Washing machines: What can modern homemade "lackers" can and know? Stuffing, technical specifications, manufacturers, price order.

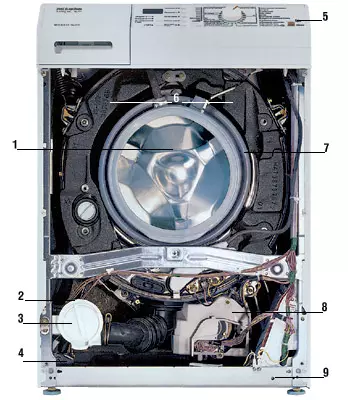

2. Drain pump with filter;

3. Cover for emergency plum;

4. Support hydraulic shock absorber;

5. Management system "SOFTTRONIC";

6. cast iron counterweight;

7. Stainless steel tank;

8. Motor with frequency converter;

9. Case machine

For a hundred years of its evolution, the washing machines made a huge path from the "rotating barrel with a mechanical drive" to the helica devices that make washing absolutely unscrewing. Perhaps the only difficulty with which potentially owner will be faced with, is the right choice of a homemade miracle model.

Today, the Russian market presents several hundred and varied models of washing machines. Among the most popular manufacturers can be called Bosch, Siemens, Aeg, Miele, Ariston, Indesit, Candy, Ardo, Zanussi, Siltal (Italy), Whirlpool (USA), Asko, Electrolux (Sweden), LG, Samsung (Korea) . Marks that appeared on the domestic market relatively recently include Beko (Turkey), Gorenje (Slovenia), Hoover (United Kingdom), Hansa (Germany). Separately, it is worth mentioning the washing machines of the domestic production "Vyatka", Zvi, "Baby", "Oka", "Eureka". These devices relate to the discharge of the cheapest cost of domestic models, as a rule, does not exceed $ 200-250. Among the foreign washing machines of the economy class ($ 300-400) - for the most part Italian and Korean models. The dasch of the most expensive stamps includes Asko, Siemens, Aeg, Miele. The cost of these products can reach $ 1300-2000.

What can be the criteria for choosing? Well, first, most importantly: the car should provide high-quality washing, as well as an effective deposition of all types of fabric. Secondly, it must be economical. Third, ergonomic. It is desirable that the device purchased by you worked quietly, and the management of them and such manipulations, like loading and unloading linen, the set and draining of water, were simplified to the limit. And finally, the reliability and security of the connection. The car is obliged to work for many years without leaks and breakdowns.

Clean class

How to evaluate the diligence of the washing machine? To do this, it is enough to see what a washing class is assigned to her according to the classification of washing machines for European manufacturers. This classification has existed since January 1995. The intercom with it all cars are divided into seven groups: A (the highest class), B, C, D, E, F, G (the lowest). In addition to the laundry efficiency class, there are indicators of energy consumption classes and annealing.The express efficiency class is determined in relation to the weight of the water remaining in the tissue after the end of the process, by weight of the dry tissue. Interestingly, some manufacturers are committed to improving the quality of the press with a constant maximum speed of the centrifuge. The fact is that the procedure is compressed, a complex technological operation consisting of several cycles. The art of technologists here just lies in the correct selection of these cycles and their duration. For example, among domestic washing machines with front loading, the record holder is the LAV 88840 RU (AEG) model, which, at a maximum spinning rate of 1800 rpm, provides an extractive index of 42%.

The most complicated is determined by the washing efficiency class. There is a clearly developed technique. There is a "standard" contaminated fabric, for which the composition of matter, types of pollutants, and even dimensions are strictly defined. Package The reference for comparison is used by the Wascator Hand-Assembly Washing Machine from Electrolux, produced at the factory, which is owned by Asko. Same samples of contaminated fabric are placed in the standard machine and in the test model. Then washing (washing powder from Henkel, manufactured specifically for tests) for an hour at a temperature of 60c. Washed samples are examined on a special device (photocolorimeter), where the whiteness of the tissue is measured (more precisely, its albedo-scattering ability). By the ratio of the whiteness of the tissue of the tested device and the reference machine and is determined by the washing efficiency index.

It is necessary, however, it is necessary to note that in almost all units, the highest laundry rates are achieved only with a strictly defined amount of linen. So, for cars with five kilogram loading, optimal quality is achieved at 2.5-3.5 kg of linen. This factor is most sensitive in the case of aggregates having small amounts of tank when you have to choose between the number of washing cycles and its quality.

Accuracy above all

The high class of washing and spinning demonstrates the efficiency of the washing machine, but does not guarantee the safety of the tissue. The "careful" wash can be achieved one of two ways: either using the structural improvements of the main working body of the machine-drum, or as a result of creating a more smart and perfect controller responsible for the process algorithm.

The drum of the washing machine is a perforated metal container in which underwear is placed. This container, in turn, is inserted into the water-impermeable pot. Rotating, the drum leads to a mass of linen. Rotation speeds can be very significant: in washing mode - up to 60-80 rpm, in the mode of pressed, up to 1800 rpm. Thus, there are significant friction forces between the inner wall of the drum and placed in it, even in washing mode (especially if we consider that the drum rotates reversible, clockwise and against it). Therefore, the internal streamlined forms of the drum are calculated by designers with the same thoroughness as, say, the parameters of the surface of the aircraft wing. So, for example, a Miele cellular drum was developed. Its design is such that in the process of rotation between its wall and linen, an aqueous film is formed, according to which the fabric gently slides and is not subjected to the destructive effect of friction force.

For greater intensity of linen and better wash, various ways of water supply are used. This is a continuous injection system of Activa (Candy), Direct Spray (Electrolux), Jet (Zanussi) or Double Moisturizing System Aquaspar (Bosch, Siemens), Aquacycle (Zanussi), Combiwash (Candy). Continuous injection used solutions are supplied to the working capacity using pump pump. Auto systems of double moisturizing water is captured by various structural elements of the drum and poured on the underwear on top. The essence of all these inventions is that with their help, the detergent solution interacts intensively with the cloth, the washing powder is completely dissolved, and high-quality rinse is provided. Unsticable Ariston and Indesit machines for these purposes uses the "System of Demanding Use of Detergent". Its work is based on the centrifugal forces and a specially calculated coal of the installation of a drain nozzle.

As for another method, the creation of new washing algorithms, then in almost every high-class washing machine there are one or more "delicate" silk programs, wool and thin linen. Thus, in the program "Manual Wash" in the Lav88840RU (AEG) model, as in most Bosch units, the drum makes swing movements with amplitude 324 to reduce the mechanical effect on the fabric. AV programs Woolmark Platinum Care used in the latest ARISTON models, and the "affectionate wave" in Electrolux is used by the increased rotational speed of the drum (90-100 rpm) with a reduced amount of water. This mode allows you to avoid filing fibers of wool.

The choice of washing machine is best carried out with the wardrobe. It is unlikely that it makes sense to spend extra $ 100-200 due to one-sole silk headscarf. Well, if your outfits are distinguished by the high cost and variety of fabrics, then for the safety net, you can choose a washing machine with Update feature (Miele, Asko, Siemens, AEG, Ariston, Ardo). It allows you to reprogram the machine when new, more efficient washing programs appear.

Just but logical

A washing machine should be easy to control. Therefore, it is important for her commander to do not have too much handles and low-touch functions.There are two groups of devices with a different management approach. The first machine of the functional group in which electromechanical control systems are used. They differ simplicity, minimal feature set and are used, as a rule, in cheap units worth $ 250-350. A distinctive feature of these control systems is the presence of handles-programmers that can be wrapped only clockwise, thus setting the type of linen and washing mode. . Cordic machines include models R 405 (ROLSEN, Korea), WM 3508 R (Beko, Turkey), SLS 40 x (Siltal), WS 105 TX (indesit).

Most of the same modern machines use electronic control systems (electronic television equipment), in which the indication of a wide variety of washing functions is implemented. Through the menu, the type of linen is set, the desired washing intensity, the inclusion delay time, rinse mode, water temperature and many other parameters. The average Russian is able to manage such a system only if there is instructions in Russian or Russified menu. The latest models of washing machine developers are abandoned by the complexity of multi-step management procedures. This case uses the principle of "fuzzy logic" FUZY LOGIC, independently controlling the washing process. The owners are sufficient to indicate the type of fabric, and then the machine, continuously analyzing the amount of water, its turbidity, temperature, the rotational speed of the drum, will select the optimal wash mode, and, if necessary it adjusts it. Machines equipped with a Fuzzy Logic system are worth $ 100-150 more expensive models of similar class. And along with convenience in control, they give a tangible (up to 20%) economy of electricity and water.

Classification of washing machines

| Energy class | Energy consumption of kWh / kg | Washing Effective Class | Washing Efficiency Index | Pressing Effective Class | Pressing Efficiency Index,% |

|---|---|---|---|---|---|

| A. | 0.19. | A. | > 1.03. | A. | 45. |

| B. | 0.2-0.23 | B. | 1,02-1 | B. | 46-54 |

| C. | 0.24-0.27 | C. | 0.99-0.97 | C. | 55-63 |

| D. | 0.28-0,31 | D. | 0.96-0.94 | D. | 64-72. |

| E. | 0.32-0.35 | E. | 0.93-0.91 | E. | 73-81 |

| F. | 0.36-0.39 | F. | 0.9-0.88 | F. | 80-90. |

| G. | 0.39 | G. | 0.88. | G. | 90. |

Ergonomics and life

Washing machines belong to sufficiently "loud" devices whose noise can reach 70 dB and more. If we consider that it is very often washed to convenience for convenience at night, it will become clear to the desire of manufacturers to reduce the "volume" of the instruments produced as much as possible. This purpose is used tanks from composite materials, soundproofing gaskets, more "quiet" electric motors. The noise level of noise was reduced by a few times the shortest models of LAV 88840 RU and LAV 86730 RU (AEG), as well as new ariston novelties with the Super Silent function.Manufacturers of washing machines pay attention to the most "manual" operations, automate which is impossible. This is loading and unloading linen. The frontal loading of the hatch is made as convenient and wide (with a diameter of 300-350mm) as possible, with a lid, leaving 180. It is especially possible to highlight the hatches of Beko washing machines. Extremely of them, for example WMN 6508 K, it is possible to outweigh the covers on one side to another, which greatly simplifies the installation of the device into a small bathroom. AU of new ariston models There is an Easy Door Lock feature, which allows you to open the hatch in the first minutes of washing, if you forgot to put some things into the car without interrupting the program.

Today it is difficult to say that it was disturbed by the designers of washing machines in the first and deal convenience of loading linen or reliability of the drum fastening. But the result of their search was the existence of three layouts of the drum location. The first is the vertical axis of rotation and loading from above. Second, with a horizontal axis of rotation. Loading here can be both frontal and vertical. In the last case, the lateral surface of the drum is equipped with drop-down flaps. But recently there were models (HV16, Hoover; PA4510B421S, HANSA), in which the tank and the drum have a tilt of 15, and in the IZ12 model from Zanussi- by 20. The frontal surface turns out to be bevelled. Such a design facilitates the owners of manipulation with erasing linen, and the inclined location of the tank and the drum reduces the level of vibration of the machine (and, accordingly, the wear of the working units). According to Swedish professionals, in cars with a vertical axis underwear, the laundry is stronger (since the rotating activator "chases" underwear to the walls of the stationary drum and back), and the apparatus with an inclined axis erase less efficiently (underwear is knocked in the "corner" of the drum). By the work of the washing machines, the tank lighting can be attributed to the work of the washing machine (WPS from Miele).

And about breakdowns

Most often, the pumps of drain nodes are out of order, heating lamps and drum drive belts.

The record holder in the breakdown in the washing machine is a drain pump. It is constantly in water and after 4-5 years "In operating mode" requires replacement (the operation costs $ 70-150). To increase its service life, it is desirable to merge all the water. It is not very convenient for daily washing, but it is certainly recommended for long-term dows of the device (for example, when the whole family leaves on vacation). When the washing machine has a long time to carry out without work, it simply needs to merge water (approximately 500 ml), which necessarily remains after washing. To do this, you just need to lower the drain hose to the floor level or (when connected to the siphon of the sink), disconnect the drain hose from the case.

One of the frequent reasons for the output of the pump is from the fall of foreign objects (buttons, coins, etc.). Even the mesh filter does not save the pump from clogging - the opposite, on the grille, "love" to settle the thread, hair and other trash. This problem solves the pump with anti-lock, used in Asko and AEG washing machines. Listening to clogging the drain pump begins to work in reversing mode and literally spits the object that fell into it. Another option-electronic control Softtronic (Miele), which reports the slightest troubles in operation and displays information on the control panel. Miele drain pump does not require special service - thanks to a special design, large items do not fall into it (they set out on an easily accessible filter cleaning). However, if a unforeseen jar suddenly happens, the inscription "Check Dumina" will immediately light up.

Another problem area for washing machines with frontal loading, door. You can wear a seal over time. Often it even flies "early" due to the negligent handling of the device. Therefore, in order to avoid troubles, it is necessary to carefully download and remove things that can damage the seal (for example, clothing with zippers). After washing, the hatch is recommended to be left open to dry the inner surface of the tank and rubber seals (especially for machines with enameled tanks).

As for electronics, it is quite often refused to operate a programmer handle. The cost of replacing the broken part is $ 10-15. A more serious breakdown can be considered a failure of an electronic control system. This is a complex and expensive device that is equipped with a processor and actually represents a microcomputer, leading all the actions of the machine. The procedure for its replacement will cost at least $ 30, and the item itself can cost $ 50-100 and more, depending on the "steep" model.

Electromechanical and electronic commanders often fail due to poor contacts in the wiring. The reason for this may be the oxidation of contact terminals due to high humidity, and even ordinary cockroaches. Electronic control systems are also sensitive to the quality of power supply. It is no secret that in the Russian power grids, cases of voltage drops, its decrease to 150-180 V or, on the contrary, increase to 250 V (such races are especially characteristic of rural areas). If networks often occur in the network with electricity, it is better to connect the power of the washing machine through the voltage stabilizer or use a model with electromechanical control.

Oh, this vibration!

Vibration is one of the main reasons for all mechanical breakdowns of washing machines. Not only belt transmission suffers from it, but also carrying the bearing of the drum, and the repair of this item will cost $ 100-200. Vibration in the car is always and occurs due to uneven linen distribution in the drum during annealing. It shortens the service life of the details of the device and makes working with it uncomfortable.To reduce vibration, serve spring suspension systems and hydraulic tank shock absorbers. This purpose uses massive inertia cargoes made from cast iron or concrete. Cast-iron parts are more expensive than concrete, but they have a smaller fragility. They are used in the most prestigious models of washing machines, in compact (narrow) devices manufactured by Bosch, Zanussi, Asko, Electrolux, in all, without exception, Miele products, as well as ... Promotable "Vyatki". It is curious that the quality of cast-iron counterweights in our machines is often higher than, let's say, in Italian. Cast-iron counterweights "Vyatok" are well acquainted to masters of car service - in form and size they are ideal for richtovka wheels. The total weight of the washing machine due to all these constructive features may be very solid. For example, all MIELE models weigh in an empty state of at least 94 kg. The greater the mass of the washing machine, the higher the smoothness of the drum stroke and, accordingly, the reliability of the entire device.

In Asko models, the vibration decrease is achieved through the framework of the fastening of the tank. The entire dynamic part is fixed on the frame with a massive base with the help of shock absorbers and in the process of operation does not contact the machine with the body. Thus, the vibration of the housing is completely excluded.

The increase in the drum has favorably affects the vibration. The standard volume of the drum of machines with a 5-kilogram load is 44 liters. Premium Vmod (Asko, Miele), in the WFH, WFO, WFR (BOSCH) series and the new AVXL 109 model (Ariston) use the beams with a capacity of over 50 liters, which makes it possible to achieve a better balance of linen with a significant load, as well as eliminate the imbalance When washing large and heavy things.

You can fight vibration with your own forces. In all the instructions for washing machines, it is said: the device cannot be included without prior placement by level. The washing machine must be fixed on the smooth and solid floor. In addition, it is not recommended to overload it with laundry when washing. But the main means of fighting vibration are e-program washing. The firms provide for operations on the automatic determination of the impassional weight of the linen (they say the imbalance of the drum) and its various procedures for the redistribution of linen until the imbalance comes to normal.

If the tank suddenly suddenly ...

To breakdowns leading to a catastrophe include tank leaks. If the tank loses its waterproof, it is fraught with flooding of an apartment and a hopeless spoke of the entire washing machine as a whole. Therefore, choosing a model for yourself, be sure to pay attention to the material from which its tank is made.

The pots of washing machines are made of stainless steel, plastic and composite materials. Saying the option is your advantages and disadvantages. Stainless steel, for example, has proven itself in professional washing technique in models of companies such as Primus, Lavamac (Belgium), as well as Miele, Electrolux, Asko, where steel has been used for several decades. Music of such tanks include their high price, as well as relatively large noise. Most of the composite tanks are preferable to CARBORAN 2000 (used in AEG, Electrolux machines), Silitech (Candy), Poliplex (Indesit, Bosch and Siemens). These materials provide Baku the necessary margin of safety and absolute chemical inertness. True, at the price a good composite turns out to be a little humane "stainless steel". Cheaper steel-coated steel products (like EVA from Ardo) and plastic, but also reliability they lower, as well as the service life shorter. The tanks of washing machines are usually the form of a cylinder. Exception is Candy Machines. Their tanks in the cross section are an oval, which reduces water consumption and increases the economy of washing. The overall disadvantage of all plastic tank is fragility. Of course, plastic is not a crystal, but different massive parts are attached on the tank. With incorrect transportation, especially in the cold, such a tank can crack. If the owner transports a washing machine on his own, then the cracked component does not fall under the guarantee, because it is "mechanical damage" (in any case, it will be very difficult to prove its failure to break). Therefore, it is better to trust the carriage of the washing machine with a non-metallic tank to the store representatives, then in the case of which the warranty will be saved.

Drums, as a rule, make stainless steel and very rarely from the composite. They are driven by the electric motor. Motor models of cars can be used DC electric motors, asynchronous single-phase or collector. The latter provide the possibility of smooth control of the rotational speed of the drum, as well as the preparation of a high speed of rotation in the pressure mode. The engines of this type are equipped with AE1000, S1000X (ARDO), P-1405J (Samsung) and almost all units from Indesit and Ariston.

Asynchronous single-phase electric motors are initially distinguished by simplicity of construction and high reliability, but they have a serious disadvantage-constant rotation speed of the shaft. It is regulated by the number of engine windings connected to power. For example, with two connected windings, the speed of rotation is maximum and is several thousand revolutions per minute, and at 16 windings (8 pairs) it, respectively, is 8 times less. The stack design of the engines was impossible to achieve a smooth adjustment of the rotational speed. Solve this problem allowed the use of electronic rotation frequency converters. Asynchronous engines with electronic rotation frequency conversion are used in all MIELE washing machines and in the Bosch WFR 3240 model, as well as in all ARISTON washing machine models with the Super Silent function (15 models). These engines are reliable, durable and silent, but cost more than similar collector power.

DC electric motors are used in Asko and AEG washing machines. Kih advantages include a high starting point. This allows you to begin the process of pressing the underwear in the presence of a washing solution in the pot, which reduces the level of vibration and eliminates twisting and fmining tissues. DC engines have good braking characteristics, which are capable of carrying out a smooth stop of the drum for 4 s after the expiration. In addition, they can work in reversing mode.

Engines and tanks are the most expensive elements of washing machines. Only work on their replace will cost $ 50-100 (as for the part itself, it can cost more than one hundred dollars). Therefore, it should be treated to tanks and engines "with due diet" and comply with the rules of operation of the washing machine. Accomplice, not allowing the inside of the tank of metal objects, which at high speed of rotation during annealing are capable of split plastic and even slim thin steel. The engines most often fail if water is hit on them or during power fails. It is necessary so necessary to ensure that the water does not fall on the body. For example, when installing the machine out of reach of the soul spray (it is better to put it in the kitchen, where there is not such a high humidity as in the bathroom). In addition, if suspicious noises are heard in the washing machine, it is categorically impossible to operate. Due to the larger mechanical loads, any trifle breakdown can very quickly lead to a cardinal damage of a tank or engine.

Another detail, often failing, is a drum drum belt. Moreover, in 90% of cases, these belts fail due to improper operation of the washing machine. Most often, the breakdown occurs when annealing massive portions of the linen, which for some reason is not amenable to balancing. Let's say, the things are clogged to the duvet cover with him, a huge com. Intensive vibration, the belt (not deflected) occurs during annealing, and the belt (not deflected) under the action of periodically arising stretching efforts, as a pulled string. It should be noted that the replacement of the driving belt of the washing machine can not be called a completely cheap procedure, together with the cost of the belt itself (about $ 10), it will amount to the amount of $ 20-30. Most of the washing machines are equipped with a belt transmission. At the time, time appeared, however, LG models with direct drum drive. Such a design is more compact and eliminates a weak link. True, so far it is unknown how the engine will behave with a direct drive and how wear it is in vibration and friction, "such cars appeared on sale quite recently, and there is no longer no damage data.

How to save TEN.

The water with a high content of calcium and magnesium ions (the so-called rigid water), as well as the impurities of insoluble mechanical pollution (for example, the smallest rust particles) can derive the washing machine in order for 2-3 years intensive operation. From mechanical particles suffers, first of all, the aforementioned electromagnetic valve. These particles fall between valve shutters, get stuck there or cause their accelerated wear. Especially a lot of similar garbage enters the washing machine after the preventive repair of water supply and water outages. A radical means that will significantly lock the parts of the machine can only be considered filters of mechanical water purification with interchangeable cartridges. They are mounted directly on the plumbing pipe.Suffer from poor-quality tap water and Tenna. A precipitable precipitate is formed on their heating surface, which dramatically worsens the thermal conductivity of the metal. Scale contributes to the overheating of the beans, up to their breakdown (up to 50% of all damage to washing machines are associated with the failure of the heating elements). The causes of the formation of calcium and magnesium bicarbonates contained in the dissolved form (the more these salts, the greater is water). When heating the salts are decomposed on carbon dioxide and an insoluble precipitate, which is the very scurvy.

Fight with it with the most in many ways. Most often used "chemical" method. In this case, the internal surfaces of the tank and the Tan 2-4 times a year are processed by acid-containing means to remove scale (such as Kron Star, Kristall-Fix, Antinakipin-M). This method is relatively affected (quarterly treatment of the elements of the machine by domestic means will cost a maximum of 50-100 rubles per year), but it is possible to use it only if the tank is made of stainless steel or plastic, but in no case from metal with an enameled coating. For such tanks, softeners are suitable, which are not able to remove scale, but reduce water rigidity. They must be added to the solution during each washing. Household chemical manufacturers are designed as "separate" softeners (the most famous Calgon brand), added to washing powders and integrated machines for machine wash (Persil, Ariel), which already includes a softener. Buying a washing machine, ask the seller, which means of the existing on sale is best suited for the selected model.

However, the chemical method of combating scale has its drawbacks: those present in the used acids of acids during evaporation adversely affect the operation of the system of automatics of the washing machines, corrosive rubber seals, resulting in water from the tank; In addition, acid evaporation worsen the ecological condition of the room.

Another method is technological. It is known that the intensity of the formation of scale is directly proportional to the degree of water heating. For example, with an increase in temperature to 40-50, only a slight amount of scale is formed. This fact takes into account the developers of new washing programs and new washing powders that can effectively clean pollution only in a slightly heated water (of course, such programs and powders are developed not only for the fight against scale, but also for the purpose of energy saving, but in this case the savings are justified in doubly) . In short, if possible, choose modes with the smallest heating modes for washing.

Unfortunately, with very high water hardness, such measures may not give a positive result. Eszyme difficult cases will have to resort to the help of external softener filters or magnetic converters. About softener filters, how to choose them, described in detail in N 3 of our magazine in 2003. Magnetic converters are a system of permanent magnets of a cylindrical form, overlapped on the outside of the water pipeline, or cut into it (there are different models). The results of the water treatment of hydrogen bonds of its crystal lattice are destroyed, calcium ions fall into the precipitate and do not reach the surface of the Tan. Thus, the scale is not formed on the agent. Moreover, previously formed deposits are loosened with magnetically treated water, and further purification of surfaces occurs. The service life of the magnetic converter of water is 50 years.

The durability of the Tan is largely dependent on the nature of the load of washing machines. It is accuravity, it is known that the Teni is much faster in scale when washing dilapidated linen (a large number of separate particles of tissue falling into precipitate and creating "soil" for lime deposits). Great harm to the tonam, and the entire washing machine is brought falsified washing powders. Therefore, it is best to buy equipment for washing not in the collapse markets, but in corporate stores.

Assess the condition of the heating element and the degree of occurrence can be independently. Ten is located at the bottom of the tank, under the drum, and directly through the holes in the drum is almost not visible. In order to consider it well, the inside of the drum is installed on the lantern (bottom light bulb). The drum slightly shake. The method of trial and error can be so pleased to make the speed of movement to achieve uniform illumination of the Tan and consider it.

Whereas the owners of Asko cars. Watch devices drum is easily removed and dressed manually, without any tools. Having removed the drum, you can not only consider the TEN, but, if necessary, remove the garbage stuck in it or the foreign object that came from the tank (and save on the call of the wizard, at least $ 30). And do not forget that when you get into the tank of any objects and jams, they can not operate there!

Connection adventure

One of the key points affecting the duration of the quality of the washing machine is its connection. It is necessary to apodo it to the water supply, sewage and power supply network, and in each case there are its subtleties. Generally accepted practice when professional professionals are invited to connect a washing machine with a license for this type of activity. Only the connection made by all the rules of the company's specialist will allow to obtain warranties not only to the washing machine itself, but also on the work and materials used in this procedure. Connection warranty should have a duration of at least 1 year.

Most washing machines are served only with cold water, but occasionally there are models, connected to both cold and hot water (for example, a DWF-5020P model from Daewoo from South Korea) in order to save electricity. A few years ago, there were much more such models on the market (up to 30% of the total washing machine), but manufacturers gradually refuse their production and deliveries to the Russian market. There are many reasons here, but the main quality of hot water and the instability of its temperature in our water supply. Heating of water directly in the unit allows you to more accurately withstand the washing regimes, which is especially important when processing "gentle", "delicate" tissues.

Water is served and merged only by flexible hoses. They are the weakest link in the Water Supply Washing Machine chain. The hose has a destructive effect not only water pressure (from within), but also all sorts of random third-party influences. Washing machines can be equipped with a single-layer and two-layer hose. In the last case, the outer layer is a protective, which has increased wear resistance. Such hoses cost 3-4 times more expensive than one-layer, but at the same time much safer. It makes sense to think about equipping the washing machine with a similar component, especially if you often have to rearrange the car from place to place or, for example, there is a dog in the house that can simply observe the hose. The enhanced WaterProof Metal protection system is mounted, for example, on one of the models with vertical load from Miele (W 180 WPM). Asko washing machines are equipped with a special Rex hose made of a special polymer, withstanding a load of 10 atm at a temperature of 90c for a long time.

Sometimes the car is connected to a rigid tube water supply. Do it undesirable. Over time, the rigid connection from the vibration of the machine will necessarily break through and the real danger of leakage will arise. It is also not recommended to splict several hoses if the washing machine is too far from the tap riser. It is better to spend a little longer amount of money and buy one long hose instead of two short. I would like to note that the progressive decision is the proposed recent supply in the water car saturated with air bubbles (aerated water). This activates the process of tissue overing. Aeration is achieved with the help of special air valves placed at the entrance to the feed hose. Such valves offer, for example, the firm Hutterer Lechter (Austria).

Brief Wicker Dictionary

The diverse terms, which are found in the descriptions of washing machines are collected below. Shooting companies are manufacturers.

Activa (Candy), ART (AEG), Direct Spray (Electrolux), Jet (Zanussi) - Diverse systems of continuous injection of detergent solution in the drum during washing. Provide the intensive effect of the detergent solution on the processed fabric, its continuous stirring and the complete dissolution of the washing powder.

Aquaspar (Bosch, Siemens), Combiwash (Candy), "Shower System" (Gorenje, Ariston), Aquacycle (Zanussi) - differing in detail, but similar on the principle of the system of "double humidification". Their essential liquid is captured by a drum when rotating and then poured on the underwear on top.

Aquasensor (Bosch, Siemens), Sensor System (Ariston) - Optical control sensor for water purity. Depending on the sensor readings, the machine calculates the amount of water for rinsing.

3D-Aquaspar (Bosch, Siemens) - Technique of water supply from three sides with forced injection through the rear wall of the drum and the door.

Aqua-Stop (AEG, Bosch, Candy, Hansa, Hoover, Siemens), Aqua-Control (AEG, Ariston), Waterproof-System, Waterproof-Metal (Miele) - leak protection systems (see table).

Bubble-Soaking (Zanussi) - a system of effective dissolution of detergents with water enriched air bubbles.

D.C.C. (Whirlpool) - Automatic control of water consumption and electricity depending on the type and mass of the loaded linen.

Easy Door Lock (Ariston) - A system that allows you to open the hatch of the washing machine without delay after starting the program.

Easy Logic (Ardo) - Automatic determination of the machine loading level and select the appropriate volume of water.

Fuzzy Logic. ("Fuzzy Logic", "Logic with a rebuilt algorithm") - the principle of programming actions of a washing machine based on continuous analysis of the obtained data, just as a person does. The processor of the washing machine receives information from a variety of sensors controlling the temperature and rigidity of water, the turbidity of the solution, the volume of the enhanced liquid and the rotational speed of the drum. According to the data obtained, the processor makes conclusions about the degree and type of linen contamination and selects the individual washing mode. The principle of Fuzzy Logic allows you to achieve high laundry efficiency and machine efficiency.

OKO-SYSTEM (Ariston) - a system that allows you to completely eliminate the loss of detergent when washing.

S-System (Electrolux) - Foaming control system. When the foam appears in the tank, water is automatically added, the drum stops for a while to give a foam to settle.

SENSISAFE (Asko) - Depending on the type and amount of linen, the machine optimizes water consumption and electricity, reduces washing time.

Super Silent (Ariston) - silent operation of a washing machine (asynchronous engine and noise absorbing panels).

Update (Miele, Siemens, Ardo, Aeg, Ariston) - A system that allows you to reprogram the electronic device of the machine as new washing programs appear, press and rinse.

"Antishok" (Ariston, Asko, Ardo) - Cooling system of hot water before draining.

Drain of dirty water is produced by a pump (drain pump). The drain hose can either directly connect to the sewage system, or simply hang onto the sink side. For the next case, it should be borne in mind that the release of the washing machine does not have a locking valve, and if the hose is laid too low, it will occur directly by the law of communicating vessels, water will slowly leave the car. In the second case, the tube must be securely fastened to under the action of a beating jet of water, it did not jump from the shell. It is also necessary to ensure that during the descent of water in the sink did not get an extraneous object, capable of overlapping the drain hole (most often such misunderstandings occur due to the fault of small children). Much more reliably connect the release of the washing machine to a special siphon of the sink or washbasin, maybe even drainage from the air conditioner with a fitting for a flexible hose.

In addition, the lack of a check valve on plum is fraught with others, maybe even more noticeable trouble when connecting to the sewage network. With a breakdown of a water castle of a siphon, to which the machine is attached (and this is a very possible phenomenon), an indous smell will go into the room, and when the riser is overflowed, even sewage drains. There is another rarely taken into account by the nuance. Since the unit can wash water with a temperature greater than 65C, it is not recommended to use pipes and siphons from PVC. Polypropylene pipes or stipulated in the machine design system of pre-cooling water before drainage. Such, for example, the antishok system in the ardo models and the cooling of the detergent solution in all MIELE models are cooling.

Finally, with an energetic drain of water, a disruption of the hydraulicature of the nearest sanitary pribor may occur (most often the sink, if the machine is connected to the washbasin). In addition cases, the shell makes characteristic wheezing or whistle, which sounds especially "effectful" at night. But this noise is possible even without any violation of the siphon. Adelo is that the pump pumped water at high speed, it means that with even greater speed, the air should fill the horizontal sewer bed (about 1 l / s of water 25 l / s air). If the riser does not cope with this (and it depends on its design and the intensity of use by your neighbors in the doorway), then the air is closer from the nearest Santechniborov, and noise to you. To connect washing (as well as dishwashers) machines to the water supply and sewage, relatively recently released special siphons with a built-in check valve. Adles of silent sewage operation without breakdowns may need to install an additional air valve. Such valves and siphons on our market are supplied by Hutterer Lechter (in the line of which they are more than a dozen (from $ 13 and $ 190), including combinations of water, drain and power supply) and Valsir (Italy).

If you have conceived to position the unit at a distance of more than 3 m from the sewer pipes or the edges of the bath / sink, know: the portion of additional troubles is provided to you. First of all, we must consult about such an opportunity with the seller, because the pump may not cope with the load. If the answer turns out to be negative, the technicians of the company "TEKHKONSTRUCTION" advise to lay an additional segment of the sewer bed. Achetle He normally worked, embed an air ventilation valve into it with a plasticized device (there are several different designs, cost about $ 15).

Made in usa.

Not so long ago, in our market, unusual washing machines of Frigidaire activator type with top loading and a tank-drum with a vertical axis appeared. Devices require connecting to hot and cold water supply lines and do not have a heating element. The products of any sizes are erased from all types of tissues, ranging from the delicate linen itself and ending with down jackets and blankets. Namashin uses the so-called "three-active" wash, in which the tank drum is moving counterclockwise, and the activator (rod with blades) - according to and counterclockwise alternately. This provides constant and uniform waters in water, thereby increasing the mechanical impact on the washed things and as a result, the most complete removal of the fabric over the entire surface without wear. Loves from machines of drum type, linen is constantly completely immersed in water with a detergent or in clean water during rinsing. The maximum duration of the washing cycle is about 30 minutes.

Extrabral polypropylene tank-drum with a capacity of 85 liters accommodates 10.1 kg of dry linen. The advantages of such washing machines are concluded in a simple and convenient design, the absence of vibration during washing due to the fact that a constant mass of water and loaded linen, durability of the service and low power consumption is mixed. The main feature of these machines is that the departure is made at low revs, which gives raw underwear at the output. Therefore, the device is best bought in a set with a drying unit in a separate or monoblock design. In addition, it consumes a large amount of water. At maximum load only for washing, it will take about 80 liters. Separately standing washing machine FWS1649 from Frigidaire will cost the buyer at $ 960, the drying machine FER341 is $ 690.

Winning dry

Connecting the water supply directly conveniently, but is fraught with large troubles: if the connecting hose, the electromagnetic valve or the hatch door seal will give a leakage, a real flood may happen. It is not surprising that almost all manufacturers pay increased attention to the problem of complex protection of washing machines from leaks. Developed systems allow us to provide reliable protection if the device is properly connected and operating. An indirect sign of their effectiveness can serve as a warranty that producers give to their products. For example, BOSCH gives a lifelong guarantee to the Aqua-Stop system, this means that if the culprits of the accident are hose or valve, the company will not only eliminate the malfunction, but will repair the apartment at its own expense (it is necessary to take into account that the warranty is valid only with the right Connecting the washing machine).In conclusion, I would like to recall that even the most careful attitude of the user to the washing machine in some cases does not guarantee its long and trouble-free operation (no one is insured from breakdown). True, it is possible to judge the quality of this or that model only a few years after the start of its sales. Therefore, if it is planned to acquire the "promoted" model, its disadvantages can be found out from master repairmen or on specialized Internet forums (most popular- http://forum.ixbt.com). If we are talking about a completely new model, here the warranties of longevity can be only indirect. We advise you to perceive "breakdown statistics" with a certain fraction of skepticism, after all, the total number of breakdowns directly depends on the number of machines of this model sold 3-4 years ago. The fact that the number of applications for the repair of Italian technology is ten times more than on repairs, say, Turkish cars does not mean that the latter ten times more reliable.

Choosing a car, you should pay attention to the possibility of its service. VMoskwe will repair the brand or hoover technique- absolutely not a problem, but in Maloyaroslavl, find a new tank for washing machine from the untimely improper company Daewoo Electronics will be very difficult. Therefore, consider in advance the ways to retreat. Find out where and how it will be possible in the event of a breakdown to fix the washing machine of the selected brand. SAMSUNG, MERLONI, LG, CANDY, ZANUSSI, ARDO, BOSCH, SIEMENS, WHIRLPOOL, ELECTROLUX have the most wide network of service centers in our country. Repair Miele equipment in Moscow and St. Petersburg is carried out through the manufacturer's service services. AB remaining regions of Russia, through authorized partnership service services. The warranty period for the repair of all washing machines - 1 year, with the exception of the Bosch and Siemens models, whose manufacturers since July 2003 switched to a complete two-year warranty on their products.

Leakage protection systems used in washing machines

| Protection System (Firm) | Short description |

|---|---|

| Aqua Detect System (Asko) | System of sensors controlling the operation of the filler valve of the machine. If the valve leaks, the system is trying several times and drains water into the sewer |

| Aqua Safe (Asko) | Multistage system of control sensors of possible water leakage (covers 16 different points) |

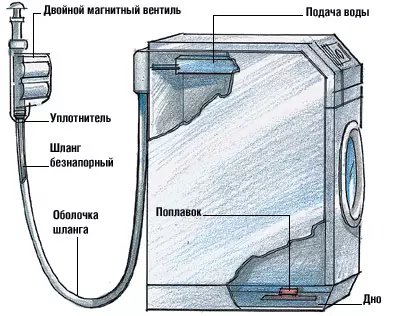

| Aqua-Control (AEG, Ariston) | In the pallet of the machine is located float. With leaks, it pops up, closer contacts of an electronic system, which automatically turns off the water supply and includes a drain pump |

| Aqua-Stop (AEG) | Two-layer hose, withstanding pressure up to 10 bar. When damaged, a special valve filled with absorbent is triggered, and automatically blocks the water supply |

| Aqua-Stop (Bosch, Siemens) | Two-layer flexible hose with high strength outer shell and double locking magnetic valve, which automatically blocks the water supply to the hose when its inner layer is deployed. Plus to this - float in the bottom of the car |

| Waterproof-System (Miele) | The system consists of a float in the bottom of the machine and automation of control (similar to the Aqua-Control system), a two-layer flexible hose with a high-strength outer shell and a double locking magnetic valve, which automatically blocks the water supply to the hose when its inner layer is deployed |

| Waterproof-Metal (Miele) | The difference between this system from WaterProof-System - to use the reinforced high strength hose |

The editors thanks a united service of the A-Iceberg service, representative offices of AEG, Ardo, Asko, Bosch, Candy, Electrolux, Merloni, Miele, Samsung, Siemens, Whirlpool, Techkontstructure for help preparing the material.