or, as experts say, weather-dependent (about the principle of weather-dependent management we will talk below). To control outdoor temperatures in these systems, a street sensor is used, installed on the building outside, from the north side. The controller (programmer) of the system is also fully responsible for the process of cooking hot water in a boiler.

Extract systems laid the principle of modular construction. It allows you to equip the system for a specific situation and customer requirements, as well as connect additional contours and control their operation by installing the corresponding module, without replacing the control panel as a whole, which gives significant cost savings.

Today, the Russian market is widely represented automatics from many foreign firms, for example KomexTherm (Czech Republic), Siemens, Kromschroder (Germany), Roca (Spain), Mitsubishi (Japan), Coster (Italy), Honeywell (USA), and some other firms.

Separately, it should be said about automatic control systems offered by the manufacturers of heating equipment such as Viessmann, Wolf, Buderus, Vaillant, Junkers (all Germany), de Dietrich (France), CTC (Sweden), and near others. The systems supplied by these firms today correspond to the most modern concepts of "heat management" and are distinguished by high reliability. Such automation allows you to solve almost any tasks associated with the control of thermal processes, and ensures safe operation of the equipment. Doggeds of these systems include relatively high costs, from 650-700 to 2000-2500 or more.

Heating contours

The implementation of automated weather-dependent heating is complicated by the fact that in modern practice it is necessary to manage a non-one contour of the house heating, but a system with several contours. Let's try to characterize them.

Almost always there is a radiator heating contour. To effectively manage it, it is necessary to maintain the flow temperature in the range of 50-85c. Sometimes several such contours are installed, for example on different floors of the house, and the temperature in them can also be different.

If independent electrical or gas water heaters are not installed, then, as a rule, they provide high-temperature (up to 70-85c) contour of heating hot water boiler. The temperature of the coolant in it should be constant.

Comfort requirements invariably grow, and today many consumers order an additional installation of one or more contours of water warm floors. This is low-temperature systems with a variable feed line temperature (30-55C).

If there is a swimming pool, water in it probably wants to have warm. To do this, a special circuit of water heating system in the pool can be mounted. It is high-temperature, with a constant temperature of the coolant 70-85s.

Similarly, heating the pool is arranged the contour of the heating of the supply air in the heat exchanger of the ventilation system. But, on the project, the temperature of the coolant here is not necessary to be constant.

Water consumption through radiator and circuit of warm floors can be variable. This is happening in cases where, for example, thermostatic valves with thermal heads are installed on radiators, the function of which is to change the flow rate of the coolant through them and, accordingly, through the entire heating circuit as a whole. Similarly, separate thermostators can be installed on the camshaft collector of the warm floor system.

The principle of weather-dependent regulation

Let us explain how room temperature is maintained, taking into account changes in the street. When setting up the controller, the so-called temperature curve is set, reflecting the dependence of the coolant temperature in the heating circuit from changing weather conditions outside. This curve is a line, one point of which corresponds to + 20 ° C on the street (while the temperature of the coolant in the heating circuit is also + 20 ° C, since it is considered that under such conditions there is no need for heating). The second point is the temperature of the coolant (say, 70c), at which even in the coldest day of the heating season, the temperature in the room will remain specified (for example, 23c). Otherwise, if the building is insulated enough, to compensate the heat loss, there is a slightly large temperature of the coolant in the heating circuit. Accordingly, the slope of the curve will be cool. In turn, if everything is in order with the thermal insulation of the house. In the manufacture of a controller in the memory of the device, many similar curves make it possible to then choose from the entire family of a suitable line specifically for the conditions of your home.

As a rule, to create a maximum level of thermal comfort, as well as to save fuel, one-sole street sensor is not enough. Therefore, an additional sensor is often mounted inside the heated room. The presence of two sensors, and room and outdoor, allows you to accurately track and quickly adjust the temperature in the rooms at home.

Typically, the room temperature sensor is installed in the so-called reference room, the temperature in it will fit your concept about a comfortable thermal background. This room should not be heated with straight solar rays and blurred with drafts. As a rule, children's and bedrooms are chosen as a reference. Installing the room sensor makes it possible to enable self-adaptation mode, in which the heating curve is selected for the appropriate room automatic microcomputer control panel. In addition, a often room sensor integrate into a thermostat, with which you can set the desired temperature and its average level in the whole house. Local temperature adjustment in a separate room at the same time is achieved by setting thermostatic valve thermostatic valves.

A very important aspect of the use of the thermostat is again saving fuel. Let us explain how it is carried out. Suppose in the room where the sensor is installed, guests gathered and there was an increase in the temperature of 2C due to the natural heat generation of people. The control panel catches these changes and gives a command to reduce the temperature of the coolant in this circuit, although the street sensor may require the reverse. Reducing the heat consumption for heating this premises naturally saves fuel. But there are problems here. If you flood in the room where the thermostat is installed, the fireplace or leave the window open for a long time, it can lead to a change in temperature throughout the house. For accounting for such factors, many systems provide for the possibility of amending the control algorithm by setting the coefficient of the influence of the room sensor on the character of the heating curve. But in general, experts simply do not recommend installing room temperature measurement devices near the fireplaces, entrance doors, windows and other heat sources or cold capable of making an error in measurement results.

Attention should also be paid to the fact that the installation of a room thermostat alone, without an outdoor temperature sensor, significantly increases the inertia of the thermal control system. Changes in a thermal background will occur with the receipt, since the automation will begin to act only when the temperature in the house, for example, decreases, and this will happen later than the real cooling on the street.

Modern controllers not only follow the weather, but also have a sufficiently large number of functions, some of which are custom, and part-service. If the first is on guard of comfort, the second is followed by the state of the system and ensure the right and safe operation of the equipment.

Schemes for strapping boiler and contour management principles

In order to organize the work of one or more heating circuits in the hydraulic system, they must be connected to the heat generator-boiler. This task can be solved in different ways, experts call them strapping schemes of boiler rooms. Consider the most common of them, as well as the principles of organizing the relevant management process with all their advantages and disadvantages.

The heating circuits by the method of achieving the temperature in them are divided into direct and mixing. The temperature of the water in the direct circuit is achieved only at the expense of the burner and depends on the duration of its operation. The temperature of the coolant is determined both the operation of the burner and the position of the valve of the actuator-mixer with a servo. After resorting to the first embodiment, you can easily associate a low-temperature boiler with one loop of radiator heating and provide automated control of it depending on the outdoor temperature. The point is quite simple and relatively inexpensive. If it is necessary to organize, in addition to heating, and hot water supply, and without resorting to mixing nodes, two types of schemes are used. The first is a three-way crane, the second scheme with two pumps.

The simplest is a diagram with a three-way switching tap equipped with a servo. Water from the boiler is sent to the crane, which, in turn, directs it either to the heating circuit or in the heating circuit of the boiler. Switching can be carried out as manually, which is usually time consuming and on the boiler control panel command. Water temperature control in the boiler carries out automation using the temperature sensor installed in it. Once the water cools down below the required level, a command is fed to switch the three-way crane. Please note that with this scheme of strapping and control during the heating of water in the boiler, the heating is turned off (that is, it is impossible to organize the control of hot water supply with a mixed priority).

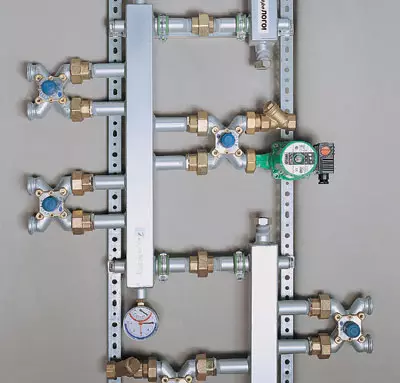

The collector scheme, as follows from the name, involves the use of boiler household collectors, which are pipes with conclusions on the required number of contours. This scheme, being quite simple, was widespread due to the appearance of the so-called quick installation components. The composition includes pumping groups that are now produced by many manufacturers of heating equipment, including CTC, Buderus, De Dietrich, Viessmann, Wolf, Vaillant, as well as Meibes (Germany). These devices allow you to quickly (the binding of the boiler room takes a few days) to assemble a system with several heating circuits. However, it should be noted that similar modules are mainly applied for boiler room small power - up to 85 kW. Nevertheless, they are extremely convenient when installing and significantly reduce the risk of error due to the notorious human factor, since they are collected and tested for performance and tightness in the factory conditions.

An interesting option for the strapping of their boilers offers Teledyane Laars (USA). This refers to the diagram of the primary and secondary rings, the principle of operation of which is: boiler water is constantly circulating in a small contour (primary ring), from which, with the help of circulation pumps, the coolant is taken by other heat consumers (various contours). The advantage of this scheme is the ability to connect a large number of secondary contours while ensuring the rated speed of the duct through the boiler and the relative simplicity of the design. To facilitate the installation process of the boiler room according to this scheme, ready-made kits are offered (for example, "hydraulic", manufactured by the Russian hydromontazh).

De Dietrich (France) recommends applying a thermohydraulic distributor (abbreviated and TGR) to be applied to strapping its boilers. When it is used, the constant consumption of the coolant is achieved through the heating device, regardless of the water consumption value in the heating circuits, where this indicator may be different. As a result, it is possible to achieve optimal balanced boiler and heating circuits.

It is important to note that the automation of many manufacturers allows you to control the boiler and contours in a wide variety of strapping schemes boiler room. However, the search for the most suitable option and the selection of automation is still better instructed by a specialist.

Custom functions

The user functions are primarily among the various heating programs that allow you to adapt the heating mode at home to the rhythm of the life of its inhabitants (sleep and wakefulness, vacation, seamless work). Similarly, hot water programs are selected. If the user does not suit any of the standard set, which is proposed by the manufacturer, it is possible to create its own individually for heating and hot water supply.Mode "Good night" . Almost all systems have the ability to install the so-called night temperature. Scientists have proven that the sleeping person feels much more comfortable when the temperature in the room slightly decreases (usually by 4C) relative to day room room (obviously, such a reaction was formed in humans during evolution and reflects their adaptation to natural temperature differences in day and night hours ). Now, all the thermal processes are inertia, and if, for example, set the time of the day of the day program at the time of your awakening, then, getting out of bed, you will feel some discomfort due to the fact that the room has not yet had time to get warm after the night. To eliminate this disadvantage, in many modern controllers use the pre-warming mode of the room (sometimes called smooth output from the night mode), according to which a few hours before your lift, the temperature in the house begins to grow smoothly. Such a function has, for example, the controllers of the Diematic family from de Dietrich or Logamatic 4000 from Buderus.

Low-temperature systems . At the present level of the development of heating technology, there is a tendency to transition to the low-temperature heating regime. In other words, to reduce the operating temperature of heating devices. This leads to a more comfortable perception of thermal radiation by man. The most important advantage of low-temperature regime is to reduce fuel consumption. Operate the heating system in low-temperature mode also allows you to install automation.

By the way, such concepts as low-temperature regime and low-temperature boiler should be divided here. The low-temperature boiler is a device in which, by virtue of the specific properties of materials used in its manufacture, or thanks to the original technical solutions, it is possible to maintain the temperature of the feed line at level to + 40 ° C (as, for example, at the IROVIT VKO boilers from Vaillant) and even Less- to + 30s (at the GT 210 boilers from de dietrich). In this case, the reverse line temperature is not regulated at all.

Low-temperature heating mode can be obtained and not using a low-temperature boiler, but for this you will need actuators - three- or four-way mixing cranes with a servo, which will be discussed separately. Drinking with them the heating boiler will operate in constant mode with a high boiler water temperature, and the temperature in heating circuits will depend on the degree of opening of the mixing crane, in which hot water is mixed with cold, reverse.

Priority system . The codec from important functions of automatic control systems include the possibility of organizing hot water management. It is priority, mixed and non-executive. The most common, priority method is not devoid of flaws: during the consumption of hot water, the heating system is simply turned off. This usually does not lead to the house in the house. Method of mixed priority allows you to use for heating at home that part of the boiler power, which is not used for the preparation of hot water. However, with a lack of capacity, the entire resource is spent on the latter. Achto such a "non-executive hot water supply" can be understood from the name.

Disinfection . The software of many control panels allows thermal disinfection of the boiler once a week. This is done by increasing the temperature in the boiler to 80c for 20-30 minutes. Such a procedure eliminates the possible presence of legionelosis bacteria in the water, causing pneumonia.

Frozening protection . As soon as the outdoor temperature drops below a certain value, the automation itself will launch the boiler and will maintain a certain temperature in the heating system to prevent its defrosting.

"Smart House" . The latest controller models provide an opportunity for both remote access to the telephone line or mobile communication of the GSM standard and its integration into the Smart Home system. This option has devices of such manufacturers of heating equipment, like Viessmann, Buderus, de Dietrich IDR. Such devices allow you to control the temperature in the house at a distance and in time to find out about any malfunctions.

Executive devices

In order to organize the work of several heating circuits with different, not always permanent temperatures, actuators are required. The most common are three- and four-way mixing cranes (mixers). The principle of their work consists in adjusting the temperature of the coolant in a separate heating circuit by mixing water from the boiler with water from the reverse line. Thus, the temperature of the coolant in the feed line can vary from the minimum, for example equal to room, to the maximum equal to the temperature of the boiler water, but not higher. Turning the crane can be done manually (it is not necessary to talk about any control automation!) Or with the help of a special engineer-servos.

Typically, several parameters of servo drives are indicated in a technical passport. This is the power supply voltage, the maximum torque created on the shaft, and the speed of the drive. The last indicator reflects the servo transition time from one extreme position to another. This is usually from 60 to 300 seconds. It should be borne in mind that a smaller time of the servo reaction is not at all guarantees the rapid temperature change in the heating circuit. Recall that all thermal processes are very inertial. It is for this reason that the actuators are usually not used with speeds of less than 60 seconds. Approximately this amount of time is required to change the sensor installed on the feed pipe, the temperature of which cannot be changed in the temperature of the coolant, the temperature of which cannot change instantly. The all-wheeling menu of many control panels has an installation parameter, taking into account the speed of the servo. For example, in the control panels of the Logamatic 4000 series from Buderus worth 1270 in the basic configuration, the opening time of the three-way mixing valve is set directly in seconds. This indicator characterizes the reaction of a particular servo and is reflected in the technical enterprise.

Mixing cranes and servo drives to them are produced by a number of manufacturers, such as Roca, KomexTherm, Wolf. The body of the crane can be made of both cast iron and brass. It is good and other material is well suited to work in heating systems. Perfectly proven mixers of the Swedish company ESBE. A three-way mixing valve with a diameter of 32mm, made by this company, can be purchased for 60-70, the servo drive will cost it already in 150-170.

Service functions

Fresh air . To reduce the number of harmful emissions in the air, multifunctional automation is capable of optimizing the operation of the burner. The minimum burning duration of the contemporary controllers is defined initially. This eliminates the operation of the burner in the "Start-Stop" mode, poorly affecting both the resource of equipment and on the ecology. The fact is that most of all harmful emissions are formed at the time of the ignition. This is due to the incomplete combustion of fuel. By default, the minimum burner time is usually at least one minute. So, purchasing a modern management system, you care not only about your wallet, but also about your health.

Smooth start . An interesting function is the so-called launch discharge. The first (cold) switching on the boiler or after its long standing in the furnace is usually there is a strengthened condensate formation. As a rule, this is a mixture of acids adversely affecting the internal elements of the device. It is to eliminate such an unpleasant phenomenon, many control systems and allow you to produce starting unloading. Its essence lies in the fact that at the time of the inclusion of heating circulation pumps still do not work, so the coolant, which is in the boiler, is quickly heated up to 40-60c. It is this range that is considered safe in the sense of condensate formation, which means that the time of the harmful effects of the latter is significantly reduced. After reaching the desired temperature, the pumps of heating circuits and the system begins to operate in a specified mode.

"Nick" pumps . In many modern systems, you can set the time "low" pumps. This feature prevents possible overheating of the boiler. The fact is that in boilers (especially pig-iron) there is an increase in the temperature of the boiler water already after disconnecting the burner. The wine occurs inside the metal heat exchange directed from the surface facing the furnace to the one that is washes the coolant. The process will occur until the temperature of the inner and outer surfaces are equal, and the boiler overheating may occur. That is why it is important not to stop circulating pumps immediately, but to give them some time to work.

An interesting way to solve this problem was offered by Buderus specialists in the Logamatic 4000 series panels, creating the function "Use of residual heat". When heating the coolant, the boiler reaches not the maximum temperature, but only a certain calculated one, in which the automation turns off the burner, and the heating continues at the expense of the effect described above. Energy allocated, of course, does not disappear in vain, but is used to obtain hot water in a boiler.

Summer . Many regulatory systems have the release function of pumps. It is implemented, for example, in the E6 series controllers from KROMSCHRODER (cost- 382), in the Vitotronic control panels from Viessmann, Digi Comfort from Wolf and many others. A long non-working circulation pump can jarny, that is why in the summer, during long-intensive inaction, they are preferably advisable for some time to include.

Reflecting boilers

Someone reading our article will still have time to task with the suppliers of the heating system to use a boiler with modern automation. Akak to be someone who already has a reliable imported boiler with a standard control panel or domestic device at all without a regulation system, but wishes to equip it with a modern weather-dependent automation?

First of all, I would like to advise to contact the company selling your brand boilers. Almost every serious manufacturer of heating equipment has similar automation in its assortment. But if this is not possible to find or if its parameters do not allow you to solve the tasks set by the customer, you have to pick up a system of another manufacturer.

There are two options for re-equipment of boilers. The first suggests automatic control of all components of the system. At the same time, a high degree of automation is achieved and a significant reduction in fuel consumption. Hospital, to equip boilers for the first option is not always possible. It is difficult to modernize the system with an atmospheric burner. For example, the popular domestic AGB boilers are equipped with a burner with a "eternal" flame, littering in manually, which does not allow to automate the process of burning. For such cases, a second option is provided, which involves maintaining the temperature in the heating circuits automatically using the actuators. The boiler with this option will work with a constant, usually the maximum, feed line temperature, and as it were, "live your life", and the heating circuits controlled by the controller.

The manufactured controllers are intended for installation on all types of boiler equipment, equipped with both blowing and atmospheric burners. Of course, it should be noted that to re-equip the boiler is unlikely to succeed, such work must be instructed by a specialist of a reliable company with experience of such modernization.

In terms I would like to note that the acquisition of modern automation is not at all tribute to fashion, but a profitable investment of money. For example, according to the company "Hydromontazh", on liquid-fuel boilers, modern automation allows you to save up to 30% of fuel and will pay off after some 1-3 years, especially with current rates of rising prices for major energy resources.

The editors thanks the company "Hydromontazh", "Rusklimat", "Termatudia", Stk-Group, representative office of Buderus for help in preparing the material.