In the case of cladding the glue - the most responsible component of the quality of the finish coating. Try to pick it up correctly.

Preparing solution, it is important to accurately withstand the proportions: the lack of water will reduce the viability of the solution and it will make it difficult to apply it, and the tile will be thrown

When finishing the room by multi-format ceramics, one brand of glue can be used. But it should be selected so that the solution holds the largest tile

The mixture on white cement will not spoil the appearance of a glass mosaic

Ready for the use of glue-paste based on water dispersion of polymers glitters on the principle "All on All"

Ceramic tile, mosaic, porcelain stoneware, natural stone ... Today, the choice of facing materials for many turns into an exciting and creative occupation. But if you want to decorate the surface of the surface in your home pleased the eye and served a long time, you need to choose the right ...

Most of us at least once in their life were glued with wallpaper. They have to be changed relatively often, even though the market has long been sustainable materials, for example, on a vinyl basis. Avot Ceramic tile is much longer, sometimes dozens of years, and the ability to "practice" in self-laying of the tile is quite rare. The same, this work itself is still more complex and time-consuming. To mount the tiles, certain skills will be required, and the quality of the finish wants to get high (so that the masonry is with even seams, the tile has not fallen off from the walls of IT.D.). Therefore, as soon as the need arises in told work, we first affect the help of a specialist. Moreover, as a rule, especially without going into the subtlety of the process, the boxes with a tile, after a few days we take work. However, gradually, in the course of the operation of coatings with a facing, then there, here the tile begins to flap, and in some places goes because of the moisture that fell inside. And perhaps the master did everything right and gently, but used the universal glue where it would be better to apply a special. Aveted in the case of facing the tile is the most responsible component of the quality of the finish coating. If it is competent to pick up, you do not have to overpay for the alteration of work and for new materials, especially since the good tile is much more expensive than adhesive composition. Therefore, do not hurry to save to the detriment of quality, buying the first glue. Try first to figure out what, where and how you are going to glue.

Collapse in composition

There was a time when the same solution was used for internal and external work, the same solution was used, which included part of the cement Mark M 400 and two or three parts of sifted river sand. The mortar was prepared by the builders themselves, and it was possible to rely only on their qualifications and conscientiousness. True, neither the other helped when in the spring on terraces and facades, the tile was discharged due to moisture ingress, which in winter he frozen and thawed several times: the solution had a low frost resistance and ensured insufficient adhesion of the finishing material to the surface. The woven rooms, bathrooms and in the kitchen, the tile was fucked by the "glue solution" - sour cream-like mass from the PVA dispersion, cement-sand mixture and water, as well as bustile type glue (also based on PVA), in whose voids of tiles Loved to shave cockroaches.

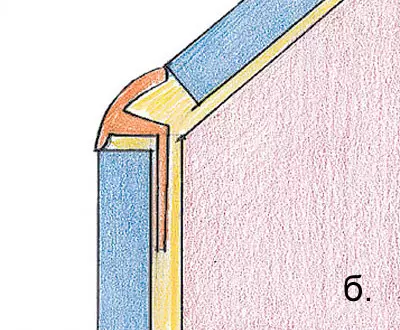

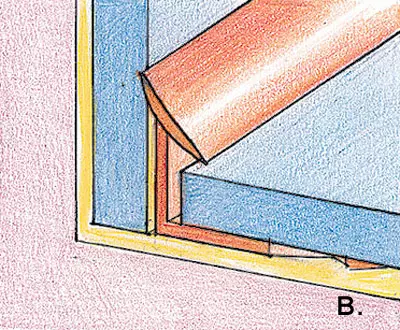

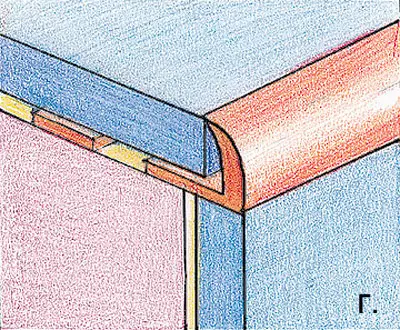

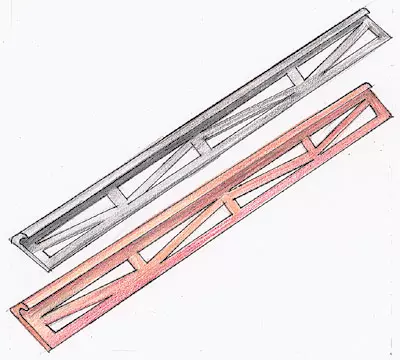

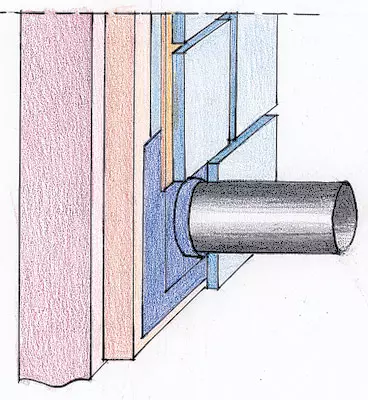

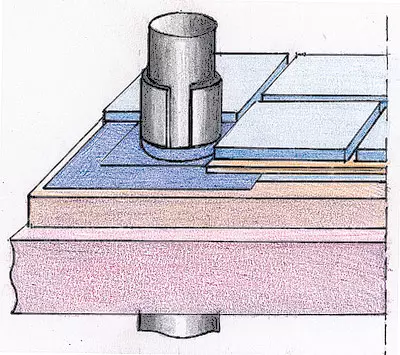

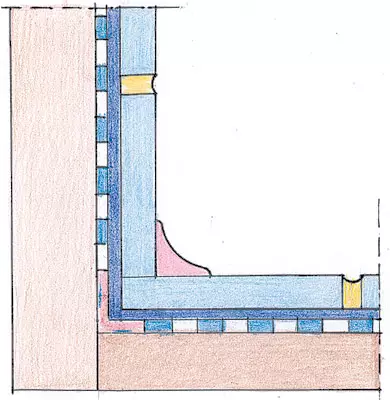

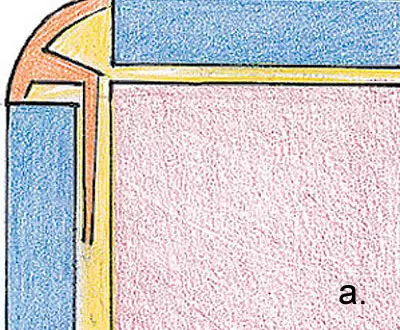

For decoration of external and internal angles, window and doorways, bath contours, showers can use special aluminum planks or PVC profiles of various colors (depicted in the bottom of the bottom). They mask the edges of the tiles and protect them from damage. PVC flexible strips are suitable for finishing any bends and curvilinear surfaces. Aluminum profiles will help keep the edges of the masonry in the zone of thresholds, stupid stages. Products are available under the tile of different thicknesses: 6, 7, 8, 9 and 10mm. Planks are put in place, indulging in the applied adhesive solution.

Today in stores and in building markets you can find a huge variety of modern adhesive compositions for fastening any kinds of ceramic tiles. The number of manufacturers presented numbers several dozen. Active expansion of the range of tiled adhesives at one time contributed to foreign firms whose products are good in demand and so on. Some Western companies have already discovered, while others reveal their own plants or joint ventures in Russia, supplying the most undercurred glue compositions to the domestic market (mainly universal mixtures, as well as mixtures for internal and external work). Prices for such products - with practically similar quality, are usually somewhat less than that imported from abroad (find out where one or another adhesive of foreign brand is easy to see if you look at the inscriptions on the package). For now, the choice of imported materials is so wide that the "Place of Relations" companies can be studied by geography. Large firms, having a large line of a variety of compounds for fastening the tile, often produce their products simultaneously in several countries. Having traveled to the campaign shopping stores, you can meet glue from French firms Bostik Findley (Sader Trademark), Semin, Emfi; German Henkel Bautechnik (Ceresit trademark), Lugato Chemie, Jobi, Knauf, MEFFERT AG, PUFAS; Polish Atlas and Anker; Finnish Optiroc Maxit Group (Vetonite Brand "), ScanMix; Swedish Terraco; Italian index S.P.A, MAPEI, as well as Litokol (Russia-Italy); Turkish Markem and others. Russian products are represented by the adhesives of companies "Bolls", "Glims-Proc." Socrates ")," Svadst "," Lacra Decor "(Lacra's trademark)," Stretch "(Brand brand" Stretch ")," ROY "(brand" Plovetonite ")," Experimental plant of dry mixtures "(trademark" Birsss ")," Ruslumus "(trademark" Eurolux ")," Petromiks "," Students "," Team Trading "(trademark" UNIS "), Stern-Dukkerhoff (Sopro trademark)," enterprise VGT "(Tradingmark" VGT ") and others.

|

| For decoration of external and internal angles, window and doorways, bath contours, showers can use special aluminum planks or PVC profiles of various colors (depicted in the bottom of the bottom). They mask the edges of the tiles and protect them from damage. PVC flexible strips are suitable for finishing any bends and curvilinear surfaces. Aluminum profiles will help keep the edges of the masonry in the zone of thresholds, steps, etc. The products are produced under the tile of different thicknesses: 6, 7, 8, 9 and 10mm. Planks are put in place, indulging in the applied adhesive solution. How can I use profiles when cladding, is shown on the top figure: |

|

| |

| a) connection at an angle of 90; b) tiles connection, located under a stupid angle; c) finishing of the inner corner; d) finishing an external angle; |

All tiled adhesives, essentially, can be divided into two large groups. The first form glue pastes, or mastic, which are sold already in the ready-to-use form and are a homogeneous mass, a consistency resembling a thick sour cream. In general, for these materials, that all of them are water-dispersion compositions: they contain finely divided, but not dissolved in water polymer (as a rule, artificial resins and their derivatives). Such a suspension hardens only after evaporation of water. The example of the example is aware of the "Bustylate" type well known for all (produced by different manufacturers), which is an aqueous dispersion based on polyvinyl acetate. Ready-made adhesives are packaged in rigid plastic buckets of different capacities (mainly up to 5kg). They do not need to be diluted or thicken, it is enough to stir the contents of the bucket, and you can immediately begin to work. Dispersion masts and pastes have good adhesive properties, are evenly distributed on the base, and after drying, they form a rather elastic layer. True, the region of their use is limited, for the most part these are simple internal works (including decorative wall decoration in dry rooms), as well as repair and restoration of old tile coatings.

The most extensive group of tiled adhesives is represented by dry mixtures that are inducing water. The shortage of such mixtures includes a mineral binder (its role is carried out by various grades of cement) and fillers (most often quartz sand). Doodles of cement-sand tiled adhesives to the share of binder and fillers accounts for 95-99%. Rest- organic binders and modifying additives. Organic and synthetic binders in a dry state are powder-sprayed and dried water dispersion of polymers. Dissolving in water, the powder restores its dispersed properties, and therefore is called redispersed. The problem of modifying polymer adding is to give adhesive with those or other required properties, depending on the application area. To do this, the recipes of different materials include water retention, plasticizers, defoamers, pigments, setting regulators (accelerators and moderators), as well as emulsifiers and hydropobizats (that is, water-repellent substances). Vitoga one glue has high adhesion and keeps heavy large-format tiles, the other has improved elasticity, the third - elevated water resistance and frost resistance of IT.D.

The overwhelming majority of tiled adhesives today are sold in the form of dry mixes closed with water. These are complex multicomponent compositions, and each manufacturer has its own natural recipe for their manufacture, which are not disclosed secrets. Therefore, we can only judge about the approximate composition of the mixture. Glue necessarily contains fillers: usually it is dry fractionated (that is, with particles of strictly defined size) quartz sand, crushed dolomites, limestone, ground calcite and slags. As a binder, both minerals (portland cement, harated lime, gypsum) and organic, based on polymers (artificial resins) are used. In order for the novel solution to be optimal viscosity and did not resolve it, cellulose esters are added to the mixture: their presence in an amount of at least half of the percent makes it possible to obtain materials suitable for the basis with strong water absorption with almost no prior processing. Due to the introduction of cellulose esters, adhesion is improved adhesion and to the base, and to the tile. In addition, the time is increasing during which the position of the tiles can be adjusted. Finally, the composition of the dry adhesive mixture includes so-called radispensable polymer powders, that is, in specially dried aqueous dispersions of polymers that restore their physical condition and properties when the solution is shown with water. Thanks to these components, the viability of the solution increases, not only the frost resistance of the glue is improved, but also its ability to adhere even with non-standard bases (plastic, chipboard, a layer of old paint, poorly absorbing moisture surfaces). And in order to give glue certain properties (elasticity, increased adhesion, additional strength IT.), plasticizers, thickeners, foaming agents and other additives are introduced into its recipe.

The advantages of dry cement-sand mixes in front of ready-made adhesive mastic mastics. These are the best mechanical qualities of solidified solutions, high fastening reliability, the possibility of use for external work. Dry glue compositions are sold packaged in bags weighing 5 or 25kg, so you can always choose the desired packaging depending on the scope of work. An important factor remains the difference in prices. The three-kilogram bucket with finished dispersion glue of imported production costs about $ 7-10. The standard bag (25 kg) with a good domestic tile glue based on a dry cement-sand mixture will cost $ 5-6.

Universality is not vice

In the line of tile adhesives of almost all manufacturers, there are always one or two types of compositions designed to carry out a wide range of simple work. Such mixtures can be conditionally attributed to the category of standard, or multipurpose. What is meant here and what works are considered uncomplicated? Typically, two main factors are the geometric dimensions of the tile and the type of base to which it will be glued. Of course, an important circumstance remains the scope of glue (either for outdoor or for internal works). Let's say if you need to put the tile of standard sizes (100100, 150150mm) or a smaller mosaic tile on the floor and walls in a dry room, it makes no sense to buy expensive glue for pools or for fixing large-format tiles. The grounds from the old concrete are considered simple (from six months or more), light concrete, plasterboard plates, as well as mineral (plastered and brick), - that is, those surfaces that do not give shrinkage and are not deformed. The basis for glue should not be also susceptible to thermal compression, which happens if the floating floors are arranged. Universal adhesive compositions contain a minimum of modifying additives that enhance certain properties of glue, due to which the price is lower and the price of the product.The standard-universal can be attributed to modern pasty mastic, such as dispersion Tile glue SuperKleber from Knauf, "Eurolux-E8-K" from "Ruslux", "Akrol" from "VGT", Glue-paste "COP Universal" from "Jenness Howes ", Terraco terraco, Dufa Gigant d 21 from Meffert AG, Sader Carrelage from Bostik Findley, Universalkleber Gigant from Jobi and others. Most of them are intended mainly for internal works and are recommended for gluing ceramic and mosaic tiles, natural stone, tiles on concrete surfaces, asbetic, aerated concrete, plaster, plywood and extruded mineral fibrous plates. As a rule, the glue is applied to the prepared (that is, primed) base and is distributed to the toothed spatula. If it is necessary to mount the tile with a smooth inner surface and dimensions of no more than 150150mm, a spatula with a height of 3mm teeth is selected. Under the installation of medium-sized (up to 250250mm), tile and mosaic sprinkle glue best, using a spatula with a teeth height of about 5mm. The practical consumption of glue paste depends on the degree of alternation of the base and the ceramics used. Thus, for small tiles, the thickness of the gluing layer (it is referred to in mind the glue-applied and smoothed with a gear spatula) can be at least 1.5-2 mm, for the mid-sized, respectively, 2-3mm. Approximate consumption of material is necessarily indicated by the manufacturer on each package. At the same time, the permissible thickness of the adhesive layer is negotiated, as well as the nature of the work. Inviro-dispersion paste BIS from Atlas The minimum thickness of the adhesive layer 3mm, and the maximum is not more than 8mm (in the first case, 1 m2 surface will leave about 2kg, and in the second 3kg glue). The thickness of the adhesive layer with any works with the glue paste "COP Universal" from the "Jenss Hauz" should not exceed 6-7mm (consumption - 1kg / m2). Be careful using dispersion glue to level the base and fill emptiness. If the surface drop is more than 4-5mm, it is better to take care of it even before tile work, applying the appropriate plaster and putty compositions. Applied to a too thick layer (over 5mm), the glue paste has a low adhesion and does not keep tile. It should not also forget that universal pasty formulations have limited water resistance, and the region of their use is not subject to high humidity. Therefore, it is more expedient to choose water-resistant grouts for sealing intercutric seams.

Compared to dispersion, cement-sand glue mixtures of multi-purpose destination, such as "Unice Plus" ("Film Trading"), "Plus" ("prospectors"), Ceresit CM 117 (Henkel Bautechnik), "ATLAS adhesive mixture" (Atlas ), "Basic" ("Lacra Decor"), Sopro FBK 372 (Stern Duckerhoff), Fliesenkleber (Knauf, Jobi), Sontact, Unibond (Index), "Glue for Standard Tile (" Stretch ") and Others, have even greater opportunities. First, the bulk of the mixtures attributable to the standard of standard can be used for both internal and external work. Secondly, the compositions are applicable to the construction of walls from aerated concrete blocks and puzzle gypsum plates. Inclined The masonry mixture is suitable, for example, "UNIS 2000", Atlas Inter, "Glims 93 Fix". The viability of the solution, that is, the time during which it is suitable for the materials of different manufacturers varies from one and a half to four hours. This is enough, To lay out, let's say, the interroom partition even in the most Storn room. Correction the same position of the blocks is possible for about 15 minutes after laying. Thanks to multipurpose mixtures, you have the opportunity directly in the process of cladding to align minor surface drops and even putty, with a layer thickness of approximately 3-5mm (if you need to eliminate small irregularities and defects of the base in the form of shells or cracks).

It is especially worth mentioning that under equal conditions, cement-sand mixtures provide better fixation of tiles on surfaces subject to mechanical loads than dispersion adhesive pastes. Of course, the floor tile can be stacked with mastic. But in the hallways, corridors, on the staircases it is more reliable to use dry mixes with cement binder.

Finally, the universal dry adhesive mixtures are suitable for laying tile, ceramic, mosaic, clinker tiles, as well as tiles of natural stone. True, unlike specialized compositions, not every multipurpose glue can be used for filling the warm floors, pools. Not all adhesives provide and proper grip with weak (PVC panels, old tile or paint) and deformable bases (such as young concrete or partitions from chipboard and drywall). Therefore, our advice, when buying an inexpensive universal glue (and in general, any glue) carefully read the annotation on the package: the overwhelming majority of manufacturers describe in the most detailed as possible, in what cases the product is used for what kind of basics. If you still doubt the choice, and the tile will have to be laid, for example, on a young concrete or difficult to clean the surface, it makes sense to carry out a small test for the strength of the compound of the base with glue, and glue with tiles. To do this, glue one or more tiles and in two days check the result. If an attempt to tear off the tile from the surface is not crowned with success, the material is selected suitable. Of course, it will still have to purchase glue, but since there is ahead of you, perhaps a large amount of work and will need a few bags of the mixture, it is best to try it in advance by bossing a small package weighing 2 or 5kg.

The bases with a high absorbent ability must necessarily be projected. This is especially important for gypsum-containing materials and plaster, drywall, hydro fiber plates. The primer creates a film that regulates the absorption of water from the glue solution and at the same time connects the surface layer if it is not durable enough. It is even better than the base from drywall or plaster to treat a special moisture content of polymer dispersions, the closing pore of the hygroscopic surfaces. In all wet rooms it makes sense after alignment or primer the walls carry out work on waterproofing. In addition to performing its main task, it prevents the propagation of cracks from the base to facing coating. Usually, waterproofing is carried out in two stages. First, the joints of the walls or walls and the floor are sampled by a special ribbon, which holds the seams in case of deformation, if the walls begged under load. Then the waterproofing layer is applied (a special mixture of polymeric materials). All the necessary funds for this are producing many firms, including Atlas, Henkel Bautechnik, Mapei, Optiroc, Index, etc. Do not forget that at all stages of surface preparation to the finishing facing the best result will be achieved if you use the materials of the same manufacturer. . In case, you will firmly know that compatibility, say, the waterproofing layer and the tiled glue is 100%.

Ultimately, universal compositions are both good that during repair you can perform a variety of facing work. With the help of ready-made dispersion mastics, not only tile, but also linoleum, various carpets, ceiling plates made of hard foam or PVCs can be glued. Many cement solutions are suitable for laying tiles and indoors, and on the street. This is where to be attentive: the inscription "for external and internal works" on the package does not mean that this glue is suitable for cladding, say, the facade base. It is better to read the annotation to the end. Often the words "for external work" in this context imply the possibility of decoration of relatively small surfaces in strictly defined places (balconies, covered terraces, external stairs). This is due to the fact that the applied adhesive composition may have limited frost resistance. As a rule, there are no particular problems if you use solutions with marking "frost-resistant" and "waterproof". For a long time to look for such a glue: it is in the lineup of almost every manufacturer, it is enough to mention as an example of Atlas Plus, Ceresit CM 117 and Ceresit CM 14, Luxury ("prospectors"), "Glims 96W", Fliesenkleber (Knauf, Jobi ), Yunis Plus, etc.

Hands on the seam!

Properly selected and high-quality glue mixture is only half of the case. Following the laying of the tile, the stage of finishing works is coming, and before the imposition of intercutric seams. It is carried out after removing the spacer cross and solidification of the solution, in standard cases not earlier than 24 hours after cladding. The dry rapid mixture, or, otherwise, the fugue is a special composition on a cement basis with the inclusion of modifying polymer additives making material plastic, moisture-resistant and non-shrum. It is suitable for use both in dry and in humid premises. So that the seams were inconspicuous, in the tone tile, or, on the contrary, emphasized the texture, coloring and shape of the finish, you can apply colored grouts where pigments are introduced. As a rule, manufacturers offer about a dozen or more colors for wall and 5-6 color variations for floor masonments. The applied and dried grout is firmly held in the seams, not washed away from there with water and is not afraid of ordinary household detergents.

One of the main parameters to be taken into account when choosing a grout is the maximum amount of seam filled. The more elastic material, the seam may be more. High-quality grout dries in a 10-millimeter seam without shrinkage and cracking.

The consumption of a grout mixture depends on the size of the tile and the width of the seam. Let's say that the seams of 2mm width will leave about 0.7-1.5kg of the grout to 1m2, and with a width of the seam from 4 to 12 mm, it may be necessary to 2kg grouts to 1m2 surface.

Existing grouts on the market are allocated in three main groups. The first is simple and universal materials for conventional tiles and ordinary operating conditions (in dry and wet rooms). They close the seams with a width from 2 to 6mm. Such a distance between the tiles is characteristic of most kinds of masonry inside buildings, if it comes to wall and floor coatings. Universal grouts produce almost all manufacturers, it is enough to name such brands like "Glims", Ceresit, Atlas, "Unit", "Yunis", "prospectors", "Birsss", Knauf, "Plovetonit", etc. when laying outdoor facing from large-format tiles, porcelain stoneware, natural stone quite often seams are performed wide, from 6 to 12 mm. In this case, there will be highly elastic core mixtures that maintain the deformation of the seam and are not destroyed under the influence of mechanical loads and thermal compression. These properties allow them to pelt the seams between the tiles laid on the heated floors, in places with elevated wear (hallways, staircases, corridors). Calculated similar materials includes a "mixture for wiping wide seams" from Atlas, "grout for floor tiles" from Optiroc, Ceresit CE 37 from Henkel Bautechnik. Stripping group of griming mixtures can be isolated on epoxy basis for pools, fountains, water tanks. When the facing surface is in constant contact with water (and under its pressure), chemically active disinfectants and detergents, preferably use the epoxy grouts, for example Fugopox AB (index), Epoxystuk (Litokol), Ceresit, etc.

Studying instructions for the use of glue from different manufacturers, you will probably come across that the same properties of mixtures and mastic are called differently. The misconception in terms is most of all striking, if you compare the annotations to domestic and imported products. Often it is connected with the features of the translation. In addition, Russian standards that would regulate the quality of dry mixtures, so far, therefore, domestic manufacturers are focused on Western requirements, mostly German DIN or uniform European norms.

If you repel from European standards, then the following basic properties of adhesives can be distinguished.

Slip resistance. The adhesive solution should have certain thixotropic qualities, that is, have a thick, but plastic consistency and a sufficient degree of adhesion so that the laid tile does not slip. Most modern solutions are not allowed to slide tiles by more than 0.5 mm, which corresponds to European standards. But there are mixtures and with high-resistant closure (no more than 0.1 mm). The bathtop to them is indicated that the glue is suitable for laying the tile by the method of top down ..

Open time (Corcoising time) - this period during which the glued glue retains all its work properties, is not tuned, covered with a thin crust, and you can put a tile on it. Open operation (in some consumption firms) for adhesive solutions is approximately 10-20 minutes, for rapidly disconnecting - twice less. Check if you can still lay the tiles, very simple: touch your fingers to the previously applied glue. If it remains on the fingers, you can continue to work. If not, you need to remove the old layer of glue and apply new ..

Permissible adjustment time (Some manufacturers call this property of correction time or tile position adjustment time) - the time when, after gluing the tile, its position can be corrected before the decaying of the solution begins. The glue must ensure a slight movement of the tile for its final alignment, but it does not allow it to crawl and change its position ..

Solution Suitability time (It is also referred to as vitality, time of use, workability IT.D.) - This is the time to continue which the cooked solution saves all its work properties and is suitable for masonry. For standard adhesives, it is usually 1-4 hours. All manufacturers in the instructions for use of the material also indicate the time of the final setting of the solution, when it is possible to start the grout of the interputric seams, and the period during which the adhesive is gaining complete strength.

In order to give standard grouts additional elasticity, frost and moisture resistance, it is recommended to use special additives that improve these properties. They are a water dispersion of polymers and sold in bottles or canisters. Such remedies are available in ATLAS, INDEX, Henkel Bautechnik, Mapei, Knauf, Litokol IT.D. The superior dispersion is dissolved in the desired amount of water, and then the resulting solution is indulged in a dry mixture. Such a grout can be used in external and internal works, in particular for sealing seams in cladding on sheets of plasterboard and chipboard, as well as in floor coatings, including with systems of warm floors.

However, multipurpose adhesive pastes and solutions are able to guarantee the required level of reliability and facing quality far from all cases. There will always be a job where specialized compositions are fully expressed. Their appointment is the best to fulfill a specific task: to ensure the laying of the facade large-format tiles, glue the mosaic panel in the pool bowl, to withstand the fireplace heat in the living room, soften the mechanical loads in the corridors and on the stairs. But all this will be discussed in another article.

| Manufacturer | Mark. | Type of binder | Types of bases for laying | Suitability of the solution to work, min | Open time, min | Permissible time adjustments Regulations Tiles, Min. | Consumption of glue, kg / m2 | Packing | Price, $ |

|---|---|---|---|---|---|---|---|---|---|

| "Profix", Russia | "Profix Standard" | Cement | Concrete, brick, gle, plaster, putty in inner dry and wet rooms | 120-180 | twenty | 12-15 | 3-4 | Bag 25kg | 3,4. |

| "Profix Universal" | Cement | Concrete, Gypsum and Foottonal Blocks, Glk, Chipboard, Plaster, Putclones in Inner Dry and Wet Rooms | 120-180 | 15-20. | 8-12. | 2.5-3. | Bag 25kg | 4.8. | |

| "Experimental plant dry mixtures", Russia | "BIRS 26" | Cement | Concrete, brick, gle, plaster, putty in inner dry and wet rooms | At least 30. | At least 10. | At least 10. | 4.5 (with a layer of 5-7mm thick) | Bag 50kg | 5.9 |

| "Jenss Hauz", Russia | "CS Universal" | Silicate based water dispersion | Plastered, wooden, wood-chip, asbestos-cement bases, GLC, tightly holding old paints and varnishes | thirty | five | 10-15 | About 1 (at a layer of not more than 6-7mm) | Plastic bucket 1,5kg | 1,2 |

| "PETROMIKS", Russia | "PETROMIKS KU" | Cement | Plastered, wooden, wood-chip, asbestos-cement bases, GLC, tightly holding old paints and varnishes | About 240. | thirty | twenty | 3-4 | Bag 25kg | 9.05 |

| Index, Italy | Unibond | Cement | Concrete, brick, plaster, putty in inner dry and wet rooms | At least 360. | 20-25 | thirty | 2 (with a layer thickness of 6-7mm) | Bag 25kg | 22. |

| "Tigi-Knauf", Russia | SuperKleber | Dispersion of polymers | Plastered, wooden, chip, asbestos-cement bases, GLK, gypsum blocks | thirty | twenty | About 10. | 1.5-2.4 | Plastic bucket 7kg | 11.3. |

| MEFFERT AG, Germany | Dufa Gigant D 21 | Dispersion of polymers | Absorbing surfaces from concrete, plaster, asbestos cement, gypsum, plywood and extruded mineral plates, old tile, as well as solid and durable paint and varnishes | twenty | twenty | fifteen | Up to 1 (depending on the surface) | Plastic bucket 1kg | 6. |

| Atlas, Poland. | Atlas Plus. | Cement | Prefab concrete structures, aerated concrete, Warm floors, asphalt, monolithic cement floor, DVP, Plaster, Glk, Old stone | 240. | Minimum 20. | 10 | From 3 (depending on the type of tile) | Bag 5kg. | 5.9 |

| "Students", Russia | "Glue tile" Standard " | Cement | Concrete, brick, gle, plaster, putty in inner dry and wet rooms | 160. | twenty | fifteen | 3-5 (depending on the type of tile) | Bag 25kg | 3,1 |

| Jobi, Germany | Universalkleber Gigant. | Dispersion of polymers | Absorbing surfaces from concrete, aerated concrete, plaster, asbestos cement, plaster, plywood and extruded mineral and fiber plates, old tile, as well as solid and durable paint and varnish coatings | At least 30. | twenty | twenty | 0.3 (with a layer thickness 4mm) | Plastic bucket 1kg | 6,2 |

| "Team Treding", Russia | "UNIS XXI" | Cement | Concrete, brick, plaster, putty, monolithic cement | 180. | About 20 | 10 | 1.3-1.5 (with a layer thickness of 1mm) | Bag 25kg | 4,1 |

| "Mirage", Russia | "Glue tiled IVSIL PROFIT" | Cement | Concrete, Brick, Lime-Cement Plasters, Gypsum and Wooden Surface, Glk, Basics with Old Tiles, Foam Foam, Foam concrete, Chipboard, Slate, Metal, Plastic, Heated floors | 240. | twenty | fifteen | 1.5-2 (with a layer thickness of 1mm) | Bag 25kg | 3,1 |

| Optiroc, Finland | "Old" (for repair work) | Cement | Walls lined with plastic, ceramic tiles, painted surfaces, lightweight concrete, plaster, GLK in dry, wet and wet rooms | 240. | 10-20. | 10 | 3-4 (standard 66mm tile); 2 (mosaic tile) | Bag 25kg | 15.3. |

The editorial board thanks for the help of the preparation of the material of the company "Convent-Center", "prospectors", "UNIS MARKET", "Stern-Du Daumaerhff", as well as representative offices of "Atlas-Rus" companies, Optiroc Maxit Group and Henkel Bautechnik.