Creating an additional residential area in city dwellings - glazing loggias with insulation.

The floor of the loggia is leveled in a horizontal plane using wooden lag. The seemingly mineral wool insulation is stacked between them

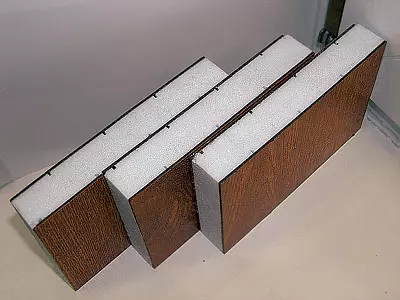

Plastic Sandwich Panels

Approximate color scheme panels

Warming of the ceiling of the loggia "Penophol". Thermal insulation properties of foamed polyethylene enhances the reflective layer of aluminum foil

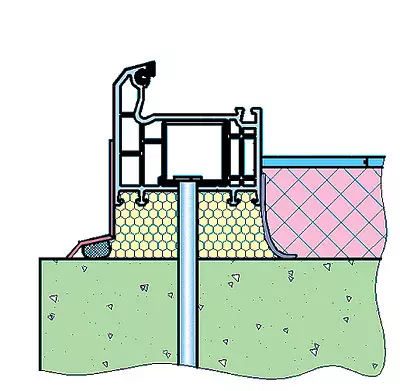

It is possible to make a window structure installed on the loggia in the rampation between the floor and the ceiling, not only from PVC profiles, but also from warm aluminum. The designs of it calmly withstand the wind load to 70 kg / m2, which allows them to install them on altitude houses

1- Installation foam; 2 decorative nickname in combination with insulating tape;

3-window frame;

4-paosoolati tape;

5 finish;

6- insulation

Finally everything is ready. On such a warmed and beautifully trimmed loggia, it is not that I want to work!

What to say, have a better loggia in the apartment than a balcony. It is better because on it, unlike the balcony, there is always where to turn around. In the summer you can just sit or work, and if there is a mood - in the company, drink tea. But in the winter ... in winter, the loggia, like a balcony, or empty, or turns into a storage of things forgotten until the next summer. Judgee harvested pickles have to be made to the apartment - diminished.

Functionally loggia is practically no different from the balcony. A small difference between them lies in the architectural binding - the balcony as it would be hung on the wall outside, and the loggia is drowning into the depths of the building (in fact, this is a niche). But this, it would seem, a little distinction pulls two more. First, the loggia in most cases is only one side is open to all winds, and three others completely or at least partially closed. Secondly, the area of the loggia is usually much larger than the area of the balcony. First of all, at the expense of a part recessed into the wall.

But this, so to speak, the classics of domestic architecture- according to such rules of the house were built into the seventies-eighties and early nineties. Runing a later building "Everything was mixed." Now the loggia is often not recessed into the wall, as well as a balcony, it stands out of it, absolutely not "eating" an apartment area. Yes, and the words "balcony" and "loggia" are perceived today practically as synonyms. Italy "protruding" loggia, not to mention the "drowning" (which absorbs part of the area of the room) The owners of the apartments consider it just to turn the saint, for example, to the office (this is what kind of square!). Well, in summer it is clear, just go to the loggia and work on health. Asima? Without insulation, there is no way to do. Methods for its execution and dedicated to this review. It is the ways, and not the legal side of the issue of glazing and insulation of the loggia, it was discussed in detail in the article "On Seven Winds". So a single reservation. The version of the loggia insulation in order to access it to the apartment with the removal of the balcony block, we also will not consider as forbidden.

The insulation process can be divided into three stages. The first is the creation of a warm design that enlightens the loggia from the side of the street, the second- insulation of parapet, gender, ceiling and walls, the third is their finish. Ateper about each stage in more detail.

"FOURTH WALL"

So, reliable gender, ceiling and walls (let the sides and partially) we have. Consequently, in order for the loggia to become "warm," it is necessary to build the missing fourth wall, which should be simultaneously translucent, moisture-and soundproof and heat-saving.What and how to glass

The modern market offers the following glazing methods: the usual (single) and so-called european.

The usual glazing is the already familiar option, in which the frames with opening or deaf sash are mounted along the perimeter of the loggia, or sliding structures in which single glass is installed. This method was very detailed in the already mentioned article "on seven winds", so I will not repeat. With all its advantages, single glazing has one big minus it is cold. Moreover, how the thickness of the glass puts, with the growth of thickness, only its sound insulation properties are improved, the heat-saving characteristics from thickness are practically independent. That is, even the most high-quality single glazing muffle the street noise (and with a large thickness of glass, quite significantly) and will ensure the absence of moisture even in protracted rains. AVOT The temperature on the loggia compared with the street glazing in the aluminum frame will increase only 2-5s, and in the frames of the tree - by 5- 7c.

However, the matter is not in the material from which the frames are made. The heat exchange coefficient at the tree and aluminum, of course, differs. And several times. But after all, the surface area of RAM is many times less glazing area. Therefore, heat-shielding properties determine not so much material frames as the design itself and the quality of its manufacture. Agalan - the absence of cracks. In general, in the slippers of tea in the winter, neither in any other case will not be drunk. It is authorized, we have no other way out with you, except for using a double-glazed window.

Double-glazed windows are bulk products consisting of several glass sheets, which are interconnected by contour using distance frames and sealants and form closed cameras filled with dyed air or inert gas. The range of glass range is wide enough. The number of glass layers can vary from two to four, and the thickness of the structure is 24, 32, 36, 42mm and even more.

What glass windows choose? It all depends on the requirements that you present to the erected fence. Let's say, not only glass thickness will affect sound insulation properties, but also the amount of its layers (2-4), as well as the amount (1-3) and the magnitude of the air intervals. The asopulation of heat transfer depends also on the type of glass used (for example, there is a heating saving to or-glass), as well as from inert gas, which is filled with the interconnect space. By the way, stopping your choice on glass windows with argon, keep in mind that they are worse absorb the sound than filled with air.

The final selection of the glass package you will have to do yourself, correlating your wishes with common sense and financial capabilities. But keep in mind: although the heat loss through the translucent design you build up and are not normalized (the loggia-room is non-residential), the laws of heat resistant here are the same in the modern windows. Therefore, to begin with, it is possible to stop on the double-glazing with a value of R0 = 0.35m2c / Vt, which keeps the heat roughly as dual wooden frames. But if the means allow, for the middle strip it is better to choose a glass with R0 = 0.56m2c / W, as for the windows of the apartment (MGSN 2.01-99 "Energy saving in buildings").

Prices for double-glazed windows fluctuate as follows. If the glass pump with formula 4-16-4 will cost about $ 25 / m2, then with formula 4-12-4-12-4- already at $ 35 / m2. The use of K- or and-glass increases the cost of 1m2 to $ 15-18. Filling argon- approximately $ 2 per chamber. The replacement of the outer glass of 4mm on the glass is 6mm. plus $ 3 / m2. The use of a triplex-plus $ 30 / m2 as the outer glass, tinted glass-plus $ 15-80. The sticker of the anti-vandal film - plus $ 45 / m2, tinting film, plus $ 25-40 / m2.

From what to produce

For this purpose, a wide range of materials is offered: wood, PVC, aluminum. That is, the same materials can be used for enclosing structures as for windows.Wood. The windows of natural wood distinguishes quite high strength, good heat and sound insulation properties, as well as high frost resistance. There may be structures of both wood array and from glued timber.

Massive wood. Of course, no self-made frames in this case and speech can not be allowed only industrial window blocks. Double glazing in frames from a conventional array, as a rule, do not apply, therefore, double frames are set (the maximum width of the sash at a height is 1.5m- about 0.8m). Irama, and the box is obtained quite massive and look at the loggia approximately as an elephant in the dishwasher. Follow their condition, paint will have to be regularly, only then they will live long. But the price of low-from $ 50 for 1m2.

Three-layer glued bar of pine, oak or larch (pre-dried to humidity 10-12% of the plank, of which the defects of wood are removed, fastened with waterproof glue) of all these flaws are almost deprived. The strength of the structures of it is 80%, and rigidity is 40% higher than from similar single-generated planks, which allows the use of double-glazed windows of almost any thickness. Maximum width of the sash at a height of 1,5m-1.1m. Constructions made of glued timber treated with antiseptic composition and protective primer and having a high-quality final coating, do not need special care. True, the price of them is quite high- $ 250 per 1m2.

Plastic (PVC). It may be offered in two versions: swing window design and sliding.

The oral plastic windows, perhaps, and tell for a long time, are not necessary, by different estimates, on the Russian market from 70 to 85% of windows is made from a plastic profile. It comes to us from a variety of manufacturers: Kbe, Kommerling, Rehau, Brugmann, HT TROPLAST AG (Trademark TRocal), Gealan, Schuco, Salamander, Thyssen, Veka (Germany), Plastmo (Denmark), DeceUninck (Belgium), Tryba ( France) IDR. Some of the listed firms have long been organized by the production of PVC profile here in Russia. What to say, the plastic profile is convenient. There you have a high strength provided by the steel-fitting steel, and a reliable (two or even three-constructive) seal system, and a high-quality locking accessories. Maximum width of the sash at a height of 1,5m-1.2m. Various width of the profile itself allows you to mount the double-glazed windows of any thickness. Price, from $ 120 / m2.

Among the sliding structures can only consider those that provide for the possibility of installing the glass package, the maximum thickness of which is 16mm. Such systems in our market offer only 2 firms: Rehau- S781 and Hanwha system (South Korea) - SLIDORS system (Sladors). The sliding design is elegant and convenient (especially for narrow loggias), since the sash does not occupy space when opening. Folding on the guides move easily and, most importantly, do not face the frame with strong winter frosts (ice and snow are easily removed from the groove). The presence of several types of angular connecting profiles allows you to glazate a non-standard loggia. In general, such a design will protect the loggia from snow, rain, wind and dust, and also significantly reduce the noise level. But ... the temperature on the loggia (without heating) will still be lower than with swinging PVC windows, since the glass stack is felt, and there is a "felt" seal between the sash. Price, from 70 $ / m2.

Warm aluminum. Aluminum profiles with a thermal survey our magazine recently devoted a big review (

"Warm" aluminum "). In thermal insulation properties, such profiles are not inferior to wood or PVC, and in strength, many times are superior to them. Aluminum enclosing design calmly solves wind load to 70 kg / m2, which allows you to apply such a system on the highest floors. This circumstance contributes to the widespread use of warm aluminum profiles during the glazing of balconies and loggias of the newly under construction houses, for example, in Moscow (according to the latest rulings of the capital government, all houses must give up with glazed loggias). Maximum width of the sash at a height of 1,5m-1.5m. The development and release of warm profiles are engaged in companies such as Reynaers, RS System (Belgium), Hueck, Metra, Heroal, Schuco (Germany), Metalplast (Poland), All.Co, Indinvest, New Tec Group (Italy), VSMPO , "Kumz", "Agrisovgaz", "Mosmek" (Russia) IDR. True, this material has one significant disadvantage: the price of glazing with its use is not small, from $ 200 / m2.

Combined designs. It can be wood-aluminum (aluminum protects the wooden frame outside), aluminum-tree (frame from the aluminum profile separated from the inside by a tree), wood-plastic (wooden frame from the outside of the window is protected by plastic) IT.D. In more detail on this topic it was said in the article "Combined windows". There are similar designs even more expensive than just wooden, plastic or aluminum.

The design options "Fourth Wall"

Perhaps several options for its manufacture. The choice of the most suitable depends on the material and reliability of the existing fencing of the loggia.

If it is a durable and quite reliable "stone" parapet or a metal balustrade, you can install the window structure in the space between the fence and the slaughter of the overlapping (the basement of the loggia). This design can be made using the materials described above.

If the reliability and strength of the metal balustrade causes doubt (with a stone parapet, it also happens, but much less frequently), or, in morestally, it seems to be "chlipkaya", then the first thing that usually comes to mind is to replace this balustrade new or at all From brick. So, none of anyone is not recommended in any way. First, the new metal balustrade or brick parapet, even if it is very beautiful, will stand out on the background of the house. The ATEA means that the local authorities will most likely have a claim to you that may well be implemented in a categorical requirement to restore the spoiled view (and where will you then take the thrown down fence?). Brickwork is not recommended for another reason. The fact is that the balcony cooker is designed for a completely defined load - from 200kg / m2 in old houses (the slab was calculated on this load when the house was built; what is the actual carrying capacity after many years of operation, it is practically impossible to evaluate) to 400kg / m2 newer. Additionally, loading the design of the brick masonry, you can easily exceed the permissible limits than to threaten not only your own life, but also the life of neighbors.

By the way, in the preparation of this material, the "window in the XXI century" specialists, which performs the insulation of loggias in collaboration with many Moscow firms involved in glazing, simply refused to discuss the demolition of the existing balustrade and replacing it with a brick parapet. Ito very significantly!

Approximate price level for various types of work when warming up and finishing the loggia, $ / m2

| Performed work | Cost 1m2 (Material + Work) / Work |

|---|---|

| Construction of foam blocks | 40/14 |

| Installation of roughing floor with insulation (timber, insulation, chipboard) | 22/12. |

| Linoleum laying | 20-30 / 8. |

| Outline carpet | -/eight |

| Flooring of the laminated parquet (substrate, parquet) | 32-36 / 12. |

| Installation of plinth | 5/1 (1 p. M) |

| Laying tile | - / 22. |

| Finishing panels "Panel" (Russia, Netherlands) - Rake, panels, insulation | 33-35 / 12. |

| Finishing of slopes plastic | 18-30 / 10. |

| Finishing Sandwich Panels PVC (Rake, Panel, Heater) | 40-43 / 12. |

| Vinyl carbonate finish, insulation, lining | 25-27 / 12. |

| Finishing with wooden clapboard | 30-33 / 14. |

| Warming "Penophol" | 10/- |

The method of first is to establish close to the balustrade and the eliminator with it an additional metal carrying structure and already open the window block on it. Weight option is both its advantages and disadvantages. The advantage is advantageous. The disadvantage of the design necessarily has a scroll (they give it hardness), which will be directed inside the loggia (the support is installed close to the parapet) and in subsequent works, it is unlikely to hide under the insulation layer. Simply put, you have under your feet at certain intervals, repeated metal elements will be located, which are stumbled apart simple. In addition, this metal support will be a cold bridge. Price from $ 40 for 1 p. M. Some firms offer the manufacture of a supporting structure from a wooden bar. It is clear that the tree is significantly "warmer" and therefore it is better than the metal. That's just it is less durable. How to follow the condition of a bar hidden under the trim, is also difficult question.

The second method is still building a wall along the balustrade. Extreme cases without such a wall simply can not do, for example, if the fence is extended beyond the projection of the ceiling of the loggia. The situation of the situation of the company "window in the 21st century" is advised to build a wall from cellular concrete blocks (foam concrete). This material is easy enough, so as not to increase the load on the stove above the critical, but at the same time it is sufficiently stronger so that it can be opened a window design. For masonry, it is necessary to use a material with a density of not lower than 500, since it absorbs moisture less. True, and cellular concrete there is deficiency, you will have to come to terms with a loss of 100-300mm of the width of the loggia.

On the first way, you will go or second, all the same created by the support will have to be insulated. What and how about this in the special chapter.

The third is able to install the window design in the space between the floor and the ceiling of the loggia. Such a structure is usually manufactured either from PVC profiles or from warm aluminum. That is, a one-piece or composite frame with a mandatory horizontal impost at the level of the balustrada railing (parapet) is obtained. Working on the horizontal impress to the ceiling are mounted opening (swivel, swiveling, folding) or "deaf" sash with double-glazed windows (everything is solved on the place, based on the wishes, as well as the convenience of use and washing).

The flooring from the floor to the horizontal impust can be filled in different ways. If the balustrade is lattice, the windows are often used (only the inner glass must be or reinforced, or a triplex, so that, God forbid, do not break it) - in this case, the lights on the loggia will be more. It is possible to fill the openings with thermal insulating sandwich panels. What it is? Three-layer panels, the external decorative layer of which form PVC sheets of domestic or imported production (for example, Vekaplan to VEKA). Sheet thickness - 1 or 1.5mm. The inner layer of the panel is performed from extruded polystyrene foam (for example, the American company Dow Chemical, the BASF Code.) Or free foamed polystyrene of Russian production. The sandwich panels are mainly produced by domestic firms (for example, "Kamoplast", "Linawa", "Om-Plast" IDR.), Who have practically supposed foreign manufacturers from this market. The surface of the panels is matte or glossy, as well as decorated, for example, under the tree. Moreover, the decorative finish can be performed both from one and from both sides. The thickness of the panels - 24 and 32mm. Standard size - 15003000mm. The price ranges from $ 60 to $ 95 per piece. The thermal conductivity of the sandwich panels does not exceed 0.08W / (MK), which allows them to be used when creating insulated structures.

With the construction of the "Fourth Wall" by any of the considered methods, the specialists of the company "Chameleon" advise to pay attention to the following points:

As lined and what dimensions are lamps (if they are assumed on a warmed loggia). Over this issue, it is worth thinking about the planning stage of large-sized lamps, fixed on the ceiling, can interfere with them to open.

As organized a drop of rainwater from a loggia located above yours. The best option would be setting a fusion tightly adjacent to its floor. But to implement such a plan may not allow balustrade design or not too good relationships with neighbors. Over the OTD, the sow will have to be attached to the bottom of the slab plate. Its width should provide water removal by 15-20 cm per edge balustrade. It is possible that it will be necessary for another point of the floor level of your loggia, so that flowing water does not get on the loggia of the lower neighbors.

When installing the design of PVC or warm aluminum profiles to the retrieve between the floor and the ceiling, it is necessary to place a drop at the level of balustrada railing. Then he, firstly, will provide a removal of rainwater flowing through glazing, and, secondly, it will cover a rather wide "gap" between the design itself and the parapet (balustrade) of the loggia.

It is equally important to the tightness of the sealing zone of glazing the glazing to the outer walls and overlaps. The gap between them is usually propum. Outside, the foam must be covered with metal or plastic nicknames or self-adhesive ribbon, otherwise under the influence of ultraviolet, it will simply collapse. From the inside of the foam loggia also must be covered with either insulation or finishing materials or plastic or metal decorative corners.

Naturally, the option of the Sandwich panel with PVC sheets is more suitable for the design of the PVC profile. For aluminum structures, there are its sandwich panels lined with thin sheets of this metal. Such products are not very expensive than plastic finished. Filling out the openings below the horizontal impripter with sandwich panels, you simultaneously kill two hares: insulate the design and give it a very aesthetic look.

Insulation

When the "fourth wall" is created on your loggia, you must necessarily insulate the walls, gender and ceiling. What and as the question is no less complicated than the choice of the glass package, because it all depends on the result you want to get. More precisely, on how much you want to insulate the loggia. If it is planned to equip, for example, an artistic studio in which you will work almost all year round, you need to warm up better. It will evidence, to ensure the heat transfer resistance of at least 1.8m2c / W (the level of heat transfer resistance of the wall of a wooden house). If your desires are more simple (for example, you want the temperature in any frost to be lowered below + 5C and not frozen cans with pickles), then it can be in a lesser extent.

For insulation, a variety of materials are used, from 100- and even 150-millimeter mats from minvati (both rigid and soft) to polystyrene foam and highly efficient insulation from modern foam materials, the thickness of the layer of which is significantly less. In every case, there is its optimal relationship between wishes (the better, the better), financial capabilities (they are also not endless) and the loss of the useful area and the height of the basement of the loggia (the thicker layer of the insulation, the same losses more). The only advice that can be given here is to apply materials that minimally increase the load on the overlap.

Since we failed to find a universal insulation recipe, we will try to briefly summarize the options that we were offered in firms dealing with this issue.

Floor. Cases are offered by the floor on wooden lags, which are necessarily processed by the antiseptic composition before stacking. The height of the lag depends on the type and thickness of the insulation used, as well as on whether you or not align the floor of the loggia (it necessarily has a bias towards the parapet that ensures the flow of rainwater). If the floor is aligned, then the minimum allowable thickness of Lag- 40mm. They are stacked on wooden lining plates of various thicknesses (due to this difference and alignment). Closer to the parapet between the lags and the floor there is a gap, the value of which can reach up to 4-6cm (it depends on the width of the loggia). Between such lags, it is easiest to place mineral wool, because it allows you to more or less smoothly increase the floor thickness (from 4 to 10 cm). Then the laying of vapor barrier and laying of the draft floor is performed. It is made of waterproof plywood (thickness of at least 15 mm), chipboard, OSB (thickness of at least 20mm) IT.P.

Preferences here each manufacturer has their own. For example, the Specialists of the "window in the XXI century" prefer the digest - since the rain and high humidity of the air loggia are practically isolated, chipboard on the floor will not creak and reliably hold the finish coating. The amphan "Hobbit", for example, applies only moisture-resistant fane ffsf. The heat transfer resistance (R0) of such a floor is within 0.97-1.97 m2c / W.

If the floor is not aligned, it is possible to insulate it in another way. KRYMERA, in the company "Chameleon" offered such an original option. The extruded polystyrene foam 30-50mm thick is attached to the floor on the liquid mortar. Sheets are not close to each other, but with a 0mmm gap, and then these gaps are proper. The result is obtained, it can be said, the monolithic layer of the insulation, on top of which the screed is satisfied (cement, polymer self-leveling) with a thickness of about 30mm. The mixing for strength is stacked by the reinforcing road grid with a cell of 100100mm. The strength of the received coverage is such that it is forgoing to ride on an auto loader. Resistance to heat transfer of such a condition of 1.8m2c / W. Afirma "Kamoplast" proposed to apply for insulation of the floor sandwich panels from extruded polystyrene foam 50mm thick (Styrodur from BASF), lined with a 12-millimeter cement-chip plate (CSP). The panels have a size of 1250600mm with a quarter sample from the side. The price is about $ 27 / m2. The panels are stacked by a lined CSP side up and attach to the floor of a dowel. The TSP surface should be treated with hydrophobic composition.

Ceiling, walls, parapet. It is usually proposed for a design on a wooden frame, in the intervals of which mineral insulation or polystyrene foam is laid (during the subsequent trim, the plasterboard is advised to use a metal profile).

Most insulation firms offer to use "Penophol". This combined material consists of a layer of foamed (self-pulling) polyethylene with closed airpasses, from one or two sides of the decomposed aluminum foil thickness of 14 microns. Subtle material (4, 6, 8 and 10mm), flexible, easy, environmentally friendly. Its action as reflective insulation is based on a high aluminum heat-reflective ability. In this case, the base (foamed polyethylene) has a thermal conductivity of 0.049W / (M2C). Thus, the "foam" is simultaneously heat, paro, hydro, wind and sound insulation material. Mounted foil inside the room with a mandatory air layer between it and a finish of at least 1 cm. Craits of the crates are attached to the nails and the stapler, the joints are sampled by aluminum scotch. R0 design with one layer of "foam" 10mm with one-sided foil is about 0.6 m2c / W, with two layers (first with one-sided foil, second with double-sided) and two gaps - up to 2.0 m2s / W.

Combined installation of "foam" (10mm) with mineral wool (40mm) is possible. Such a composition will be not only a good heat insulator (R0-1.5M2C / W), but also a more efficient soundproofer.

Some characteristics of glass packs

| Formula glass-paste | Sound absorption, dB. | Resistance heat transfer(R0), m2c / w |

|---|---|---|

| 4m1-10-4m1 | 25. | 0.29. |

| 4m1-16-4m1 | 26-31 | 0.32. |

| 4M1-AR10-K4 | 31. | 0.55 |

| 4M1-AR16-K4 | 32. | 0.59. |

| 4m1-6-4m1-6-4m1 | 30-32. | 0.42. |

| 4m1-10-4m1-10-4m1 | 32-35 | 0.47 |

| 4M1-12-4M1-12-4M1 | 36. | 0.49. |

| 4m1-16-4m1-16-4m1 | 34. | 0.52. |

| 4M1-AR10-4M1-AR10-4M1 | 32. | 0.49. |

| 4M1-AR6-4M1-A16-I4 | 33. | 0.64. |

| 6M1-20-4M1-AR16-K4 | 39. | 0.79 |

M1- polished glass; K-energy-saving to-glass; And energy saving and-glass; Ar-interconnect space filled with argon.

4m1-16-4m1-glazed glass 24mm wide, in which 2 glasses with a thickness of 4mm with a distance between them are 16mm.

4M1-AR10-4M1-AR10-I4-glazing 36mm width, in which 3 glass 4mm thick with a distance between them 10mm. Last (internal) glass - energy-saving and-glass. The second interconnect space is filled with argon.

It is quite tempting in terms of ease of installation and reduce the loss of a useful area looks like an application for insulation all the same sandwich panels. They are attached to the walls and ceiling or with the help of dowels and self-tapping screws, or with the help of glue type "liquid nails". Moreover, warming the walls, you immediately finish them.

According to the majority of specialists, the most complete solution to the problem of sealing the joint of the window structure installed with the wall ensures the use of ILLBRUCK materials (Germany). The joint is stupid and outside closes with a decorative self-adhesive nickname Fenster-R0LLLEISTE AUSSEN with a steamproof seal. Such products appeared on the market relatively recently. From the inside of the seam, it is possible to close the self-adhesive vapor insulating ribbon Fensterfolie Innen based on aluminum foil. The cost of such protection is 4 / p. m.

Finish

It is possible to decorate the walls with wooden or vinyl clapboard, panels or plasterboard. It all depends on the personal preferences and financial capabilities of the owners.

Many firms prefer to finish with plastic panels, in particular Panelit made by Wavin (Netherlands). Inno, there are a lot of reasons. They are made of a durable moisture reformable and stable plastic scratches (size 2600250mm). Installation is very simple. Thanks to the spike-groove system available on the panels, they are easily joined and so tightly adjacent to each other, which create the effect of a smooth seamless surface. Cobrette is mounted with nails, self-tapping screws or glue. A wide range of monophonic panels and panels with a modern decor under the tree, a sponge, stone and marble are offered. IWS These options are possible in several color solutions. For finishing of adjoins and angles there is a large selection of profiles of the respective shades: connecting elements, external and internal angles (including flexible and prefabricated), initial and final elements (including composite), plinths (including universal) IT.P. Standard profile length 2,6m. Price, from 100 to 170 rubles. Caring for the finish is extremely simple: from time to time it is necessary to wipe the surface with a damp cloth.

Similar panels produce domestic firms. These products are not much cheaper than imported, but their color gamut and the range of volunteers, as a rule, is significantly already.

In addition to PVC panels, the market offers many domestic and imported laminated panels from MDF. In size, they are similar to panels Panelit. The choice of colors and drawings is also diverse. Price, from 160 rub. Over the panel.

The draft floor can be covered with any cute personally to you with material - linoleum, parquet, parquet board, laminate, carpet, tiled IT.D.

Heated loggia

Since the insulated loggia is separated from the apartment with a balcony block, it is still colder than in the residential premises. Therefore, the last thing is to be thought out - than and how to maintain a comfortable temperature on it. Ovinos of the central heating radiator we advise you to forget immediately, when this fact is detected, you are guaranteed. Large! More relevant modern electrical appliances: convectors, fan heaters, infrared heaters IT.D. Those who have already conducted insulation with their help, argue that to create a comfortable atmosphere on a 6m2 loggia of 6m2 sufficiently automatically supporting the temperature of the electrical connector with a power of 2 kW installed directly under the glazing. A stable popularity is enjoyed on a warm floor loggia, this is beautiful and comfortable.How it all happens

In principle, everything happens almost the same as when ordering ordinary windows. You pretend that you would like to get ultimately, and choose a firm that will work. Note that the firms are divided into three categories: the first will produce and install a translucent design (such a majority are all companies involved in installation windows), the second will fulfill all types of work - from creating a structure to finishing, the third will be insulated and finished after How will the "fourth wall" (such minority) be erected. It must be said that with the second category work is easiest. The first and third is more difficult, since it is for you to coordinate their actions.

After the firm (firm) is selected, call the measurers (as with windows, a challenge is free). It is tasked, to identify all the necessary sizes, discuss with you detailed requirements for future design and offer possible options for its construction. You must choose the option that will arrange you both in quality and cost. Through the agreed time (from 5 to 10 days), the parts of the ordered translucent design will be delivered to the house and will begin to mount it (as a rule, it is done in one working day, but if the loggia is very big, then in 2-3 days). Mounting technology is not much different from the installation of the plastic windows described in the article "New Plastic Windows". On the next day, workers will begin to insulate and decorate. These operations will occupy from one to three business days (it all depends on the configuration of the loggia and the complexity of the selected insulation technology). Well, and how much it can pour it all, try to determine by using the given table given by the data.

We, as illustrations to all of the above, we offer you a photoxronist of the insulation of a loggia in a typical nine-story building of 1971. The author, with the support of the editor, simply checked, as it happens, on its own experience.

The editorial office thanks the company "Chameleon", "Business- Development of the XXI", "Window in the XXI century", "Allys", "Overweight", "Om-Plast" company, "Hobbit", "Metaplastika", as well as a consulting center of the trading network "Penofol" for help in preparing publication.