Review of the market of dowels and anchors. Examples of prefab fixing devices for designs of various loads.

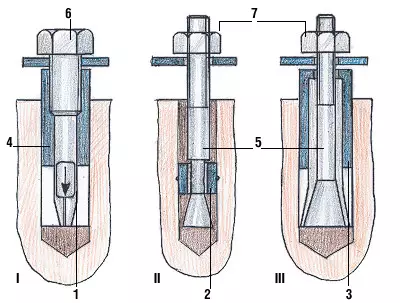

I- with a conical hole

Ine-cage;

III-sleeve;

1 insert;

2 cuffs;

3-sleeve (collet);

4- sleeve;

5-rod;

6-bolt;

7 babies

From the conversation in the subway: "Listen, it was written that in the first quarter of this year 34 thousand tons of construction fasteners were brought to Russia. And half of them were dowel and anchor products. Avot I recently made a" renovation ", but the words" Dowel " And the "anchor" did not hear never. True, and the mat did not hear ... "

The fact that the words "dowel" and "anchor" are not too widely known, not surprising. For decades, we jutter in the facilities of communal, without thinking about changing their borders. Small household tasks of the type of shelves hanging solved simple, with the help of a nail known since the Roman Empire. In the current case, we used a wooden plug in the wall and screw.

The boom of private construction, which began 12 years ago, radically changed the appearance of many houses and apartments, gave rise to dozens of new building materials. And, of course, problems began with fasteners, because and nails, and wooden stoppers with a screw was stopped. They were replaced by dowels and anchors creating universal and effective compounds, without which no quality repairs are required.

The nomenclature of dowels and anchors has hundreds of names. Why so much? And let's mentally make a list of items that in one way or another is fixed on the walls, ceilings and partitions of the apartment. Here is just a small part of this list in the order of increasing load on fasteners: switches, wall clocks and shelves, paintings, mirrors, curtains, curtains, curtains, blinds, plinths, lamps, chandeliers, suspended ceilings, hinged cabinets, hangers, built-in furniture, windows , doors and glazing of loggia, central heating radiators, air purifier over the kitchen stove, air conditioning blocks, television "dish" outside the window and many other other things. And these are only household items that you have to mount to a variety of materials. AKAK and how to fix such elements such as lags, partitions, pipes, ventilation boxes, sanitary pribers or, for example, stairs to concrete bases or beams? And if you roll up to a slit brick or warm, but not very strong foam concrete or so popular now plasterboard?

In the light of this, two remarks can be made to the monologue overheard. Or the speaker was lucky, he got a coherent team, in which everything is done without unnecessary words, or soon something will have to redo.

Sketch portrait of a worker

In the traditional understanding of the dowel, it is a plastic deforming bushing (sleeve). Embed (base) drilled hole corresponding to diameter and sleeve length. Then insert it into this hole, after which they screw the screw (screw). He cuts off the sleeve from the inside, and as a result she fills the hole tightly. Screwing the screw and attract the necessary object to the base. All quickly and reliably, if ... Dowel corresponds to the future load. The basis of the "classic" anchor is no longer plastic, but a thin-walled metal sleeve with longitudinal cuts. And they screw into it no longer screw, but a screw or even a bolt, but draw a cone-shaped metal tube-nut. Vitog Gelza firmly "smokes" inside the wall, and the bolt presses the desired object to the base. The strength of the attachment by anchors once in 5-8 is higher than dowels (with comparable sizes), and they are designed for a much higher load.This fastener is treated to the collection form, because the screw / screw works in a pair with a dowel, and with an anchor-bolt / screw / nut. In general, the axial exhaust force, rejecting force and bending moment on the resulting design, act. A dowel can break from the pulp, and can pull the base with the base. From the reverse force, the screw is cut off, the base or the material of the dowel is crushed. Andean cases of the destruction of the edge of the base. After all, strength, sawing dowel or anchor, are able to increase so much that the base material simply starts to split. Especially if the distance between the edge of the base and the point of attachment (edible) or between the mounting points (intercentrone) is little or the base is thin. The moment only increases the destructive factors.

Hundreds of designs of dowels and anchors are held in the thickness of the foundation with just one (less often two) of the following ways:

1 - friction (The essence was illustrated above). This method is especially effective on solid solid bases;

2nd form - When a portion of the fastener liner takes the shape of the rear extended part of the opening or a structural cavity at the base. The method is most effective in fragile, especially sheet, base material;

3- physico-chemical compound. The mesh sleeve or threaded stud is inserted into the base hole on the polymer resin. The method is distinguished by the lack of sawing effort and is suitable for all building materials.

The highest quality material for dowel-polyamide (PA6 and PA66), in use called nylon. Occasionally, polyethylene PE is used, slightly more often polypropylene. Steel parts protect against corrosion or use "stainless steel" or brass. By the way, hot galvanizing is better than electrocycling.

heads or tails

The problem of choosing high-quality and inexpensive fasteners Oh as difficult. And objective reasons for that two.

First, a large number of manufacturers and a wide range of products produced by each of them. In addition to such a long time and successfully operating in the market of companies like Artur Fischer (Germany), Hilti (Liechtenstein), Sormat (Finland), Mungo BefestigungStechnik (Switzerland), AllFa Du..Beltechnik (Germany), are now actively declared by Kew (Germany ), Elematic (Italy), as well as 3 Polish firms: WKRET-Met, Koelner and Technox. Most newly new to the market is the Italian company Nobex, but according to the nomenclature, it seeks to move with such a giant as Fischer. Looking for your consumer Taiwanese Omax and Wellfly Enterprise. There is a group of firms exclusively on the facade fasteners: Ejot, SK Fastening (Finland), SFS Stadler (Switzerland). Deployment and domestic companies: "Center of fasteners" (under the brand name Mr. Fix), Rys-Tox and Redon (Moscow), Nizhny Novgorod "Integral" and "Buteugs", "Biy Plant of Fiberglass" and DR .

Secondly, the complete confusion with the terminology, which is already from the basic concepts of the "dowel" and "anchor". Almost the same fastener in the catalogs of various firms is indicated by different terms. For example, the ceiling anchor-wedge is called: "Ceiling nail" (Fischer), "Anchor-Wedge" (MUNGO), "Baby Anchor" (Hilti), "Ceiling Dowel" (Kew), "Pastor Anchor" (WKRET-Met ). As a result, it is unambiguous to understand each other sellers and buyers cannot. The position is slightly saves the letter coding of products, but, unfortunately, it is not all (there is no, for example, from Allfa and Omax).

Thread Ariadna

The uniform classification of dowel-anchor devices does not exist (at least in the documentation available for the user). Each manufacturer grows products in its own way. Therefore, in our summary tables, an attempt was made to allocate "Generic signs" products of different firms. The opposite generalization is based on the principle of office of products and the method of anchoring. Of course, the scheme does not claim completeness and scientific rigor and will surely cause criticism from the specialists, but hopefully will help the ordinary consumer to better navigate in hundreds of similar designs. We asked the terms, based on the essence of the devices and the current practice of their use.To begin with, ascertaining, following most practitioners, under the dowel to understand the single body (from plastic or metal) introduced into the base (out of plastic or metal), the operated (opened) when screwing into it a fastening screw (screw). Anchor is the prefabricated construction embedded in the base and "working" as a plug ("anchor"). This cork serves either to screw the fastening screw / bolt into it, or to screw the nuts on it.

The products under consideration are conditionally divided into 2 classes: weak and medium-wide and heavy loaded Devices. Kverv belongs to all dowels and small-sized anchors, on which the static load is valid, not exceeding 6-7 kN (700 kgf). The second belongs to anchors capable of withstanding large static and dynamic efforts (7-30 kN) and be fire-resistant more than 15 minutes. Briefly discuss these products.

Fastening Communities

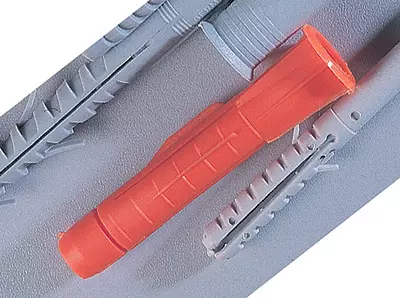

Specific (dropped) dowels. This is the most massive view of the dowels. Products are produced with a diameter of 4 to 20 mm and from 20 to 120 mm. Often have a rather complicated design. The fancy geometry of protrusions and cuts, the better the dowel is held in fragile grounds. Simple-shaped products are better used in concrete and solid brick. Screws can have cutting and heads of different shapes, but the diameter and length are strictly strictly stipulated by the manufacturer. Not all models are able to work in a pair with a metric screw, check this opportunity when buying. Stand dowels from 1 to 16 rubles. / PC., Depending on the size and firm.

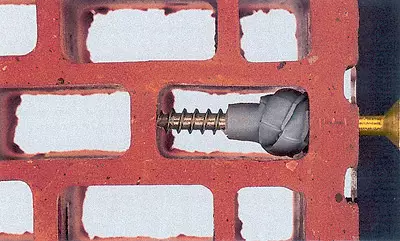

Universal dowels possess the elastic elegant middle part. Most often this is achieved at the expense of long longitudinal slots (there are 3 or 4) in the middle of the product. The main thing is that the head and tail parts are not cut. When screwing into a screw, they are attracted to each other, and the central part is distributed to the sides. It can be tightly pressing both to concrete and soft materials while holding friction. Behind the slotted brick wall or behind a drywall sheet (GCC), the central part of the dowel is twisted into the "Bulbo" or a petal playing the role of a reliable "anchor". There is a series of short narrow slots and deep longitudinal dents in the middle area of the UX from Fischer in the middle zone. This improves the action of a dowel on solid materials.

Dowels for cellular concrete. Such concretes are very popular today when erecting new partitions and even the walls of cottages. Many these materials are good, only strength has limited (from B2 to B7.5). That is why the dowels for them are enclosed only by the form in order to engage in the work as many bases as possible. The universal dowels are suitable in principle, but only with no more than 0.6 kN.

Twice the "more powerful" special auger dowels In the form of a long plastic cylinder with high auger cutting. They may simply be clogged with a hammer (GB from Fischer) or screw on the special rail (KBT from Sormat, GBD from Kew). Azpex in a dowel, as usual, screwed up screw (diameter from 4 to 10 mm).

Conical shell dowels They have the appearance of a thin-walled metal conical shell with ribs and longitudinal grooves. Diameter - from 5 to 12mm. They differ in the ability to be clogged into aerated concrete (but not in brick) even without prior drilling holes. Stand from 10 rubles. / PC.

KEW offers for foam concrete products that have no analogues. it Dowels with hero (mod. G7). The two sections have a different outer profile that does not allow the product to curl. It is clogged with a hammer in the hole and withstands the limit load at 2,3c. Used for fastening not heavy items (paintings, cable channels, etc.).

Dowels for sheet materials. The general drawbacks of the shape of the form. For relatively strong sheets with a thickness of up to 20mm (asbatement, fiberboard, chipboard), it is possible to use short metal or plastic sleeves, squeezed under the action of the screw. The use of universal dowels described above is not excluded. But reliable device with folding longitudinal segments.

First of all, these are metal anchors known as "Molly" . UNIC 3-4 folding segments, which increases the uniformity of the load distribution through a large base area. Products have a diameter from 8 to 14 mm and put on sheets with a thickness of 6 to 38mm. Wankers can be screwed screws and hooks of different shapes. Apply such fasteners for shelves, hinged cabinets, ceilings, luminaires, water heaters to designs, covered GKC, and other slab materials. There are less powerful plastic products (diameter only 10mm) "Butterfly" . 2 drop-down segments. Devices are used when mounting shelves, rails, eaves, lamps, and not only in GCL, but also on a brickwork.

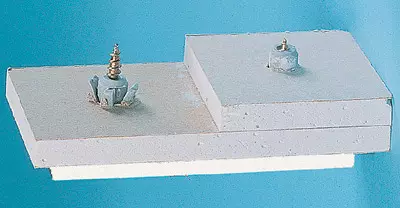

Nevable items are successfully attached to plates and hollow structures with the help of self-aligning impeller anchors. There are 3 of their varieties: Spring folding, tipping and tipped . Wings (shoulders) of products are freely skipped through the hole in the stove (rather large - 10-20mm), and the slab is strained and fit on it, forming a rigid support plate. This is done under the action of spring, weight strength or forcibly. Anchors can be equipped with threaded studs and different shape with hooks. Fastening such devices hinged cabinets, washbasins, racks, water heaters, ceiling structures.

With GLK well use dowels like "Driva". This is a short plastic or metal auger (1538mm) with a hole under the screw. There are models with end (perovy) blades for screwing into a sheet directly, without a hole (price, from 1.5 to 4 rubles. / PC.). Metallic "Driva" well apply on chipboard. Such dowels do not create painting efforts, so they can be put closer to the edge of the plate and to each other.

The following real loads on the dowel listed types of listed types are recommended when attaching a thickness of 12.5mm: "Butterfly" - 9kgs, "Driva" - 10kgs, "Molly" - 20 kgs, spring folding anchor- 24kgs. Even the appearance of new devices (GRIF-V from NOBEX in the form of a combination of "Driva" and the collet anchor; nylon petal dowels Na and A from Fischer) has not yet improved the situation. By the way, the installation of the second sheet increases the load capacity of the fastening zone by about 40%.

Frame dowels and anchors

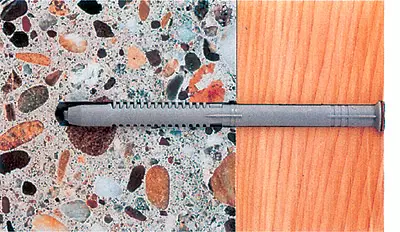

This subclass of products is used for fast and reliable installation of medium-armed structures. Devices are divided into several types: facade, nail, alterovative and window-door. Their common features: a) the presence of an extended non-spoken tail part to keep objects of increased thickness; b) Fitness for end-to-end installation. The latter means that the base and the fixed part are drilled at the place and the fastener is inserted immediately into both elements, so that work is accelerated.Facade dowels Apply for fastening of rails, bars, beams, metal strapping, consoles and facing slabs both outside and inside buildings. Layers of plaster or heat insulator with these devices are not a hindrance. They can mount window and door boxes. Available with a diameter of 6-14mm and a length of 30 and already up to 300mm. When installing on concrete, a stone, a dense brick is made by a short, and in the case of lightweight concrete and slotted brick-long lengths (about 2/3 of the total). Stand "Fazdniki" from 10 to 140 rubles. (Giant 14270).

Nail dowels. When installing them, they are clogged as nails in the pre-drilled hole. A special nail is sold with a dowel in half a wither. It has a screw cutting with an asymmetrical profile. Indispensable to quickly install a large number of fasteners on the crate, railways, plinths, pipes for pipes or for mounting the cable. The nail dowels are produced with a diameter of 5-10mm and 30-240mm long. Create details to 180mm thick to the base from different concrete and bricks.

Adjustment dowels - Rare, but very useful products. They are published only 3 firms: Fischer (models S10 J75S and JS / JUSS), SORMAT (model SKRH) and MUNGO (MJB model). The secret of these devices in a screw with two sections of a thread of different diameters. The result is the ability to smoothly adjust (from 0 to 30mm) the distance between the wall and the part is fixed. For example, when installing the crate on the uneven wall or reconciliation of the position of the door frame.

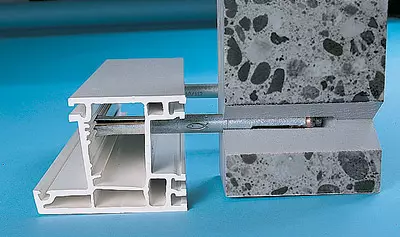

Window-door anchors. In order not to deform the frames of the windows and doors when tightening the screw, use special fasteners. Its base is a sleeve (with a diameter of 8-12mm and a length of 100-170 mm) and a taper nut. When tightening the sleeve with the helix screw, it is crushed and fixed at the base. Different blocking hooks, ribs and slots in the tail can hold the frame in the desired position relative to the opening only with cutting, and not attracting forces. In this case, plastic anchors eliminate cold bridge at the point of attachment, and the metal works well on transverse (cut-out) efforts at the time. The company KEW in its model FRD-C combined a typical window fastener with the "Molly" anchor, which makes it possible to successfully apply the product and in hollow structures.

Examples of prefab fixing devices for little and medium-wide designs

| Group | Type of fasteners | Fasteners from firms | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H. | F. | M. | S. | A. | KE. | E. | N. | W. | K. | T. | ||

| one | Speaker dowel | - | S, UX. | MN. | - | 2100. | UDD. | EB. | A. | KN. | K. | NTX. |

| one | Universal dowel | HUD1 | Fu. | Mu. | NAT. | 20000. | UKD. | TPF. | VVA. | KPU. | Ks. | Zum. |

| 2. | Shneke's dowel | - | GB. | - | KBT. | 26500. | GBD. | - | - | - | - | - |

| 2. | Dowel shell conical | - | FMD. | - | - | 7700. | MUD. | - | - | KGM. | KGS. | - |

| 3. | Anchor sleeve | - | Pd. | - | - | - | - | - | - | - | - | - |

| 3. | Dubel type "Driva | - | GK. | - | Driva | 2600. | GKD. | - | Sp. | DRN. | Driva | Driva |

| 3. | Dowel type "Butterfly" | HLD. | - | - | Ola. | - | KHD. | - | NAV. | KG. | GK. | TFN. |

| 3. | Anchor type "Molly" | HHD-S. | HM. | - | Mola. | HRD. | MHD. | - | CPV. | MOL. | SM. | - |

| 3. | Anchor folding spring | - | KD. | MF. | - | - | AF | - | M4AV. | M4L | Spo | - |

| four | Facade dowel | HRD-U. | S-R, FUR | MBR | Kat. | 22955. | Rdd. | FPP. | TNAP. | KPK. | 10L | TXS. |

| four | Dowel nail | HPS. | N. | MNA. | Lyt. | 28854. | ND. | HCX | TNSM. | SMN. | Kwd. | SMT. |

| four | Window-door anchor | HT | F-M. | MMS. | KRH | 22830. | FRD. | ETFP. | AFL | LO. | O. | - |

| five | Wedge-anchor | Dbz. | FDN. | Nan. | - | - | DN. | - | TDN. | KRW. | - | - |

| five | Anchor nail | - | - | MHN. | - | 77200. | HD. | AFL | SMM. | KMW. | Izlm. | |

| five | Anchor ceiling cuff. | - | FNA. | Moa. | - | - | WAM | - | TC. | - | - | - |

| 6. | Dowel whole | IDP. | DHK. | MIS. | - | 23000. | - | - | Isop. | - | Gok. | IZL |

| 6. | Pouring dowel with a rod | - | DHN. | MMD. | - | 23530. | - | - | - | LFM. | - | Izlm. |

| 7. | Fastening for toilet | - | WCR. | MWC. | - | WCB. | - | WC. | KMM. | - | - | SA |

| 7. | Mount for sink | - | Wst. | MWT. | - | WTB. | - | FL | KMU. | - | RPU | SU. |

| Notes: 1-general construction; 2- for foam concrete; 3- for sheet materials; 4-frame; 5-ceiling; 6- for insulation; 7- for plumbing. Firms: H-Hilti, F- Fischer, M- MNGO, S-SORMAT, A- ALLFA, KE-KEW, E- ELEMATIC, N- NOBEX, W-WKRET-MET, K- Koelner, T-technox. |

Examples of prefab fixing devices for severely loaded structures

| Group | Type of fasteners | Fasteners from firms | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H. | F. | M. | S. | A. | KE. | E. | N. | W. | K. | T. | ||

| one | Anchor clogging | HKD. | EA. | ESA. | LA, MTA. | - | DRM. | Ethd. | Drop. | TSW. | ST / TM. | - |

| one | Brass anchor | - | PA4. | MMD. | MSA. | - | MSD. | ETO. | Nto. | KRM. | - | - |

| 2. | Anchor cant | HSA, HST. | FAZ, FBN. | M3, MSD. | S-KA. | 72000. | WAM | Etd. | TM. | - | - | - |

| 3. | Anchor sleeve sterine | HLC. | FSA. | MMD. | TA. | - | HNM. | - | SXC. | Lsi. | Kt. | - |

| 3. | Anchor LC | HDA | FZA. | - | - | - | - | - | - | - | - | - |

| 3. | Anchor with nut cone | HSL. | FHY, FH. | - | PFG. | - | HT | - | HAC. | Lmp | SLR. | SLM. |

| four | Anchor ampool | HVU. | R. | MVA. | Kem. | Allchem. | VP / AS. | - | VPK. | - | - | - |

| four | Anchor injection rod | Hit / Has. | FIS. | - | - | - | VM / AS. | - | - | - | - | - |

| four | Anchor Injecting Gelzoy | HIT / HIS. | FIS-HN. | - | - | - | VM / SH. | - | - | - | - | - |

| Notes: 1- with a tapered hole; 2-bed (wedge); 3- with retractable cone (sleeve); 4- chemical. Firms: H-Hilti, F- Fischer, M- MNGO, S-SORMAT, A- ALLFA, KE-KEW, E- ELEMATIC, N- NOBEX, W-WKRET-MET, K- Koelner, T-technox. |

Ceiling mounts

The practice of fixtures on ceiling structures is clearly abnormal. Right and nearby plastic dowels are used here, which is unacceptable. After all, according to the requirements of fire safety, all elements of ceiling floors must have increased fire resistance (more than 60 minutes). Annovometric multi-level ceiling superstructures, put on plastic dowels, when the fire is the first to collapse on our head. So that this does not happen, they should be attached to one of two ways: or shooting, or with the help of metal "anchors". For the first case, the mounting speed is high (the holes are not drilled), but the strength, contrary to the current opinion, is almost the same as the plastic dowels, because in the concrete around a crab rod, a crack zone is created. Yes, and it is worth a lot of work: one "shot" costs rubles in 20-30. The method is true, indispensable for fastening to steel structures (wall thickness up to 4mm). Anchorovka- more universal and economical option.Wedge Anchors Climb in drilled holes by end-to-end installation. Wedge-shaped parts of the anchor are shifted relative to each other and opened on a long length. The method can be used to fix the frames with a thickness of up to 65mm, metal profiles and suspensions. Working load- up to 0.5kn. It is worth noting that drilling with perforation in the middle strength concrete provides quite high productivity - 400-700mm / min (diameter 8mm). Adriaration of equipment with a dusty nozzle increases the speed of installation.

Nail Anchors Consist of a split metal sleeve with a mushroom-like sideboard and a special nail. When his clogging, the segments of the sleeve are opened and "anchor" of it in the hole. AllFA makes such anchors with color (4 options), which allows them to use them as decorative elements.

Ceiling Ceiling Anchors . Wake-based base is a steel rod (6mm diameter) with a conic shank and a split cuff. When clogging anchor cuff slightly squeezed and fixes it in the hole. When you try to pull the cuff anchor even more with a cone and is jammed in the hole, which is on the stretched side of the slab (so scientifically referred to our ceiling) successfully opposes the exhaustive strength to 0.6k. The outer end of the rod can be drawn up in the form of a wide hat, a threaded stiletto, hooks, eyeles. Anchor is used to fasten the suspended ceilings, air ducts, suspensions, cables, and even geepboard.

Dowels for fastening thermal insulation

This is an extensive subclass of products with its specific functioning and, accordingly, devices. It all depends on how the thermal insulator is above or under the layer of plaster, whether the exhaust force from the wind suction and what the weight and thickness of the insulation acts on it.

The fastener consists of a spacer dowel and a pressure disk (plates). The latter diameter is 45 to 90mm. Length of a dowel - from 40 to 300 mm, but the diameter is almost unchanged, 8mm. Such devices are capable of pressing soft, semi-rigid, and some and hard insulation (glass and minorvatu, polystyrene foam, foam, mats from traffic jam, etc.) thickness from 40 to 250mm. They put them in the method of end-to-end installation. For light insulation, the dowel is made solid, and for everyone else-space. The split rod (nail) is performed from plastic or steel. Listening to thick or heavy insulation plates can be made removable. For ceiling structures and fire hazardous conditions there are fully metallic holders with a plate. Well, if you need to install any design on top of the heat insulator, for example, to mount the crate, bars, corners? In this case, facade dowels are used, equipping them with elongated studs or anchors with long studs, as in TA and EN models from Sormat. There is even a special service, in which there is a nest for installing a second, smaller dowel. They fix the desired design to the first, carrying screw (for example, in MBR SK from MUNGO).

Functional fixtures

This is a rapidly developing subclass of devices, the role of which will increase with an increase in the requirements for residence comfort. Already today, thanks to the dowels, much work is saved when installing sanitary devices, laying hundreds of meters of all sorts of communications (tube, electrical, cable-information). Moreover, in each case, used, in addition to a dowel, their additional functional elements. We will consider only some of them.Plumbing devices fixing devices . They have to function both on solid and void structures. The basis of the fastening kit is a dowel or anchor suitable to the base of the type, for example, a spacer or facade dowel, a chemical anchor. The kit for the toilet and the bidet is equipped with a special screw-made of brass or stainless steel, locking sleeve (to eliminate direct contact contact with metal) and a decorative cap. The attachment of the sinks includes a screw-stud, an eccentric sleeve, nut and a decorative cap. The sleeve allows you to adjust the position of the device and warns the chips of the faience.

Installation settings for the fastener of the concrete base (based on Sormat data)

| Type of fastener | Minimum base thickness s | Minimal intercentrose distance A | Minimum edge distance C under load action | |

|---|---|---|---|---|

| Spit | Shifting | |||

| Cantry anchor | 1.5 T. | 20 D0 | 10 D0. | 10 D0. |

| Scoring anchor | 1.5 T. | 4 T. | 2 T. | 3 T. |

| Gelzene (collet) anchor | 1 T. | 4 T. | 2 T. | 3 T. |

| Brass anchor | 1.5 T. | 4 T. | 6 D0 | 10 D0. |

| Chemical anchor | 1.5 T. | 15 D0. | 1.25 T. | 1.5 T. |

| Dowel frame | T + 20mm. | 2.5 T. | 50mm. | 75mm. |

| Dowel nail | T + 10mm | 10 D0. | 1 T. | 1 T. |

| General destination dowel | T + 10mm | 1 T. | 1 T. | 1 T. |

| Notes: D0-diameter of the hole at the base; T-depth of anchoring. It is recommended to take: A- T = (5-6) D0- with a solid base; B - T = 8 D0- with a porous base |

Fastening for hard loaded structures

This class of fasteners include only anchors. Put them in the most responsible places: on beams, mauerlats, stairs, blocks of air conditioners, metal chimneys, garage gates IT.P. Anchors of small diameters (5-8mm) can successfully replace the dowels when fastening to solid materials when it is economically justified. With dynamic loads, anchors are generally out of competition. According to the method of formation of fixing forces they are divided into mechanical and chemical devices. The first are very diverse in designs (over 40 varieties), but according to the principle of operation, they can be divided into 3 large groups.A group of bushings with a conical inner hole. Longitudinal cuts (2-4pcs) on the sleeve form its spacer segments or petals. They can be distributed to the sides and press the walls of the opening in a different way. For example, twisting the bolt / screw in the sleeve. This principle employs so-called Brass anchors . IN Scoring anchors Petals are pushing, scoring the conical liner, already installed by the manufacturer inside the bush. The scoring tool is also attached. Control of fastening efforts lead to the movement tool - it is clogged to a certain tag. The sleeve anchors are small: diameter from 8 to 25 mm, and length 25-80mm. But they are withstanding a solid, for example, about 20kn with a diameter of 10mm and a length of 40 mm.

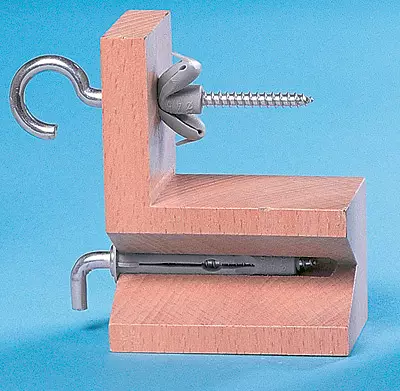

Cuffs (Wedge) Anchors Designed as a rod-stud with a reverse conic shank. In front of the cone on the rod, an outstand is made to which a split cuff (subtle) with several tuberculous protrusions are worn. Anchor is clogged into the hole, and the cuff is fixed in it using protrusions. A fixed part is installed on the threaded end of the anchor, after which the nut is delayed. At the same time, the shank cone shakes on the cuff and crushes it, creating a fixing force. Its value is controlled by the moment of tightening (builders need a dynamometric key). Form and amount of cuff varies. They cost from 14 to 350 rubles. / PC.

The most extensive third group Anchors of a sleeve (collet) type. The basis of the device is long with a sleeve slide groove. It can be equal or composite, including with plastic elements. Inside the sleeve passes a rod-stud with a reverse conic shank. When tightening the nut on the end of the stud, the cone is cutting the sleeve segments on a long length. As a variety of devices of this group, anchors perform, in the sleeve of which the cone-shaped nut is drawn. Outside, you can screw the bolt or hook. Some particular "flexible" anchors, such as PFG (SORMAR), H-OA (Nobex), MSS (MUNGO), are able to be installed even into slotted bricks.

The main danger with mechanical anchors - "drag" them and, as a result, overvolt the base material that can split. Therefore, the company Sormat does not recommend putting on brick anchors with a carvings more than M8.

The same group includes the so-called Curling anchors , carrying out anchoring form, not friction, thanks to which the danger of "dragging" decreases. HDA (Hilti) and MMB (MUNGO) and MMB (MUNGO) in the spacer end of the sleeve are additional belts, which are deformed by the cone so much that they are cut into the walls of the hole and work as an "anchor". Afirmism Fischer offers to make a conical expansion of the bottom of the hole for the FZA model (even a special drill) is attached, behind the walls of which and the edges of a strongly precipitable sleeve are engaged.

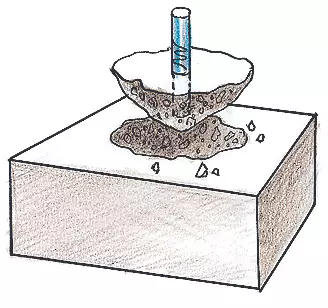

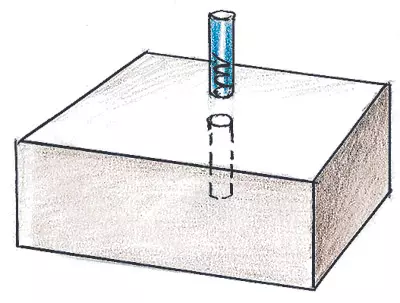

Chemical anchors

This is perhaps the most reliable fixing devices today. They are universal, suitable for any materials, if only he could stand. B1.5-3 times stronger mechanical. The main feature of their distinctive feature is the absence of spacers, therefore small edge distances are allowed. However, the speed of their installation is slowed down, as it takes time to rejection of the resin. Yes, and prices are high: from 75 rubles. Fastening.

We divide such fasteners into two groups: ampully and injecting anchors. Forward resins and hardener are in one glass ampoule, but in different tanks. The ampoule is freely inserted into the base hole and destroys when the fastening rod is driven there. The series of resin and hardener are stored separately in the sections of one cartridge (cylinder). When compressing the cartridge (need a mounting gun), the components are stirred in the mixer and through the nozzle are injected into the base hole. Then there also insert the fixing rod. If the base is not solid, a flexible mesh sleeve is inserted into the hole at first. When feeding the gylide resin is deformed and after harvesting the resin forms a durable "anchor". There are many varieties of sleeves and paired fasteners. The cartridge can be used repeatedly.

Smart Power

Catalog data on loads should be consistent with various types of data. So, Fischer can report recommended (or permissible) loads, as well as limit (destroying), and mungo- only recommended. Hilti cites the calculated and recommended loads (differ by about 35%). Sormat and Kew report limit loads. Therefore, in order to obtain a permissible load, it is necessary to solve (limit) to divide the NF strength coefficient. Approximately NF = 7 for plastic parts and NF = 4 for metal.

Data on concrete efforts also differ also because they relate to the brands of different strength class, starting with B15 from Fischer and ending at Hilti. On the same information in relation to our homes will have to correlate- depending on the role of the wall in the building design. Thus, in the houses of the series P44T, P44N, P46M, PD4, P3M, CE and a number of other internal bearing walls are made of concrete class B22.5 (M300), and outdoor, three-layer, from concrete class B7.5 (M100). So, for them, the permissible load is better to take as for solid bricks. This problem has another aspect, rarely affected by specialists and ever sellers. It is aging, or creep, plastic dowels under load. It turns out that over 50 years of service even nylon will reduce its strength by 2.5 times. So, the dowel must be relying on the load less recommended. In other words, security makes all of us carefully handle the numbers.

Such is a somewhat simplified picture of the range of dowels and anchors. We hope it will help you more consciously treat their choice and use. You should buy them in the stores of the dealer network of manufacturers or in building supermarkets, but not in markets, where many poor-quality products.

The editors thanks the company "Center of Fastening Materials", ECT, CO, "F-Expert" and representative offices of Hilti, Mungo for help in preparing the material.