The device of ceilings in wet rooms. Painted, saved, wooden, suspended and stretch ceilings - a choice for the consumer.

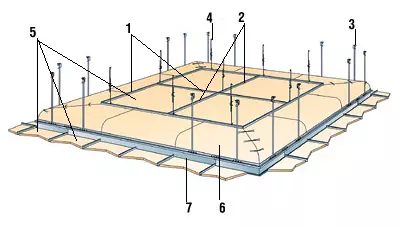

1. Wheels

2- transverse guide;

3- Hard suspension;

4- adjustable suspension;

5- Tile module;

6-curved panel;

7-reference caisson profile

Moving daily by its dwelling, we rarely pay attention to the ceilings. They were so organically fit into the interior of the premises, which is no longer disputed as independent designs. It is not easy, this is the case - every day, without praise and special attention from the owners and guests, carry your service! Today it will be about the ceilings in wet rooms.

During the construction and decoration of premises with high humidity, it is necessary to show special attention to the selection of materials, because they must all resist the destructive effects of water. In other words, be moisture-resistant. No exceptions, the materials used to finish the ceilings. In this case, "wet" is called the premises where air humidity exceeds the normal indicator (60%). The books include pools, saunas and baths (humidity of more than 90%), bathrooms and toilet rooms, shower, kitchens, laundries, winter gardens (70-80%), as well as all unheated premises (terraces, verandas, cold storerooms, garages), Very strongly dependent on weather conditions and experiencing periodic moistening. The surface of the ceiling, in addition to constant contact with the air of high humidity, can directly contact with water (for example, in shower) or be a condensate formation site (say, with sharp differences in the room temperature).

Materials with incorrectly selected moisture resistance after a while begin either flax and the ceiling saves, or to undergo corrosion, the effects of fungi and bacteria. All other requirements are reflective and sound-absorbing ability, fire resistance, environmental purity, minimal care is fully consistent with the general, submitted to conventional ceiling constructs, which our magazine wrote repeatedly in the articles "Ceilings there is no limit to perfection", "Ceilings for desperate videos" and " Ceilings for the most practical. "

The ceilings can be divided into two groups. The clerva includes those of which the foundation for finishing is the overlap itself. Such ceilings are drawn up by a rather limited number of methods (for example, plastering and painted, stick to them decorative finish; wooden surfaces can be treated with various impregnations). The second group includes ceilings, providing for the construction of an additional construction based on the main and formative fundamentally new plane (suspended, cortex and stretch).

Painted ceiling

Coloring is the cheapest and traditional way to finish the ceiling. Work on paint should be carried out before the design of the walls and floor in the room. Old layers of materials are pre-removed, after which the base is ground, plastering and putty. Moreover, depending on the surface irregularities, you will need to apply different number of layers. When irregularly less than 3 amphibes of deep penetration (it ensures the adhesion of materials and the waterproof of the overlapping itself; well, if there are additives that prevent the appearance of fungus and mold), moisture-resistant putty (for thin surface alignment), moisture-resistant finish primer and moisture-resistant paint. When defects are 3-10mmmmmed, plaster on a plaster basis, primer, putty, primer, paint (all materials after layer plastering should be moisture-resistant, the plaster itself can be strengthened with a glass tape net). In case of deviations from the plane, more than 10mm, the procedure for applying layers remains the same, but the plaster on a sandy-cement basis is used.In construction practice, as a rule, use the most ordinary plasters, achieving waterproof materials due to the moisture resistance of all subsequent decoration layers. But there are also special waterproof plaster, such as Vetonit TT (Optiroc, Finland), Deumisal (Index, Italy).

The temperatures on the basis of chalk or lime, as well as the usual water-level paint for wet premises in this case, are not suitable, from permanent interaction with water pairs covered with them the surface cracks and is resolve. Only special compositions, which are called - "paints for wet premises" (these can be compositions on acrylic, latex or silicone basis, separate water dispersive, as well as oil paints; true, the latter are very quickly yellow). In the Russian market, water resistant paints are presented highly wide: FUR Kuche Bad (Practic, Germany), Indeco-W (Caparol, Germany), Duefa Eco-Weiss (Mesffert, Germany), Crown (Akzo Nobel, Netherlands), Dyoterm (DYO, Turkey ), and some, such as Dyostop (DYO), can be applied even on raw surfaces. From domestic news paint for wet rooms A-25 (Akron-B), Rainbow M4 (Rick). Exportable premises are recommended to use universal materials intended for external and internal work (for example, Flutex 10 on latex based, producer- flugger, Denmark - Sweden; "Interior-3" of the Russian-German Derufa Association). And this is understandable, because in such cases, both moisture resistance and frost resistance is important.

The ceilings are usually stained either in white, or in any other by adding special kokes. Colored ceilings are most often pickled into the wall tilt. If the paints do not contain antifungal components in its composition, you can buy a special solution (for example, WeatherShield Fungicidal Wash, the manufacturer of Ici Paints, the United Kingdom; consumption-30m2 / l, the cost of liter packaging is $ 8) and process them the entire surface to color.

The ceiling finish can be carried out independently or with the help of specialists - in the latter case you will have to pay from $ 10 for 1m2 (full cycle of work, without taking into account the value of materials).

In addition to the paints, there are entire sets for finishing the ceiling in wet rooms. For example, Tikkurila Luja designed specifically for bathrooms. The unit includes 4 components: moisture insulation primer, moisture-resistant adhesive Assatex, fiberglass wallpaper and actually Luja paint (acrylic). The ceiling finish is made in several stages: first apply a layer of primer, then the moisture-resistant adhesive of Assatex, to which the glassy is attached. A day after the wallpaper roller is replaced by a moisture insulating primer and only after that, 2 layer of paint. If desired, changing the appearance of the ceiling earlier than the expire for the shelf life of such a coating, you can simply impose a new layer of paint. Coating withstands washing not only by ordinary household, but also strong detergents, including disinfectant. The paint itself is able to withstand more than 10,000 passes with a brush. The cost of one liter is from $ 7. A set of waterproof primers (Resistent Tackfarg) offers also the Swedish firm Beckers.

The disadvantage of painted ceilings is the need for a long cycle of work on preliminary preparation and surface coloring, the advantage of the availability of materials.

There are three main ways to remove old coatings: mechanical (scraping brushes, Occuring with a coarse abrasive skin, removal with grinding machines and special nozzles on a drill, sandblasting), thermal (using a construction dryer, thermopystole; oil paint also remove "Dedovsky "In a way, having warmed the surface with a conventional iron through an aluminum foil) and the chemical, for which the Russian, and the foreign industry produce a huge number of diverse washes. We serve only a few examples: Tapeten und Leimfarbenabloser (PUFAS, Germany), DFA Abbeizer (Mesffert, Germany), Exterminator B-52 ("Top", Russia). For each type of paints, its solvent is added to the wash. Theoretically, any paint can be removed by one of these methods.

Embedded ceiling

"Glued", "glued", "past" - in the lexicon of builders and merchants building materials you can meet one of these names related to the same method of finishing the ceilings. It consists in the following: various decorative coating tiles made of polystyrene foam, glass materials, or such exotic materials, such as cork or laminate panels, are glued to the smooth surface of the base ceiling, the base, and the cork or laminate panels, as well as ceramic tiles.

The most popular of the listed plate from the foamed polystyrene (or, as it is also called, the styrofoam). For use in wet rooms, only extruded panels are suitable. The extrusion method that is used in their production allows to achieve maximum density (about 70kg / m3) and the homogeneity of the material, and therefore waterproof. In the manufacture of panels with other methods, stamping and injection - the structure of the plate is not so homogeneous, and the coating can absorb moisture.

Extruded plates are easy to distinguish in appearance: their facial surface is smooth, has a homogeneous structure, in the context panel looks like a porous chocolate tile. Valid dreams from them, stamped and injection materials have a clearly pronounced grain structure, tangible even to the touch. Panels also differ in thickness: extruded - 2.5-3mm, stamped- 6-7mm, injection - 10mm. Standard tiles size in all manufacturers are equally 500500mm. Punching additional elements are available rectangular panels 16.5 mm wide and 1000 mm long, as well as ceiling plinths 1000-1500mm. The most popular color is white, the variety here is achieved through the choice of one or another texture (in the catalogs of firms is presented to several tens). Although, if desired, you can choose color models, including imitating wood, fabric or stone.

In the Russian market today there are mainly plates of domestic manufacturers - "Greaches", "Decomaster", "Plast Gamma Decor" and some foreign-decora, Marbet, VTM (Poland), Schafer, Deckenplatten (Germany). The cost of white panels is about 40 rubles / m2, color- about 60-70 rubles / m2.

Tiles are glued on any surface-concrete, brick, clay blocks, wood (well, if you spend their pre-primer). When decoking the old surfaces, be sure to remove the exfoliating paint layers, it is not necessary to delete all the paint. It is best to use glue for polystyrene or a special composition for ceiling floors, and necessarily moisture-resistant (Decomaster of the Russian company "Decomaster", Gigant Dufa German Mesffert, Titan Polish Marbet, etc.) - In this case, you are guaranteed not to spoil the tile, and later you can easily To dismantle it. It is easy to care for adhesive ceiling: you will need to carry out wet cleaning from time to time.

Despite the rapidness, foamed polystyrene is quite easy to melt (already at temperatures above 80s, the material begins to deform). Therefore, one should not be placed wall and ceiling lamps at a distance closer than 20-30 cm from the ceiling surface. Pipes of water heating, based on the practice of specialists, are not heated to the melting point of polystyrene, the panels can be placed even close to these pipes. Stirores also does not withstand the effects of organic solvents (gasoline, turpentine, acetone IDR), but traces of fat from white plates can be washed with alcohol. And finally, polystyrene foam-artificial material, for which it dislikes fans of all "natural." Buyers also often complain about a large scatter of sizes in one batch of tiles.

The use of glasses is also one of the most comfortable, and even inexpensive ways to finish the ceiling in a wet room. The advantages of using them are the possibility of repeated ceiling staining (10-15 times; as it is known, the glass windows are stained after sticking) and a long service life (up to 20-30 years). In the Russian market, glazed windows of such European manufacturers are offered as Baumax (Germany), IHT Interglas HGT (Austria), Fintex (Finland), the cost of the roll is 50m, from 800 rubles. Surface texture is the most diverse: parquet, rhombus, diagonal, christmas tree, cargo.

You can also glue cork tiles treated with a special water-repellent impregnation. Special ceiling tiles are not found on sale, so that they go both outdoor and wall articles from the traffic jam. This material, by the way, has very good thermal insulation properties. In the same way, waterproof laminate coatings or ordinary ceramic tiles can be used.

Wooden ceiling

Wooden ceilings - happy feet of country houses, where it is not necessary to separate these structures by anywhere waterproof materials. A more promising is a variant of working with the tree itself, for example, the processing of ceilings with special water-repellent biopropites, which protect the tree not only on the effects of moisture and rotting, but also from the spread of pest bugs (for example, the BB-11 bio-eyed composition, the manufacturer "Antiseptic" , Russia (cost- 60 rubles / kg); The composition of "Sezheng Bio", producer "Seine preparations", Russia (cost- 166 rubles. For packing 10kg, applied in 2-3 layers); combination of the compositions "SotEks" and " Aquateks "Firms" Rogned "(65 rubles / l). Processing materials better before construction, but it is more expensive.A separate conversation is about the sauna and a bath, where the ceiling together with walls and floor is subjected to a periodic "massive" moisture attack. Here, a tree (with the exception of aspen, which is the best material for saunas) should be treated with special compositions withsting the effects of high temperatures. For example, the impregnation of the "Teflex sauna" ("bioprotect") or composition based on acrylate SUPI-SAUNASUOJA (Tikkurila, Finland). Although some builder specialists categorically recommend leaving a tree in the Pure Parils and not to handle any compositions. Explain this inability to achieve the complete absence of evaporation of "chemistry".

Suspended ceiling

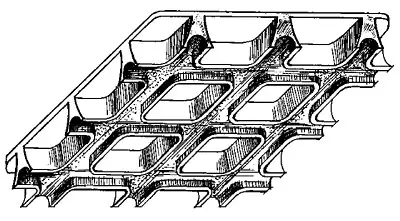

This is a system consisting of a metal frame suspended to the overlap, and the finished modules (railings, plates, panels, cassettes) forming the new surface of the ceiling, which is below the base.

Suspended system, or frame, - The basis of any suspended ceiling. Consists of the main guides, transverse guides, angular elements and suspensions. Adjustable suspensions (rods, brackets, thick wire) allow you to change the distance between the suspended and base ceiling. This design makes it possible to mask irregularities, create multi-level ceilings, use the resulting space for laying the necessary engineering communications and installation of lamps. Standard color suspended system - white, other possible options are color, under chrome, under gold. The width of typical guides is 15 and 24mm. Kbasy ceiling the suspensions are attached with the help of dowels and screws.

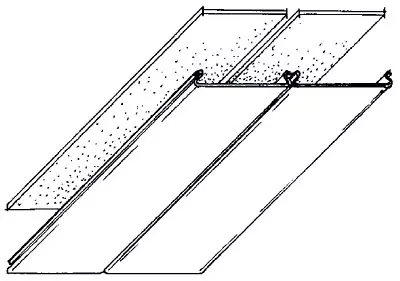

Rack structures Collected from narrow long rails, which may vary in width, height, shape of the panel itself and edge, on the texture (matte or mirror) and color. Neighboring modules are able to assemble the joint-B-joint, separated by insert or be located at some distance from each other, in the latter case it turns out the maximum opened ventilated structure. Reiki curved shape (work is carried out at the factory, under the order, according to the size of the customer) allow you to create not only flat, but also curvilinear ceilings. Water structures can be combined by the modules of flat and curved shapes, panel of different colors, inserts, lamps and insertion, ventilation blocks. The standard length of the RECEX is 6m, width - from 30 to 300 mm, thick - from 0.3 to 0.6mm. It is made of aluminum or galvanized steel, for wet rooms it is recommended to choose aluminum. They are present in the assortment of all manufacturers of rush ceilings: ArmStrong (USA), GeiPel (Germany), Catena, Prometal (Italy), Hunter Douglas (Luxalon Trade Brand, Germany), Inlook (Finland), Lumsvet, Albes (Russia ).

The cost of the rush design of Russian production is $ 10-20 per 1m2, foreign production - $ 20-40 per 1m2, the cost of installation, from $ 8 for 1m2. Volusay leaks on top of the rail should be dismantled and dried, after which it is returned to the place; Open design will dry yourself. Such suspension structures are very beloved by the customer for their practicality and most often installed in the bathrooms.

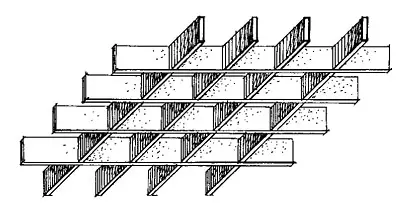

Tile modular designs. The Russian market presents overhead systems of two standards. According to the European cell, the system has dimensions of 600600mm, and modules - 595595mm. Recompute with the American standard, the size of the cells must be equal to 610610 mm, the size of the modules is 605605mm. Systems are universal and allow you to hang plates of various manufacturers of one standard.

Modular elements can be made from various materials: metal (steel or aluminum), wood, Feds, MDF, mineral fiber (including fiberglass), plastic, drywall. No restrictions on use in wet rooms steel and aluminum- They are produced by Albes, Conter (Italy), AMF (Germany), plastic (Sibu Design, Austria), from Orcsekla- Altuglas (Holland), Barlo Plasrics (Slovakia) , Plexiglas (Germany), "Plexiglas" (Russia), modules from large sheets are cut for ceilings. The rest should necessarily have a moisture resistance of at least 95% (and for pools - 100%) and ideally the manufacturer itself is recommended for premises with high humidity (as plates made from NewTone and Ceramaguard mineral fiber, producer- armstrong, they are able to withstand even constant contact with Water; wood fibrous fibracoustic and plate from the Mineral Wool Thermatex, manufacturer- AMF). Including example, we will give more fiberglass plates POP (Ecophon, Sweden), the front side of which is covered with PVC film, and Ceramic Radar mineral fiber panels (USG, USA). The thickness of the plates depends on the material from which they are made: from 0.5 mm (metallic) to 20-30 mm (made of mineral fiber). The surface can be smooth or rough, matte, glossy or mirror, have a different color and texture. Separate modules or parts of them are capable of replacing lamps. The cost of plates - from $ 11 for 1m2.

The original version of the ceiling organization is the use of stained glass modules from plexiglas. 600600mm tiles are attached to a standard suspended system, to create a decorative effect of "glow" of stained glass, the design is supplied with internal illumination. The cost of tiles is high, from $ 100 to $ 500 per 1m2, which fully corresponds to the exclusivity of the material. Stained glass windows from Venetian glass will cost even more expensive.

Modular ceilings from tiles, cassettes, grids, cellular modules and panels have a very formal appearance and more often installed in offices and public premises than in private homes and apartments. There are no such decorative tiles of wood fiber or plexiglass. The overall disadvantage of suspended structures - they are "eaten" 12-15 cm of the room height. The main advantage is the possibility of hidden accommodation, maintainability and transformability.

Steer ceiling

Bearing is called structures in which carrier elements (metal bars, profiles) are attached directly to the base ceiling, and not hang on, as in the suspended systems. Therefore, the distance between the basic and stitched ceiling is determined only by the thickness of the carrier frames of the frame. Most often there are metal robes (their design is similar to suspended rush) and tail drywall ceilings (this is a design collected from plasterboard sheets and a metal or wooden frame). For wet rooms, it is necessary to use the sheets of moisture-resistant drywall (marking G CLEV). His sheets are painted in green, in contrast to the usual gray. In the Russian market, this material is offered by Gyproc (United Kingdom) and Knauf Gypsum (Russia). Standard dimensions of sheets - 25001200, 30001200mm with a thickness of 12.5 mm, the cost of € 70 / m2, less commonly there are sheets with a thickness of 9.5 and 6mm. You can also grab the gypsumous material intended for wet premises (GVLV).Wet drywall is easily lightning and after drying takes the form given to it. This property is used to create complex geometric sites (arches, domes, multi-level ceilings). The ceilings from G Coles today are quite great popularity - they are inexpensive, allow you to create individual configurations and equip the design of built-in lighting. Wearing premises The ceiling plane is collected from several sheets, the seams are sinking with a sealing ribbon and processed with putty. After that, the ceiling must be treated with primer and cover any paint, both compositions must be intended for use in wet rooms.

Stretch ceiling

The ceilings of stretch design are a thin film or tissue, stretched on a special frame (baguette). The baguette is fixed on the base ceiling or around the perimeter of the walls and, depending on the fastening method, can be visible or hidden. The resulting ceiling plane is ideally smooth and homogeneous, has a form of a solid ceiling. It is made of polyvinyl chloride film (PVC) or polyester tissue, the framework in both cases is made of PVC, but only more rigid than film itself, or from aluminum. Running and high humidity of air stretch ceilings are completely indifferent, so they are installed in wet rooms without any restrictions. Lisps leaks from above the film saves, forming a huge bubble. According to the manufacturers, the material withstands the load of 100 l / m2, the practical tests carried out by MAL-C, showed higher results - up to 170l / m2. You can drag the water altogether with a similar emergency, through a hole for the lamp (if the ceiling is equipped with built-in light) or dismantling one of the corners for a while. In the second case, you will definitely need to call a specialist. The dried cloth is heated, after which the ceiling completely restores its tension.

The lack of PVC film is the absence of frost resistance, at temperatures below 0s, the material becomes rigid and fragile, however, it starts to collapse only during the frost below-40s. Therefore, if you installed the stretch ceiling in a country house without constant winter heating, be vigilant: try not to clap the door and do not touch the plane with sharp objects until you get the room, otherwise the ceiling will collapse.

The Russian market presents a fairly large number of firms offering stretch ceilings from PVC: Barrisol, Carre Noir, Extenzo, Grupa Dps, Novelum, Newmat, Prestige Design, Skol (France), Mondea (Netherlands), Deckenfest and Decomat (Germany) and only One firm selling ceilings from polyester fabric is Swiss CLIPSO.

Principal differences in the design between the ceilings from PVC film from different manufacturers are not. When heated above 65С, the elasticity of the material increases, and it is well amenable to deformation, this property is used when installing the stretch ceiling. The differences in the manufacturers can be found in the color range (usually in the catalog shows from 50 to 100 shades and several types of textured matte, glossy, under marble, under the tree, suede, skin, from practice it is also known that about 90% of the ceiling-plated with a matte surface).

Manufacturers may also differ in fasteners and product pulling method (cartoon and flawless: wedge, cord and cam). With harpoon (Barrisol, Carre Noir, Decomat, Extenzo, Newmat), the canvas is made in strict accordance with the size of the room minus 10-15%. In return conditions, harpoon is welded to the edges of the prepared canvase. With a ringpurpose method, careful measurements and factory works will not need, the canvas are simply delivered to the place, heat up to 70s and snap into the baguette.

Stretch ceilings can be installed in rooms of the most different configuration, building multi-level structures, creating arches, vaults and tents.

The ceilings made of polyester clipso clips are installed at room temperature. Color, in contrast to film, is made after editing. Validity from the PVC film, the fabric is a frost-resistant material and is not afraid of negative temperatures. Creating a complex configuration ceilings is impossible.

The minimum distance on which can be attached to the stretch ceiling from the base, is 0.5-3cm (depending on the fastener system of a particular company).

When equipping a tension ceiling with built-in lighting, each lamp (usually point sources) is mounted using a separate suspension to the main ceiling, and the holes are cut in the canvas, which are covered by a special thermal insulation ring in the perimeter. You can use lamps with power up to 60W (for incandescent lamps) and up to 35W (for halogen). To install lamps of greater power, you will need additional thermal insulation between the casing of the lamp and the ceiling body, otherwise the film is simply melted.

The cost of the ceiling is from $ 30 for 1m2, including installation, and the presence of complex constructive sites increases the amount to $ 80 per 1m2.

In the pool or bathroom, you can build a ceiling "Star Sky". This is a tensioning design of a PVC film of a dark color, additionally equipped with a system of tiny lamps-stars. There are several technologies for creating such a "starry sky":

1. Using optical fiber technology. In this case, the fiber can be placed relative to the ceiling plane in three ways. First, displayed below the ceiling level at a distance of 10-50cm, the film is pre-punctured. In this case, the fiber itself is lit, and its reflections in the surface of the ceiling create an additional effect. Secondly, the tips of optical fiber threads can be removed by one level with the web, the surface is also punctured. The third option is to supply the fiber from the back side to the surface, and then the film does not puncture. In daytime lighting it is just a neat smooth ceiling.

2. Using SWAROVSKI Austrian Firm Luminagional Elements. In the afternoon, with natural light, it is beautifully lit crustals, in the evening they give a rainbow game of light. Lighting of lens provide inside the cartridges of the beams of optical fiber threads. It is also possible to combine lens with optical fiber.

3. Using LEDs that are displayed on the surface of the ceiling and look like a very small (1-2 mm diameter) light bulb. They are installed in special connectors and require a special power source. The programming panel allows you to set up to 10 flicker modes of diodes.

The choice of songs from the stars is yours.

The editors thanks the company "Dipris", "Decotek", "Karee Nouire", "Mal-C", "Planet Ceilkov", "Trekking Square", SKOL and Architect Igor Bobenko for help in the preparation of material.