Long burning furnaces for heating of private country houses and cottages.

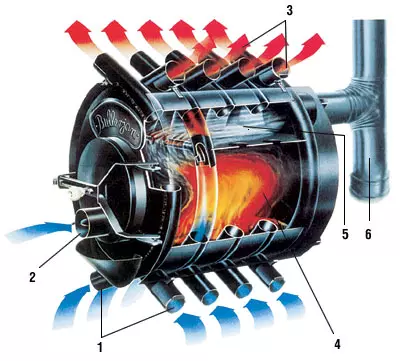

Bullerjan furnace for a bath

("Meta-Inzh", Russia)

1,3-input and outlet holes of the pipeline pipes;

2- air flow regulator;

4-coil chamber;

5- Dovzhiga camera;

6-chimney

Grand Large fireplace with banquets, niches, arches in the cap. Inclusion Finishes are usually used a porous golden shell

Fireplace fireboxes are easily installed in the portals of the most different form

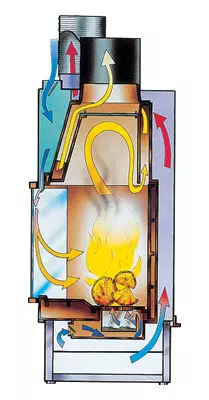

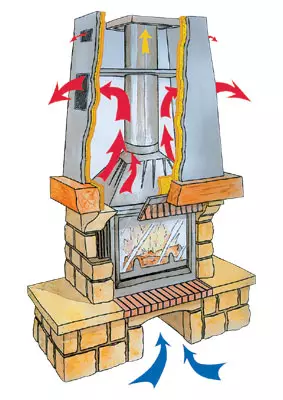

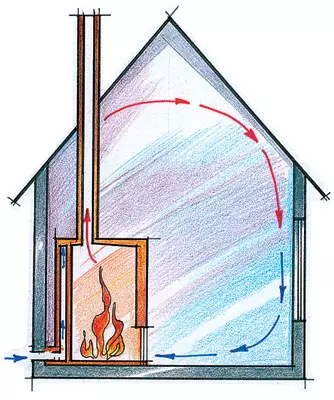

Air Movement Scheme Heated due to contact with fireplace firebox

Long burning furnaces can be designed to premiems of the most different volume. This "crumb" with dimensions is only 413040cm able to heat the room with a volume of up to 50m3

Furnace "fireplace tower". Even the form is noticeable similarity from the tower of Zheelsinki

Corner furnace-fireplace with oven and heat panel mass of stone 1870kg

"You can also drink to assignments," D.I. Indelaev wrote at one time, referring to the irrationality of the use of crude oil as a fuel. Of course, it is possible to trammed with assignments, and manuscripts, and even alcohol. But for most owners of country cottages there are much simpler and effective solutions.

The farther in the forest, the more firewood.

(Proverb)

Life and rest on the Nature Lowe, every year attracts an increasing number of citizens, tired of the fuss and noise of megacities. Hospital, pastoral pictures of rural life will noticeably spoil the lack of heat supply networks. Not in all the "paradise corners" our province is a main gas. Selectricity is the situation better, but most rural power grids are hardly able to withstand the load of 2.5-3 kW, and the power required for the housing electrical heating systems is tens of kilowatt. Therefore, many country household owners are forced to use imported fuel-diesel, coal, firewood. The last two species are characterized in cheap and widespread access. Accessory furnaces allow them to apply them with maximum efficiency.

Dancing from ...

The furnaces are generally called all heat generators without water shirts operating on solid fuel. The main advantage of their dignity is complete autonomy of use. Alas, the process of fireboxes of even the most modern furnace is much more difficult than maintaining a heating boiler operating on the main gas (about various types of furnaces, fireplaces and heating boilers in detail in the article "Autonomous heating systems"). To facilitate the life of owners of such devices, in country houses use ovens and fireplaces of the latest design, capable of working in heating mode for a long time and distinguished by high efficiency (not lower than 70-80%). This level of efficiency ensures that the firewood will not be wasted, on heating the atmosphere. We mean the so-called long-burning furnaces, long-burning fireplaces and masonry stoves accumulating heat.For the soul

Often the owners of cottages prefer wood stoves and fireplaces from aesthetic considerations. Even in the presence of the most modern heating system, the living room can decorate a wood-haired fireplace, not be economical, even if not for heating, but but for the soul. The modern furnaces and long-burning fireplaces make it possible to combine the pleasant with the useful- and home to heat, and admire the flame, not putting the next portion of firemakes every minute. The additional finish of the housing of the furnace in the tiles or the fireplace will give the room even more cozy appearance.

All existing furnaces can be classified by appointment (for heating, cooking, baths IT.D.), material (brick, metal and mixed), a device of a fuel (with a grate grid or without it), the type of fuel, as well as the duration of action. Not every device of this kind is intended for long burning. According to, for example, the French standard NFD 3537 or German DIN 18891, furnaces and fireplaces are divided into three categories: A- decorative; B-holding fever less than 10 hours (when bookmarking one fuel portion); Long burning, that is, holding a heat for more than 10 hours. At the same time, the heating ability of long-burning devices for 10 hours should not be reduced by more than 50% (DIN 18891) from the rated power. Nominal called the average power measured with three-hour tests - no need to be confused with maximum power (measured for 15 minutes), which can be several times more. In almost the same, long burning furnaces are called a wide variety of devices capable of maintaining a comfortable temperature from 2-3 to 4-5 hours and a lot depends on the good faith of manufacturers and sellers.

You go quiet, you will be longer

Furnaces and fireplaces can be made both in factory conditions (fully prepared for use, with cast iron or steel housing), and in the form of a brick masonry, the Master-Kube is directly in place. It is often used and a combined method when the working chamber made in the factory conditions is mounted in brickwork. Each option has its advantages. Metal devices are usually smaller by weight and can be installed on sufficiently weak floors, for example, on the second floor of a light country house. These devices are quickly warmed up, but "keep warm" worse masonry, simply due to their insufficient mass. Now, it is known that, for example, a Russian oven even with a relatively low efficiency, it is capable of keeping heat for semissions. Metal models of the factory design after combustion of fuel cooled literally per hour. Therefore, you need to choose the heating device depending on how often the owners visit the country house. For short-term visits, a quickly heated stove is needed (this can be both ordinary bourgeitogo and a long-burning device) or an open fireplace. For permanent residence, a masonry design is needed or a long-term combustion device.

Improving the efficiency of heat generation is achieved due to a number of technical improvements. Deposit models, for example, are often made a change in the design of the smoke channel system (smoke-rotation), where the main part of the heat exchange process is the hot gas gives its energy to the body and the cold air surrounding it. To improve heat exchange, the system is made of multi-turn, with horizontal and vertical smoke channels. Such channels of increased lengths allow to provide uniform heat transfer and smaller heat loss, flying out "Proudub" (more on this it will be discussed below). Other enhancement of coaching gas surgery is used in factory manufacturing gas generators.

Why "generate gas"?

Furnaces gas generators can serve as a visual confirmation of the expression "better less, yes better." Indeed, in the course of work, the fire is hardly smoldering in them gives much more heat than the most "violent" flame. This is because the firewood in the furnace at high temperature and disadvantage of oxygen is almost completely converted to the so-called flue gas (a complex mixture of carbon monoxide, methane, hydrogen and other components). This gas, in turn, forms a lot of heat during combustion. Isaone the main fuel is burned almost completely, that is, it is consumed much more efficiently. That is why the efficiency of overseas gas generators is 40-50% higher than that of ordinary stoves. These devices have other advantages. So, firewood in the mode is decomposed slowly, which allows to maintain a long burning mode. In addition, in the process of operation, there is little ash and polluting the air of volatile compounds - the "smoke" stove is very weak.

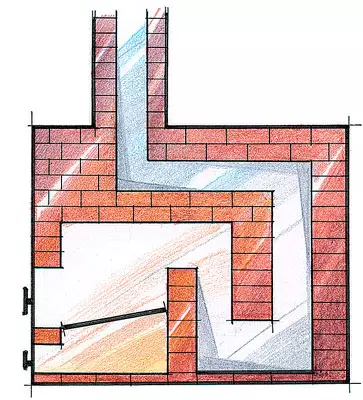

To work in the mode of gas generation (or, as they say, in the mode of tension), two chambers are provided in the furnaces-gas generators, for the fuel laying, and the top, the survival chamber. Firewood is placed in the lower chamber, are ignited, and during the first 10-20 minutes, the device works in normal mode. It lasts until the movie is completely spoiled. Then the technological holes, with the help of which the influx and outflow of the air are adjusted, are covered. Valid dreams from ordinary furnaces, devices-gas generators do not have a "classic", through which any intense flow of air would flow into the flock chamber, but is equipped with an incoming air flow controller (power regulator) and gasifier outflow (regulator-gasifier). The door is tightly covered, and the air flow through the slots is minimal. Firewood is starting to smooth. The formed flue gases come to the upper chamber, where they are finally burned due to the special injectors, adding air jet from the outside to burn fuel gases into this container.

It must be remembered that the usual oven is not capable of working as a gas generator, even if the air has impassing access to it through impassing and the outflow through the chimney. The resulting gases will not survive and at best will "leave" in the chimney into the atmosphere, and in the worst - penetrated through a loosely closed door to the room. It is very dangerous because combustion products are extremely harmful to people's health and life, in particular, carbon monoxide (carbon monoxide). Initious death from the ugon due to improper operation of the furnaces was very common. Therefore, in no case should it be experimenting with conventional devices, trying to increase their efficiency and duration of work with the help of gas generation!

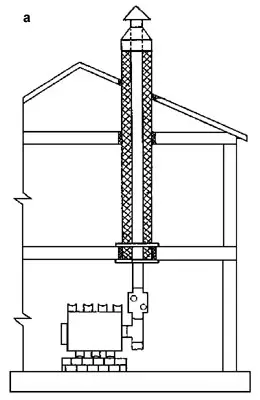

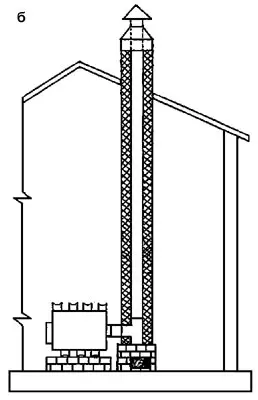

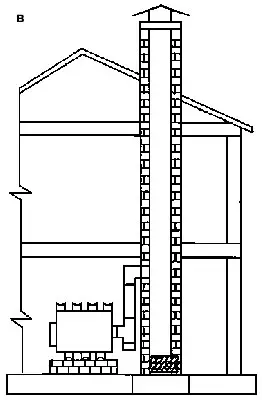

Installation scheme of furnace gas generators:

Gas-generator furnaces appeared on the Russian market not so long ago, although the principle of gas generation is successfully used in many models of solid fuel boilers already dozens (you can recall at least the famous GAZ-42 truck, produced in 1939-1946). One of the first to market the most famous Russians model of the Bullerjan gas generator (Bullerjan), developed in Canada more than 30 years ago. Such devices are available not only in Canada, but also in other countries. For more than 10 years, they have been producing them for more than 10 years under Energetec license (Canada). Competitors "BULLERYANA" - SUKHOV'S SUKHOV furnaces developed in Russia ("Feringer and K", Voronezh, "Sisel" ("Sinel", Moskva), "Camelk", "Emelya" ("Machine-building Plant Mayak ", St. Petersburg) and some other domestic appliances.

Between themselves, these devices differ in the produced thermal power (from 4 to 50 kW), on which the maximum amount of heated space depends. Most models are designed to premise with an area of 50 to 1200m2. The efficiency of gas-generating furnaces is about 70-80% - it is higher than that of masonry furnaces (15-30%), and even more so, than among traditional fireplaces with an open furnace (10-15%). Another important parameter is the continuous burning time after full fuel boot. This value can vary from 5 to 15 hours. Depends on the design of the stove and chimney, as well as the quality of the manufacture of the device, the magnitude of the technological gaps and the slots through which air flows and on the type of fuel. The heated area of the room depends on the volume of the furnace chamber (than the camera is larger, the the-heated volume is greater).

As for the individual characteristics of the models, then the differences are, first of all, in the design of the housing and the device, with which heat is transferred to the surrounding air. For better warming up the room, the gas generators furnaces are supplied with heat exchanger-calorifer. It can be a system of convective pipes, such as, for example, in the "Bullerian" furnaces: cold air is absorbed through the bottom holes, and the already heated is released from above. The pipes come into contact with the furnace, so they immediately take the heat generated and quickly transmit it to the flowing air. Modele "Sukhov", "Emelya", "Sinel" The function of the carrier performs a metallic casing (shell), surrounding the coating part of the furnace from the sides. It is formed by an annular air gap around the furnace around the furnace, through which, thanks to the thoughtful use of convection processes, the flow of the firebox is continuously passed. Such a construct of the carrier is less effective than the pipe system rather than the system, but it is easier and cheaper in the manufacture.

The intensity of air heating depends on the construct of the carrier and ultimately the speed of the heating of the room. The greater the surface of the pipe heating or the air contact area with the body of the working chamber, the more intense the ambient temperatures increase. Therefore, even when using furnaces with approximately the same thermal power, the rate of heating the room may vary 1.5-2 times.

For greater efficiency, the furnace is sometimes supplied with an economizer. It is a device for an additional heat selection from gaseous combustion products. According to the principle of action, it is the same calorifer: gas coming out of the oven, heats the air indoors.

The problem of all gas generator devices is the "reverse side" of their economy - the output is quite cold gas. If the chimney pipe is not insulated, the resulting condensate flowing back to the furnace is formed. Therefore, for such devices, it is necessary to use pipes with insulation of the "Sandwich" type. These are nested pipes (inner and outer) with a thermal insulating layer between them.

By itself, the process of operation of the gas generator ovens differs little from the usual one. A pitch chamber is laid a portion of firewood or other fuel, such as peat briquettes, wood waste of IT.P. For a long action, it is recommended to completely fill in the chamber, that is, one masonry should take 80-90% of its volume. It is important to use only the type of fuel to which the device is calculated. Let's say, in the furnace "Bulleryan" is allowed to use only brown coal. And, it would seem first-class anthracite, exclusively in a mixture with a tree and only in models from 200 to 1000m3, since it has too high heat dissipation and metal metal can simply turn around. Gas generator devices cannot be operated in combustion mode, they are not calculated for it. The dust of the gas generation in the furnaces "Bulleryan" is not used by trees, since, according to manufacturers, the process of gasification of fuel is normal only on the ash cushion. The gas generators' instrument housings are not heated over 200-250c, so they are more fireproof than traditional burzhuyki. True, the low temperature of the housing does not allow to use the furnace as a kitchen plate.

As for the cost, the furnaces gas generators, without a doubt, the cheapest option from all solid fuel devices of long-burning burning. The price, depending on the model, can fluctuate from $ 100-150 to $ 300-350, which in terms of 1 kW of power is $ 6-25.

And warm and light

In addition to furnaces, there are fireplaces of long burning. True, "Fireplaces of long burning" - the concept is very conditional, since they work from one load of fire for a maximum of 4-5 hours. Of course, such devices with a closed firebox produce heat several times longer than in the case of an open firebox, but gas-generated furnaces in the duration of action they are still inferior. Therefore, unlike furnaces, such devices are rarely used in residential buildings as the main heating devices. But they are often installed "for beauty", and even for heating garden and hunting houses. Important advantage of fireplaces compared to printers long burning - Universality: they can be operated both in the usual mode (active combustion) and in economical (for heating). Yes, and enjoy the bizarre game of flame language, it is possible only with the help of a fireplace equipped with a larger glass (it provides a good overview of the furnace).For long-burning fireplaces, the furnace chambers are made of cast iron or steel and are supplied with tightly closing doors with heat-resistant glass, which misses infrared radiation well. Also, devices are mandatoryly equipped with a gaming flap, overlapping chimney. When the power regulator is closed and the grooved flap, the fireplace begins to operate in mode, since the air enters the furnace in a minimum amount. For convenience, the damper control knob is usually taken out on the body facing body. In order to eliminate the danger of carbon monoxide poisoning and combustion products, in modern models of fireplace furnaces, an automatic opening of the gate valve is provided when the door is opened.

There are also furnaces-fireplaces - a special category of heating units, quite popular recently. Among them, you can call both ordinary bourgearies with a window and long-burning models. According to its design, they are among the average between the printers of long burning and the fireplaces with a closed firebox. Thus, they use a similar firecrap camera with a large window with a large window, through which you can observe the combustion process. However, unlike fireplaces, such furnaces are equipped with a ready-made metal case, which does not need additional facing.

Companies such as Rene Brisach, Tinvicta, Seguin Duteriez, Totem Fire S. A, Supra (France) and Piazetta (Italy) are engaged in the production of long-burning fireplaces. Durable burning furnaces are manufactured by Meta-Ing and Prokki Energetk (Russia) firms. As a rule, long-burning fireplaces are quite expensive, the value of the imported fuel chamber can be $ 500 and higher, and domestic - from $ 300. I will need $ 700-800 for the "inexpensive" cladding. Therefore, it is not surprising that during the device such a fireplace, the owners have to lay out the amount from $ 3,000. Cheaper stand ready-made fireplaces of Russian production without facing. For example, the model "Munich" ("Prokkin Energetack") will cost buyers of about $ 800 (without installation), and the Fireplaces "Volga" or "Narva" ("Meta-Ing") - approximately $ 300.

The price largely depends on the sizes of the furnace, devices and shapes of glass (Waich products used glass Robax produced by the German company Schott, withsting temperatures up to 800C). There are furnaces that use glass of a complex curved shape, or, for example, through fireplaces with two glasses, "working" for two adjacent rooms. Affects the cost and design of the door. Summers of simple furnaces are mounted on hinges, opening sideways. The so-called "guillotine" mechanism is used in the most expensive models, the door rises up on chains or cables. Adlya of relief of this action its mass is balanced by counterweight. "Guillotine" mechanism complicates and increases the design of the construction, but the hidden doors allow you to get a complete pleasure from the living fire.

Viewing glass over time inevitably dumps so much and loses transparency, so it is necessary to periodically wipe. In order to somehow protect the window, many manufacturers use the design of the furnace with descending air flows, interfering with particles of soot fall on the glass. Sita the goal is used for firewood limiters (metal arms), which do not allow wood to roll up to the window. Cleaning glass is made with hot water with the addition of detergents. At the same time, it is necessary to wait for the complete cooling of all the firemark details.

Closed fireboxes of fireplaces can be both cast-iron (Rene Brisach, Seguin Duteriez, Supra) and steel (Piazetta, Supra). Steel or cast iron does not matter, since the quality is very high and the service life (and cost) of products is approximately the same. The inner side of the furnace is laid out with cast iron or chamotal materials. Ceramic "filling" is not inferior in the physical characteristics of the cast iron, but it is not cheaper.

Most of the fireplaces for long-burning fireplaces have the doors with a width of 70-80cm. However, there are also "giants" to 1.5 m wide, for example Horizon 1500 (Totem Fires.a). But with increasing size, the price is growing very rapidly. Closed fireboxs width more than 1.5 m theoretically can be made under the order, but their price will be very high. The furnace chambers are supplied with ash spanking - retractable (as a drawer) or with a lifting grid. The retractable ash bar is more convenient in small models, but for large floors it turns out too bulky.

Lookingmatizing the fireplace of long burning, it is better to pick up the furnace and facing at the same time. Most manufacturers produce both components that are suitable for each other on geometric sizes. If for some reason the facing is planned to be purchased separately from the furnace, it is necessary to clarify the sellers, whether the selected models are compatible. It is also possible to make an individual cladding - according to its own sketch or such that will best fit into the design of the room (such services provide, for example, specialists from the firms "Fireplace" and "KaminspetsStroy"). However, it is impossible not to take into account that the costs of the firebox, cladding and any heating unit is not all. Very sinking, and without him all these wonderful stoves and fireplaces do not work. But we will talk about the device of chimneys now, but in a separate article.

Heat stone stone

The masonry devices are not able to compete with gas generator models or fireplaces in the air heating rate in the room after the extract. And in general, they suggest a completely different mode of operation - the stove begin to trample in the fall and finish in the spring. If, for example, an episodically stir up a Russian oven, alternately warming up and cooling it, then cracks and it is most likely to be repaired on the surface and it will most likely require repair. Therefore, the main thing for such aggregates is the ability to accumulate, keep heat. To do this, they are made massive- among them are not uncommon "heavyweight" in several tons.

The traditional Russian oven, isolated from red brick, has a mass of 5-7 tons. This is a universal device that allows not only to dwell the home, but also to prepare food. Hospital, the design of such a furnace, not involving the presence of smoke-rotations, does not provide for heating the bottom of the masonry and the air in the immediate vicinity of it remain cold. Yes, and the effectiveness of heat recovery among the traditional Russian furnace is small, the efficiency is at 20-30%. Therefore, designers were developed (and are developed by this) a variety of options for masonry devices of improved design: with smoke channels located horizontally ("screws") and vertically ("wells"); with one channel or several, located in parallel; with several channel bends, as if folded by the harmonica (multi-turn) and with one bend (single-rectal); Without smoke channels, but with an extra chamber "Cap." As a rule, such models are more economical and heated evenly. True, it is necessary to understand: an increase in the length of the channels and the amount of turns in them leads to the loss of air velocity inside the device and the complication of the structure as a whole.

With high roughness of casually performed chimney walls, it is possible to accelerate falling in the soot channels. Therefore, in the equipment of complex smoke, it is necessary to accurately close the quality of the masonry and thoroughness of the finish (about masonry fireplaces and chimneys, they were told in the article.

"Fire, firewood and smoke pipes ..."). Hospital, not all modern livenists have sufficient qualifications (especially if we consider that most of the fires manufactured by them perform mainly decorative functions). In addition, the furnaces with smoke-robes of complex shape is extremely difficult to clean from soot.

The absolute majority of stone stoves are available on individual projects, too hard it turns out to enter a ready-made model in the design of the room. From firms involved in the production of masonry furnaces, you can mention KaminspetsStroy, "Agroproekt", as well as a Glenrich company, which specializes in tiled tiles for facing fireplaces and furnaces. Among the devices manufactured by the factory method, the market shows the model of the Finnish company Tulikivi. The so-called "pot stone" - Talc chlorite is applied. It has a very high heat capacity - 2.5 times greater than brick. Thanks to this, Tulikivi models are characterized by much greater compactness compared to brick furnaces and can be installed even in small rooms. After the end of the furnace, the heated talc chlorite highlights heat for 12-36h, depending on the mass of the furnace-fireplace. The ACAP of such devices reaches 80-88%. The cost of furnaces (together with installation) is, depending on the materials used and the size of the model, $ 2000-3000 or more.

In general, it is believed that the stone furnaces give a more comfortable heating than metal bourgeities, since the surface does not heat up too much and does not "overtake" air. The disadvantage of all massive devices is the need for installation on a reliable, durable foundation. Therefore, before making a purchase, it is necessary to consult with the liver, who should inspect the installation location.

Of course, not only the heating furnaces need economy. The principle of heat accumulation is used in bathing chambers, and efficient use of fuel is assumed in many cooking devices. But we will tell about these furnaces in the following publications.

The editors thanks the company "Fireplaces and furnaces Tulikivi", "Art-tone", "Prokki Energetk", "Nii Fireplace", Glenrich, Representative Office Supra in Russia for help in the preparation of material.