Autonomous power supply systems for use in a country house: a variety of mini-power plants, their features.

We have long become hostages of comfort and not imagine yourself without the use of electricity, wherever they are. Even in the most modest summer cottage, today they do not cost without refrigerator and lighting devices. One misfortune: about uninterrupted and high-quality power supply for now you have to dream. Fan electricity shutdowns, outdated networks, shortages of capacity, cable theft ... the great many problems, and solve them, it seems, no one, except the developer itself. That's when you start thinking about your own, home energy! Why not? The dream is quite achievable.

Objective reality is such that almost all modern communications and system of life support of a country house to one degree or another depend on the power supply. Heating, water supply, sewage, water treatment, alarm and video surveillance devices, lighting, air conditioning and ventilation, finally household appliances, computers and communication - it all needs uninterrupted energy supply. When electricity ceases to enter your site, some systems may also go into emergency operation. But most of them simply refuse to function. And it's not even in reducing the level of comfort, expensive equipment can exit. For example, a long-lasting stop of the boiler in winter will be wrapped by freezing the heating and water supply system.

Of course, ideally planning a reserve energy supply system is better at the construction or finishing stage. In order for the power quality when connecting to the local substation, it is relatively high, you can at least set the stabilizer with the frequency filtering function (stabilizer-air conditioning). It will maintain a 220V voltage on your network, and at the same time filter an electric current from high-frequency and pulsed interference. The input voltage range in which domestic stabilizers (128-275 B) work, allows you to guarantee the normal action of household appliances in conditions of low-quality power supply (outside the city most often have to deal with reduced voltage).

And in order for the home power grid to receive independence from the whims of the local substation, you need your own reserve source of electricity. Uninterruptible nutrition blocks are unlikely to come out of the position, they work until the capacity of the batteries used. But what if the renewal of the energy supply is postponed indefinitely? Today, gasoline or diesel generator sets, or mini-power plants are widely used as relatively reliable de-energization protection. Often this equipment will be seen already during construction, if a constant power supply line has not yet been carried out on the construction site.

What it is?

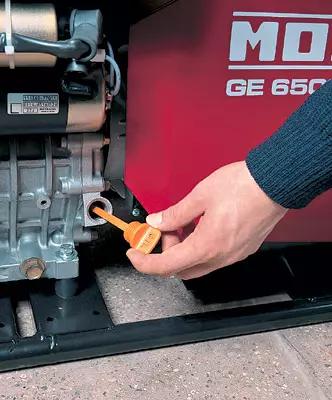

The same autonomous device generating electric current is often referred to as different. So in the store you can hear the words "electric generator system", "Electric unit", "generator installation", "Power station" IDR. In principle, all these names are appropriate. We will agree to call such equipment with mini-power plants. This refers to the device in which the two main elements are an internal combustion engine and an electric generator. If you simplify the principle of operation of the power plant as much as possible, it looks like this: the motor, burning the fuel, rotates the shaft directly with the generator rotor. The generator, in turn, transforms mechanical energy into electric. If not concerned with industrial samples, and only talk about relatively small-sized stations for domestic use, then, as a rule, the "engine generator" bundle is mounted on a solid spatial frame made of metal pipes, equipped with a fuel tank, a device for launching a power unit, an oil level sensor, Counter of Motocami, as well as control systems. If an electric starter start-up is provided, the station is equipped with a battery (though, on some manufacturers it is not included in the basic bundle and is proposed additionally for a fee).The list of electrical equipment of the station can be wide enough. Depending on the model, a voltmeter, an ammeter, an automatic or manual voltage adjustment regulator, a protective device against current leakage (UZO), isometer (protective block with constant insulation control between network and protective wire), waterproof outlets, 12-volt exit DC for charging batteries IT.D. True, each element complicates the construction of the station, which means it grows its ultimate cost. Therefore, in most cases, manufacturers offer basic models, and additional electrical equipment can be ordered for a fee.

Most power stations are supplied with standard connectors (simply speaking, sockets). But if the unit is designed for a stationary installation as a constant backup power source, it makes sense to connect the electrocabilities directly to the output terminals, which are usually located on the generator dashboard. Recompute with the international standard of more, sockets at stations have a color marking depending on the voltage: yellow color- 110V, blue- 230V, red-400V.

We consider power - 1.

Simple additions of devices for devices will not give you the right idea of the required power of the station. More precisely, the power can be summed as long as you make calculations for instruments, all the energy consumed is converted to heat or light. Such consumers (electric stoves, heaters, incandescent lamps, ITEGs IT.P.) are called active. Remove everything just: if the instrument on the passport consumes, say, 1kW, then it is enough to provide it with 1kW. All other consumers (luminescent lamps, drills, televisions, air conditioners IDR) are called the reactive, part of their energy turns into heat, and part is spent on the formation of electromagnetic fields. Vinnoler calculations of the reactivity measure is indicated as COS (cosine FI).

To calculate the actual energy consumption of such a device, it is enough to look into his passport. Let us give an example. AC electric motor purses indicates its power in kilowatts- 4kW. But this is the mechanical power on the motor shaft. The active power of the electricity consumed by the engine is determined by this value divided by the efficiency of the efficiency, also specified in the passport. For the engine of such power, the efficiency of the efficiency is usually 86.5%, that is, its active power is approximately 4.62kw. However, an alternating current electric motor has except active (thermal) and the reactive component of the power. To determine the full engine power, turn to his passport again. Cosine fi is indicated and, suppose, is 0.89. Consequently, the total power consumed by our electric motor from the network is not 4.62, but already 4.62: 0.89 = 5.19, but not kilowatt, but special units of kilovolt-ampere (KVA), in which the power is calculated district substations. It is for this reason that a number of manufacturers indicate power output power plants not in kilowatts, but in kilovolt amperes, which is more correct. Thus, it is necessary to know the complete power of electrical appliances in Volt-amperes. To estimate the full power, manufacturers offer to divide the known values by 0.8-0.9 if the efficiency of the efficiency of the ICOSJ is unknown.

Mini-power plants are collected under various brands with a fairly wide range of firms from Japan, USA, Great Britain, Germany, Italy and Russia. Moreover, two groups of manufacturers can be quite clearly distinguished. Some manufactures power plants based on their own engines by purchasing generators on the side (this series includes Mitsubishi, Lombardini, Yanmar). Others produce stations using producers of our own production and purchased power units. This is done by F.G.Wilson (United Kingdom), Metallwarenfabrik Gemmingen (Germany), MOSA (Italy), Sparky (Bulgaria), etc. There are firms dealing with only assembly. All the most important components (engines and generators) they receive from other manufacturers. KRYMERA, from imported components collects its stations under the trademark "VEPER" Firm "AMP-set" (Moscow). Treat suspicion of one or another manufacturers, as well as to firms engaged only by assembly, there is no reason: all over the world all three approaches are common. Why spend the forces on the development of your nodes when you can take the most reliable components from a specialized company and thereby reduce the cost of the station?

If we are talking about gasoline engines, the power plants are equipped with power units from manufacturers such as Kubota, Mitsubishi, Robin, Honda, Yamaha, Suzuki (Japan), Briggs Stratton (USA), Lombardini, Tecumseh (Italy). Diesels are made by the already named Honda, Tecumseh, Robin, Yamaha, Kubota, as well as Yanmar (Japan), Acme, Iveco, Ruggerini (Italy), Hatz, Deutz (Germany), etc. Metallwarenfabrik Gemmingen, most often completed with electric generators (trademark Geko), Generac, Stanford (United Kingdom), Leroy Sommer (France), Yamaha, Sawafuji Electric (Japan), Sincro (Italy) and others.

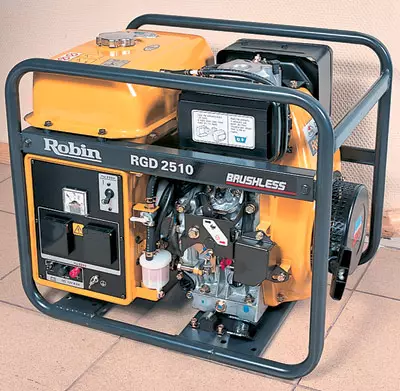

In our market there are power plants produced by Japanese Robin firms (division of the Fuji Heavy Industries concern), Sawafuji Electric (Energo trademark), Honda, Kubota, Yamaha, German Metallwarenfabrik Gemmingen, Endress, French SDMO and Worms, as well as Mosa, Sparky, FG Wilson et al. Metallwarenfabrik Gemmingen factory has two units and two trademarks: under the GEKO brand produced predominantly stations with asynchronous, and under the brand EISEMANN- with synchronous generators.

Power selection

Of course, the main criterion for choosing a power plant is its power, which must correspond to the power of the feeding equipment. The intelligent owners of country houses The list of consumers connected to the backup power supply may coincide, here only the technical characteristics of these systems, their combination and mode of operation are likely to be different. Take at least the last factor that is determined by the frequency and duration of the shutdowns, the lifestyle and the number of inhabitants of the house.

Therefore, it is very important to determine what exactly you want to connect to the power plant, and calculate the total power, taking into account the starting power of those or other electrical appliances and the inclusion simultaneity coefficient. It should be especially highlighted by consumers with increased sensitivity to the quality of electricity, such as computer equipment, Hi-END equipment, measuring instruments, etc.

Here is the time to think about which devices and systems available in the house really need to be powered first. The fact is that the power plant is a relatively expensive equipment. Yes, and electricity that it produces is expensive: if you take into account the cost of fuel, kwch home electricity is about fourwise more than "network", from the local distribution system. Therefore, the complete transition to "its" electricity is economically inexpedient. It is reasonable to divide all consumers into several categories. So, the least responsible can be attributed to devices and systems, without which if the power supply is turned off, you can do, such as saunas, shower cabins, cable heating systems of float, etc. The second category will be consumers providing comfortable accommodation. Here you get, say, kitchen appliances (stove, refrigerator, kettle, dishwasher), TVs, audio and video equipment, irons, electric shavers, finally, computers. The third category is the most important, since it provides life support systems (emergency lighting, security and fire alarms, video surveillance devices, electrical locks, heating and water supply).

Obviously, consumers of the first category should work only in the case when the main power supply is valid. Reserve any power for them is meaningless due to the disadvantageous ratio of "necessity-value". Avot to power from the backup source the most necessary electrical appliances and life support systems makes sense. As practice shows, most often the list includes boiler room, security alarm, water pump, TV and refrigerator, several lighting lamps and heating appliances. As a rule, their total capacity is about 5kW, but with a large desire you can reduce your own needs half, to 3 kW.

There is a significant amount of electricity consumers, directly at the time of starting which the starting power may exceed a nominal 2-3 times. Large starting currents (and therefore large power consumption) in the inclusion mode is characteristic of instruments with asynchronous electric motors. For example, the average rated power of the refrigerator compressor engine is 02kW, and at the time of the start it will be required about 1kW. The power of the submersible pump can be, for example, only 1kW, and the power value at the time of launch due to the large start current may turn out to be 5 times more. So, if you do not take into account the launchers, burn or generator, or an electric motor. Almost all manufacturers equip the power plants with overload protection by installing the temperature sensor on the winding of the electrical generator stator. So the Elemax SX-DX series is arranged (joint development of the Japanese Sawafuji and the Russian NGO "Power Supplies"), EX Series from Honda, RGV Station Family from Robin, etc. All generators in Honda stations are equipped with thermal protection, and when power overload (If you, for example, try to remove 5kW from the 4kW station) The thermostat turns off the unit.

Experts believe that the power plant should work "with a reserve", 80-90% of the established rated power. This is the most effective mode from the point of view of stability, the duration of the motor and economic efficiency. That's just the power of the stations themselves manufacturers indicate differently. Vatechnical documentation for European units is registered, as a rule, rated power. In the case, only the equipment can be connected in the case, the power of which in the starting modes total does not exceed the rated power of the power plant. Almost any Japanese unit has two characteristics - nominal and maximum power. At the nominal station, it works for a long time until the fuel refuel or oil change is required. The difference between the maximum indicated by the manufacturer and the rated power is the power supply required to provide starting currents for a small period of time. The station from the nominal to a maximum station can operate within 5-10, a maximum of 20-30 minutes, after which the thermal protection is triggered by turning off the unit. Long-term load mode is designed to work at 80% of the rated power. In the case, connect so many devices so that the start power in the amount does not exceed the maximum power of the station.

About generators

When choosing a power plant, pay attention to which generator is equipped with a simultaneous or asynchronous. The synchronous type generator issues stable voltage and frequency parameters. A station with such a generator is good for stationary use, withstands high starting currents, it can be loaded at full power, connecting various power tools, not too demanding to quality quality, as well as household appliances (pumps, refrigerators, washing machines, etc.). In the early time in the construction of power plants, brushless synchronous type generators are used that do not need maintenance.Asynchronous generators give out the purest sinusoid, but overloading with starting currents in this case is extremely undesirable. It is best to connect to stations with an "asynchronic" sensitive to the voltage drops, electronic devices, computers, tape recorders, CD players, etc. Altitude the use of the station for powering incandescent lamps, electric heaters, or if the power of the connected electric motors and other inductive loads in 3-4 times less generator power, it is better to also apply "Asynchronics".

Single-phase or three-phase generators can be used in power stations. The first give an alternating current with a voltage of 220 V and a frequency of 50 Hz, the second is designed to 220, and 380V. Moreover, if only single-phase loads can be connected to single-phase generators, three-phase can provide energy to the instruments calculated both by 220 and 380 V. If you are going to purchase a power station with a single-phase generator, it is enough without errors to calculate the necessary consumers (taking into account their launchers) and pay for an aggregate with a suitable output power (adding 25-30% for stock).

As for three-phase generators, when connecting to them single-phase consumers, the problem of skew phases may occur: one of them will be loaded less, the other is more. First, the phase skew (that is, the difference in the power of the consumers connected to them) at the station with a synchronous generator should not exceed 1/3, or 30%. If, for example, your three-phase unit has a power of 6kW, the total power of single-phase consumers should not exceed 2kW on the same phase. If you also connect the heater, at least 1.5 kW, there is a chance that the generator burns. Secondly, even if there is a three-phase network in your house, the backup power supply technically can be organized in single-phase mode. But it is necessary to calculate which of the phases of the generator is loaded more, but what is less to avoid skew. Well, when there are constant three-phase consumers in the house, for example, a deep pump is working, the choice falls on a three-phase asynchronous generator (installed, for example, on models such as GEKO 6000 ED-A / HHDA, ESE 204 from Endress or GE Station Series from MOSA). It can withstand phase skews up to 80%.

We consider power - 2.

To calculate the active power, the total installed power of the selected most responsible consumers multiply to the demand ratio. It takes into account the likelihood of non-use of the inclusion and the likelihood of the full load of consumers. The value of the demand coefficient is usually 25-30%. For our calculations, it can be accepted equal to one or close to it. Then we calculate the full power by dividing the active power on COS. The power of the mini-power plant should exceed this value, taking into account the starting conditions.

Suppose the installed active power of all consumers of the house with three-phase input is 30 kW with power factor (cosine fi) 0.9. The fill of consumers indicates: 1) Lighting - 3kW, 2) Emergency lighting - 1kW, 3) Electrical installation - 12kW, 4) Equipment boiler room- 2kvt, 5) Refrigerator- 0,5kW, 6) Security alarm- 0,5kvt, 7) Power supply Computers- 0.5kW, 8) Other equipment - 10,5kW. What devices to donate, solve you. Strictly speaking, to particularly responsible consumers include positions 2, 4 and 6. Their installed active power is 3.5kW, and the demand ratio is 1 (after all, they will work simultaneously and with full load), the approximate power factor (cosine fi) - 0.9. Starting current due to the lack of electric motors is insignificant, the starting current coefficient can be accepted with 1.1. Then the estimated active power of responsible consumers will be 3.5 1 = 3.5 kW, and their calculated full power is 3.5: 0.9 = 3,68 kva. Supporting the starting current and the reserve coefficient, which must be designated in the passport of the power plant (say, 1,2), the power plant should be selected with a power of at least 3.68 1.1 1.2 = 4,85kva.

Motor!

Mini-power plants are equipped with internal combustion engines, or gasoline or diesel. The aggregates with a gasoline engine are produced in the power range of 0.5-12kW, with diesel - from 2kW and higher. So the problem which engine choose, occurs only if you need a power station from 2 to 12kW: the aggregates are more powerful 12kW are usually produced, as a rule with diesel.

In comparison with diesel engines, gasoline installations, in addition to lightness and compactness, are less noisy and less vibrating, and with the same sizes and most powerful. The aggregates on gasoline fuel is equipped with most small stations (up to 6kW) and medium (up to 12kW) power, and almost only four-stroke engines with upper valve arrangements are used. Such a layout allows you to reduce the surface area of the combustion chamber (and, accordingly, reduce the heating of the node itself) and increase the degree of compression, thereby increasing the efficiency of fuel combustion. Such units have OHV labeling (the most famous products from Honda, Briggs Stratton, Yamaha, Suzuki). All modern motors already in the basic configuration are equipped with oil level sensors, and if the oil level in the crank is lower than the norm, the system is forcibly jammed the engine.

Gasoline stations with a capacity of 6-7kWs are most often equipped with a single-cylinder four-stroke engine with air-cooled and have an open frame structure. Such, for example, portable single-phase electrical unit EF-4600E from Yamaha, "outstanding" alternating current 15.9A, or an EP3000 model from Honda (220V, alternating current 9a). The interval between that Motors from Honda is 100h, the maintenance is reduced to the oil change. The fuel is the usual automobile gasoline of the AI-92 or AI-95 brand (mainly AI-92). The oil is used semi-synthetic or mineral.

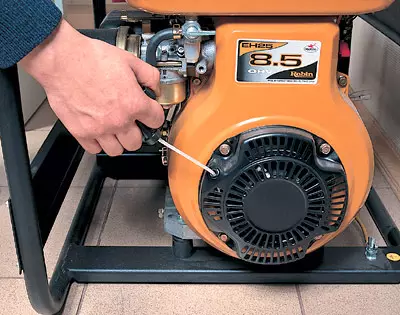

To start a cold gasoline engine, you will have to cover the air damper and, as the engine is warm up, open it. Of course, it is possible to alleviate manual launch. Thus, on Motors from Honda, a system is used, which at the time of jerking lace opens the valves to facilitate the effort. But what if you live in the house periodically or at the time of disabling the network in it there are only older people and little children? In this case, it makes sense to retain the station by the electric starter or acquire a remote manual remote control. Just specify by the seller if your selected model allows the installation of the electric starter and remote start using the remote control connected to the cable station.

The station with a gasoline engine should be purchased if it is not required to include too often and for a long time and you need relatively small power (5-6kW). This is a good option of a compact "emergency" or seasonal (let's say, for a cottage house) of the power supply. Or, suppose you have no light for a maximum of two weeks a year. Buying a diesel economically unprofitable: the most expensive gasoline models are not worthy of $ 900, while the cheapest diesel (from 2kW) will cost $ 1400-1500. In fact, the cost of the same in power of gasoline and diesel engines varies 2 times.

Since soon, you are looking forward to the fact that the station will be operated quite often or serve as a constant source of electricity, or, finally, a large (over 10kW) is required, the choice in favor of the diesel engine is obvious. Diesel installations are more economical than gasoline. Forward queue, there is a low fuel consumption, and therefore less costs for the purchase of diesel. Because, in fact, the stations are more powerful 12kW and are represented only by diesel models. In addition, the upper limit of their power is not limited, and the power of gasoline aggregates does not exceed 9-12kW. And also: in comparison with gasoline, a diesel fuel is less fires and may be more convenient to use. But you need to not forget to move on time to winter grade fuel: at a temperature of about-15s, the summer fuel saturated with various impurities is crystallized, becoming more viscous. Another important argument in favor of a diesel engine is a greater resource of work (if compared with gasoline modifications). I will have ever about 8 thousand hours.

Diesel power plants differ according to the cooling method: air is cooled by the influx of air, and the liquid as the refrigerant is used toosol. Liquid cooling diesel engines are used mainly in stationary power plants, such as ESE Family Units from ENDRESS, in EXT 12D models from Honda, Energo SHT 15D from Sawafuji, GL6500S from Kubota Idr. As a rule, the radiator in them is installed in a noise-protective casing, where it is impossible to provide sufficiently effective air cooling. On portable and portable stations (for example, TYP 15000 from Geko, EDA 5000 TE from Yamaha, the entire Robin line) diesel has air cooling, which significantly reduces the cost of equipment.

Running diesel engines can be made at-25c. To facilitate the launch, it is possible to heighten the air intake manifold equipped with an electric heater (this option is offered for a fee). But with a sharp drops of temperatures, the moisture pair condenses, which may adversely affect the electronic components of the diesel power plant (the electrical start panel, control chains, generator). Therefore, the passport temperature of the work of power plants (for example, the French SDMO) -5c. So you have to think about ensuring the heating of the room, where the station is equipped.

Automation

So, you defined which electrical appliances will need to be lit from a backup energy source. Some of them, it is necessary to stretch from the power plant to a separate wiring (without successive connections). So you will receive a reserved network. And you do not have to see the light, run around the rooms, shutting down the electrical appliances one by one before running the mini-power station. After all, it is enough to forget to turn off the plate or refrigerator, and the generator (if it is not designed for similar additional loads) burns. The arrangement of a separate electrocups is best to provide for the design and construction. If you buy a station to a finished house, wires can be breed through cable channels.But how to abominate the usual home and backup network among themselves? To do this, you can use special manual or automatic devices.

In the first case, it should be installed in the house the so-called cake chopper having two independent positions: "from the network" and "from the station" with a mechanical blocking that impede the simultaneous, oncoming incorporation of both sources of energy.

Imagine that you have all the lighting, TV, electric stove, audio equipment and a submersible pump. And suddenly centralized energy supply stops. You go down to the basement, start the power plant and connect to the reserved home network. After a while they give light again, and if you stop the electroagregat on joys, but do not turn off the station from the network, the generator simply burns. This will not happen if a shift switch is installed in the house.

In order not to suffer with manual launch, buy the electric starter station to the station ($ 50-150). In this case, the station will start with one click of the button. You can also purchase a remote wired control panel (its value varies from different manufacturers from $ 200 to $ 350) - provided that in the design is not mechanical, but an electric starter.

But there are devices that allow the station automatically, without your participation. Electronics tracks the state of the main power supply network and independently starts the station in case of disappearing or stress prepires at least in one of the phases. When recovering stationary power, the load switches back, the station itself switches to standby mode. The minimum time of the absence of voltage between the voltage loss in the main network and the resumption of supply of the load from the generator is from different manufacturers from 20 to 50 seconds.

You can easily calmly solve the problem of automated control backup network by stopping your choice at electronics stations. It is, for example, in single-phase ESE804BS / S ES models (gasoline synchronous unit; $ 2760) from ENDRESS, ENERGO EA7000A (gasoline synchronous; $ 2950) from Sawafuji / "Energy RegionStivers", "WEPER" ABP-6-230-WFBSG (gasoline synchronous; $ 3100) from "AMP-kit", EISEMANN P700UBLC (gasoline synchronous; $ 3770), etc.

ESE804BS / S stations ES and "VEPER" ABP-6-230-WCHBSG switching unit and control electronics is mounted separately, in its own housing, next to the distribution switch. The control cabinet and station are switched to each other signal loop and power cable. The automation tracks the decline (usually to the level of 150 V) or the voltage disappearance and decides on the transfer of reserved electricity consumers to autonomous food. The remaining stations from the above have built-in electronics. For example, to the input terminals of the "Energy" EA7000A (rated power of 5kW), it is sufficient to connect the "zero" and "phase" of the external power grid (the installation housing is grounded), and the inner home network can be considered reserved. When the external network is proper, the power supply of consumers is switched to it - the station skips the current "through itself". As soon as it fails (it drops, voltage is overstated or disappeared), the station independently starts. When recovering stationary power, the installation switches to an external source. In addition, the power plant will work as long as the tank does not end fuel. It will only be necessary to periodically add gasoline.

Automatic control cabinets, switching blocks (programmable controller, power contactors, devices of Uzo IT.D.) Mounted near the electrical panel. All necessary installation and electrical work can be entrusted to large sellers companies with their own service (such, for example, the firms "Aoyama Motors", "AMP-set", "Energy Veneware", "Economics-Techno"). For small stations, the automatic start-up unit when the load is lost in the main network costs up to $ 600, and for powerful aggregates will cost $ 1500-1900 or more (taking into account the complexity of the work). The cost of the node depends on the load power. For example, the EAS 5 / 5D automation cabinet from MOSA, designed for 3.6 and 5kW, is asked 900, and for the EAS 22/40 model (with a capacity of 8kW) - already 1900. The system of autonomous control of domestic assembly (using imported components) It will cost $ 1500-3000, including the cost of mounting.

What to pay more?

Like any unit with an internal combustion engine, a power plant is noise. And the stronger, the less comfortable you feel. A long noise is unpleasant, so it is important to provide certain measures to protect against it. What can be done? In addition to the fact that the station is best placed in a special room (basement or an extension not far from the house), it would be nice to choose a model with a modified silencer or in a noise-protective casing. The latter will increase the cost of the station for $ 800-1000. The association of relatively high prices can be said that the casing is not just a metal cap, but a well-thought-out structure in which the manufacturer has taken into account the problems of cooling, removal of exhaust gases, noise insulation, assembly layouts (for example, the location of the tank and its neck), etc.

The time of continuous operation of the station without refueling is determined by the volume of fuel tank and fuel consumption. For example, at small stations with a good motor tank capacity of 6.5l, it is enough for 3-3.5 hours of operation when loading at rated power. The tank of an enlarged capacity (say, 25l) will allow you to work on one refueling of 9-10 hours. You can, buying a standard model, subsequently acquire an enlarged tank or immediately stay at the station with a large tank. Please note that the fuel consumption specified by the manufacturer is relative: when working on different loads from the rated power, the indicators can differ significantly. For a large stationary electrical unit used only as a backup power source, of course, you can buy an external fuel tank to constantly not add fuel. But is it nice to "sit on a barrel with gasoline", and where to store his reserves? Perhaps it is better to periodically add fuel to the tank. It is easier to deal with Diesel. It is often bought if the boiler room works on the diesel fuel and the fuel storage space is already available.

Save fuel (up to 25%) and reduce noises (by 5-6dB) allows an electronic system for automatic revolutions. Under the load, the station engine rotates with a nominal frequency of 3000 rpm, and when the electrical consumers are disconnected, it turns into idle. The re-inclusion of consumers leads to an instantaneous increase in the number of revolutions to the nominal. Such blocks are installed on a series of models from Honda, Sawafuji, Robin, at the Geko station from Metallwarenfabrik Gemmingen (in this case, they are called Geko Silent Economic). The system of automatic control of the speed of the engine speed increases the cost of the power plant by about 10-15% (among different manufacturers).

To install and connect the power plant, you should use the services of a specialist. The price of such services is approximately 10% of the order value (if everything you need is acquiring "from one hand").

Finally, several recommendations for the placement of the power plant. It must be installed on a flat surface, in a separate room, protected from moisture, located away from flammable materials and having good ventilation. Installing the power plant in the boiler house also prohibit gases, and firefighters. Alternatively, you can order a precast mini-container with a heating system in winter time, fire extinguishing systems and ventilation. The cost of domestic samples is from $ 1000. The lack of such a solution is that not everyone will decide to spoil the type of site "Iron Box".

So, if you decide to make your home territory independent of the whims of the local power grid, your dream may well become a reality. And dinner do not have to dinner. At least forced.

The editorial board thanks for the help of the preparation of the material of the company "Aoyama Motors", "Econica-Techno", "Energy Veterishman"