This material is environmentally friendly, beautiful, wearless, and with proper care is still durable. In general, a multi-layer parquet board is worthy of your attention.

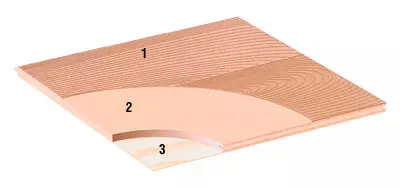

2. Intermediate layer of HDF or coniferous rocks

3. Lower layer

It was invented as a radical replacement for a piece parquet and a massive parquet board. A relatively new material is as environmentally friendly and completely natural, it is also beautiful, no less durable and wearless, and with proper leaving, and very durable. At the same time, it is significantly easier in laying, lighter, thinner and finally cheaper. Alternatively, Europe is 60% of wooden floors - these are floors from the three-layer parquet board

Three magical layers

It is known that the plate glued from several layers of the tree is stronger than the plate of the same thickness of the wooden array. The body of the modern parquet board consists of three layers. The upper, "working" layer has a thickness of 0.5 to 4-6mm (for example, at KHRS Linnea from Khrs, Tarkett, Hohns, Forbo, from Haro model from Hamberger, etc.). It is made from the valuable tree of wood and are usually the fibers along the long side of the board. The fibers of the middle layer are across the top fibers, and the fibers of the lower layer again across the fibers of the previous one. When changing moisture, wood changes dimensions along the fibers much less than across. Wet and consists of the entire range of the invention: mutually perpendicular layers are constrained by the linear expansion of each other, which minimizes the deformation of the entire product as a whole. That is why the three-layer parquet board is deformed under the influence of fluctuations in the temperature-humidar mode three times less than the piece planks or a massive board.Working layer It can be solid, for example, a single layer of a veneer or a thin slice of valuable wood. In this case, the laid coverage cannot be distinguished from the massive geepboard. It happens and a typical glued from the planks that the surface makes the surface indistinguishable from the present piece parquet. Thin strips can be stuck in a different order: in the form of "Christmas tree", "braided", "squares", but today the most common models with the "deck" laying are the most common. The top layer of the Haro parquet board is also gaining from an end cut of an oak or larch. Then the surface turns out to be 2 times harder. Planks in the upper layer can fit in one, two or three rows. On this basis, the so-called single-band, two-band and three-band boards are distinguished. Moreover, their width is 18-20 cm, regardless of the number of bands. But the smaller the rows on the board, the more roads.

Medium layer - These are short and flat bars (lamellas, plates) from resinous conifers glued together. But it happens that the middle layer is made from a durable HDF (thin plate, compressed from finely ground wood), even less prone to deformation. bottom layer As a rule, it is a spruce or pine pine fane with a thickness of 2mm.

As with a massive parquet, a tree for a puffled parquet board is cut in winter (with the exception of exotic rocks), dried in special chambers and glue high pressure. At the level of the middle layer, the ridges are arranged along the two sides, and along the two others. The elements of the castle (blessing) compound also have. Boards are fastened in four sides.

Large, ready-made parquet boards can be laid in any of the existing orders of "square" or "Christmas tree". However, in today's practice, we preferably see all the same "deck" laying, or parallel walls or diagonal.

The task of the floorboard manufacturers is to create a wooden floor covering, as ready as possible for mounting. And indeed, thanks to the large size of the boards, their laying takes quite a bit of time. The ease and speed of assembly contributes to high-quality calibration of elements, the stability of their geometric sizes. The parquet board you only need to lay, after that it is not required to grind. Moreover, it is pre-covered with varnish (up to 7 layers), and not as parquet at the facility, in the conditions of "room climate", and at the production, sometimes even using hot pressing technology. Program is used primarily acrylic varnishes (without formaldehydes), whose durable polymer film is formed at the factory, as a result of irradiation of the surface with ultraviolet lamps. This is a more wear-resistant layer of varnish than the one that is applied by the roller manually. Another option is possible - when the tree is not covered with varnish, and soak the oil, wax and natural resins. Then the color and texture of wood are obtained especially "delicious" - the saturated tone and clear drawing of the fibers are manifested. But there is a third option about which they say: "looks like oil, works like a varnish." Such a varnish coating is called Proteco Natura (Tarkett) and Natural Matt (Haro). The floor looks like oil covered.

Since parquet boards are already a finished coating that does not need additional processing, its "floating" laying is carried out faster and 2 times cheaper than the flooring of the parquet or massive board. The traditional method of fastening - gluing to the base is completely similar to the fastening technology of the piece parquet.

Wood

The parquet board offered on the market from different manufacturers is very and very diverse not only in drawing of laying, but also in varieties of wood pasted on the top layer. Dullness, for these products manufacturers choose the same breeds and varieties as for piece parquet slats or massive parquet board. You can find the most different trees from traditional oak, beech, maple, walnut, birch and cherries to exotic breeds Merbau, acacia, dossia. For example, UPofloor offers more than 50 options for boards of various appearance from 15 tree breeds, Tarkett and KHRS - more than 140 modifications. A large collection of products with a working layer of oak (different selection and heat treatment) in Harro-more than 100 varieties. Usteirer Parkett is more than 100 versions of 15 breeds.

Expansion of the range is achieved not only due to the species diversity of the tree. The surface pattern depends on the selection (saw) and may vary from homogeneous to intricate, with bitch and streaks. Modern wood processing methods also contribute a variety of decorative row. Earbing (applied to the beech) makes the color of the natural tree more rich and "juicy", while increasing the stability of the material. After bleaching (oak, maple, beech), the board acquires a light, cold blood tone. "Antik" is an artificial formation. So handle products from oak to give them a noble deep shade of the "palace" parquet in the colonial style. "Brush" is the combing of weak fibers with a rigid metal brush. As a result, the surface becomes textured, ribbed and well suited to country style. The wear resistance of such a board rises, it can be laid in public spaces with high load on the floor.

Sizes, prices

Most solid producers produce a wide range of products that differ in sizes. The main characteristics of the thickness (0.5-6mm) and the strength of the working layer. The thickness of the boards themselves can also vary (from 7 to 25mm). The thicker the working layer, the greater the number of grinding is able to withstand the floor, this is an indicator of the durability of the coating. So, the three-layer board from Tarkett is produced with a thickness of 8.5; 12; 14 and 20mm with a top layer of valuable rocks 0.6 thickness; 2.2; 3.6 and 6mm, respectively. The board of the VIVA collection of this company has a thickness of 8.5mm (with a thickness of the working layer 0.,6mm), the Rumba-12mm collection (the working layer is thick, 2.2 mm). Enclosures of Classic and Trend The thickness of the working layer is 3.6mm and at the same time a large length is over 2.5m (2525mm). Dimensions of products from different manufacturers oscillate: Length - from 1800 to 2500 mm, Width - from 130 to 200mm. But in any case, a parquet board is a large module that closes the large part of the floor at once. Hence the speed and simplicity of laying, ease of creating a solid coating. It costs 1m2 parquet board, depending on the model, the wood of the upper layer and varieties, from $ 20-60 to $ 95-110. The more expensive one in which there is a tree of exotic rocks (Wenge, Yatoba, Tik, Iroko). The working layer of which is made of a solid reservoir of the veneer (as a massive board), 1.5 times more expensive than the board of the same tree, but with a set working layer (glued from several rows of planks). Trendy trends are inclined to gender homogeneity, preferring large textures with a fine figure. A wide range of single-band parquet board (with a width of 182mm) produce, for example, the company Steirer Parkett, Hamberger, etc.Choice

A variety of such coatings on the Russian market is extremely wide. In addition to the products of the already listed manufacturers, you can find the products of Par-Ky factories, Osmo Ostermann Scheiwe, Vito, Olavi Rasanen, Scheuler Holzindustrie Gezellschaft, etc. This should please the architects and designers, because you can very accurately choose an outdoor coating for the design of almost any interior.

By admiring the color and pattern of the parquet board you like, still ask the degree of hardness of the top layer, which means that its wear resistance, learn whether the coating will correspond to the operating conditions, especially if it is supposed to be laid it in the zone with an increased load. The thickness of the board is determined not only by wishes to wear resistance, but also the possibilities of the floor design. If it is impossible to raise it, due to low ceilings, reluctance or inability to increase the thresholds and cut down the lower edges of the doors, the so-called thin parquet board becomes indispensable (KHRS Linea, Viva Tarkett Ultralo, Furnet Hamberger). It is relatively inexpensive, but with proper operation will last at least 12 years. It is good for bedrooms, children's or second floors of cottages, that is, for rooms with low loads.

The most popular board with a thickness of 13-15mm with a 4mm working layer ("Bamo", "Dok-13", Upofloor, Mafi, Maister Boden, etc.). It is suitable for both residential and public premises. The coating of a thickness of 23 and 25mm is well resisting dynamic shock and mechanical loads and is suitable for special floors (for example, in gymnasium). Under its four-and-six-million top layer (respectively) - three more (!) Internal intermediate layers, not two, like all other boards.

"Floating" floor

The mandatory quality of the concrete floor to which the parquet board can be laid is determined by four words memorable as a saying: "Durable, smooth, dry and clean." "Durable" is if the nail on it is carried out- and cement dust will not remain; "even" means curvature not more than 3mm per 2Pog (under a two-meter straight line, pressed to the floor, should not be asked more than 3mm). "Dry" - it is necessary to measure a hygrometer: the moisture content of the ripe tie is 3.5%. And "clean" - walk the vacuum cleaner and also remove glue, fatty and sticky stains.A multilayer parquet board can be laid in several ways: adhesive (solid gluing boards to base), "floating" and on lags. In love, in the room where wooden floors arrange, during the period of work, it should not be hot, not cold (+20 2c) and not too dry (relative humidity, from 30 to 60%).

Water under the "floating" floor, of course, no. This technology of the so-called "fast" floorboards are not attached to the base, but simply put on special thin substrates and connect only with each other, gluing the comb in the groove (glue from KHRS or BONA-Tech, for example, BONA-175) or Without glue (on a special "lock" connection). "Floating" Paul can be laid independently, not inviting the masters, and there is a lot of money on it (work on laying parquet boards cost $ 8-10 / m2). Enough to read the instructions in the material of the material and accurately comply with all the simple rules. By the manufacturer's company, there are small technological subtleties and recommendations that it is advisable to follow. To protect yourself from errors, it is better to store the purity of the prescribed technology, although in general the installation of a "floating" is a clear series of several simple stages.

Between the boards and the tie, the polyethylene film is placed, and to enhance sound insulation, the sheet polyethylene foam (or extruded tube) spread over the film. If the joints should be glued together, then this is done in two ways: they apply glue either on one (bottom) side of the groove, or on both and never in the bottom of the groove or ridge. Between the walls and edges of the boards, it is necessary to leave expansion clearances, as a rule, not less than 10mm. As a result, nothing prevents the plan from the collected boards to slide ("swim") in all four directions, obeying, of course, is not the movement of steps, but by changing the temperature and humidity regime. If any floorings over time too erased or damaged, it is easier to replace these boards, because the flooding "floating" on the castle connecting the floor, insert new boards and make a change in several hours. Of course, new boards must be "related" - the same manufacturer company, the same size (so that the grooves and ridges or locks are coincided), the same variety. "Aliens" just do not fit. The floors laid down by the "floating" way can be ground and even Ot Cycician. This is true and with respect to the lock connection, for example, KHRS WoodLox.

With a pleasant sound "Click"

At first, the technology of the volatile compound of laminated floor coatings was invented. Then the manufacturers of the parquet board, while making the idea of a progressive installation system, created their variations on this topic. Now not only laminate, but also a natural wooden coating can be collected by the "light movement of the hand", while creating a high-quality and durable surface. Our market presents a board with a variety of mobile locking compounds, which are divided by the assembly method into two groups. The first group is the compounds acting on the principle of "rotation and click" (WoodLoSk- in KHRS and Karelia Parketti, Combilox- at TARKETT). The second group includes connections collected by "hitting and clicking" (Click Connekt from Haro, Baltic Lock, Baltic Floor from Baltic, UltralOnt from Tarkett).

Errors with such stacking are practically excluded, and dismantling and a new coating assembly can be made on any side, regardless of the initial direction. The strength of the blinkless connection (Woodlok or Combilox) is higher than glue. Votchchychi from them, locks over time do not form even small-gross gaps. For comparison: the strength of the adhesive compound is 700-1000kg / run. M, and the strength of the castle- 1400kg / m. The engine and the same manufacturer's company can choose the board for different options for "floating" laying - with a glued joint connection or with mechanical "snaps".

Several parquet board models release, for example, Steirer Parkett. Let's say, the Steirer Parkett Original model is designed to lay with joint gluing on the principle of "Spool-groove" (or, as the parquetters, "Combs"). By this floor, you can walk 24 hours after installation, this is the time of complete drying of the adhesive composition. Amodel Steirer Parkett Novoloc has a lock connection, it is not necessary for the glue, the boards are joined by the "dry way" manually. Vito boards are also on the castles, and with the "Spool-groove". Both the grooves and the comb here have difficult on the outlines of the profiles that, being closed, provide a dense mutual proof of the top layer of the boards. At the same time, the gaps remaining inside the compound are not visible to the eye, the floor is saved from the charge when the humidity changes.

Such a floor can be created in a few hours it will be ready, you can hardly collect it, the technological pause does not need to withstand here. No glue, there is nothing to dry. Similar "dry" assembly is available to almost everyone. For example, moving all the furniture to one wall of the room, you can start laying from another wall, and reaching the middle of the room, rearrange the furniture for a new coating and bring the installation to the end. Subsequently, you can change the drawing and direction of the floor laying. It can even be carried with him, moving to a new apartment, or shifted from one room to another. However, this version of the development of events should be provided in advance, even when buying boards to make some reserve (about 10%) in case of some inconsistency of the old and new area.

Sticking parquet board

If you are not afraid to lift the floors for extra 1.5 cm, if you are a fatal supporter and want to firmly attach the floorboard to the floor, if you are ready to incur additional costs and money, then you can glue the floor covering to the base.The easiest way to operate in a new apartment with bare concrete floors without finishing. Here you will not have to spend money on the dismantling of the old coating and handate the glue stains or bitumen with an old screed, which are absolutely unacceptable. For gluing you need a more even base than for floating laying. Therefore, the screed, already made by the builders, should be "subject to" mixtures, to impregnate with penetrating primer or, as a last resort, replace the new one.

Parquet board of all solid producers (including Hohns, Haro, Calista, Tek, etc.) can be glued directly on the concrete base, but only a very qualitatively prepared and having a stable residual humidity is not more than 5%. If there is a chance that the concrete under the parquet board will become more humid (for example, from the penetration of vapors from the lower room), then under the boards it is necessary to retrieve vapor and waterproofing (film thickness 0.2 mm). Campling, naturally, boards are not glued, so there is an intermediate layer between it and the parquet board, it is either plywood with a thickness of 12mm, or a wood chipboard with a thickness of 19 mm. Watching a higher quality screed can be taken by a chipboard.

Roll polyethylene strips Steel on the shrewing with the adhesive 20cm, and no waterproof primer of this film is unplanned. It is possible to equip the wooden floor with additional sound insulation by placing a layer or foamed polyethylene with a thickness of 3-3.5mm, or pressed cork, or leaf rubber. Sometimes a construction cardboard is used, but it is bad sound insulation. In love, no matter how from the named materials you choose as an obstacle for noise, it is placed directly on the waterproofing film, but only an online jack. Fall is unacceptable, otherwise the thick seam is formed, lifting the board. The feather sound will not be. Phaneur or chipboard sheets cut, as a rule, with squares 5050 or 7070cm and are attached to the black semi dowel-nails or screws so that the compensation clearance of 10mm remains between sheets. Parquet boards can be mounted on the Fauer with alcohol-based glue. Boards shoot with brackets. The grooves do not glue

And a warm floor?

Most of all for a warm floor system, a thin parquet board is suitable, such as KHRS Linea (7mm) or Tarkett Viva (8.5mm). A parquet board can be glued or laying a "floating" manner and over the heat-mall system, but the temperature on the cable surface should not exceed 50c and the heating cable must be distributed under the packed floor uniformly, the heating board is equally all over the area. The floor from a thin puff parquet board is well rolled with the heating system, while with a thick parquet board (22-25mm), the floor heating system is better not to combine. Between the flooring board and floor heating system, the layers of foamed polyethylene and tubes cannot be reduced, they strongly resist the penetration of heat upstairs, and the cable itself may fail against overheating.

Parquet board in a country house

Parquet board can be laid on the lags and on the beams. This is especially relevant for country houses. The beams and lags should be dry and not seen, otherwise the floor will begin to creak. The space under them should be well ventilated in order not to accumulate water vapors. The beams and lags must lie in a step of at least 60cm, and the parquet board needs to buy thick- 22 or 25mm. You can pre-Wait for Phaneru, if you can align the ceilings and thresholds, and then lay the boards by either a "floating" method of a polyethylene substrate, or without it, to glue to plywood. Mounting boards is permissible and straight to the lagamships or shoot with brackets (they are scored in a bar of diagonal). The "floating" method (on a plastic film) can be elevated parquet board and on top of a black milking floor, if it is smooth (irregularities it is necessary to open, complain, compatient). On the boardwalk flooring the parquet board is allowed and pasted. However, if under the flooring there is a concrete slab or a screed, you need to know whether waterproofing is between it and concrete. If not, the black floor boards will have to shoot and lower the film for them. In case, it is more reasonable to apply "floating" technology.Second layer

Parquet board of all listed manufacturers, as well as GRABO, Siberian Forest, Berry Wood, Green Wood, etc. You can lay (but only a "floating" way) and on the floor, separated by linoleum. Even the old linoleum (but without holes, cuts and bubbles, of course) serves as good pair and sound insulation. Sometimes it is still placed additionally polyethylene film, if not confident in the waterproofing properties of the black floor under it (for example, in the country). If the old coating is the so-called "linoleum PVC" (or simply PVC), then the film is not needed, since PVC provides good hydro-insulation. Avot to stick the board either on the linoleum, not recommended on plastic.

On the floor, lined with ceramic tiles, if you wish to see a tree instead of her, you can safely lay a parquet board ("floating" way right on the tile), and the film is not needed here. If you have conceived to stick the boards on the ceramic base, it is real, but the surface of the tile, and especially the seams, you need to carefully degrease.

A parquet board can be laid (of course, without gluing) even on a carpet with a rigid pile (up to 4mm) - the wooden floor will become warmer and "deaf". The pile must be well cleaned and dry so that there are no organic particles in it, otherwise the mold is formed under the boards. It is best if the carpet has a rubber or any other moisture-proof base, is a guarantee of reliable waterproofing of boards from below. In contrast, if the black floor under carpeted is capable of perceive and give moisture, the carpet must be removed and reducing the waterproofing. The plinth, under which the edges of the carpet cover are embedded, have to be removed in any case and return to the place after mounting the board, attaching not to its surface, and to the wall. Not too pressing to the boards to leave them the opportunity to move within compensation gaps.

"Floating" flooring of puff (15 and 22mm) boards can be stacked on any gender, which is placed as the insulation plate of wear-resistant foam (density of at least 30kg / m3). In order for when walking on the floor, the foam did not creak, the construction cardboard is first at him. The secoal is a subtle parquet (10mm) put even a chipboard of the same thickness. If the boards need to be glued, then, of course, not on the foam, but on the usual in this case, the planer or chipboard. And under the layer of polyfoam, and it should always be treated with a thick (2mm) polyethylene film.

Care

With proper care (protection against dirt, water and scratch, timely coating with varnish during abrasion) a thick parquet board can also serve as long as a piece parquet. Since the thickness of the wood before the combination of the "comb-groove" (or the castle) at the piece parquet after cycles and grinding is 6 mm, it is comparable to the thickness of the top layer of many parquet pattern models.Varnish coating (5-7 layers of varnish in factory conditions), more durable than on the parquet, sometimes it is still worth "pamping" - to process decorative protective "rapidly". These compositions choose depending on the degree of pollution of the floor and, taking into account the desired result, simply refresh the surface, clean, give one or another degree of gloss, prevent slipping, to protect from bacteria, create additional protection against intensive loads. For example, Parkett Polish (Bona) and Refresher (Tarkett) are applied simply using a flat swivere floor will be "look good" and the dust will easily remove it. The composition will strengthen the water-repellent properties, and the surface will stop sliding. The floor washes a weak soap solution without alkali. Instead of soap in water, you can add a BioClean (Tarkett) tool. So that the moisture does not penetrate into the jokes of the parquet board, they are pre-closed with the composition of Bona Care or Sicura Haro. For dirty floor, Parket Polish Remover (BONA) is better - he will remove the old "Polish" and clear the lacquered surface.

For boards with a thin working layer, grinding, of course, is not provided, but a multiple surface varnish is quite possible. No need to wait until the lacquer layer wipes and the wood will be affected. The old varnish is simply slightly ground, the floor is cleaned with a vacuum cleaner, after which the new layer rolling the roller. When buying a parquet, Mark Laka will tell the seller. Better is the lacquer, how the board was covered at the factory. For example, Tarkett for its floors recommends MEDIUM and HIGH varnishes. You can use the prevention and Nanosol-cleaner compositions, Nano Kliner Pro Lak (removes the spots) and the freshener of Nano Refresher Pro Lak.

Parquet board, treated with oil, is another care, more frequent. But for this there is your "helpers", for example Carl`s Cleaner (BONA), the oil-wax composition Carl`s Oil-Wax, Nano Klimer Pro Oil, Nano Pefresher Pro Oil. The remainder of wax and old polishing can be removed using Nano Polish Remover. Following it, the composition of Nano Polish lines visible wear, scratches, protect the surface and give it glossy radiance (flow rate per 80m2). There are more reliable protection for sex undergoing intensive loads - liquid oil wax D 505 POLISH (for lacquered and waxed floors). True, after applying this composition, a polishing of the surface is needed. Relatively recently began to apply the so-called UV-oil, which gives wood even greater strength. Result - simple care: regular cleaning and processing, for example, Kahrs Oil Refresher once every six months. Like any wooden coating, a parquet board "does not like" sharp heels and furniture legs without felt linings.

Comparative characteristics of some parquet board models

| Manufacturing firm | Collection | Selection | Type of connection | Dimensions | Price, $ |

|---|---|---|---|---|---|

| Tarkett (Sweden) | Oak | Natur. | Ultralo | 252518814. | 36. |

| Viva cherry (two-band) | Natur. | Ultralo | 122019085. | 27. | |

| Beech | Select. | Ultralo | 252518814. | 47.5 | |

| "Oak Original" | Natur. | Paz-comb | 252515514. | 28.5 | |

| Ovenkol | Select. | Ultralo | 252515514. | 62.5 | |

| KHRS (Sweden) | "Oak Copenhagen" | Natur. | Woodloc. | 242320015 | 45. |

| Linnea ash (two-band) | Natur. | Woodloc. | 12251937. | 28. | |

| "Oak Stockholm" | Select. | Woodloc. | 242320015 | 54. | |

| "Oak Granada" | Rustic. | Woodloc. | 242320015 | 37. | |

| "Beech Copenhagen" | Natur. | Woodloc. | 242320015 | 45. | |

| HARO HAMBERGER (Germany) | "Oak Trend" | Natur. | Clic Connect. | 220018013. | 42. |

| Cherry Furnett (two-band) | Natur. | Clic Connect. | 12821958. | 28. | |

| "Beech excvised" | Select. | Clic Connect. | 220018013. | 53. | |

| "Oak Tundra" | Rustic. | Clic Connect. | 220018013. | 27.95 | |

| "Oak Trend" | Natur. | Paz-comb | 220018013. | 32.4 |

The editorial board thanks the company Tarkett, Elitparket, "Parquet Center", head of the representative office "AB Gustav Cherniv" (KHRS) Olga Koshelev, President of the company "Parquem" Eduard Flagnikova, General Director of Polimpex Fyodor Nico for help in the preparation of material.